Pile FDN Tower

Diunggah oleh

Kausik DewanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pile FDN Tower

Diunggah oleh

Kausik DewanHak Cipta:

Format Tersedia

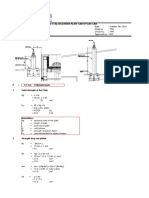

SPEC.

:

CALCULATION

NO. :

4-LEGGED ANGULAR TOWER FOUNDATION AT REV. No. :

TILJOLA, PORNOSHREE & GARFA PS PAGE :

BORE HOLE NO. 1

1. PILE PROPERTY

1.1 Pile type : 400 Φ PHC PILE, A type

1.2 Diameter of the pile (Dp) = 400 mm

1.3 Unit weight of the pile (Wp) = 0.178 ton/m

1.4 Young's modulus of the pile material (Ep) = 350000 kg/cm 2

1.5 Moment of inertia of the pile section (Ip) = 125663.71 cm4

1.6 Ultimate moment of the pile section (Mu) = 10 ton.m

1.7 Allowable load-bearing capacity of the pile section (Pa) = 112 ton

2. SOIL PROPERTY : BH-02

2.1 Soil stratum data

EL - N value Ls Nave. Ls x Nave. Description DRILL LOG

0.00 0 0.00

3.00 4 3.00 2 6.00 soft & wet soil

13.00 10 10.00 7 70.00 soft soil

17.00 20 4.00 15 60.00 silty sand

SUM 17.00 24 136.00 10 20 30 40 50

2.2 Average value of N of soil stratum (Ns)

Ns = Σ(Ls x Nave.) / Σ(Ls) = 8 < 25 ∴ Ns = 8

2.3 Average value of N near the pile point (N")

above 4.0DpPile point under 1.0Dp N" < 50

24 50 50 41 ∴ N" = 41

2.4 Internal friction angle ( Φ)

Φ = √[20N] + 15 = 28 < 40 ∴Φ= 28

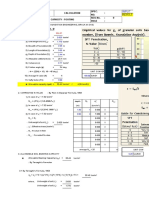

3. ALLOWABLE AXIAL BEARING CAPACITY (Qpa) : When Long Term : By Mayerhof's Formula

3.1 Ultimate axial bearing capacity (Qu)

Qu = Qp + Qs

where, 1) Qp : Point bearing capacity

2) Qs : Skin resistance capacity

3.2 Point bearing capacity (Qp)

Qp = 40*N*Ap = 213 ton

where, 1) N = N" : Value of N in vicinity of the pile point = 41

2) Ap : Area of the pile tip = 0.13 m2

3) Dp : Diameter of the pile = 0.40 m

3.3 Skin resistance capacity (Qs)

Qs = 0.2 x (Ns x U x Ls) = 34 ton

where, 1) Ns : Average value of N of the soil stratum = 8

3) U : Perimeter of the pile = 1.26 m

2) Ls : Depth of the soil stratum = 17.00 m

3.4 Allowable axial bearing capacity (Qpa)

Qu = Qp + Qs = 247 ton

Safety factor (FS) = 3.0

Qpa = Qu / FS = 82 ton < 112 ton

∴ Used allowable axial bearing capacity (Qpa) = 80 ton/set

4. ALLOWABLE UPLIFTING RESISTANCE CAPACITY (Qta) : When Long Term : By Mayerhof's Formula

4.1 Ultimate uplifting resistance capacity (Qt)

Qt = Wpo + U*L*fav = 35 ton

where, 1) Wpo : Weight of the pile except the buoyancy = 0.89 ton

Wpo = (Wp x L) - (Ww x Vp)

