Milwaukee 4203 838a PB Catalogación

Diunggah oleh

Juan carlosDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Milwaukee 4203 838a PB Catalogación

Diunggah oleh

Juan carlosHak Cipta:

Format Tersedia

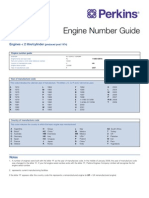

BULLETIN NO.

SERVICE PARTS LIST 54-46-2250

REVISED BULLETIN DATE/

b .,A Am. ‘96

LL Y I AIYIJ

WIRING INSTRUCTION

STARTING

3 I SERIAL NO. 836A * SEE NOTE

EXAMPLE:

Component Parts (Small #)

Are Included When Ordering

The Assembly (Large #).

* NOTE:

WIRING DETAILS ALONG WITH A

LISTING OF COMPONENTS FOR

(FIG. NO. 12) PANEL ASSEMBLY ARE

SHOWN ON BULLETIN 54-30-0151

i3 \

24

FIG. PART NO. DESCRIPTION OF PART

27 06-97-4050 l/4” Split Ring Lock Washer

28 45-30-0160 Bras&lug _

29 06-75-3090 l/4-20 x 7/8” Socket Hd. Screw

30 06-97-4050 l/4” Split Ring Lock Washer

31 06-75-2900 l/4-20 x 3/8” Socket Hd. Screw

32 06-88-0110 114-20 x 314” Wing Screw

33 45-30-0160 Brass Slug

34 43-82-0080 Gauge Indicator

35 06-82-7252 8-32 x 3/8” Pan Hd. Sit. Taot. T-20

36 44-80-0070 Rack

37 30-84-0180 Slide

38 06-85-0200 6 x l/4” Rd. Hd. Type Z Screw

39 43-46-0150 Graduated Gauge

40 44-94-0165 Depth Gauge Rod

41 49-96-0080 3/l 6” Socket Wrench

42 49-96-0050 3132” Socket Wrench

43 43-94-0060 Wrench Keeper

44 06-75-3005 l/4-20 x 518” Socket Hd. Screw

45 06-97-4050 l/4” Split Ring Lock Washer

46 43-48-0100 Gib

48 06-57-4050 Lock Nut

49 06-75-3100 l/4-20 x 1” Socket Hd. Screw

50 06-97-4050 l/4” Split Ring Lock Washer

51 06-75-4220 5/16-18X 2-l/2” Socket Hd. Screw

52 06-97-4110 5/l 6” Split Ring Lock Washer

53 44-66-4180 Locking Plate

54 02-02-0340 1 l/32” Steel Ball

FIG. PART NO. DESCRIPTION OF PART NO. REQ. 55 44-20-0090 Adjusting Lock

1 45080160 Shaft 56 45-52-2010 Adjusting Stop

2 06-42-3750 l/8 x 3-112” Square Key

57 02-02-0360 l/2” Steel Ball

3 43-78-0260 Handle Hub

58 43-62-0540 Locking Handle

4 43-62-0055 Feed Handle

5 43-98-0050 Plastic Knob 59 06-65-l 586 3/l 6” x l-3/8” Roll Pin

6 42-40-0060 Bushing 60 42-32-0120 Locking Bolt

7 32-60-2120 Pinion Gear 61 06-65-l 534 l/8” x 5/8” Roll Pin

8 22-64-0076 Cord Set 62 30-72-0050 Adjusting Plate

9 12-99-1295 Service Nameplate 63 06-65-0575 3/32” x 5/l 6” Roll Pin

10 06-95-0075 6-32 x 3/8” Truss Hd. Taotite Screw 64 45-36-0800 Locking Spacer

11 23-16-0760 Panel Insulator ’ 65 06-75-3975 5/l 6-l 8 x 1” Socket Hd. Screw

12 --_______--____ Panel Assembly (See Note)

66 06-97-4110 5/l 6” Split Ring Lock Washer

13 06-82-7252 8-32 x 3/8” Pan Hd. Slt. Tapt. T-20

14 28-50-7830 Support Housing 48-58-0080 6’ Safety Chain (Incld. 43-74-0080)

