Cast-Resin Dry-Type Transformers - Characteristics

Diunggah oleh

Ashishrock Singh0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

18 tayangan2 halamanCast-resin dry-type transformers provide excellent moisture protection through complete encapsulation of windings in epoxy resin. They can operate at 100% humidity without service disruptions and have higher impulse and short circuit withstand strength than oil-filled or conventional dry transformers. Additionally, they require no maintenance, are non-flammable, and help reduce installation costs by eliminating the need for oil containment or LT cables.

Deskripsi Asli:

Cast Resin Dry type Transformer

Judul Asli

Cast Resin

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniCast-resin dry-type transformers provide excellent moisture protection through complete encapsulation of windings in epoxy resin. They can operate at 100% humidity without service disruptions and have higher impulse and short circuit withstand strength than oil-filled or conventional dry transformers. Additionally, they require no maintenance, are non-flammable, and help reduce installation costs by eliminating the need for oil containment or LT cables.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

18 tayangan2 halamanCast-Resin Dry-Type Transformers - Characteristics

Diunggah oleh

Ashishrock SinghCast-resin dry-type transformers provide excellent moisture protection through complete encapsulation of windings in epoxy resin. They can operate at 100% humidity without service disruptions and have higher impulse and short circuit withstand strength than oil-filled or conventional dry transformers. Additionally, they require no maintenance, are non-flammable, and help reduce installation costs by eliminating the need for oil containment or LT cables.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

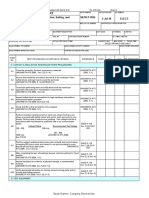

Cast-Resin Dry-Type Transformers -Characteristics

Moisture Proof In cast-resin dry-type transformers, the

complete encapsulation of primary and

secondary winding in epoxy resin prevents

penetration of moisture into windings. The cast

resin offers very good protection against adverse

ambient conditions. These transformers can work

without disruption of service at 100% humidity.

Immediate Switch on Due to the high grade insulation material, coils

are non hygroscopes & the transformer can be

switched on directly without pre-drying even

after a long period of service interruption.

Impulse Strength Contrary to the conventional dry type

transformers the cast coil transformers are better

in respect of impulse voltage withstand strength.

Short Circuit Strength Higher dynamic short circuit withstand strength

as compared to oil immersed and conventional

dry type transformers because of fibre glass

reinforced epoxy encapsulation.

Free of partial discharge's No partial discharges can occur during operation.

Resistant against The insulation material used is glass fibre

temperature Fluctuation reinforced with epoxy resin of class 'F' which can

withstand wide temperature variation.

Hardly inflammable and Due to high quality insulation material the

self extinguishing transformer is practically non-inflammable by an

electrical arc, special fire protection measures

are not required.

No Maintenance Required Due to encapsulation of coils with cast resin the

coils dimensions are stable & no coil tightening is

required to maintain the short circuit strength.

Also no check of oil level and electrical

insulation/oil is required. This leads to saving in

cost on account of maintenance.

No leakage or Pilferage of As cast resin transformers are solidly cast,

Oil problem associated with oil filled transformers

like oil leakage and pilferage of oil is completely

avoided.

Saving in Space These transformers are generally smaller in

dimensions and lesser in weights. The

construction and installation cost for the sub-

station can be reduced by adopting dry type

transformers.

Saving in Civil work cost Without fire or danger of explosion, it is possible

and LT cables to place the transformers near to the load centre.

Also, these transformers do not need

construction of special fibre brick walls or oil pits,

which reduces the overall civil works.

Additionally, since LT cables are not required,

thers is also saving in cost on account of

expensive cable laying works.

Eco-friendly Since no oil is used in these transformers, there

are no chances of contamination of ground water

due to oil leakage.

Anda mungkin juga menyukai

- Powerfullstop Katalog 2017 02Dokumen18 halamanPowerfullstop Katalog 2017 02PredragPeđaMarkovićBelum ada peringkat

- Advantages of Dry Type Transformers With VPI Technology Using NOMEXDokumen3 halamanAdvantages of Dry Type Transformers With VPI Technology Using NOMEXavam46100% (2)

- Advantages of Dry Type TransformersDokumen2 halamanAdvantages of Dry Type TransformersgabrielBelum ada peringkat

- History and Emerging of The Industry: Industrial Training at Industry PremisesDokumen21 halamanHistory and Emerging of The Industry: Industrial Training at Industry PremisesDharam PatelBelum ada peringkat

- Oil Filled Transformers: More Information On The Design of An Oil Filled TransformerDokumen16 halamanOil Filled Transformers: More Information On The Design of An Oil Filled Transformery_larryBelum ada peringkat

- LS Transfomer 225kva-2500kvaDokumen20 halamanLS Transfomer 225kva-2500kvasonech khorngBelum ada peringkat

