Vacuum Modulator: Composition

Diunggah oleh

NOJ ADNUBJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Vacuum Modulator: Composition

Diunggah oleh

NOJ ADNUBHak Cipta:

Format Tersedia

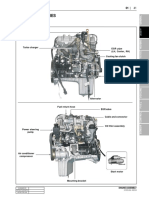

42 04

VACUUM MODULATOR

COMPOSITION

Layout

EGR valve

Turbocharger

actuator

Vacuum pump hose

Vacuum pump

Turbocharger vacuum modulator

EGR vacuum modulator

Vacuum Modulator for VGT Vacuum Modulator for EGR Valve

Turbocharger Actuator Control

IP internal fuse Engine ECU

IP internal fuse Engine ECU (RH) No.63-7.5A No. 96

(RH) No.63-7.5A No. 95

EXHAUST SYSTEM CHANGED BY

ACTYON SM - 2006.03 EFFECTIVE DATE

AFFECTED VIN

04 43

REMOVAL AND INSTALLATION OF EGR VALVE

GENERAL

EGR Valve and Pipe

1. Remove the inlet hose to the intake manifold and disconnect the vacuum hose of the EGR valve.

ASSY

Inlet hose to Intake Manifold Vacuum Hose to EGR Valve

HOUSING

EXHAUST I N T A K E

Tightening torque

6 ~ 7 Nm

LUB

2. Remove the mounting bolt/nut to remove the left pipe of the EGR valve and unscrew four hexagon bolts to remove

the EGR valve assembly.

COOLING

EGR Valve Pipe (LH) EGR Valve Assembly

Tightening torque (bolt)

10 ± 1.0 Nm

FUEL

CONTROL

SENSOR

Tightening torque (bolt) Tightening torque (hexagon bolt)

10 ± 1.0 Nm 10 ± 1.0 Nm

3. Remove the right pipe of the EGR valve and remove the center pipe.

EGR Valve Pipe (RH) EGR Valve Pipe (Center)

Tightening torque (bolt) Tightening torque (M8 X 30)

10 ± 1.0 Nm 25 ± 2.5 Nm

Tightening torque (nut) Tightening torque (M8 X 25)

35 ± 3.5 Nm 25 ± 2.5 Nm

CHANGED BY EXHAUST SYSTEM

EFFECTIVE DATE ACTYON SM - 2006.03

AFFECTED VIN

44 04

4. Install in the reverse order of removal.

NOTICE

1. Observe the tightening torque of the bolts and nuts when installing pipes.

2. Replace the gaskets of the pipes with new ones. The protruding side should face to pressurized section.

EGR RH Pipe and Gasket EGR LH Pipe and Gasket

Center pipe bolt (2 EA) Intake pipe bolt (4 EA)

(M6 X 16: 10 ± 1.0 Nm) (M6 X 16: 10 ± 1.0 Nm)

Exhaust manifold nut (2 EA)

(M8: 35 ± 3.5 Nm)

* M8 mounting nut should be replaced with new one.

EGR valve

Center Pipe EGR Valve

Center pipe upper bolt (2 EA) EGr valve mounting bolt (4 EA)

(M8 X 25: 25 ± 2.5 Nm) (M6 X 25: 10 ± 1.0 Nm)

Center pipe lower bolt (2 EA) LH pipe mounting bolt (2 EA)

(M8 X 25: 25 ± 2.5 Nm) (M6 X 16: 10 ± 1.0 Nm)

EXHAUST SYSTEM CHANGED BY

ACTYON SM - 2006.03 EFFECTIVE DATE

AFFECTED VIN

04 45

Inspection for EGR System

GENERAL

If the EGR system is malfunctioning, the engine power may be decreased or the exhaust gas may be increased. If

these happen, troubleshoot the system according to the following procedures.

ASSY

1. Inspection for EGR vacuum system

Check the EGR vacuum system (engine vacuum pump - vacuum modulator for controlling EGR valve - EGR valve) for

HOUSING

malfunction. Specifically, check the vacuum hose, connections, kinked hose and leaks due to interference with

surrounding components. Also check the EGR vacuum modulator's wiring connector. Make sure that the vacuum

system source functions properly by checking the engine vacuum pump for leakage.

EXHAUST I N T A K E

EGR valve

Main vacuum when

idling: 690 mmHg

LUB

Vacuum modulator

for turbocharger Brake booster

actuator

COOLING

IWE locking

hub

FUEL

Vacuum modulator

for EGR valve

CONTROL

2. EGR related DTC check using SCAN-100

Connect the SCAN-100 to the CAN module and check if

SENSOR

there is any DTC related to EGR.

