Martin IBC

Diunggah oleh

puput utomoHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Martin IBC

Diunggah oleh

puput utomoHak Cipta:

Format Tersedia

www.oricaminingservices.

com

Blasting Technology for Extracting

Dipping and Variable Coal Seams

Summary

Dipping, thin and variable coal seams can be

blasted in bulk;

This allows better productivity, increased

reserve definition, better recovery, lower costs

and reduced environmental footprint;

Today’s blasting technology allows this to be

done better than ever before.

© Copyright Orica Limited Group

Traditional Method

for blasting thin, variable, dipping seams

© Copyright Orica Limited Group

Dipping and Variable Seams

Thin & Intermittent Splitting Faulted

Anti & Synclinal Anticlinal Dipping

© Copyright Orica Limited Group

Dipping and Variable Seams in Indonesia

Thin & Intermittent Splitting Faulted

Anticline & Syncline Anticline Dipping

© Copyright Orica Limited Group

Challenges Extracting Dipping & Variable Seams

Using Traditional Method

3 – 8 Metres

Reduced Vertical Advance per Drill and Blast Cycle

© Copyright Orica Limited Group

© Copyright Orica Limited Group

Challenges Extracting Dipping & Variable Seams

Using Traditional Method

Narrow Operating Bench

Variable Coal OH&S Risks Dozer Required to

Model – Low Rip Terraced

Coal Recovery Bench for Drill Access

& Dilution

Hard Toe in

Interburden

Short Benches Wedge

< 10 m

Variable & High

Powder Factors

© Copyright Orica Limited Group

Challenges Extracting Dipping

& Variable Seams Using Traditional Method

Small Drills With Low Productivity Inefficient & Labour Intensive

Bulk Explosives Loading

© Copyright Orica Limited Group

Challenges Extracting Dipping & Variable

Seams Using Traditional Method

Poor Coal Model Limited Coal Faces Reduced Excavator

Difficult for Short Exposed for Blending Strike Length

Range Planning

Low Broken Stocks

Slow Hauls on

Ramps and Bench

Hard Toe in

Short Benches Interburden

< 10 m Wedge

© Copyright Orica Limited Group

Introducing Modern Through

Seam Blasting (TSB)

© Copyright Orica Limited Group

© Copyright Orica Limited Group

Solution – Modern Through Seam Blasting

Improved Coal Model

& Short Term

Planning

Increased

Strike

Length > 120 M

Increased

Broken Stocks Increased

With Reduced Vertical

Eliminate Dozer Advance

Surface Area Ripping Coal > 15-25 M

Vertical Advance Not Limited by Roof and Floor of Coal

Blast Size Increased Up to 600,000 BCMs

© Copyright Orica Limited Group

Solution – Modern Through Seam Blasting

Decked Explosive Decked Inert

Charge Stemming

in Waste in Coal

Overburden

Decked Explosive

Charge

in Waste

Interburden

15 M

© Copyright Orica Limited Group

Solution – Modern Through Seam Blasting

Coal

Fragmented

In Tensile

From

Lifting and

Settling

of Strata

but Intact

Hard Interburden

Bands Fragmented

to < 600 mm for

efficient loading

© Copyright Orica Limited Group

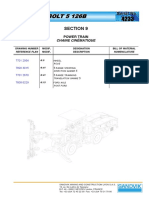

Technology behind Modern TSB

© Copyright Orica Limited Group

Modelling – Stand Off from Coal

Coal (Green)

© Copyright Orica Limited Group

Modelling –

initiation

direction

Modelling Powder Factor and Mixing

© Copyright Orica Limited Group

Orica Technology Services – Gamma Logging of

Blast Holes for Coal Model and Strata Location

mudstone

Coal Seam #3

shale

Gamma Density Logging Interpretation Loading Design

© Copyright Orica Limited Group

Orica Technology Services

– Design software (SHOTPlus®-i Pro)

Stemming

5.0 95.0

EEc600 1660.4kg

‘Charge to’

A 34.0 66.0 Horizons

Stemming

B

Intercepts 42.0 58.0

EEc641 412.2kg

48.0 52.0

C

Stemming

54.0 46.0

EEc661 446.6kg

60.0 40.0

Electronic Field

Load Sheets

Through Seam

Design Capabilities

© Copyright Orica Limited Group

It’s all about quality control in delivery...