- Wp : Unit weight of the pile = 0.178 ton/m

-L : Length of the pile = 17.00 m

- Ww : Unit weight of water = 1.00 ton/m3

- Vp : Volume of the pile = 2.14 m3

- Dp : Diameter of the pile = 0.40 m

2) U : Perimeter of the pile = 1.26 m

3) fav : Average unit frictional resistance 1.60 ton/m2

=

fav = 0.2 x Ns < 5.00

- Ns : Average value of N of soil stratum < 15 = 8

4.2 Allowable uplifting resistance capacity (Qta)

Qt = 35 ton

Safety factor (FS) = 3.0

Qpa = Qu / FS = 12 ton

∴ Used allowable uplifting resistance capacity (Qta) = 10 ton/set

5. ALLOWABLE LATERAL RESISTANCE CAPACITY (Qha) : When Long Term : By Chang's Formula

5.1 Lateral soil reaction factor (Kh)

Kh = (α x Eo x Dp(-0.75) ) x y(-0.50) = 3.87 kg/cm 3

where, 1) α : Numerical factor = 0.2

2) Eo : Soil deformation factor (28 x Ns) =308 kg/cm 2

3) Ns : Average value of N of soil stratum = 11

4) Dp : Diameter of the pile = 40.0 cm

5) y : Displacement of head of pile =1.0 cm

5.2 Characteristic value of the pile ( β)

4

β = √[(kh x Dp) / (4 x Ep x Ip)] = 0.545 m-1

where, 1) Ep : Young's modulus of the pile material 350000

= kg/cm 2

2) Ip : Moment of inertia of the pile section 125664

= cm4

5.3 Ultimate lateral resistance capacity (Qh)

Qh = {(Kh x Dp) / (2 x β)} x y = 14.00 ton

where, 1) y : Displacement of head of pile =1.0 cm

※ βL = 9.27 > 3.00 : Long Pile

1) L : Length of the pile = 17.00 m

5.4 Allowable lateral resistance capacity (Qha)

Qh = 14 ton

Safety factor (FS) = 3.0

Qpa = Qu / FS = 5 ton

∴ Used allowable lateral resistance capacity (Qha) = 5 ton/set

6. SUPPORT REACTION FROM TOWER

Dead load in each support = 20.96 kN

Maximum moment 1573.202 kN-m

( I S-456:2000, Including Ammendment-1)

PI LE ARRANGEMENT

Pedestal

I nclude Pedestal? Yes

Pedestal Shape : Rectangular

Pedestal Height (Ph) : 0.500m

Pedestal Length - X (Pl) : 0.700m

Pedestal Width - Z (Pw) : 0.700m

Pile Cap Geometrical Data

Pile Cap Length PCL = 4.000m

Pile Cap Width PCW = 4.000m

Initial Pile Cap Thickness t I = 0.700m

Pile Geometrical Data

Pile spacing Ps = 2.000m

Pile Edge distance e = 1.000m

Pile Diameter dp = 0.400m

Pile Capacities

Axial Capacity PP = 800.000kN

Lateral Capacity PL = 100.000kN

Uplift Capacity PU = 300.000kN

Material Properties

Concrete f' c = 30000.005kN/ m^ 2

Reinforcement f y = 500000.084kN/ m^ 2

Concrete Cover

Bottom Clear Cover CCB = 0.050m

Side Clear Cover CCS = 0.050m

Pile in Pile Cap PCP = 0.075m

Loading applied at top of cap

Load Fx Fy Fz Mx My Mz

Case (kN) (kN) (kN) (kNm) (kNm) (kNm)

1 -0.771 -20.956 -0.771 0.000 0.000 0.000

2 -0.013 -0.375 -0.004 0.000 0.000 0.000

3 33.898 786.599 22.145 0.000 0.000 0.000

4 22.145 786.601 34.106 0.000 0.000 0.000

101 1.697 51.800 1.464 0.000 0.000 0.000

102 1.464 51.800 1.701 0.000 0.000 0.000

Pile Cap size (in investigated direction) H= 4.000 m

Pile Cap size (in investigated perpendicular

B= 4.000 m

direction)

PI LE CAP DESI GN CALCULATI ON

Self Weight Calculation

Self Weight : 279.990 kN

Pedestal Weight : 6.125 kN

Soil Weight : 0.000 kN

Extra weight for Surcharge : 0.000 kN

Buoyancy Reduction : 109.785 kN

Pile Reactions

Total pile number N = 4

Critical Load Case = 4

_ Arrangement Reaction

Pile X Y Axial Lateral Uplift

No. ( m) ( m) ( kN) ( kN) ( kN)

1 -1.000 -1.000 0.000 10.166 169.443

2 -1.000 1.000 0.000 10.166 148.979

3 1.000 1.000 0.000 10.166 135.693

4 1.000 -1.000 0.000 10.166 156.156

Reinforcement Calculation for Pile Cap

Maximum bar size allowed along length Ø25

Maximum bar size allowed along width Ø25

Bending Moment At Critical Section = 211.554kNm (Along Length)

