System Planning Guide

Diunggah oleh

Sardar PerdawoodHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

System Planning Guide

Diunggah oleh

Sardar PerdawoodHak Cipta:

Format Tersedia

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page 1 of 36

Essential Asset Monitoring

System Planning Guide

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page 2 of 36

Disclaimer

The contents of this publication are presented for informational purposes only, and while

every effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, express or implied, regarding the products or services described

herein or their use or applicability. We reserve the right to modify or improve the designs or

specifications of such products at any time without notice. This document is not to be

redistributed without permission from Emerson Process Management.

Copyright and Trademark Information

© Emerson Process Management, 2014. All rights reserved. Printed in the USA.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

AMS, PlantWeb™, SNAP-ON™, DeltaV™, RS3™, PROVOX™, Ovation™, FIELDVUE™,

SmartProcess® and ValveLink™ are marks of one of the Emerson group of companies

HART® and WirelesssHART® are registered trademarks of the HART Communications

Foundation of Austin, Texas, USA

All other marks are property of their respective owners.

Revision History

Rev Status Description Date Developed By Reviewed By

P1 Initial Release For EAM application v.R3 Sept 6, 2014 KSP PS

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page 3 of 36

Table of Contents

1 INTRODUCTION ______________________________________________________ 4

1.1 Intended Audience ............................................................................................................ 4

1.2 Reference Publications ..................................................................................................... 4

1.2.1 EAM Application Documentation ....................................................................................................... 4

1.2.2 Product Data Sheets .......................................................................................................................... 4

1.2.3 White Papers and Sales Information ................................................................................................. 5

1.3 Introduction to EAM Solution ............................................................................................. 5

1.4 Glossary ............................................................................................................................ 7

2 SYSTEM CONSIDERATIONS ____________________________________________8

2.1 EAM Application Overview ................................................................................................ 8

2.1.1 EAM Pump ......................................................................................................................................... 9

2.1.2 EAM Heat Exchanger ....................................................................................................................... 10

2.1.3 Blower ............................................................................................................................................... 11

2.1.4 Compressor ...................................................................................................................................... 12

2.1.5 Air-Cooled Heat Exchanger ............................................................................................................. 13

2.1.6 Cooling Tower .................................................................................................................................. 14

2.2 Architecture Overview ..................................................................................................... 14

2.3 EAM Multiuser Architecture ............................................................................................. 15

2.3.1 Thin Client Approach ........................................................................................................................ 16

2.3.2 Thick Client Approach ...................................................................................................................... 17

2.3.3 Hybrid Approach............................................................................................................................... 17

2.4 EAM Requirement Specifications .................................................................................... 18

2.4.1 AMS Asset Graphics License Specifications ................................................................................... 19

2.4.2 Hardware Specifications .................................................................................................................. 19

2.4.3 System Software Specifications....................................................................................................... 19

2.4.4 EAM Functional Specifications ........................................................................................................ 20

3 Systems Integration ___________________________________________________ 22

3.1 Interface with DeltaV ....................................................................................................... 22

3.2 Interface with Ovation...................................................................................................... 26

3.3 Interface with Historians .................................................................................................. 26

4 OTHER CONSIDERATIONS ____________________________________________ 27

4.1 Application Support ......................................................................................................... 27

4.2 Upgrades and Extensions ............................................................................................... 27

4.3 Backup and Recovery ..................................................................................................... 27

Appendix A - Fault Matrices

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 4 of 36

1 INTRODUCTION

This document provides guidelines to help users successfully plan, implement, and

use Essential Asset Monitoring applications. This guide also contains information on

application types and their architectures, licensing requirements, and general

planning considerations.

1.1 Intended Audience

This guide is intended for sales and service personnel at Local Business Partners

and Field Sales Offices (LBP/FSO) as well as company personnel of Emerson

Process Management.

The information in this guide should be considered as confidential.

1.2 Reference Publications

1.2.1 EAM Application Documentation

The EAM Application is delivered with the following documentation:

- Installation Guide

- Configuration Guide

- User Manual

Access to the EAM demos and documentation is provided for Emerson or Local

Business Partner employees. Access requires a valid Emerson Active Directory

account. You may request access to these files by sending an email to:

EAM.Support@Emerson.com.

1.2.2 Product Data Sheets

A Product Data Sheet for the EAM solution as well as customer flyers for each of the

assets are available on the Emerson Global Sales Portal.