- SETFt RIP Transformer Outdoor BushingDokumen12 halamanSETFt RIP Transformer Outdoor Bushingp m yadavBelum ada peringkat

- Cast Resin TransformerDokumen29 halamanCast Resin Transformerkrmurali2000Belum ada peringkat

- Dry Type TransformersDokumen5 halamanDry Type TransformersPrashant TrivediBelum ada peringkat

- Dry Type Vs Liquid Filled TransformerDokumen5 halamanDry Type Vs Liquid Filled TransformerEngineeringBelum ada peringkat

- Oskf-Ansi-Brochure-En (CT-245kV)Dokumen4 halamanOskf-Ansi-Brochure-En (CT-245kV)Trương Quang SơnBelum ada peringkat

- Assignment IT101Dokumen3 halamanAssignment IT101khojizekiahBelum ada peringkat

- BEST Transformer Dry-Type TransformersDokumen20 halamanBEST Transformer Dry-Type Transformerstajudeen100% (1)

- Polyphase TransformersDokumen7 halamanPolyphase TransformersRahul RaiBelum ada peringkat

- CarepolebrochureDokumen4 halamanCarepolebrochurenivya machadoBelum ada peringkat

- Resimold Resiglas CRT DryType CommercialBrochure enDokumen12 halamanResimold Resiglas CRT DryType CommercialBrochure engreyllom9791Belum ada peringkat

- Transformer Training Inputs JMD 26 8 2015Dokumen14 halamanTransformer Training Inputs JMD 26 8 2015dombipinBelum ada peringkat

- Market Analysis: Switches and WiresDokumen12 halamanMarket Analysis: Switches and WiresShalini SBelum ada peringkat

- Inductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVDokumen6 halamanInductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVOscar Francisco Astudillo Paillamilla100% (1)

- Cast Resin Transformers Oil Immersed Transformer: Technical PerformanceDokumen32 halamanCast Resin Transformers Oil Immersed Transformer: Technical PerformanceIm ChinithBelum ada peringkat

- Transformer Design-01Dokumen21 halamanTransformer Design-01Anoop BhattacharyaBelum ada peringkat

- Flat Plate Collectors Vitosol 200-FmDokumen4 halamanFlat Plate Collectors Vitosol 200-FmSenn OdrapmasdBelum ada peringkat

- LS Cast Resin Transformers: Technical PerformanceDokumen16 halamanLS Cast Resin Transformers: Technical PerformanceSayemAbusadat100% (1)

- Transformer Basics To Those Unfamiliar With Transformer Manufacturing, Terms Such As Fish, Kraft, NaturalDokumen6 halamanTransformer Basics To Those Unfamiliar With Transformer Manufacturing, Terms Such As Fish, Kraft, NaturalluroguitaBelum ada peringkat

- Model: 12-Volt, 75 AhDokumen2 halamanModel: 12-Volt, 75 Aharturo velazcoBelum ada peringkat

- Recent Trends in Electrical MachineDokumen58 halamanRecent Trends in Electrical MachineMurtazaImtiyazBelum ada peringkat

- MELODY-Oil Immersed Transf.Dokumen4 halamanMELODY-Oil Immersed Transf.Ahmet TosunBelum ada peringkat

- Station Intermediate Class UsDokumen28 halamanStation Intermediate Class UsManny RiveraBelum ada peringkat

- Vitosol - FM - Flyer 2Dokumen4 halamanVitosol - FM - Flyer 2Todd CrossleyBelum ada peringkat

- TRIDELTA Surge Arresters BrochureDokumen12 halamanTRIDELTA Surge Arresters BrochureNeil AcquatellaBelum ada peringkat

- Advantages of Shell Form Power TransformerDokumen2 halamanAdvantages of Shell Form Power TransformerJumpstart LeeBelum ada peringkat

- RTV Pre-Coated Cap-And-Pin Toughened Glass Insulators - A Wide Experience in The Italian Overhead Transmission SystemDokumen4 halamanRTV Pre-Coated Cap-And-Pin Toughened Glass Insulators - A Wide Experience in The Italian Overhead Transmission SystemDayan YasarangaBelum ada peringkat

- Oskf Iec Brochure enDokumen4 halamanOskf Iec Brochure enSamir SassiBelum ada peringkat

- Capacitors LolololDokumen5 halamanCapacitors LolololJerimiah MirandaBelum ada peringkat

- Line Insulators & OHL TowersDokumen10 halamanLine Insulators & OHL Towersm4_mehdeeBelum ada peringkat

- Completecoat™ Corrosion Protection: Corrosion-Resistant, Flexible Coating Uniformly Bonded To All Condenser Coil SurfacesDokumen2 halamanCompletecoat™ Corrosion Protection: Corrosion-Resistant, Flexible Coating Uniformly Bonded To All Condenser Coil SurfacesdjoletetBelum ada peringkat