If DTC is appeared, it may be due to the vacuum system.

Therefore, check the EGR system again.

DTC Related to EGR System

P0400 Faulty EGR valve control

P1405 Short circuit to EGR vacuum

modulator (GND)

P1406 Short circuit to EGR vacuum

modulator (B+)

All DTCs are related to EGR valve vacuum modulator.

Therefore, check the power supply and ground con-

dition by performing the following electrical check

for EGR valve vacuum modulator.

CHANGED BY EXHAUST SYSTEM

EFFECTIVE DATE ACTYON SM - 2006.03

AFFECTED VIN

46 04

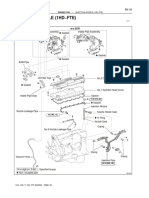

3. Electrical check for EGR valve vacuum modulator

The EGR valve vacuum modulator is supplied with power from the main relay and fuse No. 63 (7.5 A) in the interior

fuse box which is located in the instrument panel (RH). Therefore, those relays and fuses should be checked first.

The vacuum modulator for the VGT turbocharger actuator is installed on the top of the vacuum modulator for EGR

valve. Both are supplied with the same power and controlled (duty cycle) by engine ECU. The following is the

procedure for checking the power supplied to the vacuum modulator.

IP Interior Fuse Box (Passenger Side) Vacuum Modulator

Engine ECU

main relay Vacuum modulator for VGT

turbocharger actuator

VGT & EGR vacuum

modulators, HFM

Vacuum modulator

for EGR valve

HP pumpIMV

Hazard Connector

warning lamp

Connector Installtion of multimeter

Terminal No. 1

IP interior fuse (RH) Engine ECU

No.63-7.5A No. 96

EXHAUST SYSTEM CHANGED BY

ACTYON SM - 2006.03 EFFECTIVE DATE

AFFECTED VIN

04 47

GENERAL

4. EGR valve check

If there is no problem found so far, check the EGR valve as a unit.

The EGR valve is working as a passage for exhaust gas. It may not operate due to the contamination by the carbon

or other foreign materials.

ASSY

Check the unit according to the following procedures.

HOUSING

1. Remove the intake inlet hose. 2. Connect the vacuum tester to EGR valve.

EXHAUST I N T A K E

LUB

COOLING

3. Check if EGR valve starts to open when the vacuum 4. Check the conditions of EGR valve.

gauge indicates approx. 220 ~ 250 mmHg.

If the valve is severely contaminated, completely wipe FUEL

CONTROL

SENSOR

it out with soft cloth. Be careful not to damage it.

CHANGED BY EXHAUST SYSTEM

EFFECTIVE DATE ACTYON SM - 2006.03

AFFECTED VIN

48 04

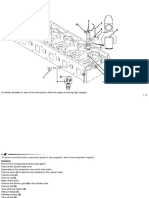

REMOVAL AND INSTALLATION OF VACUUM MODULATOR ASSEMBLY

Removal and Installation

1. Separate the vacuum hose to EGR valve (1), the vacuum hose to turbocharger (2) and the vacuum hose to

vacuum pump (3) in turn.

EGR valve vacuum hose Vacuum pump hose

Vacuum hose for

turbocharger actuator

Brake

booster

IWE locking hub

2. Disconnect the vacuum modulator connectors 3. Unscrew the mounting bolts and remove the

to turbocharger (A) and EGR valve (B). vacuum modulators.

Tightening torque

10 ± 1.0 Nm

EXHAUST SYSTEM CHANGED BY

ACTYON SM - 2006.03 EFFECTIVE DATE

AFFECTED VIN

04 49

GENERAL

4. Unscrew the mounting bolts and remove the

vacuum modulator bracket.

ASSY

HOUSING

EXHAUST I N T A K E

Vacuum modulator

5. Install in the reverse order of removal.

LUB

COOLING

FUEL

Components

Vacuum modulator for VGT

Bracket turbocharger actuator

CONTROL

Port to VGT turbocharger actuator

SENSOR

Port to vacuum pump

IP internal fuse (RH) Engine ECU

No.63-7.5A No. 95

Port to EGR valve

Vacuum modulator for EGR valve

IP internal fuse (RH) Engine ECU

No.63-7.5A No. 96

CHANGED BY EXHAUST SYSTEM

EFFECTIVE DATE ACTYON SM - 2006.03

AFFECTED VIN

50 04

ELECTRICAL CIRCUIT RELATED TO VACUUM MODULATOR

Main relay

Engine ECU

Vacuum modulator Vacuum

for VGT turbo- modulator for

charger actuator EGR valve

Engine extension wiring

IP Fuse Box (Passenger Side) Engine Main Relay & Fuse No. 63

Engine main relay

Fuse No. 63 (7.5A)

