U W Civil Utility Tunnels and Trenches: Facilities Service S Design Guide

Diunggah oleh

Ramces AsisiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

U W Civil Utility Tunnels and Trenches: Facilities Service S Design Guide

Diunggah oleh

Ramces AsisiHak Cipta:

Format Tersedia

U NIVERSI TY OF W ASHI NG TON Civil

Facilities Services

Design Guide Utility Tunnels and Trenches

Basis of Design

This section applies to reinforced concrete utility tunnels and trenches.

Background

Utility Tunnel is a utilidor for mechanical and electrical services, installed by drilling and/or

tunneling. The tunnel has an arched top.

Utility Trench is a utilidor for mechanical and electrical services installed by open cut

excavation with both inside and outside of the walls formed or prefabricated. The trench has

a flat top.

The University of Washington main campus distributes mechanical and electrical utilities in

tunnels. See University drawings 802RU-01, 803RU-01, 803RU-04, 803RU-06, 804RU-01,

and 807RU-01 for tunnel mechanical utilities. For information regarding tunnel electrical

utilities, contact Engineering Services. For information regarding tunnel communication

utilities, contact UW Technology.

Refer to University drawings 875RU-1 through 875RU-18 for utilities not routed through

campus utility tunnels. The above drawings are updated regularly, but are schematic and

may not be accurate or complete.

Design Criteria

Install the following utilities in reinforced concrete utility tunnels, or utility trenches; steam,

condensate, compressed air, central cooling water, power, and communications.

Do not install water, gas, sewer, or storm drain piping in utility tunnels or utility trenches.

Locate tunnels and manholes based on existing and planned facilities. New facilities shall be

planned to avoid hindering egress out of tunnel system and to avoid affecting tunnel

ventilation.

Do not locate manholes in roadways. Do not locate manholes in walkways unless approved

by Engineering Services. Tunnel manhole covers, if placed in paved areas, shall meet

AASHTO H20 loading criteria.

Design utility tunnels and trenches in accordance with ACI standards and as shown in the

tunnel and trench sections.

Provide embedded inserts and plates for piping and cable tray supports.

Slope floors towards the piping side of the tunnel to minimize water on walking surfaces.

Maintain uniform tunnel slope between manholes.

Provide a tunnel drain as shown on tunnel and trench sections.

Provide permanent tunnel lighting at manholes and as shown on the Tunnel and Trench

Sections.

Ensure adequate natural ventilation.

Provide for drainage of storm water entering the top manhole grating and offset the manhole

opening to prevent rain water from entering the tunnel.

At top manhole grating at grade, provide steel grated ventilation openings with security locks

bolted from below.

Below the top manhole section, provide steel grated landings connected by stairs and pipe

railing, or 60 degree ships ladders.

REV:07 – SEPT2017 2U - 01

© University of Washington – Engineering Services 2017

U NIVERSI TY OF W ASHI NG TON Civil

Facilities Services

Design Guide Utility Tunnels and Trenches

At the top manhole section to grade, install galvanized, safety type, ladders for tunnel access

through the top grating. Provide ladder extension to provide safe access/egress.

Install tunnel manholes with the riser offset from the tunnel main as shown on Utility Tunnel

Manhole Plan.

Provide a permanent waterproof access opening for convenient installation and removal of

tunnel equipment and 20 foot lengths of pipe.

Secure tunnel portals to buildings with six-inch concrete masonry block walls and 2’X6’X1-

3/4” hollow metal doors fitted with pin tumbler locks (lock cylinder furnished by the

University).

Design Evaluation

The following information is required to evaluate the design:

Programming Phase: Statement of design intent, tunnel route, and a list of utilities to be

connected to campus systems.

Schematic Phase: Drawings showing existing tunnels and utilities, a narrative material and

system description, and a new tunnel preliminary alignment plan and profile.

Design Development Phase: Demolition plans, plans showing new and existing utilities,

utility and tunnel details, an outline specification, and developed tunnel plans and profiles.

Construction Document Phase: Complete plans and specifications.

1) Provide general tunnel plans, sections, and details. Include pipe and cable tray

supports, trench and bedding details, connection and joint details, manhole details,

building connection details, tunnel profile with utility elevations, tunnel invert

elevations at manholes and building connections, tunnel drains, and final tunnel

plans and profiles.

2) Include plans showing existing underground tunnels and utilities (power,

communications, gas, water, storm drain, sanitary sewer, and street lighting).

