Stivuitor Electric

Diunggah oleh

Dan DumbravescuHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Stivuitor Electric

Diunggah oleh

Dan DumbravescuHak Cipta:

Format Tersedia

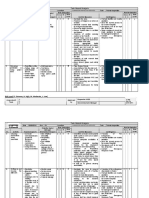

Plant and Equipment Risk Management Form

1. Hazard Management Details – General

Plant/Equipment Item: Forklift (Electric) Make/Model No.: Serial No.:

School / Work Location: Region:

Name of Person(s) Conducting Activity: Date Conducted:

Description of Use: Summary of Key Risks:

(refer to appropriate subsections)

A forklift is a motorised vehicle which Entanglement

uses power-operated prongs/tines to Impact and cutting injuries

lift and move heavy loads.

Shearing

Electricity

Ergonomics

Slips, Trips or Falls

Last Updated: 21 August 2018

Plant and Equipment Risk Management Form

2. Documentation

Relevant Legislation/Standards Y/N Comments

Is plant required to be registered? Y N

Is a user license required? Y N

Key Reference material AS 2359 Powered Industrial Trucks – General Requirements, WorkSafe Victoria Guidance

Note: “Forklift Safety, Reducing the Risk.”

Plant Documentation Y/N Comments

Are operator’s manuals accessible? Y N Operators manual should be supplied on purchase of the vehicle

Is this a restricted use item? Y N Operators must have an appropriate fork lift licence

Does this item require safe use Y N Operators must have an appropriate fork lift licence

documents/test?

3. Hazard Identification

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ENTANGLEMENT Major Rare Medium Loose clothing, long hair, Ensure clothing, gloves, hair or

Can anyone’s hair, clothing, gloves, cleaning gloves, body parts and other such items are kept clear

brushes, tools, rags or other materials other material may of moving parts of the forklift

become entangled with moving parts of the become entangled in when operating or performing

plant or materials? moving parts of the maintenance (e.g., overalls can

Y N forklift (e.g. chain mast). be used to restrict loose

clothing etc.).

Remove or secure any

packaging that may become

entangled in the chain mast.

Forklift (Electric) Risk Management Form Page | 2

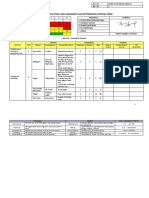

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

IMPACT AND CUTTING INJURIES Materials could fall from Ensure only licensed persons

Can anyone be crushed/cut/struck etc. due the tines of the forklift or operate the forklift and have

to: pallet whilst in operation been trained in any Safe Work

Material falling off the plant? Y N Major Possible High if not appropriately Procedures (SWP).

secured.

Uncontrolled/unexpected movement of Major Rare Medium

Y N Ensure the forklift is only

plant/load? Forklift could rollover if operated on appropriate

Lack of capacity to slow, stop or Severe Rare Medium the load is unbalanced, surfaces (i.e. level ground) and

Y N

immobilise plant? operated on an uneven a seatbelt is worn at all times.

The plant tipping or rolling over? Y N Severe Rare Medium surface or traversing a

Parts of the plant disintegrating or Severe Rare Medium slope. Ensure the load is within the

Y N forklifts lifting capacity and is

collapsing?

Contact with moving parts during testing, Major Rare Medium The mobility of the forklift appropriately secured before

inspection, operation, maintenance, Y N poses a significant risk to lifting and moving.

cleaning or repair? pedestrians and property.

Being thrown off or under the plant? Severe Rare Medium Ensure the forklift is serviced or

Y N

Use of inappropriate repaired by a qualified person

Contact with sharp or flying objects? parts could lead to and only manufacturer

Y N

(e.g. work pieces being ejected) mechanical failure. recommended parts and

The mobility of the plant? Y N Severe Rare Medium accessories are used.

Operator error (e.g. poor

Inappropriate parts and accessories Severe Rare Medium visibility, fatigue etc.) Ensure appropriate traffic

Y N

being used?

Forklift (Electric) Risk Management Form Page | 3

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Other may lead to an accident. management controls have

been implemented. For

example:

Designated and marked

pedestrian paths (e.g.

painted walkways,

bollards/fenced

walkways etc.)

