Projectprofile Expansionspinningmills

Diunggah oleh

kraftpaperJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Projectprofile Expansionspinningmills

Diunggah oleh

kraftpaperHak Cipta:

Format Tersedia

PROJECT PROFILE FOR EXPANSION OF SPINNING MILL

(25200 SPINDLES)

1.0 SCOPE OF THE PROJECT IN THE AREA OF OPERATION:

Sufficient information needs to be collected about the existing procedure for procurement

of raw material from members/other sources and existing procedure for marketing and

selling of cotton yarn. Also identify the market for surplus production.

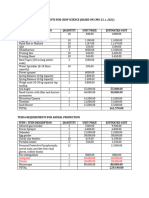

The mill proposes to work 355 days in a year on 3 shift basis. The mill proposes to

produce cotton yarn of count 20sK, 26sCH, 30sK, 30sCH, 34sK, 40sKH and 40sCH with

average count of 30s. The Yarn production per spindle per shift on 40s conversion basis

estimated at 105gms. Total yarn production after expansion is expected to be about 8738

MT per annum.

2.0 FOR IMPLEMENTATION OF THE PROJECT:

The society has to raise the requisite share capital;

Land purchase/leased by the society;

NOC from Pollution control board;

Prepared plan and estimates for civil work of main plant and ancillary buildings;

Obtained quotations from suppliers of plant & machinery required for modernization and

other equipments;

Obtain assurance from state electricity board for providing extra required electricity

connections

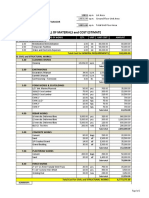

3.0 PROJECT COMPONENTS AND THEIR TENTATIVE COST

(Rs. in Lakhs)

3.1 Land and Site Development 00.00

3.2 Civil Works

Main factory building for plant and machinery

(12000 sq.mtr) 840.00

Ancilliary building (2000 Sq.M.) 120.00

Humidification Plant (1400 Sq. M) 77.00

Cotton & Yarn godowns (3000 Sq.M) 150.00

Overhead & underground water tanks 50.00

Cable Trenches, plumbing, sanitation, internal

Water supply etc. 13.00

TOTAL 1250.00

3.3 Plant & Machinery

Blow room with blendomat 120.00

Contamination control system 50.00

High production cards with can changer 470.00

H.S. breaker draw Frame with double delivery 60.00

H.S. finisher draw frame with single delivery 110.00

Lap Former 60.00

Comber 280.00

Speed frame with overhead cleaner 240.00

Ring Frames with O.H.C.(1200 Spindles each) 840.00

Automatic cone winding machine 1000.00

Yarn conditioning machine 30.00

AWCS for B.R. and cards 35.00

Stores & Spares 105.00

TOTAL 3400.00

3.4 Miscellaneous Fixed Assets

Electrification 225.00

Humidification Plant for ring frames

(Capacity 8 lakh CMH) 235.00

Compressor (2 Nos.) 50.00

Fire fighting equipment 20.00

Card room and cot room accessories 25.00

Uster Eveness Tester 70.00

Classimat Tester 35.00

TOTAL 660.00

3.5 Pre operative expenses 40.00

3.6 Margin money for working capital requirement 650.00

TOTAL PROJECT COST 6000.00

4.0 PROJECT IMPLEMENTATION SCHEDULE:

It is expected that the project is completed within one and half year after sanction of

final assistance.

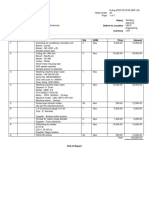

5.0 REQUIREMENT OF STAFF:

The mill will require 648 workers and 15 staff.

6.0 PATTERN OF FUNDING:

As per NCDC’s pattern of Funding for cooperatively developed states 90% of loan is

sanctioned to the state Govt. for passing on to the beneficiary societies as 60% loan

and 30% share capital contribution. For cooperatively under developed states and

cooperatively least developed states 92.5% of loan is sanctioned to the state govt. for

passing on to the beneficiary societies as 60% loan and 32.5% share capital.