EAM:

https://sales.emersonprocess.com/IndustriesandApplications/IndustrySolutionsPacka

ges/Pages/Essential-Asset-Monitoring.aspx

Pumps:

http://www2.emersonprocess.com/siteadmincenter/PM%20Central%20Web%20Doc

uments/PumpsREF_CustFlyer.pdf

Blowers:

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 5 of 36

http://www2.emersonprocess.com/siteadmincenter/PM%20Central%20Web%20Doc

uments/BlowersREF_CustFlyer.pdf

Heat Exchangers:

http://www2.emersonprocess.com/siteadmincenter/PM%20Central%20Web%20Doc

uments/HeatExchangersREF_CustFlyer.pdf

Air-Cooled Heat Exchangers:

http://www2.emersonprocess.com/siteadmincenter/PM%20Central%20Web%20Doc

uments/Ache-REF_CustFlyer.pdf

Compressors:

http://www2.emersonprocess.com/siteadmincenter/PM%20Central%20Web%20Doc

uments/CompressorsREF_CustFlyer.pdf

Cooling Towers:

http://www2.emersonprocess.com/siteadmincenter/PM%20Central%20Web%20Doc

uments/CoolingTowersREF_CustFlyer.pdf

1.2.3 White Papers and Sales Information

Many white papers and sales material are available for each of the asset types on

the Global Sales Portal. In particular, there are Application Opportunity Briefs (AOB)

for each asset type that outlines the solution, the benefits to a customer and which

customer roles care.

1.3 Introduction to EAM Solution

Emerson’s EAM solution is a combination of software, hardware, and measurement

devices designed to monitor the performance and ascertain the “health” of particular

types of assets. The solution that Emerson provides to an end customer must be

tailored to the specific requirements and infrastructure available at a plant.

Depending on the level of instrumentation that exists, the types of faults that need

detecting, and the user interface preferences, an EAM project will likely involve

installing new field devices, wireless gateways, a new EAM server hardware and

software and integration with an existing DCS or historian.

Emerson’s EAM software can be delivered as a stand-alone server connected to the

plant LAN and any wireless gateways, providing the database, calculation logic and

user-interface through dedicated monitors and remote sessions. Alternatively, the

EAM Server can be treated as a “black box” for the calculations and logic, and the

user interface is provided on a DeltaV, Ovation or OSI-PI platform. These options

are explained further in Section 2.

EAM software modules are currently available for the following asset types:

- Pumps

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 6 of 36

- Blowers

- Heat Exchangers (Shell/Tube)

- Air-Cooled Heat Exchangers

- Compressors (Max 3-stage, Roller Bearings)

- Cooling Towers

Each of the EAM modules uses a common look and feel for the standard User

Interface. Each module is designed for the maximum potential instrumentation

possible, but a user can select which inputs are available (based on which faults

they need to detect) and the system will automatically disable the calculations that

are not required.

It should be noted that Emerson’s EAM applications use a statistical approach to

determining health as opposed to the 1st principles models found in AMS

Performance Advisor and AMS Performance Monitor. The intent is to simplify the

configuration, installation and setup of the EAM modules and use these as indicators

to flag attention when something does not look right. The system can automatically

capture a base-line or a signature and calculate statistical limits for alarming.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 7 of 36

1.4 Glossary

Term Definition

ACHE Air Cooled Heat Exchanger

AMS AG AMS Asset Graphics

DCS Distributed Control System – Could be DeltaV,

Ovation or something else.

EAM EAM – Usually references the EAM software

that performs the algorithm and logic

OPC OLE for Process Control - Standard protocol

use to exchange real-time data between

systems

UI User interface – The application running on

the user’s PC which displays the EAM

variables, calculations and alerts.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 8 of 36

2 SYSTEM CONSIDERATIONS

2.1 EAM Application Overview

EAM applications are designed to continuously monitor the health of industrial

assets by combining both process and equipment data in a patent-pending approach.

The EAM Suite is built on Emerson’s AMS Asset Graphics (AG) platform. AG

typically runs on a dedicated PC or Server with the EAM application engine scanning

the measurements, running the logic and setting alerts and statuses. The AG

platform has been designed to easily integrate with the existing control system at a

customer site using OPC.

Emerson’s wireless technology for the field instruments provides additional

advantage for using the EAM applications in remote, hazardous areas.

Using the built-in OPC client in AMS AG, the EAM applications read the field

instrument data over OPC communication. This data is then processed to generate

alarms, alerts, KPIs and asset Health as indicated in the flowchart below (Figure 2-1).

Statistical Alarms

for Vibration

EAM Functional Flowchart

Static & Dynamic

Record Calculate Process Alarms

Process &

Baselines & Alarm

Vibration Data

Signatures Limits

Process Alerts

Performance Indices

Health Calculation

Data Trending

Data Exporting

Events Logging

Figure 2-1

EAM Functional Flowchart

Presently, the EAM Suite is available for following assets:

EAM Pump

EAM Heat Exchanger

EAM Blower

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 9 of 36

EAM Multistage Compressor

EAM Air Cooled Heat Exchanger

EAM Cooling Tower

These modules are licensed on a per-asset basis with volume discounts starting at 5

of more. A description of each is provided below. Further material can be found on

the Emerson Global Sales Portal.

2.1.1 EAM Pump

Figure 2-2

EAM Pump Process Overview

This module is designed to monitor the health of centrifugal pumps, in essentially any

type of service. It uses vibration sensors on the pump and motor, combined with

process data on the flow, suction and discharge pressures and seal flush system to

detect when one of the parameters is outside it’s expected operating range and

detects faults like bearing or alignment issues, cavitation, plugged suction strainers,

hydrocarbon leaks and seal flush problems.