15 45-04-0100 Cord Retaining Screw 43-74-0080 Chain Hook

16 06-81-8820 Ground Screw 1o-98-6095 Chain Label

17 42-20-0680 Magnetic Base Assembly

20 06-83-2520 1 O-32 x 1” Headless Socket Screw FOR MOUNTING DRILL MOTOR TO STAND USE:

21 43-33-0150 Grease Fitting 06-97-4050 l/4” Split Ring Lock Washer

22 45-88-7160 Thrust Washer 06-75-3050 l/4-20 x 314” Socket Hd. Screw

23 45-88-5247 Hub Washer

24 06-97-4050 l/4” Solit Rina Lock Washer

MILWAUKEE ELECTRIC TOOL CORPORATION

25 06-88-0110 114-29 x 314” “Wing Screw 13135 W. LISBON RD., BROOKFIELD, WI 53005

26 06-75-2900 l/4-20 x 3/8” Socket Hd. Screw Dnva. 1

BULLETIN NO.

SERVICE PARTS LIST 54-30-0152

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS REVISED BULLETIN DATE

54-30-0151 Aug. 2010

MAG STAND CONTROL PANEL

WIRING INSTRUCTION

CATALOG NO. 23-35-0312 SERIAL

NUMBER SEE BELOW

EXAMPLE:

00 0

Component Parts (Small #) Are Included FIG. PART NO. DESCRIPTION OF PART NO. REQ.

When Ordering The Assembly (Large #). 1 --------------- Circuit Board Assembly (1)

2 23-33-0495 Receptacle Assembly (1)

3 44-66-0810 Panel Plate Assembly (1)

4 06-82-5268 4-40 x 3/8" Pan Hd. Taptite T-9 (4)

5 42-42-0385 Drill "OFF" Button (1)

6 42-36-1770 Receptacle Bracket (1)

7 --------------- Switch Button (1)

42-42-0405 Push Button - Green (Solid) (1)

42-42-0400 Push Button - Yellow (Solid) (1)

42-42-0440 Push Button - White (Clear) (1)

8 42-42-0450 Push Button - Push Button Blank (1)

9 23-18-0080 Speed Dial (1)

10 06-82-7252 8-32 x 3/8" Pan Hd. Slt. Tapt. T-20 (2)

11 45-06-0650 Receptacle Seal (1)

12 06-81-8650 6-32 x 1/4" Rd. Hd. Sems (1)

13 10-98-0225 "Drill-OFF" Label (1)

14 23-16-1580 Panel Insulator (1)

SEE REVERSE SIDE

BEFORE WIRING FOR

IMPORTANT NOTES

AND OPERATIONAL

CHECK PROCEDURE

WIRING

INSTRUCTIONS

Cord Set Terminals

Wire Color Part Number

Black 23-74-0970

White 23-74-0970

Green 23-74-0320

1. ROUTE TWO MAGNETIC BASE LEADS (RED WIRES WITH 5. ATTACH THE LEADS FROM THE MAGNETIC BASE ,

YELLOW SLEEVING) THROUGH ADJUSTING PLATE AND AS SHOWN. NOTE: THE LEADS FROM THE MAGNETIC BASE

PAST ADJUSTING LOCK MECHANISM, ONE ON EACH SIDE. CAN BE ATTACHED TO THE PANEL IN EITHER LOCATION.

MAKE SURE SLEEVING IS NOT ABRADED DURING ROUTING.

6. ATTACH THE POTTED PCB ASSEMBLY TO THE SUPPORT

2. SECURE LINE CORD IN SUPPORT HOUSING. HOUSING.

3. ATTACH GROUND TERMINAL TO SUPPORT HOUSING WITH 7. GENTLY PUSH THE BUNDLE OF WIRES DOWNWARD AND

GROUND SCREW. POSITION GROUND WIRE TERMINAL AS INSTALL THE CONTROL PANEL INTO THE HOUSING. AVOID

SHOWN, SO IT CAN SET FLAT AGAINST HOUSING BEFORE PINCHING WIRES OR THE RIBBON CABLE AS THE CONTROL

SECURING. PANEL IS BEING INSTALLED.

