Inpex Scope

Diunggah oleh

JustinHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Inpex Scope

Diunggah oleh

JustinHak Cipta:

Format Tersedia

Quality Surveillance & Support Services- Execution Plan

Issue: 3.0

ITP: Inspection & Test Plan

IVB: Independent Verification Body

KOM: Kick Off Meeting

MWS: Marine Warranty Surveyor

MDR: Manufacturer’s Date Report

NCR: Non Conformance Report

NDT: Non Destructive Testing

PIM: Pre Inspection Meeting

PMI: Positive Material Identification

QA Quality Assurance

QC Quality Control

GL ND Contracting Country (GL ND CC): The GL ND country (entity) holding the

contact and contracting with the client. In this instance the Contracting country is GL ND

Australia

GL ND Performing Country (GL ND PC): Any overseas GL Country (to Australia)

where the work is to be carried out, with the Performing country reporting back to the

GL ND CC

3 Introduction

3.1 Background to the Ichthys Project

In August 1998, INPEX CORPORATION was awarded a petroleum exploration permit for permit

area WA-285-P in the northern Browse Basin about 200km north-west of Western Australia’s

Kimberley coast, at the western edge of the Timor Sea. That same year, the subsidiary company

INPEX Browse, Ltd. was established.

INPEX’s exploration drilling program from March 2000 to February 2001 resulted in a significant

gas and condensate discovery in what is now called the Ichthys Field. Based on that discovery,

INPEX commenced the Ichthys Gas Field Development Project (the Project).

In August 2006 INPEX transferred a 24% participating interest in the Project to TOTAL E&P

Australia (TOTAL). TOTAL has had a long-standing partnership with INPEX elsewhere in the

world and also has in-depth experience and expertise with oil & gas projects, including liquefied

natural gas (LNG).

In September 2008 the Ichthys Joint Venture (between INPEX and TOTAL) announced the

selection of Blaydin Point on Middle Arm Peninsula in Darwin Harbour as the site for the onshore

LNG processing facilities (refer to Figure 1-1).

Access Restricted Page 2

Quality Surveillance & Support Services- Execution Plan

Issue: 3.0

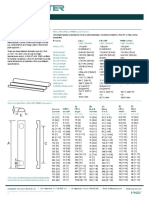

Figure 1-1: Location of the Ichthys Field Showing the Proposed Gas Export Pipeline Route

3.2 Development Description

Offshore, INPEX intends to install a floating Central Processing Facility (CPF) to develop the

Ichthys Field. The greater part of the condensate will be transferred from the field via a

subsurface pipeline to a nearby Floating Production, Storage and Off take (FPSO) facility where

it will be treated and transferred to off-take tankers for export (refer to Figure 1-2). Natural gas

from the field will be directed through an approximately 850km long gas export pipeline from the

field to the onshore facilities in Darwin for processing into LNG and LPG. A small percentage of

the condensate

will also be sent via the gas export pipeline and shipped from Darwin after treatment at Blaydin

Point.

The most likely resource estimates of the Ichthys Field are 12.8 trillion cubic feet of natural gas

and 527 million barrels of condensate. The Project is expected to produce more than 8 million

tonnes of LNG and 1.6 million tonnes of LPG per annum. It will also produce 100,000 barrels of

condensate per day at peak.

Access Restricted Page 3

Quality Surveillance & Support Services- Execution Plan

Issue: 3.0

Figure1-2: Indicative Schematic of the Offshore Floating Facilities

The Project’s infield facilities, including the offshore component of the subsea pipeline, fall under

Commonwealth jurisdiction, while the near-shore and onshore facilities in Darwin fall under

Northern Territory jurisdiction.

The onshore facilities at Blaydin Point will include a 6-km-long onshore pipeline corridor from the

shore-crossing area to the Blaydin Point gas-processing plant site; two gas liquefaction trains,

each capable of producing approximately 4.2 Mt/a of LNG; an LPG (propane and butane)

fractionation plant; a condensate stabilisation plant; seven storage tanks (two for LNG, three for

condensate, one for propane and one for butane); and associated utilities and administration

facilities. Figure 1-3 is an indicative schematic of the main components of the onshore and near

shore infrastructure at Blaydin Point, showing the processing plant, the module offloading facility

and the product loading jetty in the foreground.