Construction Submittals

Provide standard industry submittal requirements.

Products, Materials and Equipment

Cast-In-Place Concrete:

Portland cement: Conform to requirements of ASTM C-150.

Sand: Conform to the requirements of ASTM C33.

Reinforcing steel: Conform to the requirements of ASTM A615, Grade 60.

Apply waterproofing at joints

Prefabricated Concrete:

Prefabricated concrete for tunnels shall be steel reinforced and in conformance with ACI

standards.

Installation, Fabrication and Construction

2U - 02 REV:07 – SEPT2017

© University of Washington – Engineering Services 2017

U NIVERSI TY OF W ASHI NG TON Civil

Facilities Services

Design Guide Utility Tunnels and Trenches

Prefabricated concrete: Install gaskets at joints of prefabricated concrete sections and apply

grout and waterproofing to interior and exterior joints.

Install in accordance with ACI standards.

Cure cast-in-place concrete for a period of 7 days. If the formwork is removed before the 7-

day curing period, the concrete must be thoroughly wetted and a moisture retaining cover

provided. Place the cover in the widest practical width with side and ends lapped at least 3

inches and sealed by waterproof tape or adhesive.

Install water stops at concrete joints.

Install damp-proofing to exterior walls, roof surfaces of tunnels, trenches, and manholes.

Refer to the following University drawings:

1) Utility Tunnel Section

2) Utility Trench Section

3) Utility Tunnel Manhole Section

4) Utility Tunnel Electrical Tray Bracket Detail

5) Utility Tunnel Mechanical Pipe Supports Detail 1

6) Utility Tunnel Mechanical Pipe Supports Detail 2

END OF DESIGN GUIDE SECTION

REV:07 – SEPT2017 2U - 03

© University of Washington – Engineering Services 2017

U NIVERSI TY OF W ASHI NG TON Civil

Facilities Services

Design Guide Utility Tunnels and Trenches

PIPE ROLLERS

SHOWN, SLIDES

ALSO ACCEPTABLE

26”

Utility Tunnel Section

2U - 04 REV:07 – SEPT2017

© University of Washington – Engineering Services 2017

U NIVERSI TY OF W ASHI NG TON Civil

Facilities Services

Design Guide Utility Tunnels and Trenches

Utility Trench Section

REV:07 – SEPT2017 2U - 05

© University of Washington – Engineering Services 2017

U NIVERSI TY OF W ASHI NG TON Civil

Facilities Services

Design Guide Utility Tunnels and Trenches

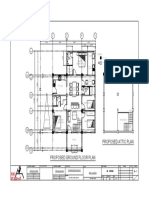

Utility Tunnel Manhole Plan

2U - 06 REV:07 – SEPT2017

© University of Washington – Engineering Services 2017

U NIVERSI TY OF W ASHI NG TON Civil

Facilities Services

Design Guide Utility Tunnels and Trenches

Utility Tunnel Electrical Tray Bracket Detail

REV:07 – SEPT2017 2U - 07

© University of Washington – Engineering Services 2017

U NIVERSI TY OF W ASHI NG TON Civil

Facilities Services

Design Guide Utility Tunnels and Trenches

Utility Tunnel Mechanical Pipe Supports Detail 1

2U - 08 REV:07 – SEPT2017

© University of Washington – Engineering Services 2017

U NIVERSI TY OF W ASHI NG TON Civil

Facilities Services

Design Guide Utility Tunnels and Trenches

Utility Tunnel Mechanical Pipe Supports Detail 2

REV:07 – SEPT2017 2U - 09

© University of Washington – Engineering Services 2017

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Fm-200 Cylinder Dimension Fm-200 Discharge Nozzle at Room Space Fm-200 Smoke Detector at Room Space Fm-200 Cylinder DimensionDokumen1 halamanFm-200 Cylinder Dimension Fm-200 Discharge Nozzle at Room Space Fm-200 Smoke Detector at Room Space Fm-200 Cylinder DimensionRamces AsisiBelum ada peringkat

- Walkalator Walkalator: Tile Pattern at UgfDokumen1 halamanWalkalator Walkalator: Tile Pattern at UgfRamces AsisiBelum ada peringkat

- MeeeeDokumen1 halamanMeeeeRamces AsisiBelum ada peringkat

- DettvDokumen1 halamanDettvRamces AsisiBelum ada peringkat

- Reflected Ceiling Plan: TarlacDokumen1 halamanReflected Ceiling Plan: TarlacRamces AsisiBelum ada peringkat

