Activated Sludge Design: Treatment Process F/M KG Bod /KG MLSS/day Extended Aeration Conventional High Rate

Diunggah oleh

MhelveneJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Activated Sludge Design: Treatment Process F/M KG Bod /KG MLSS/day Extended Aeration Conventional High Rate

Diunggah oleh

MhelveneHak Cipta:

Format Tersedia

Activated Sludge Design

𝑘𝑔 𝑚3

𝐹 𝐵𝑂𝐷5 (𝑚3) 𝑥 𝑄 ( )

𝑑𝑎𝑦

=

𝑀 𝑘𝑔 𝑀𝐿𝑆𝑆

𝑋 ( 𝑚3 ) 𝑥 𝑉 (𝑚3)

F= food

M= microorganism, MLSS

Q= influent flow

X= reactor solids

V= reactor volume

𝐹 𝐵𝑂𝐷5

=

𝑀 𝑋𝑥𝑡

𝑉

t= hydraulic retention time= 𝑡 = 𝑄

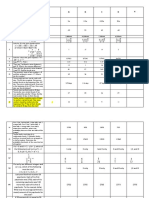

Treatment F/M

Process

Kg BOD5/Kg MLSS/day

Extended 0.03 - 0.8

aeration

Conventional 0.8 - 2.0

High rate > 2.0

Design parameters for activated sludge processes

Process q c (d) q (h) F/M Qr/Q X (mg/L)

Conventional 5-15 4-8 0.2-0.4 0.25-5 1,500-3,000

Complete-mix 5-15 3-5 0.2-0.6 0.25-1 3,000-6,000

Step-aeration 5-15 3-5 0.2-0.4 0.25-0.75 2,000-3,500

Modified- 0.2-0.5 1.5-3 1.5-5.0 0.05-0.15 200 – 500

aeration

Contact- 5-15 0.5-1 0.2-0.6 0.25-1 1,000-3,000

stabilization 3-6 4,000-10,000

Extended- 20-30 18-36 0.05- 0.75-1.5 3,000-6,000

aeration 0.15

High-rate 5-10 0.5-2 0.4-1.5 1-5 4,000-10,000

aeration

Pure-oxygen 8-20 1-3 0.25-1.0 0.25-0.5 6,000-8,000

Operational characteristics of activated sludge processes

Process Flow model Aeration system BOD5 removal

efficiency (%)

Conventional Plug-flow Diffused air, mechanical aerators 85-95

Complete-mix Complete-mix Diffused air, mechanical aerators 85-95

Step-aeration Plug-flow Diffused air 85-95

Modified- Plug-flow Diffused air 60-75

aeration

Contact- Plug-flow Diffused air, mechanical aerators 80-90

stabilization

Extended- Complete-mix Diffused air, mechanical aerators 75-95

aeration

High-rate Complete-mix Diffused air, mechanical aerators 75-90

aeration

Pure-oxygen Complete-mix Mechanical aerators 85-95

Design Example of Extended - Aeration Activated Sludge Process (Package

Plant)...

A prefabricated package plant is to be used to treat the wastewater from a resort area consisting of 550

individual family residences. The average occupancy has been estimated to be 2.9 persons per

residence. Use a flow of 230 L/person.day and a daily peaking factor of 2.5 for flow, BOD 5 and SS. Use

an hourly peaking factor of 4 for sizing the sedimentation facilities. Select the type of package plant and

size the principal components of the plant. Effluent BOD5 concentration of the process must be or lower

than 30 mg/L.

Solution...

