Sample Project of Mini Oil Mill

Diunggah oleh

Lajpat LalaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Sample Project of Mini Oil Mill

Diunggah oleh

Lajpat LalaHak Cipta:

Format Tersedia

Sample Project of Mini oil Mill

PROJECT REPORT OF MINI OIL MILL By http://www.help4jobs.com/

1.0 INTRODUCTION

Consumption of edible oils is increasing year after year and India

imports large quantities every year. Different types of oilseeds are

grown in the country like groundnuts, cotton seeds, mustard,

rapeseed, sunflower etc. Oilseed crop occupies important position in

the agricultural and industrial economy of the country and accounts for

about 13% of the cropped area. Mustard seed is one of the five major

oil seeds from which edible oil is produced. Edible oil is an integral part

of the Indian palate since long and different varieties are popular in

different parts of the country.

2.0 PRODUCT

Edible oils are a medium of cooking. Mustard oil is the medium of

cooking in almost all the states of eastern India like Bihar, West

Bengal, the North-East states etc.It is also used for massage in a big

way. Mustard oil-cake (a by-product) is common cattle and poultry

feed and used as manure in view of its high nutritional value.

3.0 MARKET POTENTIAL

Oil milling is an age-old activity which has gone through many phases

of development. Mini oil mill is a concept meant to cater to the local

market unlike large oil mills with huge capacities and catering to

regional markets with established brands and different varieties. Due

to very peculiar food habits of the Indians, every household uses

edible oil as a cooking medium almost everyday. Vegetarian as well as

non-vegetarian food preparations need edible oils. Groundnut, cotton

seed, rapeseed and mustard are the most popular edible oils in the 43

country but eastern-states prefer mustard oil as cooking medium.

Other states prefer Groundnut Oil, Coconut Oil , Til, Sunflower Oil ,

Karadi Oils etc.Oilseeds production in these states is growing year

after year and there is a good scope for oil milling.

4.0 MANUFACTURING PROCESS

The manufacturing process is well-established and simple. To begin

with, dry mustard seeds are fed to oil expellers for extraction of oil

wherein about 90% of the oil is extracted. Liquid oil and solid portion

(oil cake) is then separated in the filter press. Oil is packed either in

tins or jars or plastic pouches and oil cake is sold to cattle feed

manufacturers. Recovery of oil from oilseeds depends upon quality of

edible/non-edible seeds and it is in the range of 30% to 35%.

CAPITAL INPUTS

5.1 Land and Building

There is no need to buy a piece of land and then undertake

construction. Instead a

readymade constructed shed of around 100 sq. mtrs. may be bought.

Machines would occupy around 45-50 sq. mtrs. and balance space can

be utilised for storage and packing. Cost of building would be around

Rs.2.00 lacs.

5.2 Plant and Machinery

In view of the size of the market and keeping in mind the financial

viability, it is assumed that the rated capacity would be to process 25

tonnes of mustard seeds per month based on working of 10-12 hours

everyday. Mustard seeds will be available for not more than 8 months

and thus per season processing capacity would be 200 tonnes.This

would necessitate installation of following machines.

Prices of 6 Bolt Super Deluxe Oil Expeller

(Crushing Capacity 25 Tons/Month)

Based on working of 12 hours/day

DESCRIPTION UNIT PRICE

A) 6 Bolts Super Deluxe heavy duty oil bath system Steel Body Oil

Expeller, Crushing Capacity-60-80 Kgs Oil Seeds per hour.

Chamber Size 24”x4’. PRICE (EXCLUDING MOTOR) 72,000/-

B) Filter Press 16”x16”-12 Plates with Filter Pump.Brass Cocks &

collection Trey 32,000/-

C) Steam Ketly Round for Cooking Seeds. 16,000/-

D) Boiler – for preparing Steam-suitable for above Expeller. 25,000/-

E) Motor 10 H.P. of 960 R.P.M. 24,500/-

F) Miscellaneous Electrical and Non-Electrical items

1.) Main Switch 1450.00

2.) Starter 5550.00

3.) Filter Cloth 1760.00

5.) Pulleys 1500.00

6.) F. Bolts 850.00

11,110/-

Total 1,80,610.00

5.3 Miscellaneous Assets

Assets like furniture and fixtures, storage tanks, packing tables,

storage racks etc. are likely to cost Rs.50, 000/-.

5.4 Utilities

Power requirement will be 20 HP whereas about 50 ltrs. of diesel will

be required every month. Per day water requirement will be 350-400

ltrs.

6.0 MANPOWER REQUIREMENTS

Particulars Nos. Monthly

Salary (Rs.) Total Monthly

Salary (Rs.)