Loan application forms are available with the office of Registrars of cooperative

societies/Regional Directorates of the NCDC besides Head Office at New Delhi.

Application forms can also be downloaded from NCDC website(http://ncdc.in).

Anda mungkin juga menyukai

- ProjectProfile ExpansionspinningmillsDokumen2 halamanProjectProfile ExpansionspinningmillsNeelakandan DBelum ada peringkat

- Project Profile For Establishment of 48 Automatic Loom: 1.0 Scope of The Project in The Area of OperationDokumen2 halamanProject Profile For Establishment of 48 Automatic Loom: 1.0 Scope of The Project in The Area of OperationSelva KumarBelum ada peringkat

- Project Profile For Dal Mills (Capacity 30 TPD) : Land and Land DevelopmentDokumen7 halamanProject Profile For Dal Mills (Capacity 30 TPD) : Land and Land DevelopmentShailendra ShrivastavaBelum ada peringkat

- Non-Current Asset Register of RJSLDokumen6 halamanNon-Current Asset Register of RJSLEngineering EntertainmentBelum ada peringkat

- Project Profile For Expansion of Spinning Mill (25200 SPINDLES)Dokumen3 halamanProject Profile For Expansion of Spinning Mill (25200 SPINDLES)Bala SubramaniBelum ada peringkat

- Specifications of Equipmentand MaterialsDokumen9 halamanSpecifications of Equipmentand MaterialsNHASSER PASANDALANBelum ada peringkat

- Project Profile For Modernization of Spinning Mill (21600 SPINDLES)Dokumen2 halamanProject Profile For Modernization of Spinning Mill (21600 SPINDLES)Karthik MaxxBelum ada peringkat

- Proposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)Dokumen2 halamanProposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)John Axl LajomBelum ada peringkat

- Sewage Treatment Plant 350CmD (MBBR)Dokumen2 halamanSewage Treatment Plant 350CmD (MBBR)John Axl LajomBelum ada peringkat

- 2019JJGD102319 MTSCoolRoomDokumen2 halaman2019JJGD102319 MTSCoolRoomJayVee Verallo BeBitBelum ada peringkat

- Proposed Bataan Warehouse Mechanical UpgradeDokumen2 halamanProposed Bataan Warehouse Mechanical Upgradesimeon james villacrusisBelum ada peringkat

- Cold Storage Project ReportDokumen13 halamanCold Storage Project ReportpawanBelum ada peringkat

- Project Cost DetailsDokumen3 halamanProject Cost DetailsNandagopal PooncholaiBelum ada peringkat

- Machine Rates MIRDC FacilitiesDokumen6 halamanMachine Rates MIRDC FacilitiesEfren CamposagradoBelum ada peringkat

- Internal Boq: Ralgo Industries, IncDokumen4 halamanInternal Boq: Ralgo Industries, IncElton John EvangelistaBelum ada peringkat

- Capital CostDokumen2 halamanCapital CostRajibDebBelum ada peringkat

- Medical Equipment Proforma InvoiceDokumen2 halamanMedical Equipment Proforma InvoiceMmaBelum ada peringkat

- TO, Mr. Rathi JiDokumen5 halamanTO, Mr. Rathi JiDeepak BaliyanBelum ada peringkat

- Equipment List For Proposed Project of Herbion Pakistan (PVT) Limited, LahoreDokumen1 halamanEquipment List For Proposed Project of Herbion Pakistan (PVT) Limited, LahoreMuhammad Rizwan KhanBelum ada peringkat

- Model Project ProfilesDokumen7 halamanModel Project Profilesnitin pBelum ada peringkat

- SMP Installation Works For Gravity Circuit Upgrade: Sanitation and HousekeepingDokumen3 halamanSMP Installation Works For Gravity Circuit Upgrade: Sanitation and HousekeepingMark Roger Huberit IIBelum ada peringkat

- Request For Quotation For Installation, Testing and Commissioning of 100 KWP Grid Interactive SPV SystemDokumen5 halamanRequest For Quotation For Installation, Testing and Commissioning of 100 KWP Grid Interactive SPV SystemRitesh MishraBelum ada peringkat