© Copyright Orica Limited Group

Orica Technology Services –

Operational Loading Accuracy < 200mm

Six Sigma Loading Practices Field Digital Design Implementation

© Copyright Orica Limited Group

Electronic Detonators - Essential

© Copyright Orica Limited Group

Benefits of Modern TSB

© Copyright Orica Limited Group

Productivity with Conventional Method is low…

Blast Size < 25,000 bcm

Blasting Every Day = Frequent Delays

© Copyright Orica Limited Group

Through Seam gives higher productivity

Average Blast Size around 200,000 bcm

Blasting Every 3-4 days

© Copyright Orica Limited Group

Mining Rate Increases……

> 100% Increase in Mining Rate

© Copyright Orica Limited Group

Recovery, Resource, Reserves may improve....

• Minimum economic coal recovery

to 200mm

• Increase % of Resource Recovered

(can recover more than 100%)

• Reduce Strip Ratio

• Ability to selectively mine multiple seams

• Reclassify coal resources as

economic reserves

© Copyright Orica Limited Group

Environment & Community

• Minimise capital requirement and operating

costs for Coal Wash Plants

• Reduce water used for washing of coal;

• Reduced tailing dam footprint

• Less blast events – Neighbour

issues

© Copyright Orica Limited Group

Example - Wahana

© Copyright Orica Limited Group

Wahana Site Location

Wahana

© Copyright Orica Limited Group

Progress at Wahana to date

Since Feb 2010 :

• fired over 275 TSBs = 57 Mbcm

Waste Volume Blasted at Wahana

• Best month 3.85 Mbcm

• Average 200,000 bcm per TSB

• Increased blasted inventory by

140%

• Decreased (short hole) blasting

by 90%.

• NO COAL LOSS

• IMPROVED RECOVERY

TSB is Standard Practice for LCI at Wahana – 1st in Indonesia

© Copyright Orica Limited Group

Went from this……

Difficult Working Conditions

Inefficient, hard to manage

© Copyright Orica Limited Group

and from this……

© Copyright Orica Limited Group

……to this

© Copyright Orica Limited Group

…and this.

© Copyright Orica Limited Group

Thru Seam Results

Vertical Seams recoverable

Disturbed zone coal

Coal seam 100% recoverable

© Copyright Orica Limited Group

Wide, Flat

Shovels wellbenches for from

separated efficient operation

drills and eachofother;

Heavy Mobile Equipment

© Copyright Orica Limited Group

Improved Shovel Productivity…..

Traditional:

Disruption due to

blast, walk, blast

Excavator Productivity

BCM/ hr

2,000

6 Blasts

Dig rate: 1,726 m3/hr

174 hours

(Elapsed time for excavation)

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Dig

Blast Blast Blast Blast Blast Blast Blast Blast Blast Blast Blast Blast

Walk Walk Walk Walk Walk Walk

300k BCM Excavation

Optimised Design, Load, Fire Sequence

Excavator Productivity

BCM/ hr

2,000 1 Blast

Dig rate: 1,949 m3/hr 154 hours

(Elapsed time for excavation)

300k BCM Excavation

Dig

Dig

Dig

Dig

© Copyright Orica Limited Group

Drilling Activity

Improved Drill Utilisation…..

Percentage of Time

100%

75%

64%

85%

50% Drilling

Tramming

25%

36%

15%

0%

Conventional Thru-Seam

From Time-in-Motion study at Pit-J

© Copyright Orica Limited Group

Drilling

(metres)

and reduced drill metres…..

1,000,000 869,595

800,000

600,000

391,210

400,000 -55%

200,000

0

Conventional

Current TSBTSB

© Copyright Orica Limited Group

Detonators

(units) and reduced detonators used…..