Pedestrian no go zones

High visibility clothing is

worn by

operator/persons in the

work area

Signs and barricades to

be installed to warn

other employees/

Y N persons in area

A documented Traffic

Management Plan is in

place

Relevant employees

have attended traffic

management training.

Ensure forklift is fitted with

appropriate safety features. For

example:

“Dead Man’s”

control/emergency stop

Park brake

Seatbelt

Rollbar/cage and

Reversing alarm.

Forklift (Electric) Risk Management Form Page | 4

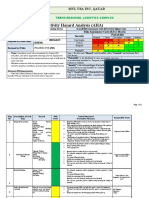

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SHEARING Severe Rare Medium Forklift/pedestrian Establish a Traffic Management

Can anyone’s body parts be sheared interaction could lead to a Plan.

between two parts of plant, or between a person being trapped

part of the plant and a work piece or Y N between the forklift and Ensure appropriate traffic

structure? another object. management controls are in

place (refer to cutting and

impact injuries section).

PRESSURISED CONTENT

Can anyone come into contact with fluids or

Y N

gases under high pressure, due to plant

failure or misuse of the plant?

ELECTRICITY Damaged or frayed Operator to check for damaged

Can anyone be injured or burnt due to: electrical cords or electrical components prior to

Live electrical conductors? (e.g. exposed components would pose use as part of a Pre Start

Y N an electrical hazard. Check.

wires)

Working in close proximity to electrical

Y N Ensure equipment is serviced

conductors?

Access to electricity? on a regular basis, tested &

Y N tagged and appropriate isolation

procedures (e.g. lock out tags)

Damaged or poorly maintained electrical Severe Rare Medium

Y N are in place.

leads, cables or switches?

Water near electrical equipment?

Y N

Lack of isolation procedures?

Y N

Other

Y N

Forklift (Electric) Risk Management Form Page | 5

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ERGONOMICS Operating the forklift for Ensure the forklift is not

Can anyone be injured due to: extended periods of time operated for extended periods

Poorly designed workstation? Moderate Possible Medium or poorly designed or of time.

Y N degraded seats may

Repetitive body movement? Moderate Possible Medium cause musculoskeletal Ensure appropriate rest breaks

Y N injury. are taken.

Constrained body posture or the need

Y N Ensure forklift seating is in good

for excessive effort?

Design deficiency causing psychological condition and can be adjusted

Y N for different body types.

stress?

Inadequate or poorly placed lighting?

Y N

Does the plant impact on the

surrounding workplace and create

potential hazards? (Consider potential Y N

impact on the design and layout of the

workplace)

Is the location of the plant inappropriate?

(Consider potential effects due to Y N

environmental conditions and terrain)

Other

Y N

Forklift (Electric) Risk Management Form Page | 6

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

RADIATION

Can anyone using the plant, or in the vicinity

of the plant suffer injury or illness due to

exposure to radiation in the form of any of

the following: Y N

infra-red radiation

ultra violet light

microwaves

NOISE Moderate Unlikely Medium Operation of the forklift Appropriate hearing protection

Can anyone using the plant, or in the vicinity could result in high noise should be worn whilst operating

Y N

of the plant, suffer injury due to exposure to levels. the equipment (if required).

noise?

VIBRATION

Can anyone be injured or suffer ill health Y N

from exposure to vibration?

FRICTION

Can anyone be burnt due to contact with

Y N

moving parts, materials or surfaces of the

plant?

SUFFOCATION

Can anyone be suffocated due to lack of Y N

oxygen, or atmospheric contamination?

CONDITION

Is a hazard likely due to the age and

condition of the plant? (Consider how hard Y N

the machine has been worked, and whether

it is used constantly or rarely).

Can anyone be injured as a result of the

plant not serviced appropriately and/or

Y N

maintained in line with manufacturer’s

recommendations?

Forklift (Electric) Risk Management Form Page | 7

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SLIPS/TRIPS/FALLS Access and egress to the Ensure operator wears slip

Can anyone using the plant, or in the vicinity forklift could pose a risk resistant footwear to reduce risk

of the plant, slip, trip or fall due to: of slip, trip or fall. of slips/falls.