Bending Moment At Critical Section = 211.636kNm (Along Width)

Pile Cap Thickness t = 0.700m

Selected bar size along length Ø12

Selected bar size along width Ø12

Selected bar spacing along length = 130.00mm

Selected bar spacing along width = 130.00mm

Pile Cap Thickness Check

Calculated Thickness (t) = 0.700m

Check for Moment (Along Length)

Critical load case for thickness is reported only when required thickness is more than the given minimum thickness

Critical Load Case : 3

Moment along Moment along

Pile No. x 1 - x 1 ( kNm) x 2 -x 2 ( kNm)

1 110.095 0.000

2 101.459 0.000

3 0.000 88.239

4 0.000 96.875

Effective Depth(def) = = 0.538 m

Depth of neutral axis for balanced section(xu) = 0.245 m

As Per IS 456 2000 ANNEX G,G-1.1 C

Ultimate moment of resistance(Mulim) = = 4611.739 kNm

We observed Mu < = Mulim hence singly reinforced and under reinforced section can be used

Check for Moment (Along Width)

Critical load case for thickness is reported only when required thickness is more than the given minimum thickness

Critical Load Case : 4

Moment along Moment along

Pile No. y1 - y1 ( kNm) y2 -y 2 ( kNm)

1 110.136 0.000

2 0.000 96.835

3 0.000 88.199

4 101.500 0.000

Governing moment (Mu) = 211.636 kNm

We assume singly reinforced and under reinforcement section

Effective Depth(def) = = 0.538 m

Depth of neutral axis for balanced section(xu) = 0.245 m

As Per IS 456 2000 ANNEX G,G-1.1 C

Ultimate moment of resistance(Mulim) = = 4611.739 kNm

We observed Mu < = Mulim hence singly reinforced and under reinforced section can be used

Check for One Way Shear (Along Length)

(Clause No. 34.2.4.1(a), Ammendment 1)

Critical Load Case = 4

Shear Force Shear Force

Pile No. x 1 - x 1 ( kN) x 2 -x 2 ( kN)

1 169.443 0.000

2 148.979 0.000

3 0.000 135.693

4 0.000 156.156

TOTAL 318.422 291.849

Design Shear Force for One-Way Action Vu = 318.422 kN

As Per IS 456 2000 ANNEX B,B-5.1 and Clause No

34.2.4.2

Design Shear Stress (Tv) = = 148.103 kN/ m^ 2

Allowable Shear Stress (Tc) = = 300.367 kN/ m^ 2

Where Beta = = 22.073

and percentage of steel required (pt ) = = 0.158

Here Tv < = Tc Hence safe

Check for One Way Shear (Along Width)

(Clause No. 34.2.4.1(a), Ammendment 1)

Critical Load Case = 4

Shear Force Shear Force

Pile No. y1 - y1 ( kN) y2 -y2 ( kN)

1 169.443 0.000

2 0.000 148.979

3 0.000 135.693

4 156.156 0.000

TOTAL 325.599 284.672

Design Shear force (Vu) = 325.599 kN

As Per IS 456 2000 ANNEX B,B-5.1 and Clause No 34.2.4.2

Design Shear Stress (Tv) = = 151.442 kN/ m^ 2

Allowable Shear Stress (Tc) = = 300.367 kN/ m^ 2

Where Beta = = 22.073

and percentage of steel required (pt ) = = 0.158

Here Tv < = Tc Hence safe

Check for Two Way Shear

Critical Load Case = 4

Tw o-w ay Shear

Pile No. at column face

( kN)

1 169.443

2 148.979

3 135.693

4 156.156

TOTAL 610.271

Design Two-Way Shear force = 610.271 kN

As Per IS 456 2000 Clause 31.6.2.1

Two Way Shear Stress(Tv) = = 401.019 kN/ m^ 2

Where,perimeter of critical section

(b0) = = 2.800 m

As Per IS 456 2000 Clause 31.6.3.1

Allowable shear stress = = 1369.307 kN/ m^ 2

Where,ks = = 1.000

Ratio of shorter to longer dimension

(Bc) = 1.000

and,Tc = = 1369.307 kN/ m^ 2

Tv < KsTc hence Safe

Punching Shear Check for Corner Piles

Shear Force

Pile No.