Fuse No. 63 (7.5A)

EXHAUST SYSTEM CHANGED BY

ACTYON SM - 2006.03 EFFECTIVE DATE

AFFECTED VIN

04 51

Operation Principle of Vacuum Modulator

GENERAL

Vacuum

pump

ASSY

Output vacuum

HOUSING

ATM

Plunger

EXHAUST I N T A K E

Connector

LUB

COOLING

Vacuum

control

Diaphragm

FUEL

Seat assembly

Atmospheric pressure Spring

Plunger

CONTROL

SENSOR

Air flow

During duty increase (B) During duty reduction (C)

Vacuum is controlled according to relationship between chamber pressure (I) in rolling nipple cover

and magnetic force (II) in plunger.

According to ECU signals, the solenoid valve controls the vacuum pressure that is generated by vacuum pump (-900

± 20 mbar) with PWM type control and drives the mechanical EGR valve and turbo charger.

CHANGED BY EXHAUST SYSTEM

EFFECTIVE DATE ACTYON SM - 2006.03

AFFECTED VIN

52 04

Operating principle: Balance between original vacuum pressure and magnetic forcs (see aboe figure)

1. Normal state (Fig. A): Original vacuum and seat section, 3 stoppers keep sealing

2. Duty up state (Fig. B): Original vacuum pressure is connected to inside of diaphragm chamber

3. Duty down state (Fig. C): Increased diaphragm chamber pressure is connected to atmosphere to compensate

the pressure.

Floating plunger Stroke

(mm)

Max. Distance

DUTY 50% 1mm

Output C/V

Operating principles when duty is applied from 0 to 50 %

Vacuum consumption: Compared to 50 % of duty, ON/OFF periods are most unstable and

vacuum consumption is most high.

Flowing

volume

Output characteristics

Output vacuum (-mmHg)

Up

Down

EXHAUST SYSTEM CHANGED BY

ACTYON SM - 2006.03 EFFECTIVE DATE

AFFECTED VIN

04 53

Operating conditions

GENERAL

1. Engine is running

2. Engine RPM is within a specified range. (EGR OFF under high RPM range)

3. Engine torque is within a specified range. (EGR OFF under high torque range)

ASSY

4. Vehicle speed is within a specified range. (EGR OFF under high speed range)

5. Atmospheric pressure is within a specified range. (EGR OFF under high altitude and low atmospheric pressure)

6. Coolant temperature is within a specified range. (EGR OFF under high or low temperature)

HOUSING

7. EGR OFF under extended period of idling.

EXHAUST I N T A K E

Control logic

1. Main map: EGR volume is controlled based on intake air volume

2. Auxiliary map

1) Coolant temperature (Coolant temperature sensor)

2) Engine rpm (Crankshaft position sensor)

3) Engine load (TPS): Detection of sharp acceleration

4) Intake air temperature (HFM): Decreases when over 60°C

LUB

5) Atmospheric pressure (Barometric sensor): Compensation of altitude

3. Compensation value of auxiliary map will be increased/decreased based on main map then ECU calculates EGR

volume finally to regulate the vacuum duty that applies to the vacuum modulator to control EGR valve openings.

COOLING

Shut-off conditions

FUEL

1. Engine rpm: over 2,950 rpm

2. Vehicle speed: over 105 km/h

3. Coolant temperature: over 100°C or below 10°C

CONTROL

4. Idle period: over 50 seconds

SENSOR

CHANGED BY EXHAUST SYSTEM

EFFECTIVE DATE ACTYON SM - 2006.03

AFFECTED VIN

Anda mungkin juga menyukai

- CH8 FuelSystem 05 Up TRX450R ER 8Dokumen26 halamanCH8 FuelSystem 05 Up TRX450R ER 8PD DiagnosticosBelum ada peringkat

- Emission Control System: PurposeDokumen12 halamanEmission Control System: Purposeapi-3833108Belum ada peringkat

- Accent Compession Pressure InspectionDokumen12 halamanAccent Compession Pressure Inspectionflash_24014910Belum ada peringkat