Uneven, slippery or steep work Major Rare Medium

Y N

surfaces? Poor housekeeping could Ensure operator maintains three

Poor housekeeping, e.g. spillage in the Moderate Possible Medium result in a slip, trip or fall points of contact when

Y N

vicinity? hazard. accessing or exiting the vehicle.

Obstacles being placed in the vicinity of Moderate Possible Medium

Y N

the plant? Ensure good housekeeping

Inappropriate or poorly maintained floor Major Rare Medium practices are maintained

or walking surfaces (i.e. lack of a slip- throughout the work area.

Y N

resistant surface, unprotected holes,

penetrations or gaps?)

If operating or maintaining plant at height

can anyone slip, trip or fall due to:

Use of work platforms, stairs or ladders?

Y N

Lack of guardrails or other suitable edge

Y N

protection?

Other

Y N

Forklift (Electric) Risk Management Form Page | 8

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

FIRE AND EXPLOSION

Y N

Can anyone be injured by fire?

Can anyone be injured by explosion of

gases, vapours, liquids, dusts, or other Y N

substances?

TEMPERATURE/MOISTURE

Can anyone come into contact with objects Y N

at high or low temperatures?

Can anyone suffer ill health due to

Y N

exposure to high or low temperatures?

Can anyone be injured or suffer ill health

Y N

due to exposure to moisture?

OTHER

Can anyone be injured or suffer ill health

from exposure to:

Chemicals? Y N

Toxic gases or vapours? Y N

Fumes / Dusts? Y N

Other? (please specify) Y N

4. Risk Assessment Signoff

Authorised By: Signature: Date:

Forklift (Electric) Risk Management Form Page | 9

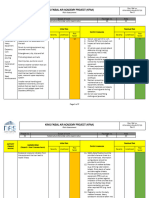

Plant and Equipment Risk Management Form

1. Consequence - Evaluate the consequences of a risk occurring according 2. Likelihood - Evaluate the likelihood of an incident occurring according to the

to the ratings in the top row ratings in the left hand column

Descriptor Level Definition

Descriptor Level Definition

Rare 1 May occur somewhere, sometime (“once in a life time /

Insignificant 1 No injury once in a hundred years”)

Minor 2 Injury/ ill health requiring first aid Unlikely 2 May occur somewhere within the Department over an

extended period of time

Moderate 3 Injury/ill health requiring medical

attention Possible 3 May occur several times across the Department or a

region over a period of time

Major 4 Injury/ill health requiring hospital

admission Likely 4 May be anticipated multiple times over a period of time

May occur once every few repetitions of the activity or

Severe 5 Fatality event

Almost 5 Prone to occur regularly

3. Risk level - Calculate the level of risk by finding the intersection between the Certain It is anticipated for each repetition of the activity of event

likelihood and the consequences

4. Risk Level/Rating and Actions

Likelihood Consequence

Insignificant Minor Moderate Major Severe Descriptor Definition

Almost Medium High Extreme Extreme Extreme

Certain

Likely Medium Medium High Extreme Extreme Extreme: Notify Workplace Manager and/or Management OHS

Possible Low Medium Medium High Extreme Nominee immediately. Corrective actions should be taken

Unlikely Low Low Medium Medium High immediately. Cease associated activity.

Rare Low Low Low Medium Medium High: Notify Workplace Manager and/or Management OHS

Nominee immediately. Corrective actions should be taken

within 48 hours of notification.

Medium: Notify Nominated employee, HSR / OHS Committee.

Nominated employee, OHS Representative / OHS Committee

is to follow up that corrective action is taken within 7 days.

Low Notify Nominated employee, HSR / OHS Committee.

Nominated employee, HSR / OHS Committee is to follow up

that corrective action is taken within a reasonable time.