4. ATTACH THE BLACK AND WHITE LEADS FROM LINE CORD,

AS SHOWN. MILWAUKEE ELECTRIC TOOL CORPORATION

13135 W. LISBON RD., BROOKFIELD, WI 53005

Drwg. 8

Anda mungkin juga menyukai

- Manual de Taller - John Deere 997 Z-TrackDokumen284 halamanManual de Taller - John Deere 997 Z-TrackKevin Andrés Garzón MijaresBelum ada peringkat

- ELC 4-Speed Automatic Transaxle (Part 1 of 6) : Diagrams Electrical Diagrams Transmission Control SystemsDokumen7 halamanELC 4-Speed Automatic Transaxle (Part 1 of 6) : Diagrams Electrical Diagrams Transmission Control SystemsVikas NarangBelum ada peringkat

- Service Parts Manual: Series 51: 160 CC Variable Displacement MotorsDokumen104 halamanService Parts Manual: Series 51: 160 CC Variable Displacement MotorsJose Manuel Barroso PantojaBelum ada peringkat

- TM1403 John Deere 450G, 455G, 550G, 555G, 650G Crawler Diagnostic Operation Test Technical ManualDokumen11 halamanTM1403 John Deere 450G, 455G, 550G, 555G, 650G Crawler Diagnostic Operation Test Technical Manualtteelsars0% (1)

- Hyster K019 (H300HD2, H330HD2, H360HD2, H360HD2-EC, H210-48HD2, H230-48HD2, H250-48HD2) Forklift Service Repair ManualDokumen62 halamanHyster K019 (H300HD2, H330HD2, H360HD2, H360HD2-EC, H210-48HD2, H230-48HD2, H250-48HD2) Forklift Service Repair ManualGilo MonterrubioBelum ada peringkat

- Machine Elements in Mechanical Design Solution PDFDokumen309 halamanMachine Elements in Mechanical Design Solution PDFazkonaBelum ada peringkat

- PI221227 (S.parts For M6D30 Series)Dokumen3 halamanPI221227 (S.parts For M6D30 Series)jesusbritomBelum ada peringkat

- Dokumen - Tips Ford New Holland 6610 Tractor Service Repair Manual 1628616661Dokumen18 halamanDokumen - Tips Ford New Holland 6610 Tractor Service Repair Manual 1628616661Anastasio Diaz50% (2)

- Arme y Desarme Bloque de Control de La Transmision 928GDokumen10 halamanArme y Desarme Bloque de Control de La Transmision 928GAlex Consuegra Medina100% (2)

- PDF ALLANADORADokumen30 halamanPDF ALLANADORAjhonathan guadalupe100% (1)

- Control de Trasm 410g. 3 PDFDokumen2 halamanControl de Trasm 410g. 3 PDFdavidBelum ada peringkat

- Wacker Neuson Light CompactionDokumen13 halamanWacker Neuson Light CompactionBusiness Trade Import100% (1)

- Service Parts Manual: Series 40 M25 Axial Piston MotorDokumen24 halamanService Parts Manual: Series 40 M25 Axial Piston Motorjose manuel barroso pantojaBelum ada peringkat

- Parts Catalog: 0CW10-M00800ENDokumen24 halamanParts Catalog: 0CW10-M00800ENSeibBelum ada peringkat

- 3TNV70 ASA BroDokumen1 halaman3TNV70 ASA BroSaMos AdRiianBelum ada peringkat

- Manual de Partes para Motor KUBOTADokumen124 halamanManual de Partes para Motor KUBOTApedroBelum ada peringkat

- Aa10vg Rexroth PDFDokumen44 halamanAa10vg Rexroth PDFJonathan GiraldoBelum ada peringkat

- Part Cat Dp70Dokumen6 halamanPart Cat Dp70boy qsi100% (1)

- Afloat 2Dokumen256 halamanAfloat 2Matthaios SkantrzourakisBelum ada peringkat

- A45GDokumen1.127 halamanA45GBayuBelum ada peringkat

- A E300aj, E300ajp JLG Parts EnglishDokumen346 halamanA E300aj, E300ajp JLG Parts EnglishДмитрийBelum ada peringkat

