Engineering Aspects of Food Processing

Diunggah oleh

William EdwardsHak Cipta

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniEngineering Aspects of Food Processing

Diunggah oleh

William EdwardsCHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol.

V - Engineering Aspects of Food

Processing - P.P. Lewicki

ENGINEERING ASPECTS OF FOOD PROCESSING

P.P. Lewicki

Warsaw University of Life Sciences (SGGW), Warsaw, Poland

The State College of Computer Science and Business Administration in Lomza, Poland

Keywords: Metabolic energy requirement, food production, wet cleaning, dry cleaning,

homogenization, membrane filtration, cyclones, clarifixator, coating, extrusion,

agglomeration, fluidization, battering, uperisation, pasteurization, sterilization, baking,

chilling, freezing, hydrocooling, cryoconcentration, glazing, extrusion-cooking, roasting,

frying, thermoplasticity, logistics.

Contents

TE SS

S

1. Introduction

2. Food industry

R

AP L

3. Food processing

3.1. Mechanical Processes

H O

3.2. Heat Transfer Processes

3.3. Mass Transfer Processes

C E

3.4. Materials Handling

3.5. Hygiene of Processing

E O–

3.6. Food Engineering

4. Concluding remarks

Glossary

Bibliography

PL C

Biographical Sketch

M ES

Summary

The main aim of this chapter is to show the impact of chemical and process engineering

SA N

on the development of nowadays food industry. The contribution presents food as a

substance needed to keep a man alive, which is consumed every day and must be

U

produced in enormous amounts. Food industry is a manufacturer of food, employs

hundred of thousands of employees and uses considerable quantities of energy and

water. Basic processes used in food processing are briefly described. They are divided

into three groups of unit operations that are mechanical processes and heat and mass

transfer processes. In each group of unit operations specificity of the process is

emphasized. At the same time, it is shown how theories of momentum, heat and mass

transfer developed by chemical engineering are applied in designing food-processing

equipment. The question of hygienic design and processing of safe food is explicitly

stressed. The role of food engineering as a discipline accounting for specificity in

design of food processing equipment and its exploitation and assisting chemical

engineering is shown. Some additional sources of information are recommended for

those readers who would like to expand their knowledge on engineering aspects of food

processing and production.

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

1. Introduction

Food is any substance that can be eaten or drunk by a man to keep him alive, nourished

the body and give the pleasure. Food usually contains carbohydrates, proteins and fats

as main constituents. Vitamins, minerals and hundreds other organic and inorganic

compounds are important components of food responsible for nourishment, growth and

well-being of man.

Food composition depends on its origin and the way of processing. Food is mainly

sourced from plants and animals, but some inorganic compounds such as water and salt

are important items of human diet.

Food is a source of energy and components for growth and repair of injuries. It is

estimated that some 109 cells/min. are under constant repair and replacement in a human

TE SS

body. The requirement for energy and nutrients depends on the age and physical activity

of a person. Energy derived from food is used for biochemical reactions (chemical

S

energy), for body movement (mechanical energy), and to maintain the body temperature

R

(thermal energy). The energy efficiency of the human body is about 60%, but half of it

AP L

accounts for thermal energy. The basal metabolic energy requirement ranges from 5 to

H O

7.5 MJ/day depending on age, sex, body mass and size. Requirement for nutrients is

recommended by WHO and local authorities. Recommended Daily Allowance (RDA) is

C E

the level of different nutrients that assure maintenance, growth and repair of the body

for 97.5% of the population.

E O–

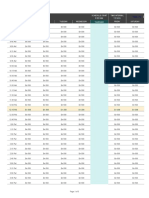

Daily energy consumption depends on availability of food, eating habits, cultural and

religious restrictions and health consciousness. It varies from less than 8 MJ/day in

areas with shortage of food to over 15 MJ/day in developed countries. Some examples

PL C

are presented in Table 1.

M ES

Country MJ/day/person Country MJ/day/person

Somalia 7.30 New Zealand 13.54

Haiti 7.68 Mexico 13.67

SA N

Zambia 7.90 Spain 13.94

Chad 8.29 Turkey 13.98

U

Bangladesh 9.35 Poland 14.13

Argentina 9.66 Denmark 14.20

India 9.87 Switzerland 14.24

Japan 11.53 Hungary 14.32

Slovakia 11.83 United Kingdom 14.34

South Africa 12.14 Germany 14.62

China 12.31 Austria 15.29

Australia 12.80 Ireland 15.43

Saudi Arabia 12.80 Belgium 15.48

Russian Luxemburg

12.98 15.82

Federation

Sweden United States of

13.06 16.02

America

Finland 13.38 World 11.59

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

FAO Statistical Yearbook 2009. Average for the years 2003-2005.

Table 1. Food energy consumption in selected countries

The food energy is supplied by main food constituents. The energy value of proteins

and carbohydrates is 16.74 kJ/g and for fats, it is 33.49 kJ/g. Hence, substantial amounts

of those constituents must be consumed every day to provide body with sufficient

energy. Taking into account that most foods contain large quantities of water and

energetic efficiency of the body is 60% it shows how large mass of food is consumed

per day by a statistical man. Consumption of some foods is presented in Table 2. The

data in Table 2 shows just the consumption of basic foods, which for example for

Poland sums up to 711.2 kg/year. Adding other commodities such as confectionery,

beverages, wine, beer and luxury products, the mass of one tone or even more is

TE SS

obtained. It shows how huge amounts of food must be supplied every day.