- Assets Liquidation Report-2Dokumen2 halamanAssets Liquidation Report-2Wajira FernandoBelum ada peringkat

- Proposed Marketing Strategy: Building & Civil WorksDokumen19 halamanProposed Marketing Strategy: Building & Civil WorkssandeepBelum ada peringkat

- Different Cost EstimateDokumen3 halamanDifferent Cost EstimateSanjay ShethBelum ada peringkat

- Annex 29 Area Calculation For Extended AerationDokumen1 halamanAnnex 29 Area Calculation For Extended AerationPradeep DavuluriBelum ada peringkat

- Construction Temp Power Supply-CommentedDokumen16 halamanConstruction Temp Power Supply-CommentedKiel BalancioBelum ada peringkat

- Unilever BOQDokumen2 halamanUnilever BOQMacky AlihuddinBelum ada peringkat

- Tugegaro Electrical and MMF SupplyDokumen1 halamanTugegaro Electrical and MMF SupplyJohn Axl LajomBelum ada peringkat

- JTI - New Leaf Vent Power SupplyDokumen1 halamanJTI - New Leaf Vent Power SupplyMarvin Jay CastardoBelum ada peringkat

- Assets & Valuaton ReportDokumen3 halamanAssets & Valuaton ReportWajira FernandoBelum ada peringkat

- Plinth Area Estimate KGDokumen1 halamanPlinth Area Estimate KGvijayBelum ada peringkat

- Fire Protection System Quote for ABHIYANTRI INFERNO ProjectDokumen2 halamanFire Protection System Quote for ABHIYANTRI INFERNO ProjectRishabh SinghBelum ada peringkat

- Gsc-Aux-000937 Ayala Land Corp - Garden Tower p2Dokumen1 halamanGsc-Aux-000937 Ayala Land Corp - Garden Tower p2noel.kabigting.rlbBelum ada peringkat

- Boq-Furniture, FixtureDokumen11 halamanBoq-Furniture, FixtureovifinBelum ada peringkat

- 500CmD Design and Build (Valley View)Dokumen3 halaman500CmD Design and Build (Valley View)John Axl LajomBelum ada peringkat

- Cma Data-414 Lacs-Aac Blocks Mfg. Unit.Dokumen22 halamanCma Data-414 Lacs-Aac Blocks Mfg. Unit.technopreneurvizagBelum ada peringkat

- BridgeDokumen7 halamanBridgeMario RufinoBelum ada peringkat

- Project CostDokumen6 halamanProject CostDemharun Young ManBelum ada peringkat

- Financial Details For IndustryDokumen6 halamanFinancial Details For IndustrySunita SinghBelum ada peringkat

- VO1 - Crockfort Stage Lift - Rev 01 - Claim Submission No 01 - Details Claim VO 01Dokumen2 halamanVO1 - Crockfort Stage Lift - Rev 01 - Claim Submission No 01 - Details Claim VO 01Norita AmeruddinBelum ada peringkat

- Star ReclamationDokumen13 halamanStar ReclamationSOURAV GOYALBelum ada peringkat

- Electric Justification June 2023Dokumen4 halamanElectric Justification June 2023Zach NervesBelum ada peringkat

- Pharmaceutics of EquipmentsDokumen4 halamanPharmaceutics of EquipmentsRahul KashyapBelum ada peringkat

- Production and Financial Details of Disposable Plastic CupsDokumen1 halamanProduction and Financial Details of Disposable Plastic Cupsk.g.thri moorthyBelum ada peringkat

- List of MaterialsDokumen8 halamanList of MaterialsJake BenliroBelum ada peringkat

- Proposed Scope of Work For Ogbotobo v3Dokumen6 halamanProposed Scope of Work For Ogbotobo v3martins73Belum ada peringkat

- (Outside Project Site Rental) (Barracks To Project Site) (Site Office, Stockpile, Workshop, Etc.)Dokumen24 halaman(Outside Project Site Rental) (Barracks To Project Site) (Site Office, Stockpile, Workshop, Etc.)Christian CabacunganBelum ada peringkat