- Matrix 2003 2zz 8Dokumen10 halamanMatrix 2003 2zz 8alan lantiguaBelum ada peringkat

- Timing chain assembly guide for D20DT and D27DT diesel enginesDokumen4 halamanTiming chain assembly guide for D20DT and D27DT diesel enginesMynor Witt100% (4)

- Timing Chain Assembly GuideDokumen4 halamanTiming Chain Assembly GuideMynor WittBelum ada peringkat

- Manual Taller PDFDokumen12 halamanManual Taller PDFDiego TorresBelum ada peringkat

- 5sfe-Timing BeltDokumen14 halaman5sfe-Timing BeltNato DlAngelesBelum ada peringkat

- Hyundai Santa FE (2005-2007) Workshop Manual - Clutch SystemDokumen12 halamanHyundai Santa FE (2005-2007) Workshop Manual - Clutch SystemJenny Mora LeonBelum ada peringkat

- I Removal of TurbochargerDokumen6 halamanI Removal of TurbochargerDavid QuispeBelum ada peringkat

- 1Hxxx Injection PumpsDokumen22 halaman1Hxxx Injection PumpsMohammed ElzainBelum ada peringkat

- A86&A88-chapter 7 (CYLINDER HEAD VALVES)Dokumen28 halamanA86&A88-chapter 7 (CYLINDER HEAD VALVES)Stojanov MarjanBelum ada peringkat

- Valve Clearance PDFDokumen10 halamanValve Clearance PDFspammed Scribd userBelum ada peringkat

- Adjust Valve Clearance 1HZ 1HD-T EngineDokumen4 halamanAdjust Valve Clearance 1HZ 1HD-T EngineArief SoehartoBelum ada peringkat

- Engine J08E TIDokumen568 halamanEngine J08E TIJarmianto100% (6)

- Engine Troubleshooting SFI Fuel Pressure Regulator Removal InstallationDokumen1 halamanEngine Troubleshooting SFI Fuel Pressure Regulator Removal InstallationGuadalupe Chambi ApazaBelum ada peringkat

- EGR Solenoid Valve Removal ProcedureDokumen2 halamanEGR Solenoid Valve Removal ProcedureGrover Martin Ticona PerezBelum ada peringkat

- Hyundai d4bh Workshop ManualDokumen8 halamanHyundai d4bh Workshop Manualnathan100% (51)

- Toyota 5l Valve ClearanceDokumen5 halamanToyota 5l Valve ClearancedennoBelum ada peringkat

- Toyota 5l Valve ClearanceDokumen5 halamanToyota 5l Valve ClearancedennoBelum ada peringkat

- Evo 8 GR00000600-17Dokumen4 halamanEvo 8 GR00000600-17MACHIBelum ada peringkat

- Nissan BD30 Valve Adjustment Procedure, Valve Lash Clearance Specifications, Nissan BD30 Engine Parts ContactDokumen1 halamanNissan BD30 Valve Adjustment Procedure, Valve Lash Clearance Specifications, Nissan BD30 Engine Parts ContactLuis BastardesBelum ada peringkat

- Steering SystemDokumen36 halamanSteering SystemClaudio Godoy GallegosBelum ada peringkat

- KIA Sorento ManualDokumen1.349 halamanKIA Sorento ManualSteven AmadorBelum ada peringkat

- Sienna Timing Belt ReplacementDokumen8 halamanSienna Timing Belt ReplacementGlenn MartinBelum ada peringkat

- Insp Valve Clearance 2.7 3rz PDFDokumen5 halamanInsp Valve Clearance 2.7 3rz PDFEdwin Versteeg100% (1)

- EX - 1NZ-FXE ExhaustDokumen4 halamanEX - 1NZ-FXE ExhaustgmantzaBelum ada peringkat

- CRF Coppie SerraggioDokumen6 halamanCRF Coppie SerraggioFedericoFoxFossaluzzaBelum ada peringkat

- Engine Tune-UpDokumen43 halamanEngine Tune-UpЮра ПетренкоBelum ada peringkat

- Propeller Shaft Removal and InstallationDokumen14 halamanPropeller Shaft Removal and InstallationMateus FumuassucaBelum ada peringkat

- Kyron 1 Engine 002 04 003Dokumen18 halamanKyron 1 Engine 002 04 003Anderson BombistaBelum ada peringkat

- Engine J08E-TI ServiceDokumen572 halamanEngine J08E-TI ServiceAndres Gomez75% (4)

- Engine Removal/InstallationDokumen10 halamanEngine Removal/Installationorly pocoateBelum ada peringkat