For more information, see this site:

https://sales.emersonprocess.com/IndustriesandApplications/IndustrySolutionsPacka

ges/Pages/Pump-Health-Monitoring.aspx

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 10 of 36

2.1.2 EAM Heat Exchanger

Figure 2-3

EAM Heat Exchanger Process Overview

EAM for heat exchangers is designed primarily for shell-and-tube heat exchangers,

although other types (e.g. plate, seawater) have been considered. The application

utilizes the process flows, inlet and outlet temperatures to calculate exchanger duty,

fouling factor and degradation cost. In addition the application utilizes differential

pressure to assist with predicting when the exchanger will need cleaning.

For more information, see this site:

https://sales.emersonprocess.com/IndustriesandApplications/IndustrySolutionsPacka

ges/Pages/Essential-Asset-Monitoring---Heat-Exchangers.aspx

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 11 of 36

2.1.3 Blower

Figure 2-4

EAM Blower Process Overview

The EAM module for blowers uses vibration sensors on the fan and motor as well as

air pressure and louver positions to detect fan blade imbalance, bearing defects,

lubrication issues, resonance speed, and malfunctioning louver drive. Health is

derived from the active alerts and distance from maximum vibration limits.

For more information, see this site:

https://sales.emersonprocess.com/IndustriesandApplications/IndustrySolutionsPacka

ges/Pages/Essential-Asset-Monitoring---Blowers.aspx

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 12 of 36

2.1.4 Compressor

Figure 2-5

EAM Compressor Process Overview

EAM for compressors is designed for single-, dual- or 3-stage centrifugal

compressors and calculates health from vibration and process parameters. The

Compressor module monitors for rotor alignment, lubrication and bearing issues on

each stage. The wireless CSI9420 is designed for rolling-element bearings. While

some customers have applied the CSI9420 vibration sensors on sleeve-type

bearings, the recommendation would be a CSI6500. The vibration signals from the

6500 can be used as EAM inputs. Additional faults include low flow, low stage

pressure ratio, and compressor instability.

For more information, see this site:

https://sales.emersonprocess.com/IndustriesandApplications/IndustrySolutionsPacka

ges/Pages/Essential-Asset-Monitoring---Compressor.aspx

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 13 of 36

2.1.5 Air-Cooled Heat Exchanger

Figure 2-6

EAM ACHE Process Overview

The Air-Cooled Heat Exchanger (ACHE) module of the EAM suite monitors both the

fan and the thermodynamic performance of these assets. For ACHE, the system

monitors for fan imbalance, louver defects, resonance speeds, bearing, lubrication

and alignment issues, exchanger fouling, and damaged heat exchanger surfaces.

For more information see:

https://sales.emersonprocess.com/IndustriesandApplications/IndustrySolutionsPacka

ges/Pages/Essential-Asset-Monitoring-Air-Cooled-Heat-Exchangers.aspx

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 14 of 36

2.1.6 Cooling Tower

Figure 2-7

EAM Cooling Tower Process Overview

EAM for cooling towers provides integrated monitoring and determination of a

combined health status for each cooling tower cell, including supply and circulation

pumps, fans, makeup and blow-down water, basin, chemical use and water

chemistry.

For more information, see this site:

https://sales.emersonprocess.com/IndustriesandApplications/IndustrySolutionsPacka

ges/Pages/Essential-Asset-Monitoring---Cooling-Towers.aspx

2.2 Architecture Overview

The EAM Software is designed to allow customers to easily bring in real-time data

either through wireless or existing wired infrastructure via OPC. Emerson delivers a

pre-configured EAM solution which only needs to be mapped to the appropriate OPC

points. The system is typically run on a dedicated server and the user interface can

be either through remote sessions or integrated into the existing DCS or historian

user screens. Refer to Section 3 for more details.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 15 of 36

Figure 2-8

Typical EAM Architecture at site

Figure 2-8 shows the basic architecture of a typical EAM application. As shown, the

source of OPC data for the EAM application could be the wireless gateway or the

OPC server in the local DCS, PLC or historian. The Blue line indicates the data flow

from the wired transmitters and the Green line indicates data flow for the wireless

transmitters.

The EAM application is designed to read data from DA (Data Access) type OPC

server which can feed a continuous stream of data. The application also reads

instrument health status of the individual data point along with its process value. The

health status is then indicated on the user interface of the EAM application and used

in the fault detection logic and asset health.

Using the built in OPC client in AMS AG, it is possible to read data from multiple OPC

servers simultaneously.

2.3 EAM Multiuser Architecture

The EAM application could be used in multiuser environments using the following

approaches

1. Thin Client (Remote Desktop) approach.

2. Thick Client (Dedicated Station) approach.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 16 of 36

3. Hybrid approach (Remote Desktop and Dedicated stations)

2.3.1 Thin Client Approach

In case of thin client approach, there is only one Master station running the EAM

application. The client machines can connect to the Master station using Microsoft

Windows remote desktop application (RDP). There could be up to 31 such thin

clients concurrently accessing the EAM Master station. A multi-user system is

licensed based on the number of concurrent sessions allowed. The following

diagram provides an example network diagram for this approach.