S

Country Meat Poultry Fish Milk Eggs Butter Potato Vegetables Fruits Grain

R

Austria 95.1 16.9 14.7 299.8 12.9 5.2 59.7 90.4 137.2 110.8

AP L

Denmark 93.5

H O 18.4 24.3 239.3 17.5 1.7 76.5 102.2 146.5 139.5

Finland 52.9 15.1 32.6 356.2 8.4 4.0 71.8 70.7 91.9 106.6

France 73.6 24.7 31.2 274.6 15.3 8.1 64.8 142.9 95.5 117.2

C E

Germany 70.9 13.8 14.9 255.6 12.0 6.8 72.1 90.5 113.2 112.9

Hungary 59.1 30.2 5.1 168.9 16.5 1.0 69.1 117.0 137.2 125.4

Poland 56.9 19.1 13.1 173.4 11.6 4.5 130.1 100.3 47.6 154.6

E O–

Spain 91.6 30.4 47.4 173.8 13.1 0.8 78.6 143.3 112.7 98.9

Sweden 64.3 12.6 33.6 377.8 10.5 3.6 54.1 78.4 115.2 103.5

Food Balance Sheets, FAO 2006. Przemysl Spozywczy, 2008, 61(8), 26-31,75.

Table 2. Consumption of food in kg/person in 2003

PL C

M ES

2. Food Industry

Food is produced by the food industry. This industry is much diversified. There are

small family run businesses almost like a craftsmen workshop, and large processing

SA N

plants employing hundreds of workers. The size of the plant depends primarily on the

U

kind of processed products, the market and expectations of consumers. Small

enterprises produce specialty goods or regional products on local market as well as

products of every day use and expected by consumers as freshly made. The example is

production of bread, rolls and cakes, pasteurized fluid milk. Large processing plants

produce basic commodities such as flour, culinary and processed meat, fruit juices,

UHT milk, milk powder, fats, confectionary and frozen foods.

Food industry as a whole is a large part of national economy. It employs large number

of people with different skills and education. In Poland, food industry employed in 2007

some 475 thousand people, which amounts to 1.25% of the population or 3.45% of total

employment. In Germany, food industry in 2005 employed 845 thousand people, and

the food industry of the European Union (EU-27) employed some 4.69 million people.

Processing of food consumes huge amounts of energy and water. In Poland in 2007 total

energy consumption by the food industry amounted to 8.82·1016 J and water

consumption was some 1.014·107 m3. Total energy consumption referred to population

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

of Poland yields some 6.36 MJ/day/person. It means that to supply a man with

appropriate food energy, food industry must input more than 45% of that value in the

form of heat and electrical energy.

Most food originating from plant and animal sources is perishable. It undergoes

senescence, biological, microbiological, chemical and physical decay. Hence, food must

be preserved in order to prevent loses. In temperate climate, agriculture is seasonal;

therefore, preservation techniques are needed in order to allow food to be available out

of the season. In developed countries more than 70% of the population live in

metropolis and big cities, while production of raw materials for food is spread all over

the country. Because of that, transportation of agricultural products and food becomes

an important issue.

TE SS

The basic aims of food industry today are as follows:

S

1. To preserve food and extend the time during which a food remains wholesome, can

R

be distributed and stored, also at home.

AP L

2. To increase variety of products, which fulfill consumer expectations as far as price,

H O

diet, habits and other likes are concerned.

C E

3. To manufacture convenience products in order to reduce the time required for meal

preparation.

E O–

4. To provide products with appropriate nutritional quality.

5. To generate income for the company.

All the above-enumerated goals of the food industry are subordinated to the most

PL C

important requirement - the safety of food. Hence, all the applied preservation

techniques must assure safety of food in first place. That prerequisite enforces special

M ES

design of processing equipment and facilities as well as management solutions.

3. Food Processing

SA N

Food processing involves combination of procedures and processes intended to change

U

the raw materials into foodstuffs. The procedures and processes are conveniently called

unit operations. The idea of unit operations allow unified description of production of

different varieties of food.

From the processing point of view, raw materials can be classified as liquids and solids.

Processing of liquids differs substantially from processing of solids, because it can be

done in a hermetic system avoiding contact with surroundings. Hence, high standard of

hygiene can be easily assured. Processing of solids is more complicated, and only partly

can be isolated from the contact with surroundings. Hygienic solutions are more

complex. Some solids are a source of liquids as semi-products, and some liquids are

processed to solids. Therefore, food processing partly as liquids and partly as solids is a

common practice.

Basic unit operations used in food processing are presented on Figure 1. All the unit

operations applied in food processing can be divided into three main groups.

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

Mechanical processes include such unit operations as cleaning, size reduction, sorting,

grading and removing of inedible parts, mixing and mechanical separation. Heating and

cooling, evaporation, freezing all belongs to heat transfer processes. Mass transfer

occurs in such processes as drying, extraction, crystallization and distillation. Nowadays

ionizing radiation and electrical current are used to process foods. Moreover, in food

processing there are also processes of complex nature, which cannot be assigned to any

of the above groups. These are fermentation and some post-processing operations.

Raw materials

Liquid Solids

TE SS

Cleaning, removing

S

inadible parts

Sorting,

R

grading,

AP L

H O separation

Disintegration

C E

Mixing

E O–

Distillation

Heating Cristallization

PL C

Forming

M ES

Drying Concentration Cooling

SA N

U

Agglomeration Extraction Freezing

Products

Figure 1. Basic unit operations in food processing

Many unit operations applied in food processing are well understood and theoretically

described thanks to the knowledge brought about by chemical and process engineering.

Application of momentum, heat and mass transfer theories in the design of food

processing equipment is wide and very successful. However, there are still many

processes, which are not fully understood or so complex, that their mathematical

description would not be useful in the design or exploitation of equipment. These

problems arise mostly from the structure and properties of processed material and their

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

dependence on weather, agricultural practices and post-harvest treatment and processing.

3.1. Mechanical Processes

3.1.1. Cleaning of Raw Material

Mechanical processes are intended mostly to change physical properties of raw material

and to prepare it to further processing. One of the first unit operations is cleaning, which

is done in a wet or dry way. The way the raw material is cleaned depends on its nature,

the type of soil to be removed, and further processing. In wet cleaning mechanical and

hydrodynamic forces are used, and water serves as a cleaning agent. Cleaning soft

materials easily damaged by mechanical forces, water is sprayed onto material surface

or air is pumped into water, and vigorous mixing is caused. For wet cleaning such

TE SS

methods as soaking, brushing, spraying, air bubbling and flotation are used. For each of

these methods equipment is designed mostly based on experience and observations.