( kN)

2 148.979

3 135.693

1 169.443

4 156.156

Governing reaction (PCr) = maximum of (Pi, Pj ,... Pn) = 169.443kN

Pile Edge distance (Pe) = 1.000m

dcritical = 0.111m

deff > = dcritical... hence, safe.

Calculation of Maximum Bar Size

Along Length

Selected maximum bar size = Ø 25 mm

Bar diameter corresponding to max bar size(db) = 25.000 mm

As Per IS 456 2000 Clause No 26.2.1

Development Length(ld) = = 1.108 m

Allowable Length(ldb) = = 1.600 m

ldb > ld hence, safe

Along Width

Selected maximum bar size = 25 mm

Bar diameter corresponding to max bar size(db) = 25.000 mm

As Per IS 456 2000 Clause No 26.2.1

Development Length(ld) = = 1.108 m

Allowable Length(ldb) = = 1.600 m

ldb > ld hence, safe

Selection of Bottom and Top Reinforcement

Top reinforcement is provided same as bottom reinforcement

Along Length

Critical Load Case : 3

As Per IS 456 2000 Clause 26.5.2.1

Minimum Area of Steel (Astmin) = = 3360.000 mm2

As Per IS 456 2000 ANNEX G,G-1.1 b

Area of steel required (Asq) = = 3360.000 mm2

Area of steel provided (Ast ) = = 3392.921 mm2

Astmin< = Ast Steel area is accepted

Minimum spacing allowed (Smin) = 40 + db = 52 mm

Selected Bar Size = 12 mm

Selected spacing (S) = 130.00 mm

Smin< = S < = 450 mm and selected bar size < selected The reinforcement is accepted.

maximum bar size...

Along Width

Critical Load Case : 4

As Per IS 456 2000 Clause 26.5.2.1

Minimum Area of Steel (Astmin) = 3360.000 mm2

As Per IS 456 2000 ANNEX G,G-1.1 b

Area of steel required (Asq)= = 3360.000 mm2

Area of steel provided (Ast ) = = 3392.921 mm2

Astmin< = Ast Steel area is accepted

Minimum spacing allowed (Smin) = 40 + db = 52.00 mm

Selected Bar Size = 12 mm

Selected spacing (S) = 130.00 mm

Smin< = S < = 450 mm and selected bar size < selected The reinforcement is accepted.

maximum bar size...

Pedestal Reinforcement Design

Critcal load Case : 4

Critcal Applied Axial Load: -604.146kN

Critcal Applied Moment Along X Direction: 14.850kNm

Critcal Applied Moment Along Z Direction: 14.850kNm

Anda mungkin juga menyukai

- Pile Foundation Design: Dr. Magdi ZumrawiDokumen20 halamanPile Foundation Design: Dr. Magdi Zumrawitemesgen yohannesBelum ada peringkat

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDari EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresPenilaian: 4 dari 5 bintang4/5 (1)

- Empirical Analysis by Utilizing Standard Field TestDokumen53 halamanEmpirical Analysis by Utilizing Standard Field TestAlya HafidzaBelum ada peringkat

- A Short Course in Foundation EngineeringDari EverandA Short Course in Foundation EngineeringPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Soil Pile CapacityDokumen26 halamanSoil Pile CapacityOmar Najm100% (2)

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Dari EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Penilaian: 3 dari 5 bintang3/5 (2)

- Pile Capacity Calculation of Abutment M2 (AASHTO LRFD, 10.8)Dokumen4 halamanPile Capacity Calculation of Abutment M2 (AASHTO LRFD, 10.8)Franklin MaldonadoBelum ada peringkat

- Solution Manual for an Introduction to Equilibrium ThermodynamicsDari EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsBelum ada peringkat

- 2.2 Capacity Base On Field TestDokumen61 halaman2.2 Capacity Base On Field TestRadifan HalifBelum ada peringkat

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Dari EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Penilaian: 4.5 dari 5 bintang4.5/5 (5)

- Purlin DesignDokumen3 halamanPurlin DesignNaveen Kumar PadmanabuniBelum ada peringkat