- Solar TreatmentDokumen1 halamanSolar TreatmentWinmin OoBelum ada peringkat

- Quotation S00345Dokumen1 halamanQuotation S00345Muhammad Tanvir MohsinBelum ada peringkat

- BOM - Mexico GasolineDokumen1 halamanBOM - Mexico GasolineKaren MunozBelum ada peringkat

- Block 74-A Champawat-A - ResourceRate - MachineDokumen3 halamanBlock 74-A Champawat-A - ResourceRate - MachineBHAWAN BISHTBelum ada peringkat

- Item No. Description Unit Qty Material Cost Labor Cost Labor & Total IDokumen6 halamanItem No. Description Unit Qty Material Cost Labor Cost Labor & Total IRonwell James CampoBelum ada peringkat

- HKHT009601Dokumen1 halamanHKHT009601RoshanBelum ada peringkat

- DPR For Walnut ProcessingDokumen74 halamanDPR For Walnut ProcessingMohd touseefBelum ada peringkat

- AGRI-SCIENCE-AND-TECH-LABORATORY-EQUIPMEMENTDokumen1 halamanAGRI-SCIENCE-AND-TECH-LABORATORY-EQUIPMEMENTJonathan PasayanBelum ada peringkat

- L&T Controls and Instrumentations PDFDokumen25 halamanL&T Controls and Instrumentations PDFjavBelum ada peringkat

- BQ Bowling Details (2) - 1Dokumen1 halamanBQ Bowling Details (2) - 1Kamarul MayoBelum ada peringkat

- Statements 3Dokumen69 halamanStatements 3ace zeroBelum ada peringkat

- TextilesDokumen22 halamanTextileskraftpaperBelum ada peringkat

- Application Graduate Diploma of Transformational Development ProgramDokumen4 halamanApplication Graduate Diploma of Transformational Development ProgramkraftpaperBelum ada peringkat

- Chemical Technology of Wood, Pulp and Paper in Culture, Education and IndustryDokumen9 halamanChemical Technology of Wood, Pulp and Paper in Culture, Education and IndustrykraftpaperBelum ada peringkat

- Paper TypesDokumen3 halamanPaper TypeskraftpaperBelum ada peringkat

- Paper ProcessDokumen54 halamanPaper ProcesskraftpaperBelum ada peringkat

- Kraftliner Vs TestlinerDokumen1 halamanKraftliner Vs Testlinerjojo narutoBelum ada peringkat

- 2014 SlittingDokumen17 halaman2014 Slittingkumarjit kolayBelum ada peringkat

- Paper ProcessDokumen1 halamanPaper ProcessWesley Apla-on MiguelBelum ada peringkat

- Energy From Biomass in Pulp and Paper Mills: Dan GavrilescuDokumen10 halamanEnergy From Biomass in Pulp and Paper Mills: Dan GavrilescukraftpaperBelum ada peringkat

- Role of Multiple Loading Cycles in Pulp RefinersDokumen10 halamanRole of Multiple Loading Cycles in Pulp RefinerskraftpaperBelum ada peringkat

- Corrugated BoxesDokumen3 halamanCorrugated BoxesAditya GhatgeBelum ada peringkat

- Papermaking process diagram explainedDokumen1 halamanPapermaking process diagram explainedkraftpaperBelum ada peringkat

- Cs8791 Cloud Computing Unit2 NotesDokumen37 halamanCs8791 Cloud Computing Unit2 NotesTeju MelapattuBelum ada peringkat

- Mechanical Specifications For Fiberbond ProductDokumen8 halamanMechanical Specifications For Fiberbond ProducthasnizaBelum ada peringkat

- Tutorial On The ITU GDokumen7 halamanTutorial On The ITU GCh RambabuBelum ada peringkat

- DR-M260 User Manual ENDokumen87 halamanDR-M260 User Manual ENMasa NourBelum ada peringkat