S

R

Dry cleaning is less efficient than the wet one, but it is used for materials with low

AP L

water content. Dry cleaning is applied for example to grains, nuts, and cocoa beans. Air

H O

is the cleaning agent, and differences in buoyancy are used to separate material from the

contaminants. Cleaned material is fed into a stream of air and is usually separated into

C E

three fractions. Heavy debris fall first, then cleaned material and the light contaminants

like stalks, husks are deposited as the last. The theory of flow of diluted mixture of

E O–

particulates in gas, as well as sedimentation principles are used to calculate the air

velocity. Aspiration cleaning is well designed and widely used in harvesting machines

and grain storage and processing facilities.

PL C

3.1.2. Removal of Inedible Parts

M ES

Removal of inedible parts from the raw material is another important operation in food

processing, which needs specially designed equipment. Mostly it is a mechanical

operation but some chemicals and heat are also used. Destoning of fruits, deboning of

SA N

meat and poultry, deheading of fish are the examples of mechanical operations, in

which force is used to push out or to cut out an inedible part of the material. Derinders

U

are very specialized machines used to deskin slaughtered animals. Mechanical force is

used to separate the skin from meat, but the deskining must be initiated manually.

Defeathering of poultry and dehairing of carcasses is done mechanically but is preceded

by scalding (heat treatment). Evisceration of poultry and slaughtered animals is done

manually, while gutting of fish is done either manually or mechanically. Peeling of

fruits and vegetables is done by abrasion or using heat. Treatment with steam, hot

solution of caustic soda or flame is practiced in food processing. From the above

description, it is evident that the equipment used to remove inedible parts of the material

is very specialized, designed just for the particular material taking into account its size

and shape, physical properties and the job, which must be done. Only peeling

equipment is more versatile. Hence, mechanically resistant vegetables such as potato,

carrot, red beetroot can be peeled in abrasive machines, while soft materials as tomato,

peaches, apricots are peeled be surface heating and removing scalded peel with water

spray.

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

3.1.3. Disintegration

Disintegration of the material is a common process in food industry. It is done in order:

1. To fulfill expectations of the consumer,

2. To facilitate further processing,

3. To enable separation of parts of the material with different properties

4. To enable joining of different materials or parts of the material with special

properties.

Food raw materials mostly contain large quantities of water; hence they properties differ

very much from the properties of brittle materials. Theories of Kick, Rittinger or Wang

TE SS

are not applicable, except of some special cases like lime stone disintegration in sugar

processing. Most of the disintegration equipment used in food processing is designed

S

based on experience and observations.

R

AP L

Appropriate design of the disintegration equipment is very important because in many

H O

size reduction processes some precautions must be undertaken. For example,

disintegration of potatoes for starch production or grain for flour must be done in such a

C E

way that the starch granules are not damaged. Disintegration of apple must assure free

flowing of juice in pores of crushed apple bed during juice expression.

E O–

In size reducing machines compression, impact and shearing forces are mostly applied.

Disintegrating machines use all three forces, but often one prevails over the others.

Disintegrators are often equipped with screens hence; material only with appropriate

PL C

size can leave the machine. Machines of that type reduce the size of the material but do

not create any shape. Specialized machines are used for cutting, slicing and dicing.

M ES

Food materials are mostly visco-elastic, some show plasticity, and only some dry

products can be treated as brittle. Because of that, use of energy for size reduction is

SA N

small. Most of energy is used to overcome inertia and friction forces in disintegrating

machines. Milling of wheat requires about 1 kJ/kg, chopping fresh meat, depending on

U

the size, needs from 1 to 20 kJ/kg, and chopping of frozen meat needs 35 or 70 kJ/kg

when pieces are 3 or 2 mm, respectively. Slicing of sugar beet requires energy from 0.9

to1.6 kJ/m2, and for potatoes, the needed energy is about 0.6-0.7 kJ/m2. The output of

the disintegrating machines depends on the kind of disintegrated material, the degree of

disintegration and further processing steps. It varies from hundreds of kilograms per

hour to some 60 t/h.

In processing of liquid food, disintegration is also applied. The disintegration is applied

to emulsions and suspensions of solids in liquids. Milk is an emulsion with variable size

of fat globules and undergoes separation (creaming) under gravity. Some fruit juices

contain fruit flesh, which sediments at the bottom of the bottle. Both, milk with the

layer of cream on the surface or the juice with layer of sediment are not attractive to the

consumer. The smaller is the size of fat drops or the pieces of fruit flesh the longer is the

time of creaming or sedimentation. Disintegration of that type of products is done in

homogenizers or colloidal mills. In homogenizers, shearing and cavitations are main

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

causes of fat globules disintegration. The emulsion is forced through the narrow slit

with high velocity. Pressure applied on the homogenizing valve is 40-60 MPa.

Application of pressures exceeding 100-150 MPa leads to disintegration of microbial

cells, and homogenization adds some pasteurization effect. In colloidal mills,

suspension is forced into clearance between stationary and rotating disc, which rotates

at 3000-15000 rev/min. Shearing forces cut pieces of suspension and retards

sedimentation. Colloid mills are also used in production of paste-like products (peanut

butter, meat paste).

Disintegration of the stream of liquid into small droplets is applied in spray drying.

Formation of liquid droplets suspended in a gas is done in a centrifugal atomizer or in a

pressure nozzle. The way the cloud of liquid droplets is formed depends primarily on

the kind of sprayed material and the output of the dryer. Milk is mostly sprayed by

centrifugal atomizers, while tea or coffee extracts are sprayed with nozzles. The

TE SS

important property of the spraying equipment is the size distribution of droplets. The

narrow is the size distribution of droplets the efficient is the drying, and better is the

S

quality of the dried product.