Skilled Workers 2 2,000 4,000

Helpers 3 1,250 3,750

Salesman 1 2,000 2,000

Total 9,750

7.0 TENTATIVE IMPLEMENTATION SCHEDULE

Activity Period (in months)

Application and sanction of loan 2

Site selection and commencement of civil work 1

Completion of civil work and placement of orders for machinery 3

Erection, installation and trial runs 1

DETAILS OF THE PROPOSED PROJECT

8.1 Building

As discussed earlier, a readymade constructed area of 100 sq.mtrs. is

adequate. It may cost Rs. 2.00 lacs.

8.2 Machinery

Total cost of machinery is expected to be Rs.1.80 lacs as explained

earlier.

8.3 Miscellaneous Assets

A provision of Rs.50, 000/- is adequate as mentioned earlier.

8.4 Preliminary & Pre-operative Expenses

A provision of Rs.50,000/- is made towards certain pre-production

expenses like registration, establishment and administrative expenses,

interest during implementation and trial run expenses.

8.5 Working Capital Requirements

At 60% capacity utilisation in the first year, working capital needs shall

be as under: (Rs. in lacs) Particulars Period Margin Total Bank

Promoters

Stock of Raw Materials ½ Month 30% 0.80 0.55 0.25

Stock of Finished Goods ½ Month 25% 1.00 0.75 0.25

Receivables 1 Month 25% 2.00 1.50 0.50

Working Expenses 1 Month 100% 0.20 -- 0.20

Total 4.00 2.80 1.20

8.6 Cost of the Project & Means of Financing (Rs. in lacs)

Item Amount

Building 2.00

Machinery 1.80

Miscellaneous Assets 0.50

P&P Expenses 0.50

Contingencies @ 10% on Land and

Building & Machinery 0.38

Working Capital Margin 1.20

Total 6.38

Means of Finance

Promoters\' Contribution 1.85

Term Loan from Bank/FI 4.53

Total 6.38

Debt Equity Ratio 2.45 : 1

Promoters\' Contribution 29%

Financial assistance in the form of grant is available from the Ministry

of Food Processing Industries, Govt. of India, towards expenditure on

technical civil works and plant and machinery for eligible projects

subject to certain terms and conditions.

PROFITABILITY CALCULATIONS

9.1 Production Capacity & Build-up

As against the processing capacity of 200 tonnes during 8 months,

actual utilization is expected to be 60% in the 1st year and thereafter

75%.

9.2 Sales Revenue at 100%

(Rs. in lacs) Product Qty. (Tonnes) Selling Price/Ton (Rs.) Sales Value

Mustard Oil 7. 55,000 38.50

Deoiled Cake 65 5,000 3.25

Total 41.75

9.3 Raw & Packing Materials

Required at 100% (Rs. in lacs) Product Qty. (Tonnes) Selling (Rs.)

Sales Value

Mustard Seeds 200 14,000 28.00

Others -- -- -- 2.00

Packing Materials -- -- 1.50

Total 31.50

9.4 Utilities

The annual expenditure at 100% utilisation will be Rs.60,000.

9.5 Interest

Interest on term loan of Rs. 4.53 lacs is calculated @ 12% per annum

assuming repayment in4 years including a moratorium period of 1 year

whereas on bank loan for working capital, it is assumed to be 14%.

9.6 Depreciation

It is computed on WDV basis @ 10% on building and 20% on

machinery and miscellaneous assets.

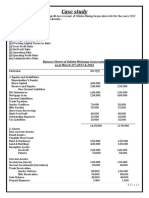

10.0 PROJECTED PROFITABILITY

(Rs. in lacs)

No. Particulars 1st Year 2nd Year

A. Installed Capacity --- 200 Tonnes ---

Capacity Utilisation 60% 75%

Sales Realisation 25.05 31.30

B. Cost of Production

Raw and Packing Materials 18.90 23.62

Utilities 0.36 0.45

Salaries 0.78 0.90

Stores and Spares 0.15 0.24

Repairs & Maintenance 0.18 0.30

Selling Expenses @ 15% 1.25 1.57

Administrative Expenses 0.42 0.54

Total 22.04 27.62

C. Profit before Interest & Depreciation 3.01 3.68

Interest on Term Loan 0.48 0.37

Interest on Working Capital 0.40 0.50

Depreciation 0.66 0.54

Profit before Tax 1.47 2.27

Income-tax @ 20% 0.27 0.47

Profit after Tax 1.20 1.80

Cash Accruals 1.86 2.34

Repayment of Term Loan -- 1.35

11.0 BREAK EVEN ANALYSIS

(Rs. in lacs)