Figure 2-9

EAM Architecture for Thin Client Multiuser Approach

2.3.1.1 Prerequisites

1. AMS AG platform needs to be installed on the Master station only with a

multiuser license. (The thin clients do not require any additional software

prerequisites).

2. The Master station must be a server-grade machine with MS Windows Server

operating system installed along with terminal server license with required

number of concurrent users.

3. The machine specifications of the Master station should ensure performance

capability to serve the required number of multiple RDP connections concurrently.

4. The thin clients must be able to connect to the master station through a remote

desktop connection.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 17 of 36

2.3.2 Thick Client Approach

In this approach, as the name suggests, the clients would be user PC’s connected to

the Master station through a physical or wireless network. Each client station needs

the AG client software to be installed. This approach eliminates the need of a server

grade machine for the EAM master station. Also, no terminal server license is

required in this case. The machine specifications for the Master station could be as

simple as that of the thick client machine.

Similar to the previous approach, the number of clients that could be connected to

Master station is limited to 31.

Figure 2-10

EAM Architecture for Thick Client Multiuser Approach

2.3.2.1 Prerequisites

1. AMS AG platform needs to be installed on the Master station as well as all the

client stations.

2. The client PC’s need to have direct network access to the Master station through

the firewall.

2.3.3 Hybrid Approach

This is special case of thin client approach wherein some thick clients are connected

to the Master station through physical network (as in case of thick client approach)

thereby offering advantages of both the approaches into one.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 18 of 36

The total number of clients (thick and thin) is licensed by concurrent user and is

limited to 31.

Figure 2-11

EAM Architecture for Hybrid Multiuser Approach

Note: When it comes to selecting one of the above mentioned approaches, following

factors are to be considered

1. Need for running the EAM application remotely (from the plant LAN or higher

level LANs)

2. Investment cost on the EAM stations

With thin client approach, the EAM application could be run on lower grade machines

(not need of workstation grade machines). However the customer needs to put more

investment in the EAM master station (terminal server license, Server grade OS etc)

In case of thick client approach, the Master station could be as simple as the thick

client (workstation grade machine), however the client machines should satisfy the

minimum specifications mentioned in Section 2.4.2.

2.4 EAM Requirement Specifications

The following sections outline EAM requirements in terms of following aspects

AMS Asset Graphics Licenses

Hardware

System Software

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 19 of 36

Configuration

2.4.1 AMS Asset Graphics License Specifications

Table 1 shows the required AMS AG licenses that should appear in a typical AMS

AG license document for the EAM applications. These are all bundled into one EAM

Solution part number and sold as an EAM system from Emerson’s AO office in

Knoxville.

Table 1

AMS AG License Specifications

License Specification

Sets the database element size to accommodate all the

System Size

assets to be monitored

Number of concurrent users supported in case of

Simultaneous Users

multiuser environment. (Refer to Section 2.3)

Runtime Program

Multilanguage Required for Multilanguage texts on the user interface

Required only in case of Multiuser environment. (Refer to

Floating License

Section 2.3 for details)

Required only in case of Multiuser environment. (Refer to

Network

Section 2.3 for details)

Required for sharing the EAM data with DCS/PLC. E.g.

OPC Server

EAM alerts in DeltaV (Refer to Section 3.1 for details)

OPC Editor Required for editing/creating OPC client tables

2.4.2 Hardware Specifications

The EAM runtime is usually executed on a dedicated computer, either a workstation

for single user or a server-class machine for multi-user systems. The main criteria

that will affect the hardware specification are the number of simultaneous users and

number of assets to be monitored. The following Table 2 lists the minimum

specification required by the EAM servers.

Table 2

Machine Specifications

Machine Specifications Related EAM Feature

EAM v.R3 (AMS AG v.6.0.2.0)

Processor : Intel Xeon Maximum 40 assets

Processor Speed : 2.4 GHz

RAM : 4 GB

Screen Resolution:

1680 X 1050 OR

1280 X 1024

2.4.3 System Software Specifications

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 20 of 36

Table 3 lists the software prerequisites that need to be installed on the EAM Master

station.

Table 3

Software Prerequisites for EAM Master Station

Software Prerequisites Related EAM Feature

EAM v.R3 (AMS AG v.6.0.2.0)

Operating System:

- Win 7 - For single user environment

- Win Server 2008 - For multiuser environment

AMS Asset Graphics A maximum of 100 assets can be supported on one

- Version 6.0.2.0 license.

EAM Project Software EAM v.R3 or later

- EAM-PUMPS - Pump Health Monitoring

- EAM-HX - Heat Exchanger Monitoring

- EAM-BLWR - Blower Monitoring

- EAM-ACHE - Air-Cooled Heat Exchanger Monitoring

- EAM-CMPR - Compressor Monitoring

- EAM-CT - Cooling Tower Monitoring

Microsoft Excel 7 Required only in case of EAM Heat Exchange application

OPC DCOM Configuration To enable OPC communication on the Master station

and on the thick clients. See Installation Guide for more

information

Table 4 shows software prerequisites for EAM thick clients.