R

AP L

In food processing stream of gas is also divided into bubbles suspended in liquid in

H O

order to produce sparkling soft beverages, foamed products or to cause and facilitate

mixing. For mixing purposes barbotage is used, while in foamed products processing

C E

vigorous mixing is applied.

E O–

3.1.4. Sorting and Grading

Some raw materials and disintegrated material often needs sorting. Sorting is done by

weight, size, shape, and color. The need for sorting arises from few reasons.

PL C

1. Sorted material is much better appreciated by consumers. It is recognized as of good

M ES

quality and subjected to appropriate technology.

2. Uniform weight, size or shape makes easier further processing and its control.

Moreover, uniformity of quality of the final product is related to the size or weight

SA N

of the material, especially in processes in which heat or mass transfer occurs.

U

3. Sorted material gives better control of filling and packing operations.

4. In some cases, size or weight of the material is related to its quality. For example,

small green peas contain less starch and are sweeter than the large one.

Sorting is done mostly taking advantage of gravity force. Screens with fixed or variable

aperture as flat or drum machines are commonly used. In the case of flat screens,

vibration is applied to move the material, while in the drum design inclination and

rotation cause movement of the material from inlet to outlet. Large objects are sorted in

cable, rope, belt or roller sorters. In these machines, the material moves in between two

cables, belts or rolls. The aperture between them increases continuously and material

with prescribed size is collected along the sorter. Sorting may damage the material,

especially that with soft texture. Hence, in some sorters material is collected in

containers filled with water. Sorting and washing can be combined in one operation.

Sorting by size or shape sometimes is done manually using special calibrators. This is

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

done for material, which must be calibrated by two dimensions. Example is cucumber

and gherkin processing. Both are sorted by diameter and length. It can be done

mechanically but the damage to the material is extensive.

Color sorting is done either manually or by image analysis. Manual sorting is applied to

large objects like fruits and vegetables, and is done by comparison with color standards.

Image analysis is also applied to sort large objects by color. The sorted material is

mostly packed and sold. Material subjected to freezing or drying may also undergo

color sorting. Hence, this sorting is aimed to fulfill expectations of the consumer. In

some instances color sorting is aimed to assure quality of the final product. For example,

in sesame seeds husk is bitter and must be removed to assure high quality of halva.

Another example is separation of bruised apple or fungi infected potatoes. Material,

which not matched the standard, is removed by the jest of air actuated by computer.

TE SS

The above-described methods of sorting divide the material into fractions on the

S

physical basis. However, separation of the material into fractions with different quality

R

is also required. It is done by grading. In many instances, size and weight of the material

AP L

are related to the quality and sorting is sufficient as a method of grading. There are

H O

some material features, which cannot be assayed by size, shape or weight. Freshness of

eggs, ripeness of fruits, crumb structure in bread, baking properties of flour are

C E

examples of quality features, which cannot be divided into classes by sorting. Grading

in most cases must be done by a laboratory tests. In some cases, physical properties can

E O–

be used for machine grading. It was already mentioned that small green peas is sweeter

than the large one. Density of peas is related to its tenderness. Hence, grading can be

done using brines of varying density. Grading is a process difficult to realize in the on-

line fashion.

PL C

3.1.5. Liquid Expression

M ES

Expression of liquid fraction from plant material is used in fruit and oil processing. The

process is usually preceded by size reduction and heat treatment. The cells must be

SA N

disrupted to release liquid; however, a bed of pressed material must be sufficiently

porous to allow free flowing of the expressed liquid. To reduce viscosity of oil, heating

U

of disintegrated seeds is, in some cases, applied. In processing of some fruit juices

heating and enzymatic treatment are used to avoid jellification of concentrated product.

In wine making grape expression is preceded by maceration, during which native

enzymes hydrolyze pectins. It results in higher yield and better color and taste of juice.

Expression is done in batch presses such as tank press or hydraulic ram press or in

continuous presses. In tank press, fruit pulp is fed into horizontal cylinder in which a

plastic bag is axially mounted. Air is pumped into the bag, which expands and exerts

pressure onto pulp. The tank can be rotated to loosen the pulp and facilitate removal of

press residue. In hydraulic ram press fruit pulp placed in cloth bags is stacked one over

another. The bags are separated by plastic ribbed plates to facilitate liquid flow. The

pressure gradually increases due to lowering of pressure plate. The juice is collected at

the base of the press. This type of presses is used for fruit juice expression.

Continuous presses are designed as belt presses, screw presses and roller presses. In belt

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

presses aperture between two belts decreases along and disintegrated material is

squeezed. In screw presses in a horizontal cylinder, helical screw is rotated. The pitch of

the screw flights gradually decreases towards the discharge and exerts higher and higher

pressure on the pulp. Screw presses are used to express oil from oil seeds. The roller

press is built of two cylinders in between which the pulp is fed. To facilitate liquid flow

the cylinders are grooved. The press residue is removed with doctor blades.

Batch presses allow better expression of liquid from the disintegrated material, because

of higher pressures applied. In continuous presses, the press residue still contains

substantial quantities of liquid and further processing is required. In case of oil seeds

extraction is applied.

TE SS

-

S

-

R

AP L

H O

TO ACCESS ALL THE 32 PAGES OF THIS CHAPTER,

Visit: http://www.eolss.net/Eolss-sampleAllChapter.aspx

C E

E O–

Bibliography

Belton P. (ed.). (2007). The Chemical Physics of Food, 264 pp. Blackwell Publishing, Oxford, UK.

PL C

[Chemical-physical aspects of food properties and structure are described. Emulsions, gels, glasses,

powders and other types of products are discussed].

M ES

Bhuyan M. (ed.). (2006). Measurement and Control in Food Processing, 340 pp. CRC Press, Boca Raton,

FL, USA, 2006 [Measurement and control equipment used in food processing is described. Computer

control of processes is discussed].