1. The total number of person : (550 home)(2.9 person/home) = 1,595 person

2. The corresponding average flowrate : (1,595 person)(0.230 m 3/person.day) = 366.85 m3/day

3. The corresponding peak daily flowrate : (366.85 m 3/day)(2.5) = 917.13 m3/day

4. The average BOD5 load : (1,595 persons)(80 g BOD5/person.day) = 127,600 g BOD5/day

5. The corresponding BOD5 concentration : (127,600 g/day) / (366.85 m 3/day) = 348 g/m3 (mg/L)

6. The average SS load : (1,595 persons)(90 g SS/person.day) = 143,550 g SS/day

7. The corresponding SS concentration : (143,550 g/day) / (366.85 m 3/day) = 391 g/m3 (mg/L)

8. The peak daily BOD5 load : (127.60 kg BOD5/day)(2.5) = 319.00 kg BOD5/day

9. The peak daily SS load : (143.55 kg SS/day)(2.5) = 358.88 kg SS/day

10. An extended aeration activated sludge process package plant is selected

11. The aeration time : 1.0 day

12. The aeration tank volume : (366.85 m3/day)(1.0 day) = 366.85 m3

13. The oxygen transfer efficiency : 6 %

14. The specific weight of air : 1.26 kg/m3

15. The oxygen content : 23.2 %

16. The air requirement : (319.00 kg BOD5/day) / (1.26 kg/m3)(0.232)(0.06) = 18,187.83 m3/day

17. The peak hour factor for the settling tank : 4

18. The overflow rate for settling tank : 24 m3/m2.day

19. The surface area of settling tank : (366.85 m 3/day)(4) / 24 m3/m2.day = 61.14 m2

20. The hydraulic detention time for settling tank : 0.5 h

21. The volume of the settling tank : (366.85 m3/day)(4)(0.5 h) / 24 h/day = 30.57 m3

Anda mungkin juga menyukai

- Activated SludgeDokumen53 halamanActivated SludgePaula MoralesBelum ada peringkat

- Activated Sludge Design (Complete Mix Reactor) : Setyo S. MoersidikDokumen34 halamanActivated Sludge Design (Complete Mix Reactor) : Setyo S. MoersidikTiti SariBelum ada peringkat

- Waste Water Treatment: Process Design Consideration On Activated Sludge ProcessDokumen31 halamanWaste Water Treatment: Process Design Consideration On Activated Sludge ProcesslukmanindranugrahaBelum ada peringkat

- ActipowerDokumen16 halamanActipowerAflyn HarianjaBelum ada peringkat

- Objectives: Chapter 4 Sludge Treatment and DisposalDokumen37 halamanObjectives: Chapter 4 Sludge Treatment and Disposalashe zinabBelum ada peringkat

- Chapter 3 Sem 1 20192020 Updated 3.9.2019Dokumen112 halamanChapter 3 Sem 1 20192020 Updated 3.9.2019Mohamad FahmiBelum ada peringkat

- ETP Review - 2Dokumen14 halamanETP Review - 2Perla KeerthiBelum ada peringkat

- Wastewater Treatment Plant Options and Design CriteriaDokumen14 halamanWastewater Treatment Plant Options and Design Criteriaahmed elbazBelum ada peringkat

- 6th Chapter CE333Dokumen7 halaman6th Chapter CE333Shahid HossainBelum ada peringkat

- 4 Material Balances Multiple Unit ProcessesDokumen18 halaman4 Material Balances Multiple Unit ProcessesSnow Drop100% (3)

- Sludge Treatment of WaterDokumen11 halamanSludge Treatment of WaterWinsam Amiel Cejudo100% (1)

- DemineralizationDokumen26 halamanDemineralizationraraeiBelum ada peringkat

- Select Oral Presentation: Ahnaf Omar Onyeka Efese Yang Yu Zaid Al-Alawi Mukriz Mahader Salem Bin LadenDokumen11 halamanSelect Oral Presentation: Ahnaf Omar Onyeka Efese Yang Yu Zaid Al-Alawi Mukriz Mahader Salem Bin LadenMukriz MahaderBelum ada peringkat

- Lewatit MonoPlus S 108 LDokumen27 halamanLewatit MonoPlus S 108 LMd Suzon MahmudBelum ada peringkat

- Design of Each Process of ETPDokumen9 halamanDesign of Each Process of ETPFaisal Sr. ExecutiveBelum ada peringkat