Table 4

Software Prerequisites for EAM Thick clients

Software Prerequisites Related EAM Feature

EAM v.R3 (AMS AG v.6.0.2.0)

Operating System:

- Win 7

AMS Asset Graphics

- Version 6.0.2.0

Microsoft Excel 7 Required only in case of EAM Heat Exchange application

There are no separate prerequisites required for the EAM thin clients except the

ability to connect remotely to the master station.

2.4.4 EAM Functional Specifications

The EAM modules come pre-configured from the factory based on the set of inputs

defined by the customer with the assistance of the local Emerson representative.

Each asset type has a specification form that must accompany the order. These

specification forms define the process inputs that are available, input tag names,

units of measure and valid ranges. In addition, some assets require physical

property constants and equipment information. This data is used to configure the

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 21 of 36

project software that is delivered to an Emerson service representative to install and

commission.

NOTE: As mentioned above, the EAM modules have been designed to allow

the maximum level of instrumentation that might ever be needed to detect a

fault or health condition for that type of asset. We recognize that not all assets

will have (or need) all the measurements that are possible. Each asset has a

“Fault Matrix” that is reflected in the Bill of Material tool on their respective

Emerson Sales Portal Page. These fault matrices define which inputs are

required to detect which faults. Using this tool, an Emerson representative can

work with customers to define which faults are important and, therefore, the

required measurements to support them.

For reference, the fault matrix and specification form for each asset is provided in

Appendix A. The reader is recommended to get the latest versions from the

referenced websites above.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 22 of 36

3 SYSTEMS INTEGRATION

In a typical scenario, EAM application users might include operators, maintenance

technicians and reliability personnel as well as process engineers and operations

managers. As a result, the EAM solution is designed to be easily integrated with an

existing DCS or process historian using the built-in OPC server. The AMS AG

system can be treated as a “black box”, performing the calculations and writing the

results back to the customer’s DCS and historian. Using this approach, EAM

graphics and displays can be replicated in the same User Interface (UI) environment

already in use at the site separately. In many systems, including DeltaV, Ovation

and PI, the UI can be setup to launch a remote session on the AMS AG Master

server, giving the user direct access to the EAM displays, trends and functions. It

should be recognized that integration with an external system requires additional

engineering to develop, install and commission. For Emerson platforms, we make

the job easier using an EAM integration library that is provided with the EAM project

software. Further description is provided below.

3.1 Interface with DeltaV

The EAM suite offers additional advantages for interfacing with Emerson’s DeltaV

system using a standard library of DeltaV modules, graphics and faceplates delivered

with the EAM Project software. This library provides a standard landing module to

minimize the efforts required to set up and use the interface. The communication

between the EAM applications and DeltaV is based on OPC. The built in OPC client

in AMS AG sends the EAM alerts to the DeltaV OPC server.

Each of the assets will have its own class module and graphic that goes with it. A

user guide provides step-by-step instruction on how to clone, configure and setup the

EAM functions in a DeltaV environment. The EAM outputs are simply mapped to the

DeltaV landing modules, and linked to the graphic templates and faceplates provided

with the software. The EAM Class Library and an example landing module is shown

in Figure 3-1 and Figure 3-2.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 23 of 36

Figure 3-1

DeltaV Interface Module Library

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 24 of 36

Figure 3-2

EAM Blower Interface Module

An example DeltaV graphic that is delivered with the EAM-Blower module is provided

in Figure 3-3.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 25 of 36

Figure 3-3

EAM Process Graphic in DeltaV

The DeltaV software library also includes a custom faceplate to acknowledge alerts,

open the standard process graphic display and launch a remote window into the

EAM AG Server. An example architecture diagram for this scenario is provided in

Figure 3-4.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 26 of 36

Figure 3-4

Integrating EAM with DeltaV

As shown in the Figure 3-4, the EAM data is sent to DeltaV using the OPC

communication. This data is displayed on operator consoles using the standard

DeltaV graphics designed for EAM applications. In this environment, the DeltaV

operator can monitor the health and asset KPI’s from the EAM application in a read-

only mode.

To get more detail on a particular asset, a DeltaV operator connects to the EAM

station through a remote desktop connection. Access to the EAM application is

required to take some actions such as capturing a baseline, acknowledging EAM

alerts, setting the asset in/out of service, etc.

3.2 Interface with Ovation

The plan is to provide a similar integration library for Ovation that we have for DeltaV.

Feedback from the field on the DeltaV interface and user requirements will drive the

next generation of platform interfaces.