- 420 E-HlsDokumen18 halaman420 E-HlsarnoldBelum ada peringkat

- D905-D1105 KUBOTA Operation ManualDokumen45 halamanD905-D1105 KUBOTA Operation ManualJORGE ARMANDO CARRASCO TICLLEBelum ada peringkat

- Catalogo de Pecas CMP18Dokumen105 halamanCatalogo de Pecas CMP18Waitylla Dias0% (1)

- Tru Pac 915 PDFDokumen2 halamanTru Pac 915 PDFGustavo FajardoBelum ada peringkat

- Parts RANGER 305D Code 11457Dokumen26 halamanParts RANGER 305D Code 11457jorge trespalacios100% (1)

- Smartlink SoftwareDokumen9 halamanSmartlink SoftwarejlmacxBelum ada peringkat

- PARTS LIST (Model EC4, ECT4, ECC4)Dokumen2 halamanPARTS LIST (Model EC4, ECT4, ECC4)Sajjad RasoolBelum ada peringkat

- Brochure PollypigDokumen4 halamanBrochure Pollypigjuan.ojedaBelum ada peringkat

- Vantage 300: Parts List ForDokumen28 halamanVantage 300: Parts List ForGabriel AmorimBelum ada peringkat

- Single and Multistage Steam Jet Ejectors: TorinoDokumen12 halamanSingle and Multistage Steam Jet Ejectors: TorinoSuman SenapatiBelum ada peringkat

- Manual Torre MULTIQUIP, PartesDokumen58 halamanManual Torre MULTIQUIP, PartesDawn HallBelum ada peringkat

- Manual de Partes y Operacion Rodillo Compacatdor Tanden Mikasa MRH-800DS2 Motor Diesel YanmarDokumen92 halamanManual de Partes y Operacion Rodillo Compacatdor Tanden Mikasa MRH-800DS2 Motor Diesel YanmarAlejandro Antonio Alvarez BalveroBelum ada peringkat

- Engine Number Guide - PP827!01!09Dokumen4 halamanEngine Number Guide - PP827!01!09Taz UddinBelum ada peringkat

- 35533Dokumen90 halaman35533genieBelum ada peringkat

- 200CLCDokumen11 halaman200CLCRASMAJONBelum ada peringkat

- Chamberlain 1215e Fs2 Manual de UsuarioDokumen80 halamanChamberlain 1215e Fs2 Manual de Usuariojuan camilo EscuderoBelum ada peringkat

- Diagrama FODR F150 1 PDFDokumen1 halamanDiagrama FODR F150 1 PDFPatricio Edgar Gualli CalagullinBelum ada peringkat

- Rhino Hammers PDFDokumen8 halamanRhino Hammers PDFBudi WaskitoBelum ada peringkat

- Manual de Servicio KubotaDokumen2 halamanManual de Servicio KubotacpaolinodBelum ada peringkat

- Equivalencias FiltrosDokumen80 halamanEquivalencias FiltrosRaul TarquiniBelum ada peringkat

- Despiece Mitsubishi y KubotaDokumen4 halamanDespiece Mitsubishi y KubotaOscar MartinezBelum ada peringkat

- Power Team P Series Manual (2 Speed)Dokumen42 halamanPower Team P Series Manual (2 Speed)TitanplyBelum ada peringkat

- Manual Lavadora DaewoDokumen36 halamanManual Lavadora DaewoJuan Carlos Sanchez GomezBelum ada peringkat

- Catalogo de Partes - M9540Dokumen226 halamanCatalogo de Partes - M9540NELSON ROMEROBelum ada peringkat

- Part Manual DP70Dokumen376 halamanPart Manual DP70Melchor Gómez CuaresmaBelum ada peringkat

- ForewordDokumen2 halamanForewordInjeletro DieselBelum ada peringkat

- Manual de Partes G-5 Sae 400 PDFDokumen24 halamanManual de Partes G-5 Sae 400 PDFamerica1591Belum ada peringkat