Forklift (Electric) Risk Management Form Page | 10

Anda mungkin juga menyukai

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDokumen11 halamanPlant and Equipment Risk Management Form: 1. Hazard Management Details - Generalum erBelum ada peringkat

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDokumen11 halamanPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralAlejandro CampomarBelum ada peringkat

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDokumen11 halamanPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralAlejandro Campomar100% (1)

- Plant and Equipment Risk Management Form: Plant/Equipment Item: High Pressure Water Cleaner Make/Model No.: Serial No.Dokumen9 halamanPlant and Equipment Risk Management Form: Plant/Equipment Item: High Pressure Water Cleaner Make/Model No.: Serial No.Letlape SamuelBelum ada peringkat

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDokumen10 halamanPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralsamBelum ada peringkat

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDokumen9 halamanPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDan Dumbravescu100% (1)

- Evaluare Risk MotoferastrauDokumen10 halamanEvaluare Risk MotoferastrauDan DumbravescuBelum ada peringkat

- Hydraulic Press Risk MG T FormDokumen10 halamanHydraulic Press Risk MG T FormAndrei VBelum ada peringkat

- ForkliftfuelriskmgtformDokumen11 halamanForkliftfuelriskmgtformAli TavakoliBelum ada peringkat

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDokumen9 halamanPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralJigar VekariyaBelum ada peringkat

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDokumen9 halamanPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralJigar VekariyaBelum ada peringkat

- JSA HEMP Well Services Pg36-40Dokumen5 halamanJSA HEMP Well Services Pg36-40Ashok SureshBelum ada peringkat

- Bsee 3b-Bosh Job Hazard Analysis Exam (Priela, Allen Kyle D.)Dokumen6 halamanBsee 3b-Bosh Job Hazard Analysis Exam (Priela, Allen Kyle D.)Allen Kyle PrielaBelum ada peringkat

- Generic Risk Assessment - General Lathe Use v.1Dokumen7 halamanGeneric Risk Assessment - General Lathe Use v.1Darus YasunBelum ada peringkat

- Plant and Equipment Risk Assessment Fgoc - NewDokumen12 halamanPlant and Equipment Risk Assessment Fgoc - Newmajid khanBelum ada peringkat

- Machine Guarding SafetyDokumen31 halamanMachine Guarding SafetyAnonymous iI88LtBelum ada peringkat

- JSA TubularDokumen4 halamanJSA TubularRahul M.RBelum ada peringkat

- Example Manual Handling Risk Assessment - Moving EquipmentDokumen8 halamanExample Manual Handling Risk Assessment - Moving Equipmentfanehhh 10Belum ada peringkat

- Maintenance Manual English ZPMC Gruas de PuertoDokumen325 halamanMaintenance Manual English ZPMC Gruas de PuertoRafael Quintero Sevilla100% (1)

- JLA Lifting OperationsDokumen3 halamanJLA Lifting OperationsFaisal KhanBelum ada peringkat

- Soil Compaction 03 Revision 00 #d349Dokumen9 halamanSoil Compaction 03 Revision 00 #d349softwaresolutionsinstantBelum ada peringkat

- Working at HeightsDokumen81 halamanWorking at HeightsJohn Paul BañariaBelum ada peringkat

- JHA MaintenanceDokumen9 halamanJHA Maintenancejherson gravidesBelum ada peringkat

- On-Site Risk Assessment & Hazards IdentificationDokumen2 halamanOn-Site Risk Assessment & Hazards Identificationzasim864Belum ada peringkat

- SMB003 Risk Assessment AutoclavingDokumen5 halamanSMB003 Risk Assessment AutoclavingtafouzeltBelum ada peringkat

- 02 Safety RulesDokumen5 halaman02 Safety RulesAnang SuryaBelum ada peringkat

- RA Personal Fall Arrest Fall Restraint Equipment 0007 July 2017Dokumen3 halamanRA Personal Fall Arrest Fall Restraint Equipment 0007 July 2017um erBelum ada peringkat

- Safety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Dokumen12 halamanSafety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Priyo DjatmikoBelum ada peringkat

- AHA-002, Geotechnical WorkDokumen5 halamanAHA-002, Geotechnical WorkBuddhikaBelum ada peringkat

- Plant and Equipment Risk Assessment Fgoc - NewDokumen13 halamanPlant and Equipment Risk Assessment Fgoc - Newmajid khanBelum ada peringkat

- 17-Using Portable Power ToolsDokumen2 halaman17-Using Portable Power Toolshsse.maltaBelum ada peringkat

- Truck Mounted Cranes: Hazard & Risk Assessment - Plant OperationDokumen3 halamanTruck Mounted Cranes: Hazard & Risk Assessment - Plant OperationsoumyakantBelum ada peringkat

