Polikim EFALON® T-100 Virgin PTFE

Diunggah oleh

Priyadarshini KrishnaswamyHak Cipta

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Polikim EFALON® T-100 Virgin PTFE

Diunggah oleh

Priyadarshini KrishnaswamyHak Cipta:

Advertise with MatWeb!

Data sheets for over 130,000 metals, plastics, ceramics, and composites.

HOME • SEARCH • TOOLS • SUPPLIERS • FOLDERS • ABOUT US • FAQ • LOG IN

Searches: Advanced | Category | Property | Metals | Trade Name | Manufacturer | Recently Viewed Materials polikim

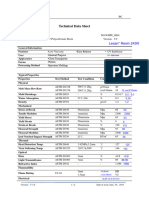

Polikim EFALON® T-100 Virgin PTFE

Categories: Polymer; Thermoplastic; Fluoropolymer; Polytetrafluoroethylene (PTFE)

Material Applications: Gaskets, seals, O-rings, V-Rings, compression packings and similar sealing parts, Bushes,

Notes: bearings and piston rings, Electrical insulators, Sliding supports, Conveyor belts, Coated tubes, valves and

joint components for transfer of corrosive material, Non-stick surface applications, PTFE coated glass fabric

manufacturing, Laboratory equipment that requires chemical resistance. In military units and marine industry

due to resistance to water, humidity, micro-organisms and sunlight.

Information provided by Polikim Polimer.

Vendors: No vendors are listed for this material. Please click here if you are a supplier and would like information on

how to add your listing to this material.

Printer friendly version Download as PDF Download to Excel (requires Excel and Windows)

Export data to your CAD/FEA program Add to Folder: My Folder 0/0

Physical Metric English Comments

Properties

Density 2.10 - 2.20 g/cc 0.0759 - 0.0795 lb/in³ ASTM D792

Deformation 7.5 - 8.5 % 7.5 - 8.5 % permanent; ASTM D621

@Temperature 23.0 °C, @Temperature 73.4 °F,

Time 86400 sec, Time 24.0 hour,

Pressure 13.7 MPa Pressure 1990 psi

14 - 16.8 % 14 - 16.8 % total; ASTM D621

@Temperature 23.0 °C, @Temperature 73.4 °F,

Time 86400 sec, Time 24.0 hour,

Pressure 13.7 MPa Pressure 1990 psi

Mechanical Metric English Comments

Properties

Hardness, 54 - 60 54 - 60 ASTM D2240

Shore D

Tensile 13.7 - 37.3 MPa 1990 - 5400 psi ASTM D638

Strength,

Ultimate

Elongation at 200 - 400 % 200 - 400 % ASTM D638

Break

Compressive 4.41 - 4.90 MPa 640 - 711 psi 1% Deformation; ASTM D695

Strength

Izod Impact, 15.5 - 16.5 kJ/m² 7.38 - 7.85 ft-lb/in² ASTM D256

Notched

(ISO)