- Covelight Detail: 0011075 Geiselle - Castro - SectionsDokumen1 halamanCovelight Detail: 0011075 Geiselle - Castro - SectionsRamces AsisiBelum ada peringkat

- Proposed Plan at LGF: Shabu-Shabu Tubo DelightsDokumen1 halamanProposed Plan at LGF: Shabu-Shabu Tubo DelightsRamces AsisiBelum ada peringkat

- Section: 0011075 Geiselle - Castro - SectionsDokumen1 halamanSection: 0011075 Geiselle - Castro - SectionsRamces AsisiBelum ada peringkat

- Bid Drawings: Existing Plan at LGFDokumen1 halamanBid Drawings: Existing Plan at LGFRamces AsisiBelum ada peringkat

- Geiselle - Castro - Reflected Ceiling PlanDokumen1 halamanGeiselle - Castro - Reflected Ceiling PlanRamces AsisiBelum ada peringkat

- Bid Drawings: Existing Plan at UgfDokumen1 halamanBid Drawings: Existing Plan at UgfRamces AsisiBelum ada peringkat

- Floor Plan & Furniture Layout: Scale 1:120Dokumen1 halamanFloor Plan & Furniture Layout: Scale 1:120Ramces AsisiBelum ada peringkat

- Work Schedule For Excavation Ang Trenching: Mahanagdong Geothermal Powerplant B Above Ground Fire Water LoopDokumen1 halamanWork Schedule For Excavation Ang Trenching: Mahanagdong Geothermal Powerplant B Above Ground Fire Water LoopRamces AsisiBelum ada peringkat

- Cv-01 Proposed Water Spray Layout Segment 2 2Dokumen1 halamanCv-01 Proposed Water Spray Layout Segment 2 2Ramces AsisiBelum ada peringkat

- Front Elevation Right-Side Elevation: Scale 1:100 Scale 1:100Dokumen1 halamanFront Elevation Right-Side Elevation: Scale 1:100 Scale 1:100Ramces AsisiBelum ada peringkat

- SmsmsmsmsDokumen1 halamanSmsmsmsmsRamces AsisiBelum ada peringkat

- Floor Plan & Furniture Layout: Scale 1:120Dokumen1 halamanFloor Plan & Furniture Layout: Scale 1:120Ramces AsisiBelum ada peringkat

- A-1 A-1 A-1 A-1 A-1 A-1 A-1 A-1: Lot Plan Perspective View 1Dokumen1 halamanA-1 A-1 A-1 A-1 A-1 A-1 A-1 A-1: Lot Plan Perspective View 1Ramces AsisiBelum ada peringkat

- A 01 PDFDokumen1 halamanA 01 PDFRamces AsisiBelum ada peringkat

- Cv-02 Proposed Water Spray Layout 2Dokumen1 halamanCv-02 Proposed Water Spray Layout 2Ramces AsisiBelum ada peringkat

- FllsjebDokumen1 halamanFllsjebRamces AsisiBelum ada peringkat

- Linear Heat Sensor Installation Details (Inside The Conveyor) 9 Water Spray Deluge Valve & Piping Details 9Dokumen1 halamanLinear Heat Sensor Installation Details (Inside The Conveyor) 9 Water Spray Deluge Valve & Piping Details 9Ramces AsisiBelum ada peringkat

- Total For Items (1-4) PHP 635,110.95Dokumen3 halamanTotal For Items (1-4) PHP 635,110.95Ramces AsisiBelum ada peringkat

- Encasement Pipe Detail: Water MainDokumen1 halamanEncasement Pipe Detail: Water MainRamces AsisiBelum ada peringkat

- Cv-01 Proposed Linear Heat Detection Layout For Segment 1 2: Asisi Systems CorpDokumen1 halamanCv-01 Proposed Linear Heat Detection Layout For Segment 1 2: Asisi Systems CorpRamces AsisiBelum ada peringkat

- (Sarangani Energy Corporation) Deluge Water Spray System Controls & Detection System ProjectDokumen1 halaman(Sarangani Energy Corporation) Deluge Water Spray System Controls & Detection System ProjectRamces AsisiBelum ada peringkat

- Cv-00 Proposed Linear Heat Detection Layout 1Dokumen1 halamanCv-00 Proposed Linear Heat Detection Layout 1Ramces AsisiBelum ada peringkat