Access Restricted Page 4

Quality Surveillance & Support Services- Execution Plan

Issue: 3.0

Figure 1-3: Indicative schematic of the onshore and near shore infrastructure at Blaydin Point

4 Overview of the Scope of Works

4.1 Company Surveillance Strategies

Dependent on whether the Purchase Order is direct to manufacturer or awarded and executed

by an EPC contractor, the Company Surveillance programme will be applied with varying levels

of responsibility and application (as defined below) :

4.1.1 Direct Purchaser Surveillance

The GL Noble Denton (on behalf of the Company) will directly oversee and verify the

manufacturer QC applications and will attend key hold point, witness and inspection events

during manufacturing, testing, certification and ship loading in order to verify that the Suppliers

execution of the Purchase Order is compliant with the Project Quality Plan technical and

verification requirements. GL Noble Denton (on behalf of the Company) may be required to

observe and report on vendor HSE practices, performance; AQIS quarantine requirements and

general expediting progress to achieve schedule.

Access Restricted Page 5

Quality Surveillance & Support Services- Execution Plan

Issue: 3.0

4.1.2 Verification Surveillance

The GL Noble Denton (on behalf of the Company) will verify EPC GL Noble Denton QC

coverage by selective criticality based intervention of key manufacturing and testing activities.

The GL Noble Denton (on behalf of the Company) may be required to observe and report on

suppliers HSE practices, performance, and general progress to schedule.

4.1.3 Field QC Assignments

The GL Noble Denton may be requested to support Company with site / field based construction

and commissioning surveillance activities for EPC packages of work. This may include QA, QC

and other specialist technical support activities including PMI, welding engineering, etc.

4.2 Core Services and Additional Support Services

GL Noble Denton will be required to supply services in accordance with the below conditions

Perform Planning, Coordination, Supervision, Inspections, Expediting and associated Reporting

responsibilities on behalf of, and as coordinated with the Company Inspection Coordinator.

Quality Surveillance duties will be provided based on criticality assessments and in accordance

with the Purchase Order, project specifications, specifically assigned Inspection and Test Plans,

and on whether the surveillance is performed as purchaser representative or verification of EPC

procurement responsibilities

Additional support services such as site QC personnel, quality audits, NDT cross-checking,

welding engineering and other special processes may be called off by Company as required.

4.3 Overall Project Work Scope for Vendor Surveillance

The work will fall under the 6 main categories, each comprising surveillance services at the

vendors/fabricators premises

• Umbilicals, Risers and Flowlines (URF)

Provision of Vendor Quality Surveillance on behalf of the Company during

procurement, manufacture, construction and installation of subsea equipment.

Likely locations to be considered for Vendor Quality Surveillance services include:

Europe, Japan, South East Asia

• Subsea Production System (SPS)

Provision of Vendor Quality Surveillance on behalf of the Company during supply

of production manifolds, Xmas Trees, well jumpers, controls systems and

associated subsea equipment. Likely locations to be considered for Vendor

Quality Surveillance services include:

Europe, USA, South East Asia

Access Restricted Page 6

Quality Surveillance & Support Services- Execution Plan

Issue: 3.0

• Gas Export Pipeline (GEP)

Provision of Vendor Quality Surveillance on behalf of the Company during

manufacture, coating and installation of the Gas Export Pipeline from the Ichthys

Field to Darwin. Likely locations to be considered for Vendor Quality Surveillance

Services include:

Manufacturing and coating – Germany, Malaysia, Indonesia

• Central Processing Facility (CPF)

Provision of Vendor Quality Surveillance on behalf of the Company during EPC

Contract for supply of semi-submersible hull, moorings and topsides. Likely to be

considered for Vendor Quality Surveillance services include:

Procurement – worldwide Note: The work does not include fabrication of the hull,

topsides, moorings etc, only the surveillance at vendor’s works for the supply of

equipment which will be incorporated into the build and construction of the CPF

Construction and at shore commissioning – South Korea

• FPSO (FPSO)

Provision of Vendor Quality Surveillance on behalf of the Company during EPC

Contract for supply of FPSO hull, moorings and topsides. Likely locations to be

considered for Vendor Quality Surveillance services include:

Procurement – worldwide: Note: The work does not include fabrication of the hull,

topsides, moorings etc, only the surveillance at vendor’s works for the supply of

equipment which will be incorporated into the build and construction of the CPF

• Onshore Facilities

Provision of Vendor Quality Surveillance on behalf of the Company during

procurement activities relating to plant and materials for the onshore LNG plant to

be located at Blaydin Point, NT Australia. Likely locations to be considered for

Vendor Quality Surveillance include:

Procurement - worldwide

5 Detailed Project Work Scope for Vendor Surveillance

5.1 Vendor Quality Surveillance Responsibilities

• Coordinate and execute vendor inspection assignments as requested via the

Company Inspection Coordinator and Inspection Request process.

• Attendance at Kick off, Pre Inspection, Pre Production, Progress meeting events as

required by the Company.

• Surveillance of all key manufacturing and testing processes and verify the QC

application by the Suppliers and or EPC organisation.

Access Restricted Page 7

Quality Surveillance & Support Services- Execution Plan

Issue: 3.0

• Attendance to monitor or witness Inspection and Testing events as determined

by the Project Quality Plan and approved Inspection and Test Plans (ITPs)

• Preparation and timely delivery of reporting to the Company of the Vendor

progress and surveillance activities performed.

• Monitor and track all reported product or process deficiencies or Non

Conformance's through to a satisfactory and formal closeout.

• Verify completion of the packaging and transportation readiness processes

and participate in the Final Inspection Release process,

• Monitor and report to the Company on the storage and transportation status of

consignments despatched from vendors.

• Coordinate and execute expediting visits as requested by Company - provide

reporting on equipment or MDR Dossier status as per agreed format and

content details.

• Provide accurate and timely reporting on all assignment activities to the

Company with look ahead forecasting of key manufacture, testing and

inspection events.

• Attend (as required by the Company) any inspection, audit, or investigative

event at the Manufacture and Test facility or load out site,

• Progressively expedite, review and endorse the supplier's compilation and

final and presentation of completed MDR dossier deliverables for the subject

order.

• Participate in the Initial (works complete) Inspection Release processes.

• Provide other support services as required including audits and specialist services

such as PMI and NDT cross checking

Organisation

GL Noble Denton will establish a project team for the delivery of the above described

Scope of Works. See below the proposed organisation chart Fig G.1 Contained in

Appendix G.1.

Access Restricted Page 8

Anda mungkin juga menyukai

- Foster Wheeler Wins Contract For Petrochemical Refinery Complex in VietnamDokumen2 halamanFoster Wheeler Wins Contract For Petrochemical Refinery Complex in VietnamJustinBelum ada peringkat

- 2012-09-17 Fluor Wins US Propylene Project Contract From DowDokumen1 halaman2012-09-17 Fluor Wins US Propylene Project Contract From DowJustinBelum ada peringkat

- Inpex, Total Seek US$20bil Loans For Australia LNG: BusinessDokumen2 halamanInpex, Total Seek US$20bil Loans For Australia LNG: BusinessJustinBelum ada peringkat

- Eni Australia Scalybutt Tieback Rev 1Dokumen1 halamanEni Australia Scalybutt Tieback Rev 1JustinBelum ada peringkat

- Fluor Selected For The Dow Chemical Company's Propylene Production Project in TexasDokumen2 halamanFluor Selected For The Dow Chemical Company's Propylene Production Project in TexasJustinBelum ada peringkat