- Activated Sludge DesignDokumen21 halamanActivated Sludge DesignChokri ChakiirBelum ada peringkat

- Process Loading Evaluation & Sludge Accountability: - Step Through The Performance EvaluationDokumen55 halamanProcess Loading Evaluation & Sludge Accountability: - Step Through The Performance EvaluationNiong DavidBelum ada peringkat

- P128794 PDFDokumen37 halamanP128794 PDFGustavo PalaciosBelum ada peringkat

- UAE University College of Engineering Training and Graduation Project UnitDokumen100 halamanUAE University College of Engineering Training and Graduation Project UnitPortia ShilengeBelum ada peringkat

- L32 RO Water ExtraDokumen58 halamanL32 RO Water ExtranaefmubarakBelum ada peringkat

- Dryer HB 2ndDokumen80 halamanDryer HB 2ndmmmtswBelum ada peringkat

- V3i4 Ijertv3is040786 PDFDokumen5 halamanV3i4 Ijertv3is040786 PDFsarikagBelum ada peringkat

- Diligent Etp 1000m3Dokumen18 halamanDiligent Etp 1000m3Prabhakar DhamaleBelum ada peringkat

- Anaerobic Sludge Digester (ASD) : Ahmad Faris Bin Mohd Napi Muhd Baktiar Bin Razali Muhd Nasrun Bin Mohd RosdiDokumen46 halamanAnaerobic Sludge Digester (ASD) : Ahmad Faris Bin Mohd Napi Muhd Baktiar Bin Razali Muhd Nasrun Bin Mohd RosdiAhmad FarisBelum ada peringkat

- FGD Comparison - Wet Vs Semi Dry Vs DryDokumen6 halamanFGD Comparison - Wet Vs Semi Dry Vs DryAnonymous wIPMQ5rhBelum ada peringkat

- Presented By: Dr. Mohamed AbdulkarimDokumen30 halamanPresented By: Dr. Mohamed AbdulkarimEri VirnandoBelum ada peringkat

- S19 - Louisiana State University - LTC2013Dokumen35 halamanS19 - Louisiana State University - LTC2013walaywanBelum ada peringkat

- Bio Gas Plant From Kitchen WasteDokumen4 halamanBio Gas Plant From Kitchen WasteBasanth NadellaBelum ada peringkat

- Modeling, Control, and Optimization of Natural Gas Processing PlantsDari EverandModeling, Control, and Optimization of Natural Gas Processing PlantsPenilaian: 5 dari 5 bintang5/5 (1)

- SBR Plant Design PDFDokumen8 halamanSBR Plant Design PDFvishuBelum ada peringkat

- Sludge DigestionDokumen13 halamanSludge Digestion1911O27 Prathikshaa KBelum ada peringkat

- Sample WW QuestionsDokumen10 halamanSample WW QuestionsKrishna Kumar MeenaBelum ada peringkat

- Suspended Growth Biological Treatment ProcessesDokumen51 halamanSuspended Growth Biological Treatment Processesalvaro.roldan1Belum ada peringkat

- Plant Design Complex Engineering Problem: Submitted byDokumen10 halamanPlant Design Complex Engineering Problem: Submitted bymirza6aqeel6ahmedBelum ada peringkat

- Lect 1.2 Principles of Food Process DesignDokumen43 halamanLect 1.2 Principles of Food Process Designmahmoud hassanBelum ada peringkat

- High-Pressure Steam Reforming of EthanolDokumen23 halamanHigh-Pressure Steam Reforming of EthanolMuhammad NaeemBelum ada peringkat

- Plant Design Process SimulationDokumen20 halamanPlant Design Process SimulationABRAR ABDULLAHBelum ada peringkat

- H2S Paper AD 10Dokumen3 halamanH2S Paper AD 10Ajit HaridasBelum ada peringkat

- Assignment 6Dokumen4 halamanAssignment 6Neeraj Gupta100% (1)