- Green's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)Dari EverandGreen's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)Belum ada peringkat

- Design of Rectangular Is0Lated Footings 1: F2: Footing MarkDokumen2 halamanDesign of Rectangular Is0Lated Footings 1: F2: Footing MarkFarly VergelBelum ada peringkat

- Design of Concrete PadDokumen3 halamanDesign of Concrete PadBeveh G SupSupBelum ada peringkat

- Pile Capacity - BR.-649Dokumen20 halamanPile Capacity - BR.-649Sangramkeshari BejaBelum ada peringkat

- Bolt calculations ensure plate safetyDokumen5 halamanBolt calculations ensure plate safetysaskiaBelum ada peringkat

- Calculating allowable horizontal and vertical load capacities of a wooden pile foundationDokumen2 halamanCalculating allowable horizontal and vertical load capacities of a wooden pile foundationghina hidayatullahBelum ada peringkat

- Design Purlins Roof StructureDokumen23 halamanDesign Purlins Roof StructureJoshua John JulioBelum ada peringkat

- Pile Spring CoeffDokumen14 halamanPile Spring CoeffpraveenBelum ada peringkat

- (Bore Hole No. 2) : Calculation Spec.: NO. Soil Bearing & Pile Capacity Rev. No: 0Dokumen22 halaman(Bore Hole No. 2) : Calculation Spec.: NO. Soil Bearing & Pile Capacity Rev. No: 0pravincs_007Belum ada peringkat

- Pile Capacity Design Sheet (Comp & Uplift) - 600 MM Tnagar0.0Dokumen16 halamanPile Capacity Design Sheet (Comp & Uplift) - 600 MM Tnagar0.0Antony Godwin100% (1)

- 3WH-36-1.00 MM DesignDokumen4 halaman3WH-36-1.00 MM DesignmohanBelum ada peringkat

- Elevated Water Tank ComputationDokumen28 halamanElevated Water Tank ComputationAiron Kaye SameloBelum ada peringkat

- Support Design CalculationsDokumen17 halamanSupport Design Calculationsajit0% (1)

- Design of Foundation For CC Pole of 10m HeightDokumen3 halamanDesign of Foundation For CC Pole of 10m HeightPrasanth BurugulaBelum ada peringkat

- RECTANGULAR COMBINED FOOTING DESIGNDokumen7 halamanRECTANGULAR COMBINED FOOTING DESIGNAiko VillaluzBelum ada peringkat

- PILE Foundations: Foundation Engineering Bearing Capacity CalculationDokumen15 halamanPILE Foundations: Foundation Engineering Bearing Capacity CalculationAndrick AlvarezBelum ada peringkat

- Steel Plate 1Dokumen105 halamanSteel Plate 1JHON CLYDE SEPADABelum ada peringkat

- Covered Drain Design Calculations for Service RoadDokumen1 halamanCovered Drain Design Calculations for Service RoadKS LeeBelum ada peringkat

- Soil Pile Capacity Soil Investigation ReportDokumen32 halamanSoil Pile Capacity Soil Investigation Reportzakaria200811060100% (1)

- (Bore Hole No. 2) : Calculation Spec.: NO. Soil Bearing & Pile Capacity REV. No.: 0Dokumen26 halaman(Bore Hole No. 2) : Calculation Spec.: NO. Soil Bearing & Pile Capacity REV. No.: 0mayureshBelum ada peringkat

- Load carrying capacity of bored pileDokumen4 halamanLoad carrying capacity of bored pileKANHA100% (1)

- Stabilitas LerengDokumen6 halamanStabilitas LerengMohamad HartadiBelum ada peringkat

- Design of Spread Footing: Kh-Villa 200 F1 Lon Lavy 4000 Footing2-Sdm 23.390 0.000 1.40 5.830 0.000 1.70Dokumen2 halamanDesign of Spread Footing: Kh-Villa 200 F1 Lon Lavy 4000 Footing2-Sdm 23.390 0.000 1.40 5.830 0.000 1.70lavyBelum ada peringkat

- Pile DesignDokumen3 halamanPile Designalinawaz91100% (9)

- Tutorial 2 FoundationDokumen10 halamanTutorial 2 FoundationJoseph BaruhiyeBelum ada peringkat