- Mobile Mooring Systems (Endorsement of Api RP 2Sk, Api RP 2Sm and Api RP 2I)Dokumen8 halamanMobile Mooring Systems (Endorsement of Api RP 2Sk, Api RP 2Sm and Api RP 2I)JustinBelum ada peringkat

- Fluor Awarded Strategic Global EPC Agreement by The Dow Chemical CompanyDokumen1 halamanFluor Awarded Strategic Global EPC Agreement by The Dow Chemical CompanyJustinBelum ada peringkat

- Capability Statement - GLNDDokumen15 halamanCapability Statement - GLNDJustinBelum ada peringkat

- 2012-12-21.TH - Pttep, Partners Award Mozambique LNG FEED ContractsDokumen3 halaman2012-12-21.TH - Pttep, Partners Award Mozambique LNG FEED ContractsJustinBelum ada peringkat

- Folder AustraliaDokumen2 halamanFolder AustraliaJustinBelum ada peringkat

- O&G Engineering Companies in VietnamDokumen10 halamanO&G Engineering Companies in VietnamJustinBelum ada peringkat

- The Star Online: Starbiz: "With The Assistance of Our Local Timorese Partner Nexus Meridian Lda, Petro-MekongDokumen3 halamanThe Star Online: Starbiz: "With The Assistance of Our Local Timorese Partner Nexus Meridian Lda, Petro-MekongJustinBelum ada peringkat

- Fluor Wins US Propylene Project Contract From DowDokumen1 halamanFluor Wins US Propylene Project Contract From DowJustinBelum ada peringkat

- Important Note:: Terms and Conditions Celcom Biz - Quarter 2 2014 Offering Plan148 With Device BundleDokumen4 halamanImportant Note:: Terms and Conditions Celcom Biz - Quarter 2 2014 Offering Plan148 With Device BundleJustinBelum ada peringkat

- I-Rod Adhesive: ºC 500 Hours 1,000 HoursDokumen1 halamanI-Rod Adhesive: ºC 500 Hours 1,000 HoursJustinBelum ada peringkat

- Sample - Global Oil & Gas Asset Integrity ManagementDokumen19 halamanSample - Global Oil & Gas Asset Integrity ManagementJustinBelum ada peringkat

- Jkgiy, Lfy, Ul, FDokumen2 halamanJkgiy, Lfy, Ul, FJustinBelum ada peringkat

- Appendix A.9 - (900) MC CTRDokumen6 halamanAppendix A.9 - (900) MC CTRJustin0% (1)

- Husky, CNOOC Charter Floater Offshore IndonesiaDokumen11 halamanHusky, CNOOC Charter Floater Offshore IndonesiaJustinBelum ada peringkat

- Jurong Shipyard Bags MODEC's FPSO Contract For Ghana's TEN DevelopmentDokumen1 halamanJurong Shipyard Bags MODEC's FPSO Contract For Ghana's TEN DevelopmentJustinBelum ada peringkat

- New Horizon 2015: JGC Corporation JGC Corporation Medium-Term Management PlanDokumen15 halamanNew Horizon 2015: JGC Corporation JGC Corporation Medium-Term Management PlanJustinBelum ada peringkat

- ContractDokumen29 halamanContractJustinBelum ada peringkat

- Review of DevelopmentDokumen43 halamanReview of DevelopmentJustinBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hazardous Area Classification DRAWDokumen76 halamanHazardous Area Classification DRAWAbdelkader BOUKHOUSBelum ada peringkat

- Gas LubricationDokumen13 halamanGas LubricationSachin Meshram0% (1)

- Catalytic Converter Based On Non Noble MaterialDokumen4 halamanCatalytic Converter Based On Non Noble Materialpamela garciaBelum ada peringkat

- Commodities Handbook Jul 2021Dokumen49 halamanCommodities Handbook Jul 2021jun luBelum ada peringkat

- High Water Cut in Stabiler TowerDokumen3 halamanHigh Water Cut in Stabiler TowerAnonymous ei87sJPBelum ada peringkat

- Phthalic Anhydride ProductionDokumen2 halamanPhthalic Anhydride ProductionNasriah Nasrudin0% (1)