- Formaldehyde Overview - TIET Telecon March 21st 2006Dokumen5 halamanFormaldehyde Overview - TIET Telecon March 21st 2006Cristian TorrezBelum ada peringkat

- A Portion of The Activated Sludge, From The Secondary Clarifier Is Returned To Mix With The Effluents of Primary Clarifier.Dokumen21 halamanA Portion of The Activated Sludge, From The Secondary Clarifier Is Returned To Mix With The Effluents of Primary Clarifier.Náģå Rájú ÇhïmąţäBelum ada peringkat

- Tutorial Ventilation Q&SDokumen5 halamanTutorial Ventilation Q&Spy.arqr23Belum ada peringkat

- Plant Capacity 200 / 300: Operation & Maintenance Manual For Sanghi-Org Oxygen / Nitrogen Gas PlantDokumen51 halamanPlant Capacity 200 / 300: Operation & Maintenance Manual For Sanghi-Org Oxygen / Nitrogen Gas PlantEdduin Rodriguez100% (5)

- Lecture 7 + Biological-Activated Sludge PDFDokumen13 halamanLecture 7 + Biological-Activated Sludge PDFAli AlibrahimiBelum ada peringkat

- Model Based Analysis of A Petroleum Refinery Plant With Hydrotreating As A Pre-Treatment UnitDokumen6 halamanModel Based Analysis of A Petroleum Refinery Plant With Hydrotreating As A Pre-Treatment UnitArunBelum ada peringkat

- Description - Components of Wet FGD SystemDokumen55 halamanDescription - Components of Wet FGD SystemDo Ngoc TriuBelum ada peringkat

- ETP ReportDokumen18 halamanETP Reportdhanu_lagwankar67% (3)

- CBEND - Ankur WBG 400 Operation and Maintenance ManualDokumen78 halamanCBEND - Ankur WBG 400 Operation and Maintenance ManualSanjivi Jagadish KumarBelum ada peringkat

- T R Ea Tment PR OcessDokumen8 halamanT R Ea Tment PR Ocessrichard gutierrezBelum ada peringkat

- Uasb PDFDokumen6 halamanUasb PDFveliger100Belum ada peringkat

- Modeling of An Isothermal Pressure Swing Adsorption Process: June 2015Dokumen28 halamanModeling of An Isothermal Pressure Swing Adsorption Process: June 2015Meghana SBelum ada peringkat

- Design of Anaerobic Wastewater Treatment Processes - 5th EditionDokumen24 halamanDesign of Anaerobic Wastewater Treatment Processes - 5th EditionTheeva RajBelum ada peringkat

- Worked ExamplesDokumen9 halamanWorked ExamplesDzung Pham0% (1)

- Chemical Process Calculations - Anna UnivDokumen10 halamanChemical Process Calculations - Anna UnivGoutham R100% (1)

- Osc Leaflet en 2935082546Dokumen2 halamanOsc Leaflet en 2935082546ramonBelum ada peringkat

- Chlorine Dioxide Generator Systems: Capacity OverviewDokumen2 halamanChlorine Dioxide Generator Systems: Capacity OverviewOchoa Para La BandaBelum ada peringkat

- Sewage Treatment Technologies Nitish RedicalDokumen60 halamanSewage Treatment Technologies Nitish RedicalDhaval GadhiaBelum ada peringkat

- Gas Sweetening and Processing Field ManualDari EverandGas Sweetening and Processing Field ManualPenilaian: 4 dari 5 bintang4/5 (7)

- Environmental Scenario in Indian Mining Industry - an OverviewDari EverandEnvironmental Scenario in Indian Mining Industry - an OverviewBelum ada peringkat

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationDari EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationBelum ada peringkat

- Day 1 Part 2 ScratchDokumen41 halamanDay 1 Part 2 ScratchMhelveneBelum ada peringkat

- Septic Tank TreatmentDokumen9 halamanSeptic Tank TreatmentMhelveneBelum ada peringkat