3.3 Interface with Historians

The interface to a process historian, such as OSI-PI, AspenTech’s InfoPlus.21 or

GE’s i-Historian can be accomplished in much the same way as the DCS interfaces

using their OPC servers. In this case, custom displays for each asset would need to

be built in their user environment (e.g. PI ProcessBook, OSI-Web parts, or

AspenTech’s Process Explorer) to accommodate the available measurements and

alerts.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 27 of 36

4 OTHER CONSIDERATIONS

4.1 Application Support

The EAM Suite and the AMS AG platform is supported after the sale through the

Emerson Global Service Center (GSC). Sales support questions can be directed to

AskAO@Emerson.com. Technical questions can be directed to

EAM.Support@Emerson.com.

4.2 Upgrades and Extensions

In order to upgrade versions or add new assets to an existing installation, the end

user or Emerson representative must contact the EAM support team on

EAM.Support@emerson.com. The process will involve exporting the project

database, making the necessary modifications and delivering a new installation.

Service fees will apply.

4.3 Backup and Recovery

There is no automated tool available to backup/recover the EAM application in case

of failure of the EAM station. It is expected that the end user will have necessary

backup procedures in place which would include the EAM Server and Project folders.

This folder can be found in the AMS Asset Graphics folder located on the main drive.

The EAM application preserves all the user configured data in the Project folder and

reloads when the application is restarted. If the system is compromised, reinstall

AMS AG, copy the backup Project folder to the AMS AG folder and the system can

be restarted as normal.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 –

Page 28 of 36

Appendix A

EAM

Fault Matrices

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page

29 of 36

Pump Fault Matrix

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page

30 of 36

Heat Exchanger Fault Matrix

Hot

Cold Side Cold Side Hot Side Hot Side Cold Side Cold Hot Side

Fault Condition Side Notes

Inlet Temp Outlet Temp Inlet Temp Outlet Temp Flow Side dP dP

Flow

Fouling Factor Option 1

Fouling Factor Option 2

Heat Duty Option 1

Heat Duty Option 2

Duty Error

If both Hot and Cold side flow exist, duty error can be calculated.

Hot or cold side flow can be used to calculate the fouling factor

Cost of Degradation and subequently the cost of degradation. If both hot and cold

Option 1 side flow are known, the average heat duty will be used to

calculate cost of degradation.

Hot or cold side flow can be used to calculate the fouling factor

Cost of Degradation and subequently the cost of degradation. If both hot and cold

Option 2 side flow are known, the average heat duty will be used to

calculate cost of degradation.

HX Cleaning Required Exchanger cleaning is determined by a high fouling factor and

Option 1 either hot or cold side high DP.

HX Cleaning Required Exchanger cleaning is determined by a high fouling factor and

Option 2 either hot or cold side high DP.

Exchanger cleaning can be determined using high fouling factor

HX Cleaning Required

AND high cost of degradation. Cost can be calculated using Hot or

Option 3

Cold side flow.

Exchanger cleaning can be determined using high fouling factor

HX Cleaning Required

AND high cost of degradation. Cost can be calculated using Hot or

Option 4

Cold side flow.

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page

31 of 36

Blower Fault Matrix

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page

32 of 36

Air-Cooled Heat Exchanger Fault Matrix

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page

33 of 36

Compressor Fault Matrix

Motor Stage/Interstage Vibration Stage Specific Parameters Compressor Parameters

Motor Motor

Stage Stage Stage Stage Spill K

Outboard Inboard Intake Lube Lube Lube

Fault Condition VFD Vibration Vibration Vibration Vibration Bearing Suct Disch Suct Disch Back Vane

Vibration Vibration Filter Flow dP Oil Oil Oil SG/MW

Speed (OV3, (OV4, (OV5, (OV6, Temp Press Press Temp Temp Valve Position

(OV1, (OV2, dP Press Temp Level

PKV3) PKV4) PKV5) PKV6) Position

PKV1) PKV2)

Resonance Freq Detection Option 1

Resonance Freq Detection Option 2

Resonance Freq Detection Option 3

Resonance Freq Detection Option 4

Resonance Freq Detection Option 5

Resonance Freq Detection Option 6

High Vibration Option 1

High Vibration Option 2

High Vibration Option 3

Bearing Fault Option 1

Bearing Fault Option 2

Bearing Fault Option 3

Plugged Intake Filter

Process Instability Option 1

Process Instability Option 2

Process Instability Option 3

Process Instability Option 4

Low dP Option 1

Low dP Option 2

High dT

Spill Back Valve Defect

Lube Oil Monitoring

Control Vane Defect

Gas Comp Change

Low/High Knock Out Drum Level

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page

34 of 36

Cooling Tower Fault Matrix – Page 1

Cooling Tower Fans

XXX CSI 9420's - Accelerometers and Bearing Temps

Fault Condition

Motor OB Gearbox HS

Motor IB Gearbox LS

Vibr Vibr

VFD Speed Vibr Vibr

(OV, PKV, (OV, PKV,

(OV, PKV, T) (OV, PKV, T)

T) T)

Resonance Freq Band (Option 1)

Resonance Freq Band (Option 2)

Resonance Freq Band (Option 3)

Resonance Freq Band (Option 4)

Resonance Freq Band (Option 5)

High Vibration Fans (Option 1)