- Chiller 8000 RT Replacement Dcap: DL LL M (DL) M (LL) 10 20000 0 0 Pile 2 Nos 0 0 0 0Dokumen1 halamanChiller 8000 RT Replacement Dcap: DL LL M (DL) M (LL) 10 20000 0 0 Pile 2 Nos 0 0 0 0Aek JanBelum ada peringkat

- Description Default Load Width Load: Minimum Design LoadsDokumen13 halamanDescription Default Load Width Load: Minimum Design LoadsRayross Jamilano YacabaBelum ada peringkat

- Lashing Lug Round Bar Design: 1. GeneralDokumen3 halamanLashing Lug Round Bar Design: 1. GeneralinnovativekarthiBelum ada peringkat

- Pre Cast Pile CapacityDokumen19 halamanPre Cast Pile Capacityyogs_184Belum ada peringkat

- BuitizonDokumen13 halamanBuitizonRocky SioresBelum ada peringkat

- Settlement Calculation Data Refer To BH-3 For Settelment CalculationDokumen4 halamanSettlement Calculation Data Refer To BH-3 For Settelment Calculationardian difaxBelum ada peringkat

- Life Line cp5Dokumen4 halamanLife Line cp5waquarshaiBelum ada peringkat

- 1.0 Input 1.1 Design Soil Parameters: 0.0 0.0 Ground LevelDokumen10 halaman1.0 Input 1.1 Design Soil Parameters: 0.0 0.0 Ground LevelsuratwaritBelum ada peringkat

- 1.0 Input 1.1 Design Soil Parameters: 0.0 0.0 Ground LevelDokumen5 halaman1.0 Input 1.1 Design Soil Parameters: 0.0 0.0 Ground LevelsuratwaritBelum ada peringkat

- Description Default Load Width Load: Minimum Design LoadsDokumen13 halamanDescription Default Load Width Load: Minimum Design LoadsRayross Jamilano YacabaBelum ada peringkat

- Description Default Load Width Load: Minimum Design LoadsDokumen13 halamanDescription Default Load Width Load: Minimum Design LoadsRayross Jamilano YacabaBelum ada peringkat

- Vs30 Correlations UC DavisDokumen38 halamanVs30 Correlations UC Davisbasum matBelum ada peringkat

- Design ReportDokumen3 halamanDesign ReportajitBelum ada peringkat

- Design of Pile Foundation For Piles in Granular Soils A) Side Friction Resistance of PileDokumen2 halamanDesign of Pile Foundation For Piles in Granular Soils A) Side Friction Resistance of PileHoque joynulBelum ada peringkat

- Tahanan Gesek (Komponen Gesekan) Kapasitas Dukung Tinag Dalam Tanah C - GDokumen16 halamanTahanan Gesek (Komponen Gesekan) Kapasitas Dukung Tinag Dalam Tanah C - GAdefi AbiogaBelum ada peringkat

- Steel Rafter Section For Eave Roof Section ReductionsDokumen25 halamanSteel Rafter Section For Eave Roof Section ReductionsJanaka KarunarathnaBelum ada peringkat

- Girder DesignDokumen3 halamanGirder DesignDhimas Surya NegaraBelum ada peringkat

- Design Thrust BlockDokumen4 halamanDesign Thrust BlockmannshiBelum ada peringkat

- PLTU BUNTOK 2X7MW foundation pile capacity calculationDokumen4 halamanPLTU BUNTOK 2X7MW foundation pile capacity calculationirne83Belum ada peringkat

- 04 - Design of PS-33Dokumen5 halaman04 - Design of PS-33karthiBelum ada peringkat

- Purlin and Girth Design for Roof StructureDokumen11 halamanPurlin and Girth Design for Roof StructureRajveer SinghBelum ada peringkat

- Sleeper Rev1Dokumen23 halamanSleeper Rev1Yatendra TyagiBelum ada peringkat

- Structural Analysis Computation Manual ExcelDokumen29 halamanStructural Analysis Computation Manual ExcelAriel B. LumacadBelum ada peringkat

- OISD Guidelines on Design and Fire Protection of Small LPG Bottling PlantsDokumen25 halamanOISD Guidelines on Design and Fire Protection of Small LPG Bottling Plantskiranphalak100% (1)