- Daikin Ducted BrochureDokumen4 halamanDaikin Ducted BrochureMULTI B AIRCON & ELECTRICAL SUPPLY INCBelum ada peringkat

- 09hermetically Sealed OilDokumen2 halaman09hermetically Sealed OiljuliancansenBelum ada peringkat

- 12 Fat 100Dokumen2 halaman12 Fat 100Juan Jesus Ureña GarciaBelum ada peringkat

- Tumetic Tunorma Oil Distribution TransformersDokumen10 halamanTumetic Tunorma Oil Distribution Transformerscojo_drBelum ada peringkat

- CapacitorsDokumen3 halamanCapacitorsSabahath N TajBelum ada peringkat

- Basic Principles and Operation of Transformer-Constructional AspectsDokumen5 halamanBasic Principles and Operation of Transformer-Constructional Aspectsrafik1995Belum ada peringkat

- Delta Protekt KL120Dokumen1 halamanDelta Protekt KL120GavinBelum ada peringkat

- Fiamm 6sla100-DatasheetengDokumen2 halamanFiamm 6sla100-DatasheetengAlberth Mauricio Casteblanco GomezBelum ada peringkat

- Study of Transformer Oil Purification: Shreya Salvi, Prof. A. P. ParanjapeDokumen4 halamanStudy of Transformer Oil Purification: Shreya Salvi, Prof. A. P. Paranjapeamitranjan20Belum ada peringkat

- The LINE No. 11 Distribution Transformer Article June 2005Dokumen2 halamanThe LINE No. 11 Distribution Transformer Article June 2005Lilanka UdawattaBelum ada peringkat

- 20KW 25KVA SIDA Engine Genset IntroduceDokumen18 halaman20KW 25KVA SIDA Engine Genset IntroduceANDRES CELYBelum ada peringkat

- Physics AssignmentDokumen5 halamanPhysics AssignmentSyed Abrar Haider GillaniBelum ada peringkat

- Cast Resin TransformerDokumen16 halamanCast Resin TransformerMahadi HassanBelum ada peringkat

- Transformer Manufacturing and DesignDokumen27 halamanTransformer Manufacturing and DesignGuru Mishra50% (2)

- M M SS M.S. R M.S. R: Air Cool ResistorDokumen1 halamanM M SS M.S. R M.S. R: Air Cool ResistorharizazrinoordinBelum ada peringkat

- Packing Brochure SADokumen20 halamanPacking Brochure SAfrederick alayonBelum ada peringkat

- Com Par Is IonDokumen1 halamanCom Par Is Ionibrahim68Belum ada peringkat

- Especificacion Transformadores CampamentoDokumen8 halamanEspecificacion Transformadores CampamentofreddyBelum ada peringkat

- 1.UPVC Column Casing Pipes CatalogDokumen22 halaman1.UPVC Column Casing Pipes Catalogsris802Belum ada peringkat

- 416532ijsetr1697 601Dokumen5 halaman416532ijsetr1697 601p41005679Belum ada peringkat

- LS Cast Resin Transformers: Technical PerformanceDokumen20 halamanLS Cast Resin Transformers: Technical PerformanceClaire BernardBelum ada peringkat

- LS Cast Resin Transformers PDFDokumen20 halamanLS Cast Resin Transformers PDFLanh Tran100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDari EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsPenilaian: 5 dari 5 bintang5/5 (1)

- Through The CBCT. But U-Turn Back Through The CBCT" and Then Earth It at The Earthing BarDokumen2 halamanThrough The CBCT. But U-Turn Back Through The CBCT" and Then Earth It at The Earthing BarAshishrock Singh100% (1)

- Technology of IronmakingDokumen55 halamanTechnology of IronmakingAshishrock SinghBelum ada peringkat

- Free Veritas Prep Complete GMAT Course Set - 12 Books Full OnlineDokumen1 halamanFree Veritas Prep Complete GMAT Course Set - 12 Books Full OnlineAshishrock SinghBelum ada peringkat

- Baker EXP4000 Dynamic Motor AnalyzerDokumen8 halamanBaker EXP4000 Dynamic Motor AnalyzerAshishrock SinghBelum ada peringkat

- BTP 502 02 D15aDokumen2 halamanBTP 502 02 D15aAshishrock SinghBelum ada peringkat

- Is 3043Dokumen92 halamanIs 3043Ashishrock SinghBelum ada peringkat

- DOE Gasification Program OverviewDokumen147 halamanDOE Gasification Program OverviewAshishrock SinghBelum ada peringkat

- Central Board of Secondary Education Continuous & Comprehensive Evaluation (Class X) - Session 2009-2011 (Results of Class - X)Dokumen2 halamanCentral Board of Secondary Education Continuous & Comprehensive Evaluation (Class X) - Session 2009-2011 (Results of Class - X)Ashishrock SinghBelum ada peringkat