SA N

Brennan J.G. (ed.). (2005). Food Processing Handbook, 608 pp. J. Wiley & Sons, Bognor Regis, West

Sussex, UK, 2005. [Principles and equipment used in food processing are described].

U

Campbell-Platt G. (ed.). (2009). Food Science and Technology, 520 pp. Wiley-Blackwell, Bognor Regis,

West Sussex, UK. [Contains 21 chapters, among them chapters on food biotechnology, food physics,

food processing, food engineering and food packaging].

Chen X.D., Mujumdar A.S. (eds.). (2008). Drying Technologies in Food Processing, 360 pp. Wiley-

Blackwell, Bognor Regis, West Sussex, UK. [All the major drying techniques employed in food

processing are described. Key methods to assess quality of dried products are given].

Evans J. (ed.). (2008). Frozen Food Science and Tdechnology, 368 pp. Wiley-Blackwell, Bognor Regis,

West Sussex, UK. [Comprehensive description of freezing and frozen storage of food. Thermal and

physical processes accompanying the process are described].

Heldman D.R., Hoover G., Wheeler B. (eds.). (2010). Encyclopedia of agricultural, food and biological

engineering, 800 pp. CRC Press, Boca Raton, FL, USA. [Contains 200 entries describing processes used

in food raw materials production and food processing].

Heldman D.R., Lund D.B. (eds.). (2006). Handbook of Food Engineering, 1040 pp. CRC Press, Boca

Raton, FL, USA. [Described are basic unit operations in food processing, their effect on food properties

and quality. Contains tables with property data].

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

IFIS Dictionary of Food Science and Technology. (2009), 424 pp.. Wiley-Blackwell, Bognor Regis, West

Sussex, UK. [Contains over 7800 entries from all the aspects of food science, food technology and

nutrition].

Rao M.A., Rizvi S.S.H., Datta A.K. (eds.). (2005). Engineering Properties of Food, 768 pp. CRC Press,

Boca Raton, FL, USA. [Application of food properties in the design of unit operations in food processing

is presented].

Sablani S.S. Rahman M.S. Datta A.K. Mujumdar A.S. (eds.). (2007). Handbook of Food and Bioprocess

Modeling Techniques, 624 pp. CRC Press, Boca Raton, FL, USA. [A comprehensive overview of

modeling techniques for the food industry].

Sastry, S.K., Cornelius, B.D. (2002). Aseptic Processing of Foods Containing Solid Particulates, 250 pp..

J. Wiley & Sons, Bognor Regis, West Sussex, UK. [Particulate foods continuous sterilization is discribed].

Scott Smith, J., Hui, Y.H. (2004). Food Processing, 528 pp.. Wiley-Blackwell, Bognor Regis, West

Sussex, UK. [Principles of processing of basic food products].

TE SS

Sun D-W. (ed.). (2005). Emerging Technologies for Food Processing, 792 pp. CRC Press, Boca Raton,

FL, USA, 2005 [The following processes are described: high pressure, pulsed electric field, non-thermal

S

processing of food. Moreover, a thorough account is given about innovations in thermal processing of

food and refrigeration].

R

AP L

Sun D-W. (ed.). (2005). Handbook of Frozen Food Processing and Packaging, 760 pp. CRC Press, Boca

H O

Raton, FL, USA, [Fundamentals of freezing, facilities for the cold chain, quality and safety of frozen

foods and packaging arediscussed in detail].

C E

Sun D-W. (ed.). (2005). Thermal Food Processingg. New Technologies and Quality Issues, 648 pp. CRC

Press, Boca Raton, FL, USA., [Contains three parts. Part I. Modeling, Part II. Quality and Safety, Part III.

Innovations in Past and Emerging Technologies].

E O–

Tamime A. (ed.). (2008). Cleaning-in-Place. Dairy, Food and Beverage Operations, 272 pp. Wiley-

Blackwell, Bognor Regis, West Sussex, UK. [A comprehensive description of CIP application and

efficiency in food processing].

Tewari G. (ed.). (2007). Advances in Thermal and Non-thermal Food Preservation, 288 pp. Wiley-

PL C

Blackwell, Bognor Regis, West Sussex, UK, [Introduction to food microbiology is given, and thereafter

aseptic processing, microwave and radio frequency heating, sous vide and cook-chill processing,

M ES

electronic pasteurization, ozonation and high pressure processing as well as active packaging are

described].

Biographical Sketch

SA N

Piotr P. Lewicki is a 1961graduate of Warsaw University of Life Sciences, Faculty of Food Technology.

U

The degree of Doctor of Science he received in 1969 from Massachusetts Institute of Technology,

Cambridge, Mass., USA. Studying at MIT Piotr P. Lewicki took his major in food science and minor in

chemical engineering. In 1975 he defended habilitation thesis and in 1976 he was nominated associate

professor in food engineering. .In 1982 Piotr P. Lewicki was nominated full professor of food

engineering.

In the years 1962 - 2008 he was employed by the Warsaw University of Life Sciences in Warsaw. In

1978 Piotr P. Lewicki was appointed the head of the Department of Food Engineering in the Faculty of

Food Technology. At that time he was also deputy Dean for student affairs in the Faculty. In the years

1981-1984 he was Dean of the Faculty and during the years 1987-1990 he was appointed a deputy-rector

(vice-president) of the University. In 2008 Piotr P. Lewicki has taken the position of the director of the

Institute of Food Technology in the State College of Computer Science and Business Administration in

Łomża.

Piotr P. Lewicki was a visiting professor of food engineering in the University of Minnesota, St. Paul,

USA (1976-1977), in Bundesforschrungsanstalt für Ernährung in Karlsruhe, Germany (1991) and in

Universidad Nacional de San Agustin de Arequipa in Peru (2001, 2003).