- Employees' State Insurance Corporation Return of Declaration Form Regulation 14Dokumen1 halamanEmployees' State Insurance Corporation Return of Declaration Form Regulation 14Kausik DewanBelum ada peringkat

- Bill Hda FireDokumen1 halamanBill Hda FireKausik DewanBelum ada peringkat

- 2720 16-CBRDokumen17 halaman2720 16-CBRRamesh100% (1)

- 33kV lighting arrestand foundation designDokumen2 halaman33kV lighting arrestand foundation designKausik DewanBelum ada peringkat

- Technical Support Email Regarding Hardware ReplacementDokumen2 halamanTechnical Support Email Regarding Hardware ReplacementKausik DewanBelum ada peringkat

- A Atualidade Do Belo - A Arte Como Jogo, Símbolo e FestaDokumen46 halamanA Atualidade Do Belo - A Arte Como Jogo, Símbolo e FestaCindy DóriaBelum ada peringkat

- A Atualidade Do Belo - A Arte Como Jogo, Símbolo e FestaDokumen46 halamanA Atualidade Do Belo - A Arte Como Jogo, Símbolo e FestaCindy DóriaBelum ada peringkat

- Tower Foundation KD Final Designcal PDFDokumen4 halamanTower Foundation KD Final Designcal PDFKausik DewanBelum ada peringkat

- Abasesh Resi MODDokumen1 halamanAbasesh Resi MODKausik DewanBelum ada peringkat

- 2792CP Stone SlabDokumen11 halaman2792CP Stone SlabKhan SakBelum ada peringkat

- 802 2Dokumen12 halaman802 2ravindrarao_mBelum ada peringkat

- Wrana 2015 4 PDFDokumen11 halamanWrana 2015 4 PDFarslanpasaBelum ada peringkat

- PhysicsDokumen16 halamanPhysicsKausik DewanBelum ada peringkat

- KPC Medical College & Hospital: 1F, Raja Subodh Chandra Mullick Road, Jadavpur, Kolkata, West Bengal 700 032Dokumen1 halamanKPC Medical College & Hospital: 1F, Raja Subodh Chandra Mullick Road, Jadavpur, Kolkata, West Bengal 700 032Kausik DewanBelum ada peringkat

- Design of Base Plate C1 Size CheckDokumen56 halamanDesign of Base Plate C1 Size CheckajBelum ada peringkat

- GCC Contract ConditionsDokumen40 halamanGCC Contract ConditionsKausik DewanBelum ada peringkat

- Civil EngineeringDokumen3 halamanCivil EngineeringDhaked Shahab67% (3)

- GCC of TenderDokumen39 halamanGCC of TenderRamkumarBelum ada peringkat

- Scope of WorkDokumen5 halamanScope of WorkKausik DewanBelum ada peringkat

- Special Instructions To Bidders For E-TenderingDokumen6 halamanSpecial Instructions To Bidders For E-TenderingKausik DewanBelum ada peringkat

- Deviation PDFDokumen1 halamanDeviation PDFKausik DewanBelum ada peringkat

- Design of Aspects of CC Roads PDFDokumen12 halamanDesign of Aspects of CC Roads PDFviharikapavuluri1290100% (1)

- BASEPLT9Dokumen27 halamanBASEPLT9Homero Silva100% (3)

- 3690 Boq PDFDokumen2 halaman3690 Boq PDFKausik DewanBelum ada peringkat

- Category Other Than Refinery, BPCLDokumen5 halamanCategory Other Than Refinery, BPCLMinal ParapannawarBelum ada peringkat

- Mix Proportioning For A Concrete of M25 Grade Is Given in ADokumen2 halamanMix Proportioning For A Concrete of M25 Grade Is Given in AKausik DewanBelum ada peringkat

- Etabs TutorialDokumen103 halamanEtabs TutorialGlenn Rey DomingoBelum ada peringkat

- Tender for design engineering & consultancy work for RCC box culverts & bridges in TripuraDokumen1 halamanTender for design engineering & consultancy work for RCC box culverts & bridges in TripuraKausik DewanBelum ada peringkat

- ASPDokumen1 halamanASPKausik DewanBelum ada peringkat

- Urban Design: The BeginningsDokumen13 halamanUrban Design: The BeginningsjohnzenlukeBelum ada peringkat