Coefficient of 0.060 0.060

Friction

Coefficient of 0.040 0.040

Friction,

Static

Limiting 0.000376 - 0.000409 MPa-m/sec 10.7 - 11.7 psi-ft/min 3 m/min

Pressure

Velocity

0.000605 - 0.000654 MPa-m/sec 17.3 - 18.7 psi-ft/min 30 m/min

0.0008502 - 0.0009156 MPa-m/sec 24.27 - 26.14 psi-ft/min 300 m/min

Electrical Metric English Comments

Properties

Volume >= 1.00e+18 ohm-cm >= 1.00e+18 ohm-cm ASTM D257

Resistivity

Surface >= 1.00e+16 ohm >= 1.00e+16 ohm 50% rel. humidity; ASTM D257

Resistance

Dielectric 2.0 - 2.1 2.0 - 2.1 ASTM D150

Constant @Frequency 50.0 - 1.00e+7 Hz @Frequency 50.0 - 1.00e+7 Hz

Dielectric 40.0 - 80.0 kV/mm 1020 - 2030 kV/in short term; ASTM D149

Strength @Thickness 0.100 mm @Thickness 0.00394 in

Dielectric 0.000050 0.000050 dry

Loss Index @Frequency 50.0 Hz @Frequency 50.0 Hz

Thermal Metric English Comments

Properties

CTE, linear 125 - 160 µm/m-°C 69.4 - 88.9 µin/in-°F ASTM D696

@Temperature 25.0 - 100 °C @Temperature 77.0 - 212 °F

150 - 190 µm/m-°C 83.3 - 106 µin/in-°F ASTM D696

@Temperature 25.0 - 200 °C @Temperature 77.0 - 392 °F

215 - 250 µm/m-°C 119 - 139 µin/in-°F ASTM D696

@Temperature 25.0 - 300 °C @Temperature 77.0 - 572 °F

Specific Heat 0.962 - 1.05 J/g-°C 0.230 - 0.251 BTU/lb-°F

Capacity

Thermal 0.230 - 0.251 W/m-K 1.59 - 1.74 BTU-in/hr-ft²-°F

Conductivity

Maximum 270 °C 518 °F continuous

Service

Temperature,

Air

Minimum -260 °C -436 °F

Service

Temperature,

Air

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistent format.

Users requiring more precise data for scientific or engineering calculations can click on the property value to see the original value as well as raw conversions to

equivalent units. We advise that you only use the original value or one of its raw conversions in your calculations to minimize rounding error. We also ask that you

refer to MatWeb's terms of use regarding this information. Click here to view all the property values for this datasheet as they were originally entered into MatWeb.

Users viewing this material also viewed the following:

Dalau Dalcon 001 100% Virgin PTFE

Isoflon Virgin PTFE Polytetrafluoroethylene

Dalau Dalcon 086 100% Virgin PTFE modified polymer

Saint-Gobain Rulon® 1045 Bearing/Seal PTFE

CoorsTek CRB-300 General-Duty Carbon Graphite

PPOLIK001 / 99811

Subscribe to Premium Services

Searches: Advanced • Composition • Property • Material Type • Manufacturer • Trade Name • UNS Number

Other Links: Advertising • Submit Data • Database Licensing • Web Design & Hosting • Trade Publications

Anda mungkin juga menyukai

- Propriedades Das Matrizes PolimericasDokumen7 halamanPropriedades Das Matrizes PolimericasllepsterlBelum ada peringkat

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Dokumen2 halamanMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraBelum ada peringkat

- T Work9000Dokumen2 halamanT Work9000Maike SongBelum ada peringkat

- SABIC Innovative Plastics Lexan® 940 PC Data SheetDokumen3 halamanSABIC Innovative Plastics Lexan® 940 PC Data SheetMRC RailBelum ada peringkat

- SL Somos PerFORM Material Specifications PDFDokumen2 halamanSL Somos PerFORM Material Specifications PDFTushar Prakash ChaudhariBelum ada peringkat

- Advertise with MatWeb! Data sheets for over 130,000 materialsDokumen1 halamanAdvertise with MatWeb! Data sheets for over 130,000 materialsPriyadarshini Krishnaswamy0% (1)

- Somos PerFORM SS-PDS Letter PDFDokumen2 halamanSomos PerFORM SS-PDS Letter PDFAdriano AraujoBelum ada peringkat

- Greco Isothane 3080A Polyetherâ Tpuâ ResinDokumen2 halamanGreco Isothane 3080A Polyetherâ Tpuâ ResinLoc PhanBelum ada peringkat

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDokumen2 halamanMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloBelum ada peringkat

- 316 Stainless Steel, Anneal...Dokumen3 halaman316 Stainless Steel, Anneal...Moisés Vázquez ToledoBelum ada peringkat

- Nylacast Moly Cast Nylon 6, MoS2 FilledDokumen3 halamanNylacast Moly Cast Nylon 6, MoS2 Filledprasad.jppmBelum ada peringkat