High Vibration Fans (Option 2)

High Vibration Fans (Option 3)

High Vibration Fans (Option 4)

High Vibration Fans (Option 5)

Bearing Fault Fans (Option 1)

Bearing Fault Fans (Option 2)

Bearing Fault Fans (Option 3)

Bearing Fault Fans (Option 4)

Bearing Fault Fans (Option 5)

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page

35 of 36

Cooling Tower Fault Matrix – Page 2

Cooling Water Pumps

RMT RMT RMT

XXX CSI 9420

3051S 3051S 3051S

Fault Condition

VFD Speed Pump Motor 2 Pump Motor

Disch Suct Strainer

(if Vibr Vibr Bearing Bearing

Press Press dP

applicable) (OV, PKV) (OV, PKV) Temp 1 Temp 2

Bearing Fault Pump (Option 1)

Bearing Fault Pump (Option 2)

Bearing Fault Pump (Option 3)

Motor Bearing Lubrication Fault

Pump Bearing Lubrication Fault

High Vibration Pumps (Option 1)

High Vibration Pumps (Option 2)

High Vibration Pumps (Option 3)

Low Head (Option 1)

Low Head (Option 2)

Low Head (Option 3)

Low Discharge

Low Suction

Strainer Plugging

Emerson Process Management 2014 – Confidential and Proprietary

System Planning Guide

Essential Asset Monitoring Essential Asset Monitoring Suite

Revision P1 – 2014-SEPT-09 – Page

36 of 36

Cooling Tower Fault Matrix – Page 3

Cooling Tower Basin

702 RMT dP

RMT 648 RMT 649 RMT 650 RMT 651 RMT 6081C RMT 6081P RMT 3051S RMT 3051S

TraceTek Level

Fault Condition

Air Out

CW

H2O In H2O Out Air Temp Wireless Wirelesss CW Makeup HC Leak

Blowdown Basin Level

Temp Temp In Temp (1 per Conductivity pH Flow Detection

Flow

Fan)

High Water Temp

Low Water Temp

Fouling (Option 1)

Fouling (Option 2)

Fouling (Option 3)

Fouling (Option 4)

Corrosion (Option 1)

Corrosion (Option 2)

Corrosion (Option 3)

High pH

Low pH

Low Flow

HC Leak in Basin

Excessive Windage/Water Loss

Emerson Process Management 2014 – Confidential and Proprietary

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- D000-EL-701 Rev 4Dokumen19 halamanD000-EL-701 Rev 4Sardar PerdawoodBelum ada peringkat

- 000-Cr-1003 r3 Plant D Process & Utilities FDN Location Plan-000-Cr-1003Dokumen1 halaman000-Cr-1003 r3 Plant D Process & Utilities FDN Location Plan-000-Cr-1003Sardar PerdawoodBelum ada peringkat

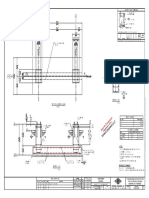

- d2400-Cr-1008 r0 v-2405 & P-2406 A&b Containment Slab & CurbDokumen1 halamand2400-Cr-1008 r0 v-2405 & P-2406 A&b Containment Slab & CurbSardar PerdawoodBelum ada peringkat

- E000-Cr-1029 R0 Process PR FDN'S Ef1 & Ef2-D000 PDFDokumen1 halamanE000-Cr-1029 R0 Process PR FDN'S Ef1 & Ef2-D000 PDFSardar PerdawoodBelum ada peringkat

- d2400-Cr-1003 r0 FDN Df7 PipebridgeDokumen1 halamand2400-Cr-1003 r0 FDN Df7 PipebridgeSardar PerdawoodBelum ada peringkat

- 000-CR-1003 R3 Plant D Process & Utilities FDN Location Plan-000-Cr-1003 PDFDokumen1 halaman000-CR-1003 R3 Plant D Process & Utilities FDN Location Plan-000-Cr-1003 PDFSardar PerdawoodBelum ada peringkat

- D2400-CR-1008 R0 V-2405 & P-2406 A&b Containment Slab & Curb PDFDokumen1 halamanD2400-CR-1008 R0 V-2405 & P-2406 A&b Containment Slab & Curb PDFSardar PerdawoodBelum ada peringkat

- d2400-Cr-1004 r0 FDN Df8 Flare PiperackDokumen1 halamand2400-Cr-1004 r0 FDN Df8 Flare PiperackSardar PerdawoodBelum ada peringkat

- 000-Cv-1005 Isbl Soil Borehole Location Plan Rev 3Dokumen1 halaman000-Cv-1005 Isbl Soil Borehole Location Plan Rev 3Sardar PerdawoodBelum ada peringkat

- 000-CV-1006 Overall Foundation Excavation Plan R0Dokumen1 halaman000-CV-1006 Overall Foundation Excavation Plan R0Sardar PerdawoodBelum ada peringkat

- 000-CV-1006 Overall Foundation Excavation Plan R0 PDFDokumen1 halaman000-CV-1006 Overall Foundation Excavation Plan R0 PDFSardar PerdawoodBelum ada peringkat