Piotr P. Lewicki is an editor and co-author of instruction manuals for students and two textbooks on food

©Encyclopedia of Life Support Systems (EOLSS)

CHEMICAL ENGINEEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. V - Engineering Aspects of Food

Processing - P.P. Lewicki

engineering (four editions) and design of food processing plant (two editions). He has done translation of

few professional books from English to Polish. In total he published over 250 publications in Polish and

international scientific journals.

Piotr P. Lewicki is a member of the Committee of Food Science of the Polish Academy of Sciences, the

Societas Sientiarum ac Litterarum Varsoviensis (Warsaw Scientific Society), Food Working Party of the

European Association of Chemical Engineers and The International Academy of Food science and

Technology. He is on the editorial board of Journal of Food Engineering (Esevier), International Journal

of Food Properties (Marcel Dekker) and Polish Journal of Food and Nutritional Sciences (Polish

Academy of Sciences).

TE SS

S

R

AP L

H O

C E

E O–

PL C

M ES

SA N

U

©Encyclopedia of Life Support Systems (EOLSS)

Anda mungkin juga menyukai

- Novel Thermal and Non-Thermal Technologies for Fluid FoodsDari EverandNovel Thermal and Non-Thermal Technologies for Fluid FoodsPJ CullenBelum ada peringkat

- Advances in Potato Chemistry and TechnologyDari EverandAdvances in Potato Chemistry and TechnologyPenilaian: 2 dari 5 bintang2/5 (1)

- Genetic and Genomic Resources for Grain Cereals ImprovementDari EverandGenetic and Genomic Resources for Grain Cereals ImprovementBelum ada peringkat

- Food Processing and PreservationDokumen11 halamanFood Processing and PreservationLaine Joy LBelum ada peringkat

- Food Safety in the Seafood Industry: A Practical Guide for ISO 22000 and FSSC 22000 ImplementationDari EverandFood Safety in the Seafood Industry: A Practical Guide for ISO 22000 and FSSC 22000 ImplementationBelum ada peringkat

- Food Preservation and MicrobiologyDokumen27 halamanFood Preservation and Microbiologykiran bhardwajBelum ada peringkat

- Food Fortification in a Globalized WorldDari EverandFood Fortification in a Globalized WorldM.G.Venkatesh MannarBelum ada peringkat

- Tropical Fruit ProcessingDari EverandTropical Fruit ProcessingJethro JagtianBelum ada peringkat

- Risk Communication Applied to Food Safety HandbookDari EverandRisk Communication Applied to Food Safety HandbookBelum ada peringkat

- The Food Industry Innovation School: How to Drive Innovation through Complex OrganizationsDari EverandThe Food Industry Innovation School: How to Drive Innovation through Complex OrganizationsBelum ada peringkat

- Handbook of Food Isotherms: Water Sorption Parameters For Food And Food ComponentsDari EverandHandbook of Food Isotherms: Water Sorption Parameters For Food And Food ComponentsPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Emerging Dairy Processing Technologies: Opportunities for the Dairy IndustryDari EverandEmerging Dairy Processing Technologies: Opportunities for the Dairy IndustryBelum ada peringkat

- Food Industry 4.0: Unlocking Advancement Opportunities in the Food Manufacturing SectorDari EverandFood Industry 4.0: Unlocking Advancement Opportunities in the Food Manufacturing SectorBelum ada peringkat

- Perspectives on Food-Safety Issues of Animal-Derived FoodsDari EverandPerspectives on Food-Safety Issues of Animal-Derived FoodsSteven C. RickeBelum ada peringkat

- Food and Drink - Good Manufacturing Practice: A Guide to its Responsible Management (GMP7)Dari EverandFood and Drink - Good Manufacturing Practice: A Guide to its Responsible Management (GMP7)Belum ada peringkat

- DavidScott - Uht Processing and Aseptic Filling of Dairy Foods (2008, Thesis)Dokumen53 halamanDavidScott - Uht Processing and Aseptic Filling of Dairy Foods (2008, Thesis)aaro_oraalBelum ada peringkat

- Food EngineeringDokumen61 halamanFood EngineeringfitsnjBelum ada peringkat

- Quality Management Systems in Dairy IndustryDokumen10 halamanQuality Management Systems in Dairy Industryravi mathur0% (1)

- Homoginezer and UHT InfoDokumen9 halamanHomoginezer and UHT InfoCarloBelum ada peringkat

- Food ProcessingDokumen73 halamanFood ProcessingAnkit SawantBelum ada peringkat

- Food Product Shelf Life: Analytical ProgressDokumen10 halamanFood Product Shelf Life: Analytical ProgressNasir MahmudBelum ada peringkat

- Bangladesh Tetra Pak Case StudyDokumen8 halamanBangladesh Tetra Pak Case StudymunemBelum ada peringkat

- Aseptic PackagingDokumen20 halamanAseptic PackagingĐivềphía Mặt TrờiBelum ada peringkat

- Production of Soy SauceDokumen12 halamanProduction of Soy SauceFerina GuoBelum ada peringkat

- Hydrocolloids Ignou NotesDokumen12 halamanHydrocolloids Ignou NotesKumar GauravBelum ada peringkat

- The Changing Face of Beverage ProcessingDokumen4 halamanThe Changing Face of Beverage Processingthanhtl_hugolataBelum ada peringkat

- Food TechnologyDokumen4 halamanFood TechnologyAnonymous dzcacBy5DBelum ada peringkat

- FDST318Dokumen149 halamanFDST318Karthikeyan Balakrishnan100% (1)

- 2013, Handbook of Aseptic Processing and Packaging. Jairus R.D.David, Ralph H. Graves, Thomas E. Szemplenski. CRC Press, Boc...Dokumen29 halaman2013, Handbook of Aseptic Processing and Packaging. Jairus R.D.David, Ralph H. Graves, Thomas E. Szemplenski. CRC Press, Boc...Fernando FerreiraBelum ada peringkat

- Whey Ready To Drink BeveragesDokumen8 halamanWhey Ready To Drink BeveragesAamir ManzoorBelum ada peringkat