- Automatic TransmissionDokumen40 halamanAutomatic TransmissionRmontaniohotmail.comBelum ada peringkat

- (Approved) DX12 Tappet Replacement ManualDokumen34 halaman(Approved) DX12 Tappet Replacement ManualLuis Ramón Argüello Real100% (1)

- Toyota Corolla: Manual de Taller 2001-2004Dokumen126 halamanToyota Corolla: Manual de Taller 2001-2004Erick Vargas MarcaBelum ada peringkat

- 10 ACG - Starting ClutchDokumen9 halaman10 ACG - Starting ClutchLuis Carlos Barrera IdarragaBelum ada peringkat

- Platz 02Dokumen7 halamanPlatz 02dawitmesfin9Belum ada peringkat

- Engine Timing ValvesDokumen44 halamanEngine Timing ValvesSlobodanBelum ada peringkat

- 1HD-T 2Dokumen37 halaman1HD-T 2HERMAWAN100% (2)

- Ford 6.4 Bomba de AltaDokumen183 halamanFord 6.4 Bomba de AltaAgustin Borge Garcia100% (1)

- Engine Service Manual Renegade 300 SeriesDokumen76 halamanEngine Service Manual Renegade 300 SeriesArul Gnana JohnBelum ada peringkat

- Injection Timing (5L) : InspectionDokumen2 halamanInjection Timing (5L) : InspectionaliBelum ada peringkat

- 3 Stromberg SingleDokumen7 halaman3 Stromberg SinglevanapeerBelum ada peringkat

- Brake Actuator Assy: On-Vehicle InspectionDokumen47 halamanBrake Actuator Assy: On-Vehicle InspectionDuy KhánhBelum ada peringkat

- Adjust Valve Clearance 2AZ-FE EngineDokumen9 halamanAdjust Valve Clearance 2AZ-FE EngineMarcos EmmanuelBelum ada peringkat

- Engine Valve Clearance Check ProcedureDokumen197 halamanEngine Valve Clearance Check Procedure0128 Nguyễn Thanh BìnhBelum ada peringkat

- 960 EGR ValveDokumen3 halaman960 EGR ValvekonepakBelum ada peringkat

- This Document Has Been Printed From SPI2. NOT FOR RESALE: Pump To ManifoldDokumen1 halamanThis Document Has Been Printed From SPI2. NOT FOR RESALE: Pump To Manifoldmoh asalanyBelum ada peringkat

- Engine Cylinder Block Disassembly GuideDokumen8 halamanEngine Cylinder Block Disassembly GuideYannick de WalqueBelum ada peringkat

- Engine Mechanical Section: PartsDokumen44 halamanEngine Mechanical Section: PartsWSMengine WSMengineBelum ada peringkat

- HQS Technician Course Exhaust Brake OperationDokumen9 halamanHQS Technician Course Exhaust Brake OperationAngga Budi Pratama100% (3)

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDokumen11 halamanAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeBelum ada peringkat

- 08erm Injector 1HD FTEDokumen15 halaman08erm Injector 1HD FTEbrettBelum ada peringkat

- Exhaust System Layout and ComponentsDokumen42 halamanExhaust System Layout and ComponentsMiguel Ángel RodríguezBelum ada peringkat

- Motor - 1NZ Manual en InglesDokumen170 halamanMotor - 1NZ Manual en InglesAbdelG100% (1)

- Torque Converter Clutch Case: Automatic TransmissionDokumen4 halamanTorque Converter Clutch Case: Automatic TransmissionAnton FortovBelum ada peringkat

- Fuel Injectors: Denny Schroeter Injectors / Removal / Fitting 25/01/23Dokumen14 halamanFuel Injectors: Denny Schroeter Injectors / Removal / Fitting 25/01/23Евгений МуллаяновBelum ada peringkat

- InspDokumen1 halamanInspMansur KhanBelum ada peringkat

- OS6850 AOS 6.4.4 R01 Advanced Routing GuideDokumen298 halamanOS6850 AOS 6.4.4 R01 Advanced Routing GuideSouhayel92Belum ada peringkat

- Deed Odeed of Sale With Assumption of Mortgage (Landf Sale With Assumption of Mortgage (Land)Dokumen2 halamanDeed Odeed of Sale With Assumption of Mortgage (Landf Sale With Assumption of Mortgage (Land)NOJ ADNUB100% (2)