- Research and Design IDokumen16 halamanResearch and Design ISoumyadeep MaityBelum ada peringkat

- Design of Biological Treatment Facility of Waste Disposal Site in Brgy. Felisa, Bacolod CityDokumen32 halamanDesign of Biological Treatment Facility of Waste Disposal Site in Brgy. Felisa, Bacolod CityMhelveneBelum ada peringkat

- Nov2016 QuestionsDokumen6 halamanNov2016 QuestionsMhelveneBelum ada peringkat

- Day3 Part6Dokumen5 halamanDay3 Part6MhelveneBelum ada peringkat

- What Is The Angle Between Two Vectors A ND B? A 4 + 12 + 6, B 24 8 + 6 A. 175.4 B. - 84.9 C. 84.3 D. 86.3Dokumen3 halamanWhat Is The Angle Between Two Vectors A ND B? A 4 + 12 + 6, B 24 8 + 6 A. 175.4 B. - 84.9 C. 84.3 D. 86.3MhelveneBelum ada peringkat

- Day3 Part6Dokumen5 halamanDay3 Part6MhelveneBelum ada peringkat

- Day 1 CalculationsDokumen7 halamanDay 1 CalculationsMhelveneBelum ada peringkat

- Day3 Part5Dokumen15 halamanDay3 Part5MhelveneBelum ada peringkat

- Day3 Part6Dokumen5 halamanDay3 Part6MhelveneBelum ada peringkat

- Chemical Kinetics - Reaction Orders: H° For This Reaction Is: H H HDokumen13 halamanChemical Kinetics - Reaction Orders: H° For This Reaction Is: H H HLinaGeneyReyesBelum ada peringkat

- Questions A B C D EDokumen9 halamanQuestions A B C D EMhelveneBelum ada peringkat

- Day3 Part4Dokumen3 halamanDay3 Part4MhelveneBelum ada peringkat

- What Is A BiogasDokumen23 halamanWhat Is A BiogasMhelveneBelum ada peringkat

- Day3 Part2Dokumen4 halamanDay3 Part2MhelveneBelum ada peringkat

- Day3 Part3Dokumen1 halamanDay3 Part3MhelveneBelum ada peringkat

- ChE Day1 Questions (Objectives)Dokumen4 halamanChE Day1 Questions (Objectives)Mhelvene100% (3)

- ChE Day1 Questions (Calculations)Dokumen6 halamanChE Day1 Questions (Calculations)Mhelvene100% (2)

- Day 1 CalculationsDokumen7 halamanDay 1 CalculationsMhelveneBelum ada peringkat

- Physical ChemistryDokumen3 halamanPhysical ChemistryMhelveneBelum ada peringkat

- Physics 1 EncDokumen84 halamanPhysics 1 EncMhelveneBelum ada peringkat

- Plant Design Lecture NotesDokumen70 halamanPlant Design Lecture NotesMhelvene100% (1)

- Day3 Part1Dokumen16 halamanDay3 Part1MhelveneBelum ada peringkat

- Gas AbsorptionDokumen93 halamanGas AbsorptionArgie Adduru73% (11)

- Inorg and Analytical Chemistry 1Dokumen39 halamanInorg and Analytical Chemistry 1MhelveneBelum ada peringkat

- DOST Priority Areas in Basic ResearchDokumen4 halamanDOST Priority Areas in Basic ResearchMhelvene AlfarasBelum ada peringkat

- Evaporation ProbDokumen4 halamanEvaporation ProbMhelveneBelum ada peringkat

- Day 3 ProblemsDokumen32 halamanDay 3 ProblemsMhelvene0% (1)

- Driver LCI 150W 500-850ma FlexC NF h28 EXC3 enDokumen7 halamanDriver LCI 150W 500-850ma FlexC NF h28 EXC3 enMoustafa HelalyBelum ada peringkat

- PS1Dokumen2 halamanPS1Nitesh Kumar DubeyBelum ada peringkat

- Lab Assignment - 2: CodeDokumen8 halamanLab Assignment - 2: CodeKhushal IsraniBelum ada peringkat