- ADM Milling Mixes Fillings IcingsDokumen8 halamanADM Milling Mixes Fillings IcingsNeena TomBelum ada peringkat

- Food Safety AssignmentDokumen10 halamanFood Safety AssignmentMeha RajBelum ada peringkat

- Food Microbiology: Presentation Prepared by Mindy Brashears, Ph.D. Assistant Professor of Food Safety and HACCPDokumen21 halamanFood Microbiology: Presentation Prepared by Mindy Brashears, Ph.D. Assistant Professor of Food Safety and HACCPFatima RiveraBelum ada peringkat

- Starches and CerealsDokumen52 halamanStarches and CerealsAllan Palma GilBelum ada peringkat

- FST556 - Dietary Fibre ObeDokumen37 halamanFST556 - Dietary Fibre Obeinshirahizham100% (1)

- Overview of Food Quality by M.SivarajanDokumen27 halamanOverview of Food Quality by M.SivarajanervaishaliBelum ada peringkat

- CodesPractice MPOBDokumen22 halamanCodesPractice MPOBMuhammad Shah Nidzinski El-ZamaniBelum ada peringkat

- Packaging For Beverage PDFDokumen12 halamanPackaging For Beverage PDFHOANGVUNL1988Belum ada peringkat

- Lecture 18 Food MicrobiologyDokumen47 halamanLecture 18 Food MicrobiologyDegee GonzalesBelum ada peringkat

- The Body ShopDokumen1 halamanThe Body Shopherminev_21Belum ada peringkat

- In West Africa: A History of ExploitationDokumen71 halamanIn West Africa: A History of ExploitationOlinka MorvayovaBelum ada peringkat

- A Guide To Carbonating Beverages at Small ScaleDokumen5 halamanA Guide To Carbonating Beverages at Small ScaledanBelum ada peringkat

- Basic Principles of FermentationDokumen11 halamanBasic Principles of FermentationJustin Cook100% (4)

- Food Technology NotesDokumen39 halamanFood Technology NotesPreeti Joshi SachdevaBelum ada peringkat

- Processing TechnologiesforcoconutsummitfinalDokumen16 halamanProcessing TechnologiesforcoconutsummitfinalPlacid RodriguesBelum ada peringkat

- Biochemical Changes Associated With The Processing of FoodsDokumen4 halamanBiochemical Changes Associated With The Processing of FoodsAdapa Prabhakara GandhiBelum ada peringkat

- Module 3 - Food Product DevelopmentDokumen16 halamanModule 3 - Food Product Developmentrbtlch1n88% (8)

- Tetra Pak Homogenizers BR 63880 LowDokumen4 halamanTetra Pak Homogenizers BR 63880 LowalfionBelum ada peringkat

- Engro Foods: Presented by Ziyad Bin BasharatDokumen16 halamanEngro Foods: Presented by Ziyad Bin Basharatshahzaib memon100% (1)

- Fortified Snacks For KidsDokumen51 halamanFortified Snacks For KidsMabel GaerlanBelum ada peringkat

- J Cofs 2020 10 030Dokumen24 halamanJ Cofs 2020 10 030William EdwardsBelum ada peringkat

- Quantitative Analysis of Reducing Sugars in Sugar Preparations Consisting of Sugar and DextrinDokumen6 halamanQuantitative Analysis of Reducing Sugars in Sugar Preparations Consisting of Sugar and DextrinMuztika Andriana RahmawatiBelum ada peringkat

- J Ijfoodmicro 2008 12 008Dokumen6 halamanJ Ijfoodmicro 2008 12 008William EdwardsBelum ada peringkat

- Fermentation 07 00301 v2Dokumen11 halamanFermentation 07 00301 v2William EdwardsBelum ada peringkat

- Future Foods: Xin Guan, Qingzi Lei, Qiyang Yan, Xueliang Li, Jingwen Zhou, Guocheng Du, Jian ChenDokumen10 halamanFuture Foods: Xin Guan, Qingzi Lei, Qiyang Yan, Xueliang Li, Jingwen Zhou, Guocheng Du, Jian ChenWilliam EdwardsBelum ada peringkat

- Accepted Manuscript: Research in Veterinary ScienceDokumen37 halamanAccepted Manuscript: Research in Veterinary ScienceWilliam EdwardsBelum ada peringkat

- Your First Choice For Analytical Testing Services - ALS TestingDokumen2 halamanYour First Choice For Analytical Testing Services - ALS TestingWilliam EdwardsBelum ada peringkat

- KlientelistDokumen30 halamanKlientelistWilliam EdwardsBelum ada peringkat

- Vitamin D - Health Professional Fact SheetDokumen52 halamanVitamin D - Health Professional Fact SheetWilliam EdwardsBelum ada peringkat

- About This TemplateDokumen3 halamanAbout This TemplateWilliam EdwardsBelum ada peringkat

- Biocide Application in Food Contact Paper and Paper BoardDokumen21 halamanBiocide Application in Food Contact Paper and Paper BoardWilliam EdwardsBelum ada peringkat

- 15221122126515Dokumen2 halaman15221122126515William EdwardsBelum ada peringkat

- Sfafasds Last NameDokumen2 halamanSfafasds Last NameWilliam EdwardsBelum ada peringkat

- Oxitop Oc 100Dokumen103 halamanOxitop Oc 100Hugo EscobarBelum ada peringkat

- HVV GGG GFFHDokumen2 halamanHVV GGG GFFHWilliam EdwardsBelum ada peringkat

- Short Communication: Effects of Increased Expression of - Lactalbumin in Transgenic Mice On Milk Yield and Pup GrowthDokumen3 halamanShort Communication: Effects of Increased Expression of - Lactalbumin in Transgenic Mice On Milk Yield and Pup GrowthWilliam EdwardsBelum ada peringkat

- Types of Chemical Reactions: Experiment 1. Decomposition ReactionDokumen4 halamanTypes of Chemical Reactions: Experiment 1. Decomposition ReactionWilliam EdwardsBelum ada peringkat