- OSHJ-GL-04 Mobile Access Towers Version 1 EnglishDokumen9 halamanOSHJ-GL-04 Mobile Access Towers Version 1 EnglishsajinBelum ada peringkat

- Ladders, Hop Ups Risk AssessmentDokumen8 halamanLadders, Hop Ups Risk AssessmentRebecca Winter100% (1)

- Jla Forklift OperationDokumen2 halamanJla Forklift OperationFaisal KhanBelum ada peringkat

- Electrical Hazards ChecklistDokumen3 halamanElectrical Hazards ChecklistMazen FakhefakhBelum ada peringkat

- JHA - Ladders TemplateDokumen3 halamanJHA - Ladders TemplateShannon Williams100% (1)

- Working Heights Risk Assessment TemplateDokumen8 halamanWorking Heights Risk Assessment TemplateJUAN NICANOR ALIAGA GIRONBelum ada peringkat

- Jha Cistern TankDokumen6 halamanJha Cistern TankHarlene Marie M. IlaganBelum ada peringkat

- Working Heights Risk Assessment TemplateDokumen8 halamanWorking Heights Risk Assessment TemplatemahmoudmakladBelum ada peringkat

- Air Compressor Risk MG T FormDokumen8 halamanAir Compressor Risk MG T FormFateh AliyaBelum ada peringkat

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDokumen51 halamanBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhBelum ada peringkat

- Basic Safety Practices For Lifts 2020 ReviewDokumen44 halamanBasic Safety Practices For Lifts 2020 ReviewCarmen Carbonell RoyoBelum ada peringkat

- Eis 28Dokumen4 halamanEis 28Ab AUBelum ada peringkat

- M05 F05 Machine Risk Assessment HoistsDokumen6 halamanM05 F05 Machine Risk Assessment HoistsEfrainBelum ada peringkat

- RMDJV Pj74 Hiradc Sube 01 (Equipment Delivery)Dokumen2 halamanRMDJV Pj74 Hiradc Sube 01 (Equipment Delivery)myn maliQueBelum ada peringkat

- JSA 173 - CRT RIG UP - Updated 21.10.2019Dokumen11 halamanJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidBelum ada peringkat

- Emergency Plan For LiftDokumen8 halamanEmergency Plan For LiftScribdTranslationsBelum ada peringkat

- Waterline Tie-In With Existing Service AHADokumen2 halamanWaterline Tie-In With Existing Service AHALawrence adeleke OmisakinBelum ada peringkat

- Machine Safety: Jenny R. Feraer, Uap, So2Dokumen11 halamanMachine Safety: Jenny R. Feraer, Uap, So2cristel talaveraBelum ada peringkat

- RSK3 #2 - Occupational HazardsDokumen53 halamanRSK3 #2 - Occupational HazardsHerman HidayatBelum ada peringkat

- 045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Dokumen7 halaman045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Zubair Ahmed KhaskheliBelum ada peringkat

- Magicolor 2490MF: Service ManualDokumen150 halamanMagicolor 2490MF: Service ManualEstanislao Amadeo AvogadroBelum ada peringkat

- Migsonic200cvcc Service Manual PDFDokumen65 halamanMigsonic200cvcc Service Manual PDFAnonymous nC9gpUWPBelum ada peringkat

- AHA-009, Construction & Removing FormsDokumen4 halamanAHA-009, Construction & Removing FormsBuddhikaBelum ada peringkat

- F05 Machine Risk Assessment Aerial LiftDokumen8 halamanF05 Machine Risk Assessment Aerial LiftEfrainBelum ada peringkat

- Assignment2 BaclayDokumen2 halamanAssignment2 BaclayJoshua Rheynaird J. AmoguisBelum ada peringkat

- Air Compressor Risk MG T FormDokumen8 halamanAir Compressor Risk MG T Formashraf100% (1)

- The Handbook of Safety Engineering: Principles and ApplicationsDari EverandThe Handbook of Safety Engineering: Principles and ApplicationsPenilaian: 4 dari 5 bintang4/5 (1)

- Hand Tools: (Contained in Individual Sets or The Tool Crib in Sufficient Quantities To Permit Efficient Instruction)Dokumen14 halamanHand Tools: (Contained in Individual Sets or The Tool Crib in Sufficient Quantities To Permit Efficient Instruction)Dan DumbravescuBelum ada peringkat