- ASM Material Data Sheet 316Dokumen2 halamanASM Material Data Sheet 316.xBelum ada peringkat

- LEXAN FST3403tDokumen3 halamanLEXAN FST3403tJose Ramon Florez OrdizBelum ada peringkat

- TDS Nylon101Dokumen2 halamanTDS Nylon101wilderness_666Belum ada peringkat

- SABIC Innovative Plastics Cycoloy C6200 PCABSDokumen3 halamanSABIC Innovative Plastics Cycoloy C6200 PCABSLex WangBelum ada peringkat

- PPS Ryton R-4-230Dokumen3 halamanPPS Ryton R-4-230thegeneral2040Belum ada peringkat

- 316 Stainless Steel, Annealed SheetDokumen2 halaman316 Stainless Steel, Annealed SheetZASSBelum ada peringkat

- 405 Stainless Steel sheetDokumen1 halaman405 Stainless Steel sheetLorena Grijalba LeónBelum ada peringkat

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDokumen2 halamanCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseBelum ada peringkat

- TP Wanhua Clarnate A1227 vs Lexan 243RDokumen2 halamanTP Wanhua Clarnate A1227 vs Lexan 243RMitja GorseBelum ada peringkat

- PBT GF17% DR48-7001Dokumen2 halamanPBT GF17% DR48-7001pava16230.meBelum ada peringkat

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Dokumen2 halamanEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioBelum ada peringkat

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Dokumen2 halamanMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealBelum ada peringkat

- Solef PVDF 6008Dokumen2 halamanSolef PVDF 6008topteam123Belum ada peringkat

- Nominal Engineering Properties of Ryton R-4: Data SheetDokumen4 halamanNominal Engineering Properties of Ryton R-4: Data SheetRakeshBelum ada peringkat

- Lexan™ Copolymer 943X: Region AmericasDokumen3 halamanLexan™ Copolymer 943X: Region AmericasAdirSchoierBelum ada peringkat

- Datasheet SD Ferralium 255 SD50 BarDokumen4 halamanDatasheet SD Ferralium 255 SD50 Barpranav kariaBelum ada peringkat

- PA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZDokumen1 halamanPA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZroberto_perraciniBelum ada peringkat

- Lexan™ 8010 Uncoated Polished Film DatasheetDokumen3 halamanLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanBelum ada peringkat

- PLUMBING PPR-Pipe DesoDokumen11 halamanPLUMBING PPR-Pipe DesoOwen Francis Arles MaongatBelum ada peringkat

- ExxonMobil LLP846029 Rotational Molding ResinDokumen2 halamanExxonMobil LLP846029 Rotational Molding ResinLuis Hernandez GarciaBelum ada peringkat

- ASM Material Data SheetDokumen2 halamanASM Material Data Sheetducchinh080Belum ada peringkat

- UHMW-PE Tivar 1000Dokumen2 halamanUHMW-PE Tivar 1000centurion2988Belum ada peringkat

- Fluteck P7500 CA v01.19Dokumen2 halamanFluteck P7500 CA v01.19fprovitaliBelum ada peringkat

- DSM Arnite® B434 SE PBT-GF20 FRDokumen2 halamanDSM Arnite® B434 SE PBT-GF20 FRcurioushoainamBelum ada peringkat

- Grade: St900 DM311: Polypropylene CompoundDokumen1 halamanGrade: St900 DM311: Polypropylene Compoundhugo santiago chavez godoyBelum ada peringkat

- Wonderloy PC 540Dokumen2 halamanWonderloy PC 540Phung LucBelum ada peringkat

- Tds A1105 en 2017pdfpdfDokumen2 halamanTds A1105 en 2017pdfpdfagungBelum ada peringkat

- PEI Filament Technical Data SheetDokumen3 halamanPEI Filament Technical Data SheetRui MatiasBelum ada peringkat

- TIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsDokumen2 halamanTIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsVictor AguirreBelum ada peringkat