- Powertech: 6068Tf220 - 120 KW at 1500 RPM 6068Tf250 - 142 KW at 1800 RPM Specifications For Gen Set ApplicationsDokumen2 halamanPowertech: 6068Tf220 - 120 KW at 1500 RPM 6068Tf250 - 142 KW at 1800 RPM Specifications For Gen Set ApplicationsJulio0% (1)

- Regulador de Voltaje TM-759 - 430391CDokumen68 halamanRegulador de Voltaje TM-759 - 430391CLider TallerBelum ada peringkat

- RH112CW62P Mrotary - DatasheetDokumen5 halamanRH112CW62P Mrotary - DatasheetAbdou_AEBelum ada peringkat

- Plano Electrico 450E EBLDokumen4 halamanPlano Electrico 450E EBLDarío Ache EmeBelum ada peringkat

- 216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 6 UBA PDFDokumen3 halaman216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 6 UBA PDFubaldo caraballoBelum ada peringkat

- Panel de Control Compresor ArielDokumen40 halamanPanel de Control Compresor ArielTatiana GomezBelum ada peringkat

- MF 2615-4WD (Brosur)Dokumen2 halamanMF 2615-4WD (Brosur)ayi3xtremistBelum ada peringkat

- S570 Elec Acs-Sjc-Op 7210761 PDFDokumen15 halamanS570 Elec Acs-Sjc-Op 7210761 PDFEvert Vargas TorrezBelum ada peringkat

- Modelo Terex Txc140lc-1Dokumen1 halamanModelo Terex Txc140lc-1DarioBelum ada peringkat

- ZX230 270 Eng eDokumen1 halamanZX230 270 Eng ejacklyn ade putraBelum ada peringkat

- Caterpillar Cat 226 Skid Steer Loader (Prefix 5FZ) Service Repair Manual (5FZ00001-06699)Dokumen24 halamanCaterpillar Cat 226 Skid Steer Loader (Prefix 5FZ) Service Repair Manual (5FZ00001-06699)rpoy9396615Belum ada peringkat

- Reyco PDFDokumen44 halamanReyco PDFJavier Yandun100% (1)

- Manual de Especificaciones Clark D155G WaukeshaDokumen2 halamanManual de Especificaciones Clark D155G WaukeshacpaolinodBelum ada peringkat

- Service Parts List: 54-46-2251 838B Electromagnetic Drill Stand 4203Dokumen1 halamanService Parts List: 54-46-2251 838B Electromagnetic Drill Stand 4203Oscarito VázquezBelum ada peringkat

- 6148-30 TYPE B71B MilwaukeeDokumen3 halaman6148-30 TYPE B71B MilwaukeeanibaltinoBelum ada peringkat

- 84690, 84690-1, 82205-1Dokumen3 halaman84690, 84690-1, 82205-1RZ EmiBelum ada peringkat

- SITRANS F US Clamp-On: Thickness GaugeDokumen1 halamanSITRANS F US Clamp-On: Thickness GaugeJuan carlosBelum ada peringkat

- 6GK60248GS2Dokumen5 halaman6GK60248GS2Juan carlosBelum ada peringkat

- GT Datasheet DuraShieldDokumen2 halamanGT Datasheet DuraShieldJuan carlosBelum ada peringkat

- 3BUR000118R15 Tk510 Cable Assembly DCN 15m 49 FTDokumen1 halaman3BUR000118R15 Tk510 Cable Assembly DCN 15m 49 FTJuan carlosBelum ada peringkat

- Cd52 Bandit Product Sheet 2Dokumen2 halamanCd52 Bandit Product Sheet 2Juan carlosBelum ada peringkat

- MT12550FTDokumen1 halamanMT12550FTJuan carlosBelum ada peringkat

- Reference Manual: GPS-Based Time ReferenceDokumen78 halamanReference Manual: GPS-Based Time ReferenceJuan carlosBelum ada peringkat

- 1133 Arbiter System PDFDokumen6 halaman1133 Arbiter System PDFJuan carlosBelum ada peringkat

- FILIPINO 2 LEARNING PLAN 3rd QuarterDokumen4 halamanFILIPINO 2 LEARNING PLAN 3rd QuarterMary Kryss DG SangleBelum ada peringkat