- Era TD 2012 04 Int en PDFDokumen15 halamanEra TD 2012 04 Int en PDFDan DumbravescuBelum ada peringkat

- Era TD 2012 04 Int en PDFDokumen15 halamanEra TD 2012 04 Int en PDFDan DumbravescuBelum ada peringkat

- Draft Implementing Act On A System of Certification of Entities in Charge of Maintenance For VehiclesDokumen38 halamanDraft Implementing Act On A System of Certification of Entities in Charge of Maintenance For VehiclesDan DumbravescuBelum ada peringkat

- Din en 12266 1Dokumen15 halamanDin en 12266 1Josip-Jenny Zrile100% (4)

- Racord dn40 PDFDokumen2 halamanRacord dn40 PDFDan DumbravescuBelum ada peringkat

- Dangerous Goods Guidance Note 10 PDFDokumen3 halamanDangerous Goods Guidance Note 10 PDFDan DumbravescuBelum ada peringkat

- Era TD 2012 04 Int en PDFDokumen15 halamanEra TD 2012 04 Int en PDFDan DumbravescuBelum ada peringkat

- Primer Crtanja Prostorija U autoCAD-u PDFDokumen169 halamanPrimer Crtanja Prostorija U autoCAD-u PDFJovanJoksicBelum ada peringkat

- en - GCU Appendix 9Dokumen115 halamanen - GCU Appendix 9Dan DumbravescuBelum ada peringkat

- Din en 12266 1Dokumen15 halamanDin en 12266 1Josip-Jenny Zrile100% (4)

- Primer Crtanja Prostorija U autoCAD-u PDFDokumen169 halamanPrimer Crtanja Prostorija U autoCAD-u PDFJovanJoksicBelum ada peringkat

- 89-96 I IvankovicDokumen8 halaman89-96 I IvankovicDan DumbravescuBelum ada peringkat

- KST Druckgeraeterichtl GBDokumen18 halamanKST Druckgeraeterichtl GBDan DumbravescuBelum ada peringkat

- Field Welding Procedures Manual - Contractor VersionDokumen102 halamanField Welding Procedures Manual - Contractor Versionlaz_k100% (2)

- 89-96 I IvankovicDokumen8 halaman89-96 I IvankovicDan DumbravescuBelum ada peringkat

- Audit Guide Full DayDokumen17 halamanAudit Guide Full DayDan DumbravescuBelum ada peringkat

- Hi Pressure Water Cleaner ProcedureDokumen11 halamanHi Pressure Water Cleaner ProcedureDan DumbravescuBelum ada peringkat

- Evaluare Risk MotoferastrauDokumen10 halamanEvaluare Risk MotoferastrauDan DumbravescuBelum ada peringkat

- KST Druckgeraeterichtl GBDokumen18 halamanKST Druckgeraeterichtl GBDan DumbravescuBelum ada peringkat

- Safe Work Procedure: Last Updated: 22 August 2018Dokumen2 halamanSafe Work Procedure: Last Updated: 22 August 2018Dan DumbravescuBelum ada peringkat

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDokumen9 halamanPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDan Dumbravescu100% (1)

- Field Welding Procedures Manual - Contractor VersionDokumen9 halamanField Welding Procedures Manual - Contractor VersionDan DumbravescuBelum ada peringkat

- Utilizare Foafece ElectricDokumen1 halamanUtilizare Foafece ElectricDan DumbravescuBelum ada peringkat

- Qatar Engineering & Construction Company WLL (Qcon)Dokumen12 halamanQatar Engineering & Construction Company WLL (Qcon)Dan DumbravescuBelum ada peringkat

- Strain 45 4 2009 PDFDokumen45 halamanStrain 45 4 2009 PDFDan DumbravescuBelum ada peringkat

- Edit Recipient - RBC Online Banking PDFDokumen2 halamanEdit Recipient - RBC Online Banking PDFDan DumbravescuBelum ada peringkat

- Hibbers TD 2006Dokumen253 halamanHibbers TD 2006Dan DumbravescuBelum ada peringkat