No. Particulars Amount

(A) Sales 25.05

(B) Variable Costs

Raw & Packing Material 18.90

Utilities (70%) 0.51

Salaries (65%) 0.51

Stores & Spares 0.15

Selling Expenses (75%) 0.94

Admn Expenses (50%) 0.21

Interest on WC 0.40 0.40 21.36

(C) Contribution [A] - [B] 3.69

(D) Fixed Cost 2.22

(E) Break-Even Point [D] ÷ [C] 60%

12.0 [A] LEVERAGES

Financial Leverage

Web Site = http://www.help4jobs.com/

Anda mungkin juga menyukai

- Mustard Oil KanpurDokumen10 halamanMustard Oil KanpurVinay YadavBelum ada peringkat

- Project Report On Mustard Oil ProductionDokumen6 halamanProject Report On Mustard Oil ProductionEIRI Board of Consultants and PublishersBelum ada peringkat

- Mustard Oil Project ReportDokumen8 halamanMustard Oil Project ReportAkhilesh KumarBelum ada peringkat

- Project Profile of Edible OilDokumen47 halamanProject Profile of Edible OilManish Bhoyar100% (2)

- Vegetable Oil Refinary Project ReportDokumen9 halamanVegetable Oil Refinary Project ReportAkhilesh KumarBelum ada peringkat

- Coconut Products: 1.0 Product and Its ApplicationsDokumen6 halamanCoconut Products: 1.0 Product and Its ApplicationsAgri NetBelum ada peringkat

- Project On National Horticulture BoardDokumen9 halamanProject On National Horticulture Boardrupeshmore145Belum ada peringkat

- Business Case (2) - RICE BRAN OIL PRODUCTIONDokumen23 halamanBusiness Case (2) - RICE BRAN OIL PRODUCTIONAhamed Naxeeb100% (3)

- Analysis of Various Brands of Soyabean Refined Oil in The MarketDokumen38 halamanAnalysis of Various Brands of Soyabean Refined Oil in The MarketDouglas OrtizBelum ada peringkat

- Bankable Project Report & Quotation For GreenhouseDokumen40 halamanBankable Project Report & Quotation For Greenhousetiyasee25Belum ada peringkat

- Groundnutdpr 04.08.23Dokumen17 halamanGroundnutdpr 04.08.23TNRTP SALEMBelum ada peringkat

- N.k.proteins Ltd.Dokumen65 halamanN.k.proteins Ltd.mbawarriorssiem67% (3)

- Agriculture and Allied Industries October 2019 PDFDokumen38 halamanAgriculture and Allied Industries October 2019 PDFIam ceo100% (1)

- Mahesh Edible OilDokumen28 halamanMahesh Edible OilIqra AfsarBelum ada peringkat

- Project Report AshwaniDokumen59 halamanProject Report Ashwanikapilsharma268683% (6)

- Project TopicsDokumen3 halamanProject Topicsshivjitiwari100% (1)

- Edible Oil ReportDokumen19 halamanEdible Oil Reportsreeramchellappa100% (1)

- Feasibility of Rice Bran Oil PDFDokumen248 halamanFeasibility of Rice Bran Oil PDFSajidur Rehman Syed100% (1)

- Project Profile On Soya Milk, Paneer & CurdDokumen9 halamanProject Profile On Soya Milk, Paneer & CurdShashank ChauhanBelum ada peringkat

- Agro Chems Indian Agrochemical IndustryDokumen42 halamanAgro Chems Indian Agrochemical Industryapi-383389367% (3)

- Pentacool Soft Drink Manufcatruing Project ReportDokumen36 halamanPentacool Soft Drink Manufcatruing Project ReportMangal DevBelum ada peringkat

- Mahajan Mini Flour Mill, UdhampurDokumen24 halamanMahajan Mini Flour Mill, UdhampurMj PayalBelum ada peringkat

- Project Report On Namkeen and Chips ManufactureDokumen8 halamanProject Report On Namkeen and Chips ManufactureSachin SharmaBelum ada peringkat

- Onion Dehydration: Project ProfileDokumen4 halamanOnion Dehydration: Project ProfileMallikarjunReddyObbineniBelum ada peringkat

- Project Report Food GrainDokumen5 halamanProject Report Food GrainNeel KhandelwalBelum ada peringkat

- Agriculture Shop Licence MaharashtraDokumen17 halamanAgriculture Shop Licence MaharashtraSomnath TayadeBelum ada peringkat