- Coverpage BLDG Projects F.Y. 2021Dokumen4 halamanCoverpage BLDG Projects F.Y. 2021Adrian PachecoBelum ada peringkat

- Security Analysis: Kumar SaurabhDokumen11 halamanSecurity Analysis: Kumar Saurabhakhil vermaBelum ada peringkat

- Introduction To Social WorkDokumen3 halamanIntroduction To Social WorkSheherbano TariqBelum ada peringkat

- Kuis ITSMDokumen31 halamanKuis ITSMHariyanto HalimBelum ada peringkat

- CV - Akhil AgarwalDokumen2 halamanCV - Akhil AgarwalIshan SaxenaBelum ada peringkat

- Documents and Data RequirementsDokumen2 halamanDocuments and Data RequirementsGerardo Leon RoblesBelum ada peringkat

- Goodman and Gilman's Sample ChapterDokumen17 halamanGoodman and Gilman's Sample Chapteradnankhan20221984Belum ada peringkat

- Steel Rebar Sizes and Weights ChartsDokumen2 halamanSteel Rebar Sizes and Weights ChartsNadiah Abdul RahamanBelum ada peringkat

- SikaWrap®-900 CDokumen4 halamanSikaWrap®-900 CN.J. PatelBelum ada peringkat

- Alternating Current Bounce Back 2.0 22 DecDokumen132 halamanAlternating Current Bounce Back 2.0 22 Decayushmanjee1303Belum ada peringkat

- Neurohealth Properties of Hericium Erinaceus MycelDokumen11 halamanNeurohealth Properties of Hericium Erinaceus Myceldokan42Belum ada peringkat

- Methods of Determining Thermal Efficiency in Spray Drying ProcessDokumen3 halamanMethods of Determining Thermal Efficiency in Spray Drying ProcessDfunz WilphenBelum ada peringkat

- Approach SlabDokumen2 halamanApproach SlabMahmood Mufti100% (1)

- BM 2 Operations Management and TQM NewDokumen9 halamanBM 2 Operations Management and TQM NewEly GragasinBelum ada peringkat

- Lecture 9Dokumen26 halamanLecture 9Tesfaye ejetaBelum ada peringkat

- CEFR Lesson Plan Let's PlayDokumen1 halamanCEFR Lesson Plan Let's PlayRashidah Zaman100% (3)

- Class 10 RespirationDokumen3 halamanClass 10 RespirationHimanshu singh100% (1)

- TestDokumen4 halamanTestAlina DushachenkoBelum ada peringkat

- Вправи на Past SimpleDokumen4 halamanВправи на Past SimpleLiliaBelum ada peringkat

- 060610at617pm Mayday Re Are We Under Terrorist Attack YesDokumen12 halaman060610at617pm Mayday Re Are We Under Terrorist Attack YesRalph Charles Whitley, Sr.Belum ada peringkat

- Assigment On Reliance Industry: Master of Business Administration (Talentedge)Dokumen14 halamanAssigment On Reliance Industry: Master of Business Administration (Talentedge)Mayank MalhotraBelum ada peringkat

- Ethics and Social Responsibilities of Entrepreneurship PDFDokumen4 halamanEthics and Social Responsibilities of Entrepreneurship PDFRevuru ArunaBelum ada peringkat

- Human Resource Management in Banking Sector in STATE BANK OF INDIA by PrinceDokumen83 halamanHuman Resource Management in Banking Sector in STATE BANK OF INDIA by Princemayur pawarBelum ada peringkat

- Equipment Mark Type Matricule N de Serie Cont, Tec 3Rd Prty Cert ComentaireDokumen1 halamanEquipment Mark Type Matricule N de Serie Cont, Tec 3Rd Prty Cert ComentaireGTP HSE SECURITYBelum ada peringkat

- PHTH 211 Lecture 1 Regulation of Body FunctionsDokumen33 halamanPHTH 211 Lecture 1 Regulation of Body Functionsmaatela7sasBelum ada peringkat

- Users of Accounting InformationDokumen4 halamanUsers of Accounting InformationfharnizaparasanBelum ada peringkat