- 03 Mn1784eu12mn 0001 Commissioning Bs24xDokumen0 halaman03 Mn1784eu12mn 0001 Commissioning Bs24xRicko HadjanganginBelum ada peringkat

- BS241 CommissioningDokumen35 halamanBS241 CommissioningNOJ ADNUBBelum ada peringkat

- Unix For Beginners - SLDokumen220 halamanUnix For Beginners - SLPavan VasanthamBelum ada peringkat

- Object-Oriented Programming Lab Manual RDokumen63 halamanObject-Oriented Programming Lab Manual RKLR CETBelum ada peringkat

- Export Promotion Councils - Final UpdatedDokumen14 halamanExport Promotion Councils - Final UpdatedUtkarsh SaxenaBelum ada peringkat

- SAP-Press - Abap Development For Sap HanaDokumen30 halamanSAP-Press - Abap Development For Sap HananicocastanioBelum ada peringkat

- MG585 Set Up and Service ManualDokumen16 halamanMG585 Set Up and Service Manualoscar albertoBelum ada peringkat

- Sabri Toyyab Resume Spring 2019Dokumen2 halamanSabri Toyyab Resume Spring 2019api-457400663Belum ada peringkat

- SM-800.11 TypeM Plus ValvesDokumen13 halamanSM-800.11 TypeM Plus ValvesAdel AhmedBelum ada peringkat

- 4-way switch wiring diagram for a 2 pickup guitarDokumen1 halaman4-way switch wiring diagram for a 2 pickup guitarNebojša JoksimovićBelum ada peringkat

- Sat - RPMSDokumen4 halamanSat - RPMSAeroz RednaxelaBelum ada peringkat

- BNI Vision April 2023 Roster BookDokumen16 halamanBNI Vision April 2023 Roster BookTushar MohiteBelum ada peringkat

- Waterfall Model - The Original Software Development Process ModelDokumen3 halamanWaterfall Model - The Original Software Development Process ModelmushfiqBelum ada peringkat

- Monocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34ADokumen2 halamanMonocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34ARia IndahBelum ada peringkat

- Acronyms Used in Offshore ConstructionDokumen32 halamanAcronyms Used in Offshore ConstructionDaniel De Assis ItaborahyBelum ada peringkat

- Samsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFDokumen9 halamanSamsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFreza_azadBelum ada peringkat

- VF1 Technicalspecifications 031997 EN PDFDokumen43 halamanVF1 Technicalspecifications 031997 EN PDFelectricistBelum ada peringkat

- QUICK GUIDE To Installing Oracle Database 11gR2 - PART1Dokumen7 halamanQUICK GUIDE To Installing Oracle Database 11gR2 - PART1Peter AsanBelum ada peringkat

- Computer LanguagesDokumen3 halamanComputer LanguagesGurvinder Singh100% (1)

- BK - Scrum and CMMIDokumen132 halamanBK - Scrum and CMMIcoolgoroBelum ada peringkat

- Tube Upsetting Machines BrochureDokumen10 halamanTube Upsetting Machines BrochuredemirilkBelum ada peringkat

- Acha Teff ThresherDokumen62 halamanAcha Teff ThresherTANKO BAKO100% (2)

- Top 145 Database Terms DictionaryDokumen13 halamanTop 145 Database Terms DictionaryUnais_Belum ada peringkat

- Business Analyst Interview QuestionsDokumen49 halamanBusiness Analyst Interview Questionsmital patel100% (4)

- Jobber JR DetailsDokumen2 halamanJobber JR DetailsUrvish PatelBelum ada peringkat

- Eye Comfort Testing by TUeV Rheinland PDFDokumen11 halamanEye Comfort Testing by TUeV Rheinland PDFevangelos!Belum ada peringkat

- Workman GTX: Utility VehicleDokumen36 halamanWorkman GTX: Utility VehicleDaniel Carrillo BarriosBelum ada peringkat

- Gta Namaste America Cheat CodesDokumen4 halamanGta Namaste America Cheat CodesGaurav PathakBelum ada peringkat

- I2C Bus ManualDokumen51 halamanI2C Bus Manualapi-26349602100% (6)

- Fossa FO 0015 0035 A Technical Data en 9aaDokumen2 halamanFossa FO 0015 0035 A Technical Data en 9aaFatih YAŞARBelum ada peringkat

- MVC Spring FrameworkDokumen34 halamanMVC Spring FrameworkRishi MathurBelum ada peringkat

- Perkins T6.354 WorkshopDokumen130 halamanPerkins T6.354 WorkshopAlexis SocarrósBelum ada peringkat