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDokumen1 halamanProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemBelum ada peringkat

- Somos PerFORM Datasheet Complete PDFDokumen4 halamanSomos PerFORM Datasheet Complete PDFAdriano AraujoBelum ada peringkat

- A GD VDBDokumen3 halamanA GD VDBthehoang12310Belum ada peringkat

- PC Calibre Technical DataDokumen4 halamanPC Calibre Technical DataMitja GorseBelum ada peringkat

- Innovations in Fluid Sealing PTFE Gasket SheetDokumen1 halamanInnovations in Fluid Sealing PTFE Gasket SheetArunBelum ada peringkat

- LEXAN™ Copolymer - SLX2432T - Americas - Technical - Data - SheetDokumen3 halamanLEXAN™ Copolymer - SLX2432T - Americas - Technical - Data - Sheetsonia soniaBelum ada peringkat

- PolycarbonateDokumen1 halamanPolycarbonatezainudinBelum ada peringkat

- Master Bond EP17HT LODokumen3 halamanMaster Bond EP17HT LORusty AllenBelum ada peringkat

- CYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetDokumen2 halamanCYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetmarceloBelum ada peringkat

- Acero Inox 410 MaterialData - 12949Dokumen2 halamanAcero Inox 410 MaterialData - 12949Arturo AguilarBelum ada peringkat

- TKGR FLON (PTFE) density, properties, applicationsDokumen1 halamanTKGR FLON (PTFE) density, properties, applicationse.vicente.caballeroBelum ada peringkat

- LEXAN™ Resin - 141R - Asia - Technical - Data - SheetDokumen2 halamanLEXAN™ Resin - 141R - Asia - Technical - Data - SheetTruc Thao NguyenBelum ada peringkat

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDokumen3 halamanCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaBelum ada peringkat

- SL Somos ProtoGen 18420 Material Specifications PDFDokumen2 halamanSL Somos ProtoGen 18420 Material Specifications PDFTushar Prakash ChaudhariBelum ada peringkat

- CYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetDokumen2 halamanCYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetKishore Gowda A SBelum ada peringkat

- Physical Properties of PVC CPVC PipeDokumen1 halamanPhysical Properties of PVC CPVC PipeBimal DeyBelum ada peringkat

- Lexan 9034 Data SheetDokumen2 halamanLexan 9034 Data SheetAdrián PonceBelum ada peringkat

- HDPE Blow Ineos-G50-100Dokumen2 halamanHDPE Blow Ineos-G50-100luisalbertolvBelum ada peringkat

- Noryl Resin Se1X: Region AmericasDokumen3 halamanNoryl Resin Se1X: Region AmericasHector GonzalezBelum ada peringkat

- General Properties: Viton® A - 66% Fluorine Chemical Resistance - GOODDokumen2 halamanGeneral Properties: Viton® A - 66% Fluorine Chemical Resistance - GOODpradeep315Belum ada peringkat

- Viton O Ring TDSDokumen2 halamanViton O Ring TDSPriyadarshini KrishnaswamyBelum ada peringkat

- Clausius InequalityDokumen53 halamanClausius InequalityNandhanBelum ada peringkat

- Work and HeatDokumen12 halamanWork and HeatAmit Singh DehuryBelum ada peringkat

- Material Report: Compound Data SheetDokumen2 halamanMaterial Report: Compound Data SheetPriyadarshini KrishnaswamyBelum ada peringkat

- Module 3Dokumen54 halamanModule 3charusat09Belum ada peringkat

- Second Law of ThermodynamicsDokumen40 halamanSecond Law of ThermodynamicscaptainhassBelum ada peringkat

- Module 5Dokumen17 halamanModule 5captainhassBelum ada peringkat

- Module 8Dokumen12 halamanModule 8Vallapureddy VenkateshBelum ada peringkat

- Pure SubstanceDokumen42 halamanPure SubstanceNitin KumarBelum ada peringkat

- Nptel - Iitm.ac - in Courses Webcourse-Contents IISc-BANG Basic Thermodynamics PDF Module 1Dokumen32 halamanNptel - Iitm.ac - in Courses Webcourse-Contents IISc-BANG Basic Thermodynamics PDF Module 1lakumas15Belum ada peringkat