- API RP 571 - Damage Mechanisms Spreadsheet Damage MechanismsDokumen38 halamanAPI RP 571 - Damage Mechanisms Spreadsheet Damage MechanismsDan DumbravescuBelum ada peringkat

- Pirate's AngelDokumen129 halamanPirate's Angelgenie1970Belum ada peringkat

- Annihilation Alex GarlandDokumen127 halamanAnnihilation Alex GarlandIan Gibbons100% (2)

- Knitted Lace Estonia ScarfDokumen4 halamanKnitted Lace Estonia Scarfvorliebye64Belum ada peringkat

- Tongue TwistersDokumen5 halamanTongue Twistersrawaida_hayaniBelum ada peringkat

- My Dad Wrote A Porno - Chapter 1Dokumen11 halamanMy Dad Wrote A Porno - Chapter 1Quercus Books80% (5)

- The Impact of Fashion On TeensDokumen7 halamanThe Impact of Fashion On TeensTatiana EşanuBelum ada peringkat

- Bobcat 753 Service ManualDokumen502 halamanBobcat 753 Service ManualOsama Farah71% (7)

- Asian Business Etiquette: Tina Fong Stacy ZhangDokumen12 halamanAsian Business Etiquette: Tina Fong Stacy ZhangGabriela MorariBelum ada peringkat

- Screen PrintingDokumen2 halamanScreen PrintingthomasjosephwelshBelum ada peringkat

- Hell Is Real by Father Carlos Cancelado.Dokumen9 halamanHell Is Real by Father Carlos Cancelado.Francisco-nunez-6588Belum ada peringkat

- TM-10-3530-203-10 1966 (C6-1988)Dokumen205 halamanTM-10-3530-203-10 1966 (C6-1988)Gramma JoBelum ada peringkat

- AdverbsDokumen10 halamanAdverbsKarina Ponce RiosBelum ada peringkat

- SWP Drill Mill AS513Dokumen2 halamanSWP Drill Mill AS513rayvathyBelum ada peringkat

- 2014 Variation CDokumen4 halaman2014 Variation CEnkhsaran BatsaikhanBelum ada peringkat

- 51477812Dokumen12 halaman51477812Benjamin HidalgoBelum ada peringkat

- L98Dokumen225 halamanL98Younjin ChoiBelum ada peringkat

- The Hunchback of NotredameDokumen48 halamanThe Hunchback of NotredameRose Ann Villanueva0% (1)

- Proposed Guidelines For Academic Regalia RentalsDokumen2 halamanProposed Guidelines For Academic Regalia Rentalsigp norsuBelum ada peringkat

- C&F CollectionDokumen16 halamanC&F Collectionreacconewilo100% (1)

- Union Jack Heart Grid Large Cushion: by Marie WallinDokumen2 halamanUnion Jack Heart Grid Large Cushion: by Marie WallinJill KrahlingBelum ada peringkat

- Brave IreneDokumen4 halamanBrave IreneMalvarosa88% (8)

- Sta - Ana v. Maliwat Digest G.R. No. L-23023 August 31, 1968Dokumen7 halamanSta - Ana v. Maliwat Digest G.R. No. L-23023 August 31, 1968Emil BautistaBelum ada peringkat

- Role of Visual Merchandising in Mid Format Retail StoresDokumen56 halamanRole of Visual Merchandising in Mid Format Retail Storesamar_guptaBelum ada peringkat

- WARG - Playtest Rules 420Dokumen32 halamanWARG - Playtest Rules 420SentientGamesBelum ada peringkat

- Intro Student BookDokumen57 halamanIntro Student BookTiago AbelhaBelum ada peringkat

- 1 - Dress Code and Uniform Policy For StudentsDokumen2 halaman1 - Dress Code and Uniform Policy For StudentsDIPESH RAJBelum ada peringkat

- Textile School Cat 0607 PennDokumen148 halamanTextile School Cat 0607 PenntixapoBelum ada peringkat

- Departmental StudyDokumen56 halamanDepartmental StudyMadhur SharmaBelum ada peringkat

- 09 - Chapter 3Dokumen27 halaman09 - Chapter 3John KAlespiBelum ada peringkat

- EXERCISE Adjective ClauseDokumen3 halamanEXERCISE Adjective ClauseAlfian IhsanBelum ada peringkat