400,000 347,826

350,000

300,000

250,000

200,000

150,000

100,000 -83% 61,126

50,000

0

Conventional

Current TSB TSB

© Copyright Orica Limited Group

Bulk Explosives

(tonnes) and reduced explosives used…

9,000 8,160

8,000

7,000 -24% 6,240

6,000

5,000

4,000

3,000

2,000

1,000

0

Conventional

Current TSB

TSB

© Copyright Orica Limited Group

In Summary

• Modern Through Seam Blasting is a cost effective method to

extract dipping, thin and variable seams;

• Modern Through Seam Blasting is proven method suitable

for the most difficult operating environments;

• Modern Blasting Technology allows us to do Through Seam

Blasting better than ever before

• The benefits include better reserve definition, better

recovery, lower costs and reduced water / CO2

© Copyright Orica Limited Group

Thank You

© Copyright Orica Limited Group

Acknowledgements

PT Leighton Contractors Indonesia for embracing technology

and working with Orica Mining Services to transform Wahana

Mine.

© Copyright Orica Limited Group

Thank You

© Copyright Orica Limited Group

Anda mungkin juga menyukai

- Estimated Owning and Operating Cost MineplanDokumen15 halamanEstimated Owning and Operating Cost Mineplanpuput utomoBelum ada peringkat

- Cash FlowDokumen71 halamanCash Flowpuput utomoBelum ada peringkat

- Geotechnical Investigation of Land Movement On Roadway at KM 23, Citatah Area, West Java ProvinceDokumen10 halamanGeotechnical Investigation of Land Movement On Roadway at KM 23, Citatah Area, West Java Provincepuput utomoBelum ada peringkat

- Race Tech May 2021Dokumen78 halamanRace Tech May 2021puput utomoBelum ada peringkat

- National Geographic IndonesiaDokumen84 halamanNational Geographic Indonesiapuput utomoBelum ada peringkat

- Valuation For High-Risk Coal Mining Project Case Study: PT. Berau Coal Block ParapatanDokumen8 halamanValuation For High-Risk Coal Mining Project Case Study: PT. Berau Coal Block Parapatanpuput utomoBelum ada peringkat

- Slimming World - May-June 2021Dokumen118 halamanSlimming World - May-June 2021puput utomoBelum ada peringkat

- SLD Elect Sect04Dokumen57 halamanSLD Elect Sect04puput utomoBelum ada peringkat

- 950G Wheel Loader: - Electro-Hydraulic Implement SystemDokumen24 halaman950G Wheel Loader: - Electro-Hydraulic Implement Systempuput utomoBelum ada peringkat

- 928G Wheel Loader: - Implement Hydraulic System (Pilot Operated System)Dokumen15 halaman928G Wheel Loader: - Implement Hydraulic System (Pilot Operated System)puput utomoBelum ada peringkat

- SLD Elect Sect01Dokumen78 halamanSLD Elect Sect01puput utomo100% (1)

- 950G Wheel Loader: - Electro-Hydraulic Implement SystemDokumen34 halaman950G Wheel Loader: - Electro-Hydraulic Implement Systempuput utomoBelum ada peringkat

- BMS Binder 1Dokumen338 halamanBMS Binder 1puput utomoBelum ada peringkat

- 07-STD Prod'Ty Alat Muat Coal.Dokumen1 halaman07-STD Prod'Ty Alat Muat Coal.puput utomoBelum ada peringkat

- OPS - SP009 - Project ReportingDokumen22 halamanOPS - SP009 - Project Reportingpuput utomoBelum ada peringkat

- Risk Management in Coal-Mines - Methodical Proposal For Polish and Czech Hard Coal Mining IndustryDokumen9 halamanRisk Management in Coal-Mines - Methodical Proposal For Polish and Czech Hard Coal Mining Industrypuput utomoBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Coal Combustion Monitoring Report Unwashed Semi Rev02 08.24.2021Dokumen17 halamanCoal Combustion Monitoring Report Unwashed Semi Rev02 08.24.2021Keith Danae SuquibBelum ada peringkat

- 4 and 6 Pole MotorDokumen6 halaman4 and 6 Pole Motorarajamani78100% (1)

- Estimate SR 14-15 02 KHANDEKARDokumen5 halamanEstimate SR 14-15 02 KHANDEKARAkshay SavvasheriBelum ada peringkat

- FL-02-01 PM SheetDokumen12 halamanFL-02-01 PM SheetBikas SahaBelum ada peringkat