- Formwork For A Concrete SlabDokumen5 halamanFormwork For A Concrete SlabRamces AsisiBelum ada peringkat

- Proposed Attic Plan: LegendDokumen1 halamanProposed Attic Plan: LegendRamces AsisiBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- On Fly Ash ConDokumen46 halamanOn Fly Ash ConSantosh Kumar MBelum ada peringkat

- Rolling Bearing Failure V2Dokumen34 halamanRolling Bearing Failure V2dshalev869460% (5)

- Integrated Design ProjectDokumen34 halamanIntegrated Design ProjectFarhanah Binti Faisal100% (2)

- Standard Description Standard Description View Image View ImageDokumen27 halamanStandard Description Standard Description View Image View ImagejiyadBelum ada peringkat

- MorenoHurtado Pedro MO6S2AI3Dokumen7 halamanMorenoHurtado Pedro MO6S2AI3PEDRO MORENO HURTADOBelum ada peringkat

- Sikagrout 280 Hs Pds enDokumen3 halamanSikagrout 280 Hs Pds enDimas SaputraBelum ada peringkat

- Case Studies: DakshinachitraDokumen8 halamanCase Studies: Dakshinachitrasabari100% (2)

- SamsdataDokumen296 halamanSamsdataSamuel AugustineBelum ada peringkat

- TDS-HU-Muszaki Adatlap MacRes System Concrete Panels ENG Rev03 Dec2013Dokumen1 halamanTDS-HU-Muszaki Adatlap MacRes System Concrete Panels ENG Rev03 Dec2013Frans van der MerweBelum ada peringkat

- Addendum To Standard Bidding Document Procurement of Civil WorksDokumen29 halamanAddendum To Standard Bidding Document Procurement of Civil WorksvivekBelum ada peringkat

- Procedures For Hot Insulation - 2Dokumen8 halamanProcedures For Hot Insulation - 2Quy RomBelum ada peringkat

- Financials For... Box CulvertDokumen5 halamanFinancials For... Box CulvertAnonymous CPEha1db7UBelum ada peringkat

- Balancing Valve (DRV) (1 4218 4x) GMFDokumen5 halamanBalancing Valve (DRV) (1 4218 4x) GMFSHINOS 3SBelum ada peringkat

- Primary SchoolDokumen57 halamanPrimary SchoolMUUTHUKRISHNAN100% (1)

- Applications of Bismaleimides ConfirmDokumen2 halamanApplications of Bismaleimides ConfirmsggdgdBelum ada peringkat

- Ground Floor Plan Second Floor PlanDokumen5 halamanGround Floor Plan Second Floor PlanElzie BarbosaBelum ada peringkat

- AtkinsDokumen37 halamanAtkinsganeshakceBelum ada peringkat

- Excavator Cat 322c Diagram HydDokumen2 halamanExcavator Cat 322c Diagram Hydmekanicobucaro100% (5)

- Check List MaintenanceDokumen1 halamanCheck List MaintenanceAbdul KepertoBelum ada peringkat

- Terminal Report OJT MTTDokumen4 halamanTerminal Report OJT MTTJun MichaelBelum ada peringkat

- Assessment Test in Tle Ict TD 10 (For Uploading)Dokumen2 halamanAssessment Test in Tle Ict TD 10 (For Uploading)Marlon Joseph D. ManzanoBelum ada peringkat

- Rodajes Miniatura NSKDokumen41 halamanRodajes Miniatura NSKenicolas2Belum ada peringkat

- Material Labor and Equipt PricesDokumen5 halamanMaterial Labor and Equipt PricesABCD EFGBelum ada peringkat

- Blast Resistant StructuresDokumen3 halamanBlast Resistant Structuresprabhay123456Belum ada peringkat

- Plinth Beam and FoundationDokumen1 halamanPlinth Beam and FoundationSteny AbrahamBelum ada peringkat

- Foundation For Civil EngineeringDokumen2 halamanFoundation For Civil Engineeringmudassir2640Belum ada peringkat

- Progress Report White CityDokumen5 halamanProgress Report White CityMhlanga Bridget TanyaradzwaBelum ada peringkat

- Features & Specifications: Round BullhornDokumen3 halamanFeatures & Specifications: Round Bullhornsalvador andradeBelum ada peringkat

- 007343.1 - Prevailing Wage ScheduleDokumen76 halaman007343.1 - Prevailing Wage ScheduleWestmere Fire DistrictBelum ada peringkat