- 2 - Elements of Interior DesignDokumen4 halaman2 - Elements of Interior DesignYathaarth RastogiBelum ada peringkat

- Uhf Leaky Feeder Rev CDokumen4 halamanUhf Leaky Feeder Rev CLuis Isaac PadillaBelum ada peringkat

- JY Series Single-Phase Capacitor Induction MotorsDokumen1 halamanJY Series Single-Phase Capacitor Induction MotorsAditya PrasetyoBelum ada peringkat

- TIA Selection Tool: Release Notes V2022.05Dokumen10 halamanTIA Selection Tool: Release Notes V2022.05Patil Amol PandurangBelum ada peringkat

- Parts of ShipDokumen6 halamanParts of ShipJaime RodriguesBelum ada peringkat

- OpenROV Digital I/O and Analog Channels GuideDokumen8 halamanOpenROV Digital I/O and Analog Channels GuidehbaocrBelum ada peringkat

- Front Wheel Steering System With Movable Hedlights Ijariie5360Dokumen6 halamanFront Wheel Steering System With Movable Hedlights Ijariie5360Ifra KhanBelum ada peringkat

- Aircraft Design Project 2Dokumen80 halamanAircraft Design Project 2Technology Informer90% (21)

- Aacra Draft Preliminary Report PDFDokumen385 halamanAacra Draft Preliminary Report PDFBeselam SeyedBelum ada peringkat

- Tds G. Beslux Komplex Alfa II (25.10.19)Dokumen3 halamanTds G. Beslux Komplex Alfa II (25.10.19)Iulian BarbuBelum ada peringkat

- Peptic Ulcer Disease: Causes, Symptoms and TreatmentDokumen24 halamanPeptic Ulcer Disease: Causes, Symptoms and TreatmentOktaviana Sari Dewi100% (1)

- Fake News Poems by Martin Ott Book PreviewDokumen21 halamanFake News Poems by Martin Ott Book PreviewBlazeVOX [books]Belum ada peringkat

- Descripcion Unidad 9, Dos CiudadesDokumen13 halamanDescripcion Unidad 9, Dos CiudadesGabriela ValderramaBelum ada peringkat

- De Thi HSG Tinh Binh PhuocDokumen9 halamanDe Thi HSG Tinh Binh PhuocDat Do TienBelum ada peringkat

- Smart Note Taker Saves Time With Air WritingDokumen17 halamanSmart Note Taker Saves Time With Air WritingNagarjuna LokkuBelum ada peringkat

- Reinforced Concrete Beam DesignDokumen13 halamanReinforced Concrete Beam Designmike smithBelum ada peringkat

- Handout Tematik MukhidDokumen72 halamanHandout Tematik MukhidJaya ExpressBelum ada peringkat

- Flood FillDokumen1 halamanFlood FillshubhamBelum ada peringkat

- 7890 Parts-Guide APDokumen4 halaman7890 Parts-Guide APZia HaqBelum ada peringkat

- Emerson EPC48150 1800 FA1EPC48300 3200 FA1 V PDFDokumen26 halamanEmerson EPC48150 1800 FA1EPC48300 3200 FA1 V PDFRicardo Andrés Soto Salinas RassBelum ada peringkat

- Monster of The Week Tome of Mysteries PlaybooksDokumen10 halamanMonster of The Week Tome of Mysteries PlaybooksHyperLanceite XBelum ada peringkat

- 24.postpartum Period-Physiological Changes in The MotherDokumen16 halaman24.postpartum Period-Physiological Changes in The MotherHem KumariBelum ada peringkat

- 07 Raction KineticsDokumen43 halaman07 Raction KineticsestefanoveiraBelum ada peringkat

- Motor GraderDokumen24 halamanMotor GraderRafael OtuboguatiaBelum ada peringkat

- Interpreting Piping and Instrumentation DiagramsDokumen41 halamanInterpreting Piping and Instrumentation DiagramsFredric Tun100% (2)

- Lec9-Rock Cutting ToolsDokumen35 halamanLec9-Rock Cutting ToolsAmraha NoorBelum ada peringkat