- Simulation of Passive Magnetic Bearing Using COMSOL MultiphysicsDokumen7 halamanSimulation of Passive Magnetic Bearing Using COMSOL Multiphysicsxiaoqi dengBelum ada peringkat

- User Manual - IFC 100 Flow MeterDokumen36 halamanUser Manual - IFC 100 Flow Meterbaranim0% (1)

- Ultraviolet/Visible Light Absorption Spectrophotometry (UV-Vis)Dokumen63 halamanUltraviolet/Visible Light Absorption Spectrophotometry (UV-Vis)MiftahAinulMardiahBelum ada peringkat

- Diodos ZenerDokumen3 halamanDiodos Zenerremanuel18Belum ada peringkat

- Dgca Module Syllabus For BAMEL HOLDERDokumen5 halamanDgca Module Syllabus For BAMEL HOLDERJagbir SinghBelum ada peringkat

- EARTHING CABLE SCHEDULE-Rev.0B - FloresDokumen4 halamanEARTHING CABLE SCHEDULE-Rev.0B - Floresbram87Belum ada peringkat

- Chapter 4 Differential ProtectionDokumen27 halamanChapter 4 Differential ProtectionJames100% (1)

- The Ideal Diode Equation LessonDokumen2 halamanThe Ideal Diode Equation LessonsamiBelum ada peringkat

- ELK-110 Voice Driver - Install GuideDokumen2 halamanELK-110 Voice Driver - Install GuideAlarm Grid Home Security and Alarm MonitoringBelum ada peringkat

- Apxvll13n CDokumen2 halamanApxvll13n CqaisersiddiBelum ada peringkat

- Noise Equivalent Power White PaperDokumen5 halamanNoise Equivalent Power White Paperabul_1234Belum ada peringkat

- PTDFDokumen2 halamanPTDFMohammed AlsuffarBelum ada peringkat

- Konica Minoltamagicolor 5650 5670 Service Manual PDFDokumen370 halamanKonica Minoltamagicolor 5650 5670 Service Manual PDFRadovan JaicBelum ada peringkat

- Alarms UpsDokumen4 halamanAlarms UpsAditya JaiswalBelum ada peringkat

- ASSIGNMENT 2020 (Feb-Mar)Dokumen10 halamanASSIGNMENT 2020 (Feb-Mar)priyaBelum ada peringkat

- Zelio Control RM17TU00Dokumen6 halamanZelio Control RM17TU00Anas BasarahBelum ada peringkat

- Saudi Aramco Test ReportDokumen7 halamanSaudi Aramco Test Reportkarthi51289Belum ada peringkat

- LM317 Linear Integrated Circuit: 3-Terminal 1A Positive Adjustable Voltage RegulatorDokumen5 halamanLM317 Linear Integrated Circuit: 3-Terminal 1A Positive Adjustable Voltage RegulatorAbraham Viviescas FigueroaBelum ada peringkat

- Switchgear Selection ChartsDokumen6 halamanSwitchgear Selection Chartsirfanbaig36Belum ada peringkat

- KT-502H en Tcd210202ab 20211221 Manual WDokumen3 halamanKT-502H en Tcd210202ab 20211221 Manual WGopal HegdeBelum ada peringkat

- Galvanometer To VoltmeterDokumen2 halamanGalvanometer To Voltmeterfaizmustafa67Belum ada peringkat

- Electrical Machines DC Motor NewDokumen27 halamanElectrical Machines DC Motor NewPranav MahadikBelum ada peringkat

- Single - Stage BJT Amplifier: Experiment No. 1Dokumen12 halamanSingle - Stage BJT Amplifier: Experiment No. 1Yousef BobadillaBelum ada peringkat

- Group Assignment 2Dokumen12 halamanGroup Assignment 2saumya desaiBelum ada peringkat

- Harness Draft - Product Knowledge - 16th Dec 2016Dokumen42 halamanHarness Draft - Product Knowledge - 16th Dec 2016manohar rajuBelum ada peringkat

- Fig 1 - GE Optima CT660 CT ScannerDokumen4 halamanFig 1 - GE Optima CT660 CT Scannerarwa zeglamBelum ada peringkat

- Service Manual: Chassis No. GA-7SDokumen29 halamanService Manual: Chassis No. GA-7SErry Kusuma WardanaBelum ada peringkat

- 15A04602 Electronic Measurements & InstrumentationDokumen1 halaman15A04602 Electronic Measurements & Instrumentation17BF1A04L7 kalyanBelum ada peringkat

- Module 2Dokumen26 halamanModule 2SohnBelum ada peringkat

- Basics of Rotary Encoders: Overview and New Technologies: Print CloseDokumen13 halamanBasics of Rotary Encoders: Overview and New Technologies: Print CloseholaBelum ada peringkat