- Chapter VI DP and NetworkDokumen66 halamanChapter VI DP and NetworkSirgut TesfayeBelum ada peringkat

- ATR4518R2Dokumen2 halamanATR4518R2estebanarca50% (4)

- L4 Subdivision of PlotsDokumen20 halamanL4 Subdivision of PlotsKenny BoatBelum ada peringkat

- Day 4 - Lesson 15 Tuples: Python Mini-Course University of Oklahoma Department of PsychologyDokumen20 halamanDay 4 - Lesson 15 Tuples: Python Mini-Course University of Oklahoma Department of PsychologyhuseyiBelum ada peringkat

- Module 1 Grade 8 (De Guzman)Dokumen9 halamanModule 1 Grade 8 (De Guzman)Kim De GuzmanBelum ada peringkat

- EConsole1 Quick Start Guide ENGDokumen21 halamanEConsole1 Quick Start Guide ENGManuel Casais TajesBelum ada peringkat

- KD-131 Asme Viii Div3Dokumen2 halamanKD-131 Asme Viii Div3comar85Belum ada peringkat

- Network Command - HPUXDokumen5 halamanNetwork Command - HPUXRashid NihalBelum ada peringkat

- Spark: Owner's ManualDokumen5 halamanSpark: Owner's Manualjorge medinaBelum ada peringkat

- MODULAR QUIZ - 57 - Steel DesignDokumen9 halamanMODULAR QUIZ - 57 - Steel DesignCornelio J. FernandezBelum ada peringkat

- Life Processes: Science Unit 1Dokumen19 halamanLife Processes: Science Unit 1patil pratikBelum ada peringkat

- 10 2Dokumen26 halaman10 2cristinatubleBelum ada peringkat

- SkyCiv Beam - Hand Calculations - AJW8CTBuLE8YKrkKaG8KTtPAw8k74LSYDokumen13 halamanSkyCiv Beam - Hand Calculations - AJW8CTBuLE8YKrkKaG8KTtPAw8k74LSYsaad rajawiBelum ada peringkat

- MD Manu en Megaflex WebDokumen58 halamanMD Manu en Megaflex WebPhu, Le HuuBelum ada peringkat

- Quant Short Tricks PDFDokumen183 halamanQuant Short Tricks PDFAarushi SaxenaBelum ada peringkat

- Edan M3B Vital Signs Monitor User ManualDokumen92 halamanEdan M3B Vital Signs Monitor User ManualJosé marino Franco AlzateBelum ada peringkat

- 3x Exemplar 2017 en PDFDokumen4 halaman3x Exemplar 2017 en PDFgudzalovBelum ada peringkat

- TOEC8431120DDokumen522 halamanTOEC8431120Dvuitinhnhd9817Belum ada peringkat

- Dual Inverter Gate: Features DescriptionDokumen19 halamanDual Inverter Gate: Features DescriptionYaju JotosBelum ada peringkat

- ProjectDokumen6 halamanProjecthazimsyakir69Belum ada peringkat

- ElutriatorDokumen9 halamanElutriatoratiyorockfan9017Belum ada peringkat

- Solution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFDokumen10 halamanSolution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFa40095824643% (14)

- Analysis and Design of Telecommunication Tower Using Different Truss System by ETab SoftwareDokumen12 halamanAnalysis and Design of Telecommunication Tower Using Different Truss System by ETab SoftwareEditor IJTSRDBelum ada peringkat

- RespiratorypptDokumen69 halamanRespiratorypptMichelle RotairoBelum ada peringkat

- Biztalk and Oracle IntegrationDokumen2 halamanBiztalk and Oracle IntegrationkaushiksinBelum ada peringkat

- Learning MenuDokumen8 halamanLearning Menuapi-464525668Belum ada peringkat

- Exercise 1 - Revision StringDokumen2 halamanExercise 1 - Revision StringKu H6Belum ada peringkat