- Kamco ProjectDokumen52 halamanKamco ProjectRobin ThomasBelum ada peringkat

- My Food Roller Flour Factory PVT - LTDDokumen54 halamanMy Food Roller Flour Factory PVT - LTDSandeep Nair67% (3)

- Project Report On King Chilli Processing UnitDokumen39 halamanProject Report On King Chilli Processing UnitPrakash Pokhrel0% (1)

- MarachekkuDokumen10 halamanMarachekkuRENUSREE ENTERPRISESBelum ada peringkat

- Oil Seed Cake CompanyDokumen2 halamanOil Seed Cake Companyhope 23Belum ada peringkat

- Industrial Visit OxyrichDokumen17 halamanIndustrial Visit OxyrichAnu Alreja67% (3)

- Marketing - BisleriDokumen23 halamanMarketing - BisleriamazonbaseBelum ada peringkat

- Project On Indian OilDokumen102 halamanProject On Indian Oiljignas cyberBelum ada peringkat

- Detergent Industry in IndiaDokumen37 halamanDetergent Industry in IndiaAjjay Kumar Gupta20% (5)

- Project Profile On Groundnut Oil and Oil Cake ManuafcuringDokumen2 halamanProject Profile On Groundnut Oil and Oil Cake ManuafcuringprtmBelum ada peringkat

- SMEDA Dehydration PlantDokumen68 halamanSMEDA Dehydration PlantUmar NaseerBelum ada peringkat

- Project Report On Soya Products (Soya Milk, Flavored Milk, Curd & Tofu)Dokumen6 halamanProject Report On Soya Products (Soya Milk, Flavored Milk, Curd & Tofu)EIRI Board of Consultants and PublishersBelum ada peringkat

- Indian Agrochemicals Industry: Insights and Outlook: February, 2019 I Industry ResearchDokumen24 halamanIndian Agrochemicals Industry: Insights and Outlook: February, 2019 I Industry ResearchSurajBelum ada peringkat

- A Project On Bail Kohlu Mastured Oil in MarketDokumen57 halamanA Project On Bail Kohlu Mastured Oil in Marketrenu356100% (1)

- Andavar The Oil Mill SolutionDokumen16 halamanAndavar The Oil Mill SolutionMECHSTER mechsterBelum ada peringkat

- A Study On The Working of Keo Food Products Pvt. LTD.Dokumen51 halamanA Study On The Working of Keo Food Products Pvt. LTD.jayachandranBelum ada peringkat

- Lignocellulosic Biomass to Value-Added Products: Fundamental Strategies and Technological AdvancementsDari EverandLignocellulosic Biomass to Value-Added Products: Fundamental Strategies and Technological AdvancementsBelum ada peringkat

- Oil MillDokumen8 halamanOil Millmanish.eer2394Belum ada peringkat

- Desiccated CoconutDokumen8 halamanDesiccated CoconutYohanes Slamet WidodoBelum ada peringkat

- Model Project ProfilesDokumen47 halamanModel Project ProfilesRaghav AgarwalBelum ada peringkat

- 09 Peanut Processing PDFDokumen8 halaman09 Peanut Processing PDFkalaamolBelum ada peringkat

- Papad MFGDokumen8 halamanPapad MFGFarhat DurraniBelum ada peringkat

- Milled Maize ProductDokumen7 halamanMilled Maize ProductFarhat DurraniBelum ada peringkat

- Papad NamkeenDokumen9 halamanPapad NamkeenSneha Dudhe YadavBelum ada peringkat

- Soya Flour Mill ProjectDokumen8 halamanSoya Flour Mill ProjectAkhilesh Kumar100% (2)

- Project Report of Soya FlourDokumen8 halamanProject Report of Soya FlourAkhilesh KumarBelum ada peringkat

- 10 Pigeon Pea ProcessingDokumen8 halaman10 Pigeon Pea ProcessingPaneendra KumarBelum ada peringkat

- 08 Peanut ButterDokumen11 halaman08 Peanut ButterMichael WambuaBelum ada peringkat

- Egg PowderDokumen9 halamanEgg PowderGisel Ingrid Puma Torrez60% (5)

- 19 Oleoresins & Spice Oil 1Dokumen8 halaman19 Oleoresins & Spice Oil 1KarachibreezeBelum ada peringkat

- Rice FlakesDokumen9 halamanRice FlakesAkhil PittyBelum ada peringkat

- Business Model For Tasty ChikkiesDokumen9 halamanBusiness Model For Tasty Chikkiesvenurao dindi100% (1)