- Scopus Preview - Scopus - Mining ScienceDokumen1 halamanScopus Preview - Scopus - Mining ScienceWilliam EdwardsBelum ada peringkat

- Lab Experiment - Titration of Sulfuric Acid (H2SO4)Dokumen2 halamanLab Experiment - Titration of Sulfuric Acid (H2SO4)gdfeiu dionwdnBelum ada peringkat

- 15221122126515Dokumen2 halaman15221122126515William EdwardsBelum ada peringkat

- So, What's The Difference?Dokumen7 halamanSo, What's The Difference?William EdwardsBelum ada peringkat

- Aflatoxin Me ELISA PDFDokumen5 halamanAflatoxin Me ELISA PDFWilliam EdwardsBelum ada peringkat

- Class Schedule: Schedule Start Time IntervalDokumen3 halamanClass Schedule: Schedule Start Time IntervalPatrick TeodoroBelum ada peringkat

- How To Generate Monthly Expense TrendsDokumen14 halamanHow To Generate Monthly Expense TrendsahmadrahmaniBelum ada peringkat

- A AaaaaaaaaaaaaaaaaaaaaaaaDokumen12 halamanA AaaaaaaaaaaaaaaaaaaaaaaaWilliam EdwardsBelum ada peringkat

- January 2017: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayDokumen12 halamanJanuary 2017: Sunday Monday Tuesday Wednesday Thursday Friday Saturdayjazz440Belum ada peringkat

- HahahaDokumen1 halamanHahahaKomang Yuni AntariBelum ada peringkat

- AbbaDokumen1 halamanAbbaWilliam EdwardsBelum ada peringkat

- GreatDokumen1 halamanGreatWilliam EdwardsBelum ada peringkat

- Store 2Dokumen19 halamanStore 2aymanBelum ada peringkat

- MS ProjectDokumen11 halamanMS ProjectSuneet SharmaBelum ada peringkat

- Bridgestone Motorcycle Factory Service Sheets PDFDokumen50 halamanBridgestone Motorcycle Factory Service Sheets PDFMoppie Hofstede0% (1)

- Binary Decimal HexDokumen7 halamanBinary Decimal Hex666667Belum ada peringkat

- Warner P50 - 80 CatalogueDokumen3 halamanWarner P50 - 80 Cataloguemokthyeluen3832Belum ada peringkat

- Technical Note An Investigation On The Causes of A Rotor Bending and Its Thermal StraighteningDokumen10 halamanTechnical Note An Investigation On The Causes of A Rotor Bending and Its Thermal Straighteningsemarasik_651536604Belum ada peringkat

- MG Engine HistoryDokumen86 halamanMG Engine HistoryDamian RoweBelum ada peringkat

- Analysis PhaseDokumen63 halamanAnalysis PhaseJoseph Josef0% (1)

- FAQ - On R12 Supplier Bank SetupDokumen2 halamanFAQ - On R12 Supplier Bank Setupjazz007Belum ada peringkat

- Exposure Calculator Noise Level (L DB) Exposure Duration (Hours)Dokumen2 halamanExposure Calculator Noise Level (L DB) Exposure Duration (Hours)Gustavo AlcântaraBelum ada peringkat

- Sieve Analysis Data Sheet: ASTM D422-63 (2007)Dokumen1 halamanSieve Analysis Data Sheet: ASTM D422-63 (2007)Bart LuceñaBelum ada peringkat

- Sika Chapdur - Floor HardenerDokumen2 halamanSika Chapdur - Floor HardenerVirah Sammy Chandra100% (1)

- Mass Transfer CoefficientsDokumen3 halamanMass Transfer CoefficientsjuandiegoCOBelum ada peringkat

- Romi Oop 05 Javadatabase 1mei2011Dokumen78 halamanRomi Oop 05 Javadatabase 1mei2011Nora AsteriaBelum ada peringkat

- Hima Fscs - Tuv Fse Sample Questions 2013Dokumen6 halamanHima Fscs - Tuv Fse Sample Questions 2013mnmBelum ada peringkat

- Transmission ALL U110824Dokumen135 halamanTransmission ALL U110824Екатерина КалашниковаBelum ada peringkat

- JNTU Study MaterialsDokumen9 halamanJNTU Study MaterialsPolisetty0% (2)

- Engineering CommunicationDokumen1 halamanEngineering CommunicationwowomBelum ada peringkat

- Powerscreen University Bronze & Silver Links - Feb 2020Dokumen5 halamanPowerscreen University Bronze & Silver Links - Feb 2020Andres AstudilloBelum ada peringkat

- Navi Loan Account StatementDokumen1 halamanNavi Loan Account StatementBorah SashankaBelum ada peringkat

- Chapter - 1 Condenser PerformanceDokumen21 halamanChapter - 1 Condenser PerformanceAhmed HelmyBelum ada peringkat

- Technical Tips - KLEI™Harmony Binding PostDokumen1 halamanTechnical Tips - KLEI™Harmony Binding PostJoseph MismoBelum ada peringkat

- SOG F5 PWR Silo Fire FightingDokumen9 halamanSOG F5 PWR Silo Fire FightingGothandaraman Muthu ManickamBelum ada peringkat

- E2S Guide For Hazardous AreasDokumen9 halamanE2S Guide For Hazardous AreasRam KumarBelum ada peringkat

- Chapter 4.b (Method of Section)Dokumen22 halamanChapter 4.b (Method of Section)LogarithemBelum ada peringkat

- LIT PAL CS Rev BDokumen16 halamanLIT PAL CS Rev ByousefdrahmedBelum ada peringkat

- Raft FoundationDokumen11 halamanRaft Foundationcapstone111100% (2)

- Quality Assurance in DialysisDokumen11 halamanQuality Assurance in DialysisHaribabu ArumugamBelum ada peringkat

- Vaio SpekDokumen2 halamanVaio SpekviedytotoBelum ada peringkat