- Properties of Heavy Fuel OilDokumen3 halamanProperties of Heavy Fuel Oilmavericksailor50% (2)

- HW3 SKKK2123 1516-1Dokumen3 halamanHW3 SKKK2123 1516-1tamil vaananBelum ada peringkat

- Biomass Conversion TechnologiesDokumen3 halamanBiomass Conversion TechnologiesYoy Sun Zoa0% (1)

- Naphtha CrackingDokumen22 halamanNaphtha CrackingSanchez JorgeBelum ada peringkat

- Brandt and Henrikson. 2000 - Decomposition of Tar in Gas From Updraft Gasifier by Thermal CrackingDokumen4 halamanBrandt and Henrikson. 2000 - Decomposition of Tar in Gas From Updraft Gasifier by Thermal CrackingStephBelum ada peringkat

- Suchit CVDokumen3 halamanSuchit CVmaheshBelum ada peringkat

- AF Series - 16 Bar: AF - Aluminium Compressed Air Fi LtersDokumen2 halamanAF Series - 16 Bar: AF - Aluminium Compressed Air Fi LtersThane MasureikBelum ada peringkat

- 15 Taber.1997 EOR - Screening.criteria - Revisited Part.1Dokumen10 halaman15 Taber.1997 EOR - Screening.criteria - Revisited Part.1Mishell Ariana GuerraBelum ada peringkat

- NEO JEE 11 P1 CHE E Equilibrium S14 209Dokumen386 halamanNEO JEE 11 P1 CHE E Equilibrium S14 209cskksc17Belum ada peringkat

- T.E Chemical PDFDokumen40 halamanT.E Chemical PDFAxone EstradaBelum ada peringkat

- WORKSHEET (Chemical Equations) PDFDokumen4 halamanWORKSHEET (Chemical Equations) PDFnobodyBelum ada peringkat

- Naim Memon Paper PresentationDokumen6 halamanNaim Memon Paper PresentationAbhi SoniBelum ada peringkat

- Batch Distillation Quiz Number 1Dokumen6 halamanBatch Distillation Quiz Number 1PRINCESS DIANNE DUG-ABelum ada peringkat

- Pearce 2008Dokumen8 halamanPearce 2008natymoraiisBelum ada peringkat

- Gii Refineria Amuay PDFDokumen197 halamanGii Refineria Amuay PDFFelipeBelum ada peringkat

- Membrane Separation ProcessesDokumen47 halamanMembrane Separation Processesma.junallie pomperada100% (1)

- Re-Drawing Sukowati - Document Control SheetDokumen5 halamanRe-Drawing Sukowati - Document Control SheetHSE TrihascoBelum ada peringkat

- Fundamentals of Petroleum and Petrochemical Engineering: Uttam Ray ChaudhuriDokumen154 halamanFundamentals of Petroleum and Petrochemical Engineering: Uttam Ray ChaudhuriEmad AliBelum ada peringkat

- Separations and Reaction Engineering Design Project Ethylene Oxide ProductionDokumen13 halamanSeparations and Reaction Engineering Design Project Ethylene Oxide ProductionKevin Javier QuispeBelum ada peringkat

- UTL600 Fuel SystemsDokumen52 halamanUTL600 Fuel Systemsmika cabelloBelum ada peringkat

- Fractional Distillattion: By: Aman Kumar To: Dr. ShivaniDokumen16 halamanFractional Distillattion: By: Aman Kumar To: Dr. ShivanimohitBelum ada peringkat

- Rate ReactionDokumen10 halamanRate ReactionTsabit AlbananiBelum ada peringkat

- Advances in Thermochemical Conversion of Woody Biomass To Energy, Fuels and ChemicalsDokumen9 halamanAdvances in Thermochemical Conversion of Woody Biomass To Energy, Fuels and ChemicalsAsem AmairyhBelum ada peringkat

- Pri STXDokumen2 halamanPri STXМаксим ГрабовскийBelum ada peringkat