- Huawei ACU2 Wireless Access Controller DatasheetDokumen12 halamanHuawei ACU2 Wireless Access Controller Datasheetdexater007Belum ada peringkat

- The Reef Wayfinding Plan and Signage Design Concept 28 August 2019Dokumen51 halamanThe Reef Wayfinding Plan and Signage Design Concept 28 August 2019Michele MontoloBelum ada peringkat

- S09 Power TrainDokumen90 halamanS09 Power TrainPLANEAMIENTO MDRILLBelum ada peringkat

- HARGA REFERENSI B2S PapuaDokumen6 halamanHARGA REFERENSI B2S PapuaAbiyoga AdhityaBelum ada peringkat

- Grundfos S Pump 5 - 29 KW Super VortexDokumen20 halamanGrundfos S Pump 5 - 29 KW Super Vortexdalveerchoudhary100% (1)

- Fast, Accurate Data Management Across The Enterprise: Fact Sheet: File-Aid / MvsDokumen4 halamanFast, Accurate Data Management Across The Enterprise: Fact Sheet: File-Aid / MvsLuis RamirezBelum ada peringkat

- 2013 11 DUPLEX EasyDokumen21 halaman2013 11 DUPLEX EasyAnonymous HC0tWeBelum ada peringkat

- Wireless Intelligent Network (WIN)Dokumen24 halamanWireless Intelligent Network (WIN)Nakul Gawande100% (1)

- Topic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1Dokumen49 halamanTopic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1BeaglelalahahaBelum ada peringkat

- Quantity Surveying Division Assessment of Professional Competence Final Assessment 2014 Practice Problems / Part Ii Written TestDokumen31 halamanQuantity Surveying Division Assessment of Professional Competence Final Assessment 2014 Practice Problems / Part Ii Written TestjackyBelum ada peringkat

- Oil & Gas Asset Integrity IssuesDokumen15 halamanOil & Gas Asset Integrity Issuesyogolain100% (2)

- Lecure Two. ReactorsDokumen56 halamanLecure Two. ReactorsSophia WambuiBelum ada peringkat

- Marine Lubricants Equivalents List: Sae 50 TBN 57 Sae 50 TBN 55 Sae 40 TBN 60 Sae 50 TBN 50 Sae 50 TBN 55Dokumen3 halamanMarine Lubricants Equivalents List: Sae 50 TBN 57 Sae 50 TBN 55 Sae 40 TBN 60 Sae 50 TBN 50 Sae 50 TBN 55spyros_peiraiasBelum ada peringkat

- Using Dapper Asynchronously inDokumen1 halamanUsing Dapper Asynchronously inGiovani BrondaniBelum ada peringkat

- Cbse PMT 2012Dokumen33 halamanCbse PMT 2012Vishal RamakrishnanBelum ada peringkat

- Biomasse-HKW Sandreuth E NQDokumen8 halamanBiomasse-HKW Sandreuth E NQValeriu StanBelum ada peringkat

- Cisco Network DiagramDokumen1 halamanCisco Network DiagramĐỗ DuyBelum ada peringkat

- Triaxial Test Systems enDokumen10 halamanTriaxial Test Systems enDetjan JuniorBelum ada peringkat

- Softening Point of AsphaltDokumen2 halamanSoftening Point of AsphaltMuhammad Rizal RamliBelum ada peringkat

- Woson 23 Litre B Class Touch AutoclaveDokumen2 halamanWoson 23 Litre B Class Touch AutoclaveBashar MohammadBelum ada peringkat

- Tharmal Analysis BasicsDokumen56 halamanTharmal Analysis BasicsNetoBelum ada peringkat

- Bubbling Kun NiDokumen7 halamanBubbling Kun NiBelen CRBelum ada peringkat

- Magneto Hydro Dynamics PresentationDokumen19 halamanMagneto Hydro Dynamics PresentationVipul GuptaBelum ada peringkat

- Chapter 7 Notes Computer OrganizationDokumen20 halamanChapter 7 Notes Computer OrganizationsriBelum ada peringkat

- Safety Data Sheet 84989 41 3 enDokumen4 halamanSafety Data Sheet 84989 41 3 enAdhiatma Arfian FauziBelum ada peringkat