- 07 Mustard OilDokumen8 halaman07 Mustard OilRajay DeshmukBelum ada peringkat

- Jowar FlakesDokumen8 halamanJowar FlakesAmit JainBelum ada peringkat

- 2012 - IsSN - Influence of Working Capital Management On Profitability A Study On Indian FMCG CompaniesDokumen10 halaman2012 - IsSN - Influence of Working Capital Management On Profitability A Study On Indian FMCG CompaniesThi NguyenBelum ada peringkat

- Case 6 MathDokumen16 halamanCase 6 MathSaraQureshiBelum ada peringkat

- FSA Sears Vs WalmartDokumen8 halamanFSA Sears Vs WalmartAbhishek Maheshwari100% (2)

- Strategic Management CH 4Dokumen37 halamanStrategic Management CH 4karim kobeissiBelum ada peringkat

- Working Capital Management For MNCs - STDokumen13 halamanWorking Capital Management For MNCs - STNikhil Mukhi100% (1)

- Financial Management Theory and Practice Brigham 13th Edition Test BankDokumen44 halamanFinancial Management Theory and Practice Brigham 13th Edition Test Bankletitiaestheru3hnxz100% (20)

- Text Book Short - CFDokumen18 halamanText Book Short - CFdevilsharmaBelum ada peringkat

- Final Version Group 4-Mid Course Group AssignmentDokumen22 halamanFinal Version Group 4-Mid Course Group AssignmentDiane MoutranBelum ada peringkat

- Analiza Pe Baza Bilantului Suciu Gheorghe 1Dokumen6 halamanAnaliza Pe Baza Bilantului Suciu Gheorghe 1Airam AiramBelum ada peringkat

- Literature ReviewDokumen4 halamanLiterature ReviewKS SubhramaniyamBelum ada peringkat

- 05 - Working Capital Management (Notes)Dokumen8 halaman05 - Working Capital Management (Notes)Cheezuu DyBelum ada peringkat

- Working Capital Management (TATA STEEL)Dokumen79 halamanWorking Capital Management (TATA STEEL)Abhaydeep Kumar Jha60% (10)

- Adam Sugar LTD Financial AnalysisDokumen20 halamanAdam Sugar LTD Financial AnalysiswamiqrasheedBelum ada peringkat

- Chocolate Shop - Business Plan Heza - ChocolitaDokumen10 halamanChocolate Shop - Business Plan Heza - ChocolitaDeepakBelum ada peringkat

- Rajapalayam MillDokumen53 halamanRajapalayam MillVijaya LakshmiBelum ada peringkat

- High Standard Office & Household FurnitureDokumen26 halamanHigh Standard Office & Household Furniturebig john50% (2)

- Chapter 13 - Working Capital ManagementDokumen38 halamanChapter 13 - Working Capital ManagementAn TuanBelum ada peringkat

- Final Assignment BBPW3203 - Financial Management IIDokumen22 halamanFinal Assignment BBPW3203 - Financial Management IIhemaBelum ada peringkat

- Sainsburry Ratio Analysis Year 2021Dokumen20 halamanSainsburry Ratio Analysis Year 2021aditya majiBelum ada peringkat

- F M ADokumen11 halamanF M AAjay SahooBelum ada peringkat

- Chaff CutterDokumen23 halamanChaff CutterFekadie TesfaBelum ada peringkat

- Puregold: Securities and Exchange CommissionDokumen81 halamanPuregold: Securities and Exchange CommissionhiBelum ada peringkat

- Muhayadeen Adam Kaleem PDFDokumen88 halamanMuhayadeen Adam Kaleem PDFananth080864Belum ada peringkat

- Sanjid Mamhud - 201803067 - Working Capital Policy - Assignment 1Dokumen5 halamanSanjid Mamhud - 201803067 - Working Capital Policy - Assignment 1Sanjid Mahmud SwarupBelum ada peringkat

- Fa I HoecDokumen32 halamanFa I HoecBunny SethiBelum ada peringkat

- Fund FlowDokumen38 halamanFund FlowSiddhartha DuhanBelum ada peringkat

- MCS-035 2018-19Dokumen9 halamanMCS-035 2018-19Jatin AgarwalBelum ada peringkat

- Igcse Accounting Ratios: Prepared by D. El-HossDokumen25 halamanIgcse Accounting Ratios: Prepared by D. El-HossDonnaBelum ada peringkat

- Tandon Committee Report On Working CapitalDokumen4 halamanTandon Committee Report On Working CapitalPranav BhattBelum ada peringkat

- Internship Report On Bahria Town PVTDokumen36 halamanInternship Report On Bahria Town PVTAngel Homes67% (3)