- Troubleshooting RPC Endpoint Mapper Errors Using The Windows Server 2003 Support Tools From The Product CDDokumen17 halamanTroubleshooting RPC Endpoint Mapper Errors Using The Windows Server 2003 Support Tools From The Product CDAnderson SilvaBelum ada peringkat

- StorNext 4 0 UserGuideDokumen413 halamanStorNext 4 0 UserGuideRay CoetzeeBelum ada peringkat

- Introduction To Xamarin FormDokumen37 halamanIntroduction To Xamarin FormKurniaBelum ada peringkat

- Copper Tubes - ASTM B88MDokumen7 halamanCopper Tubes - ASTM B88Myarzar17Belum ada peringkat

- Press Release - The House BeautifulDokumen3 halamanPress Release - The House BeautifulditiBelum ada peringkat

- 1 Table of Content: User Manual v0.4Dokumen6 halaman1 Table of Content: User Manual v0.4lancy_dsuzaBelum ada peringkat

- Memmert Heating Ovens English D13646 PDFDokumen32 halamanMemmert Heating Ovens English D13646 PDFrezaroohollahiBelum ada peringkat

- NullDokumen14 halamanNullM-NCPPCBelum ada peringkat

- Distributed SystemDokumen83 halamanDistributed SystemAli RebiohazardBelum ada peringkat

- Prequalified Seismic Moment ConnectionsDokumen2 halamanPrequalified Seismic Moment Connectionssymon ellimacBelum ada peringkat

- Translation of Architecture, Production of Babel - Mark WigleyDokumen17 halamanTranslation of Architecture, Production of Babel - Mark Wigleytadija5Belum ada peringkat

- Intel 22nm SoC BriefingDokumen11 halamanIntel 22nm SoC BriefingAnuradha PatilBelum ada peringkat

- Marina Bay Sands SingaporeDokumen4 halamanMarina Bay Sands SingaporeFitriBelum ada peringkat

- Cafco FENDOLITE MIIDokumen8 halamanCafco FENDOLITE MIINelloBelum ada peringkat

- Flexural DesignDokumen38 halamanFlexural DesignJesús Rodríguez RodríguezBelum ada peringkat

- Kingsa FD90 Test Report Body Cote - UnlockedDokumen35 halamanKingsa FD90 Test Report Body Cote - UnlockedsmartscsBelum ada peringkat

- Air Cooled HVAC BOQDokumen8 halamanAir Cooled HVAC BOQDesigner Forever100% (1)

- Bridge Overpass SP-2Dokumen21 halamanBridge Overpass SP-2sujankhanal10Belum ada peringkat

- Lapp - Pro100890en - Cabluri Olflex Classic 100 - 3g1,5-25g1,5Dokumen5 halamanLapp - Pro100890en - Cabluri Olflex Classic 100 - 3g1,5-25g1,5Mihai BancuBelum ada peringkat

- Villa SavoyeDokumen1 halamanVilla Savoyeekta kachhelaBelum ada peringkat

- MSP PrestressDokumen14 halamanMSP PrestressAmit MondalBelum ada peringkat

- E1 TesterDokumen12 halamanE1 TesterNarendra PattanayakBelum ada peringkat

- Introduction To VRF Systems PDFDokumen12 halamanIntroduction To VRF Systems PDFeimrehBelum ada peringkat

- Futera XLF IOM (XLF-IOM-9)Dokumen44 halamanFutera XLF IOM (XLF-IOM-9)Mihailo Filipovič JelicBelum ada peringkat

- Project Name: PROJECT LOCATION: Calubian, Leyte Prepared By: DateDokumen5 halamanProject Name: PROJECT LOCATION: Calubian, Leyte Prepared By: DatejoanBelum ada peringkat

- Fire Safety Executive ManualDokumen8 halamanFire Safety Executive ManualFaisal MehmoodBelum ada peringkat

- RRPP PDFDokumen33 halamanRRPP PDFAsim AwanBelum ada peringkat

- Example. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedDokumen4 halamanExample. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedJames NeoBelum ada peringkat

- Ethernet Cable Color Coding Diagram PDFDokumen2 halamanEthernet Cable Color Coding Diagram PDFFabiolaBelum ada peringkat