- 000-CV-1007 R0 PDFDokumen1 halaman000-CV-1007 R0 PDFSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- 4653 002 - PD 111 - Rev2 ModelDokumen1 halaman4653 002 - PD 111 - Rev2 ModelSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen7 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen4 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen4 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen7 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Ti01c20k00 01e PDFDokumen10 halamanTi01c20k00 01e PDFSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen5 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- MQ VersionsDokumen74 halamanMQ VersionsMadhu Srikanth ThotaBelum ada peringkat

- Ajanthan CertificationDokumen27 halamanAjanthan Certificationapi-251220352100% (1)

- Thesis Topic On Mobile CommunicationDokumen7 halamanThesis Topic On Mobile Communicationbsq39zpf100% (2)

- Free Preparation Cisco 350Dokumen83 halamanFree Preparation Cisco 350Peter KidiavaiBelum ada peringkat

- NSN Huawei LTE Feature Mapping V1.4 (20131230)Dokumen45 halamanNSN Huawei LTE Feature Mapping V1.4 (20131230)Hassan AtiqueBelum ada peringkat

- Network Topology in Cisco Packet TracerDokumen2 halamanNetwork Topology in Cisco Packet TracerÃyûsh KumarBelum ada peringkat

- Control Your PC From AnywhereDokumen3 halamanControl Your PC From Anywhere20-CM-040 Chilakani Mahesh BabuBelum ada peringkat

- Class Xii Cs 083 Syllabus 2023 24Dokumen4 halamanClass Xii Cs 083 Syllabus 2023 24somojitroy80Belum ada peringkat

- WiFi Manual WhirlpoolDokumen108 halamanWiFi Manual Whirlpoolbfsreis100% (1)

- What Are The Commonly Used Citrix CommandsDokumen42 halamanWhat Are The Commonly Used Citrix CommandssudharaghavanBelum ada peringkat

- Ccnpv7 Switch Lab3-2 Etherchannel InstructorDokumen33 halamanCcnpv7 Switch Lab3-2 Etherchannel Instructorgtr345100% (1)

- RRU3824Dokumen10 halamanRRU3824İsmail AkkaşBelum ada peringkat

- Network Performance Score PDFDokumen44 halamanNetwork Performance Score PDFsugadoor100% (1)

- ChangeAuditor For Active Directory Event Reference GuideDokumen62 halamanChangeAuditor For Active Directory Event Reference GuidevishwahBelum ada peringkat

- Sales DimensionsDokumen133 halamanSales DimensionsRishabh KumarBelum ada peringkat

- Basic Config WLC 5508Dokumen5 halamanBasic Config WLC 5508maurya7772Belum ada peringkat

- Multi-Line 2 Description of Options: Option T1 Critical PowerDokumen18 halamanMulti-Line 2 Description of Options: Option T1 Critical PowerpavictonfBelum ada peringkat

- CentrifyZTP-Corev19.6 - Lab Guide FY2019 PDFDokumen72 halamanCentrifyZTP-Corev19.6 - Lab Guide FY2019 PDFIsmael Ferreras HerreraBelum ada peringkat

- Cisco - QoSinSOHONetworkDokumen16 halamanCisco - QoSinSOHONetworkGreg KenfieldBelum ada peringkat

- Firewall Implementation Scenario in Campus NetworkDokumen5 halamanFirewall Implementation Scenario in Campus NetworkJunaid AshfaqBelum ada peringkat

- WING5X How To Centralized Deployments Rev F-v0.1-Rebranded-FinalDokumen159 halamanWING5X How To Centralized Deployments Rev F-v0.1-Rebranded-FinalJoven CastorBelum ada peringkat

- Adminguide SecurityservicesDokumen458 halamanAdminguide Securityservicesapi-3757018Belum ada peringkat

- CCN Lab Interview QuestionsDokumen13 halamanCCN Lab Interview QuestionsMurali MC MirleBelum ada peringkat

- Assignment 3 3Dokumen4 halamanAssignment 3 3api-236083981Belum ada peringkat

- Cisco MDS 9000 Family Troubleshooting Guide 2Dokumen161 halamanCisco MDS 9000 Family Troubleshooting Guide 2connect2praveenBelum ada peringkat

- 323-1853-201 (6110 R5.0 Install Commissioning) Issue 3Dokumen242 halaman323-1853-201 (6110 R5.0 Install Commissioning) Issue 3TimeslotBelum ada peringkat

- ETSI TS 123 041: Technical SpecificationDokumen73 halamanETSI TS 123 041: Technical Specificationscropio_indianBelum ada peringkat

- Grundig Fine Arts ManualDokumen164 halamanGrundig Fine Arts Manualdstoic1Belum ada peringkat

- Data Gathering Instrument For TraineeDokumen5 halamanData Gathering Instrument For TraineeArvincent Geronimo OlatanBelum ada peringkat

- FSDownloaderDokumen2 halamanFSDownloaderazfa99Belum ada peringkat