- RAC Lecture 4Dokumen14 halamanRAC Lecture 4api-3734466Belum ada peringkat

- Viton O Ring TDSDokumen2 halamanViton O Ring TDSPriyadarshini KrishnaswamyBelum ada peringkat

- Apple Rubber Chart - Hot Topics PDFDokumen2 halamanApple Rubber Chart - Hot Topics PDFPriyadarshini KrishnaswamyBelum ada peringkat

- HSN/HNBR O-RingsDokumen2 halamanHSN/HNBR O-RingsPriyadarshini KrishnaswamyBelum ada peringkat

- D 471 - 06 PDFDokumen13 halamanD 471 - 06 PDFLC Chong100% (1)

- PARKER - Oring HandBookDokumen96 halamanPARKER - Oring HandBookLuis AparcanaBelum ada peringkat

- Test Report ConformanceDokumen2 halamanTest Report ConformancePriyadarshini KrishnaswamyBelum ada peringkat

- Beams On Elastic FoundationDokumen6 halamanBeams On Elastic FoundationTRI MULYANTOBelum ada peringkat

- Advertise with MatWeb! Data sheets for over 130,000 materialsDokumen1 halamanAdvertise with MatWeb! Data sheets for over 130,000 materialsPriyadarshini Krishnaswamy0% (1)

- ASTMDokumen6 halamanASTMHTCBelum ada peringkat

- Fluorseals Ptfe Unfilled: Advertise With Matweb!Dokumen2 halamanFluorseals Ptfe Unfilled: Advertise With Matweb!Priyadarshini KrishnaswamyBelum ada peringkat

- Astm D139 PDFDokumen4 halamanAstm D139 PDFPriyadarshini KrishnaswamyBelum ada peringkat

- Astm D139 PDFDokumen4 halamanAstm D139 PDFPriyadarshini KrishnaswamyBelum ada peringkat

- Apple Rubber Chart - Hot Topics PDFDokumen2 halamanApple Rubber Chart - Hot Topics PDFPriyadarshini KrishnaswamyBelum ada peringkat

- Test Report ConformanceDokumen2 halamanTest Report ConformancePriyadarshini KrishnaswamyBelum ada peringkat

- Test Report ConformanceDokumen2 halamanTest Report ConformancePriyadarshini KrishnaswamyBelum ada peringkat

- Astm D572 PDFDokumen4 halamanAstm D572 PDFPriyadarshini KrishnaswamyBelum ada peringkat

- Astm D395 PDFDokumen6 halamanAstm D395 PDFümit özkan100% (1)

- Elite Precommissioning Procedures and Formats For SS Bay EquipmentDokumen92 halamanElite Precommissioning Procedures and Formats For SS Bay EquipmentSurya Mvs100% (1)

- General Properties of Elastomers Summary ChartDokumen1 halamanGeneral Properties of Elastomers Summary ChartvenkatramanBelum ada peringkat

- AASHTO-LRFD-AnchorsInConcrete - Part 2 PDFDokumen3 halamanAASHTO-LRFD-AnchorsInConcrete - Part 2 PDFKY PengBelum ada peringkat

- SeaGel PRESENTATION GroupDokumen25 halamanSeaGel PRESENTATION GroupMahrukh SaleemBelum ada peringkat

- Pulsed Laser Deposition (PLD)Dokumen32 halamanPulsed Laser Deposition (PLD)Mohit YadavBelum ada peringkat

- ANSI C29.17-2002 Composite-Line Post TypeDokumen22 halamanANSI C29.17-2002 Composite-Line Post Typesoc_unfvBelum ada peringkat

- Msds CuDokumen5 halamanMsds CuAssyakurBelum ada peringkat

- Winsurf QX-9: Tech Data SheetDokumen16 halamanWinsurf QX-9: Tech Data SheetFloraBelum ada peringkat

- Rewocare HV 100 - ApresentaçãoDokumen12 halamanRewocare HV 100 - Apresentaçãohenriquefxs2926Belum ada peringkat

- Structural Design For Embankment Dam BottomdischargeDokumen8 halamanStructural Design For Embankment Dam BottomdischargeAnonymous 87xpkIJ6CFBelum ada peringkat

- Multi-Directional Reach Truck UFW: SupportDokumen12 halamanMulti-Directional Reach Truck UFW: SupportJohn SlorBelum ada peringkat

- PSAR ReportDokumen94 halamanPSAR ReportKaushal PatelBelum ada peringkat

- Designguide Ankre 0408Dokumen152 halamanDesignguide Ankre 0408Federico.IoriBelum ada peringkat

- Carraro Transmission Parts CatalogDokumen15 halamanCarraro Transmission Parts CatalogMichael Kubler67% (3)

- Polycoat Rbe PDFDokumen2 halamanPolycoat Rbe PDFAmer GonzalesBelum ada peringkat

- Types of Adhesives: Structural Adhesives Refer To Relatively Strong Adhesives That Are Normally Used WellDokumen2 halamanTypes of Adhesives: Structural Adhesives Refer To Relatively Strong Adhesives That Are Normally Used WellmedanonakamaBelum ada peringkat

- Nagpur Cetp - Butibori - Member - ListDokumen7 halamanNagpur Cetp - Butibori - Member - ListKv SatishBelum ada peringkat

- Use of Waste Material in ConcreteDokumen56 halamanUse of Waste Material in Concretemanoj588Belum ada peringkat

- 20122Dokumen111 halaman20122Chandan PathakBelum ada peringkat

- S154-1209 IomDokumen66 halamanS154-1209 IomAlfredo GodinezBelum ada peringkat

- Why Soft Starts Reduce Motor Stress and Improve ControlDokumen5 halamanWhy Soft Starts Reduce Motor Stress and Improve ControlSohJiaJieBelum ada peringkat

- Production of Wire Via Friction Extrusion of Aluminum Alloy Machining ChipsDokumen7 halamanProduction of Wire Via Friction Extrusion of Aluminum Alloy Machining ChipsMartin DuarteBelum ada peringkat

- Contribution of Shear Reinforcements and Concrete To The Shear Capacity of Interfaces Between Concretes Cast at Different TimesDokumen13 halamanContribution of Shear Reinforcements and Concrete To The Shear Capacity of Interfaces Between Concretes Cast at Different TimesQurrain MirBelum ada peringkat

- Designing of HV Power Substation and Layout - EEPDokumen13 halamanDesigning of HV Power Substation and Layout - EEPSuresh Umadi100% (1)

- VACUUM PUMP DIAGNOSIS (Overall V Spectrum) - Case - Study - 10Dokumen1 halamanVACUUM PUMP DIAGNOSIS (Overall V Spectrum) - Case - Study - 10ho-faBelum ada peringkat

- 2DXL Super Loader BrochureDokumen8 halaman2DXL Super Loader BrochureJayant Kushwaha0% (1)

- Lesson 3: Lesson 3:: Properties of Steel & Timber Properties of Steel & TimberDokumen23 halamanLesson 3: Lesson 3:: Properties of Steel & Timber Properties of Steel & TimberMaria CincoBelum ada peringkat

- Apollo Experience Report The Cryogenic Storage SystemDokumen18 halamanApollo Experience Report The Cryogenic Storage SystemBob AndrepontBelum ada peringkat

- TG-500M CRANE SPECIFICATIONSDokumen16 halamanTG-500M CRANE SPECIFICATIONSnamduong368Belum ada peringkat

- Mounting AccessoriesDokumen18 halamanMounting AccessoriesJack BaeBelum ada peringkat