Poster 4 Sedimentation (A2)

Diunggah oleh

Ramco33Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Poster 4 Sedimentation (A2)

Diunggah oleh

Ramco33Hak Cipta:

Format Tersedia

General description of the sedimentation process:

•Sedimentation is a process in which gravitational settling of sediments take

SEDIMENTATION

place.

•The objective of sedimentation is to produce more clear water by settling

out sediments (hence it is also referred to as clarification or settling) before

the water is directed to the filtration process, so that the filtration process can

be more effective.

•The units in which sedimentation takes place are usually called

sedimentation tanks/basins, settling tanks/ basins, or simply as clarifiers

•Sedimentation can either be plain ( without the aid of chemicals) or can

aided by coagulant chemicals

•Plain sedimentation is employed to removal suspended solids easily

settleable by proving quiescent conditions and sufficient detention times

•Sedimentation aided by coagulant chemicals is employed to clarify water

characterised by colloidal particles that cannot settle on their own

•Coagulated water must be allowed to flocculate ( form large flocs) prior to

the sedimentation stage

•The flow velocity through the tank must be slow enough to allow most of the

flocs or particles from the flocculation channels settle to the bottom before

the water leaves the tank.

•Care must be taken to ensure that very little or no turbulence occurs as the

water flows to the clarifiers. Turbulence of the water will result in the break-

up of the floc and it will be difficult for the floc to re-form.

•The turbidity and clarity of the clarified water should be monitored and Conventional horizontal-flow sedimentation basin

recorded to assess the performance of the clarifiers. Up-flow sludge blanket clarifier

•The clarifiers must be desludged regularly, on the accumulation of sludge in

the system. During rainy seasons when the turbidity of the raw water is high,

sludge should be removed more often than normal.

•The channels from the clarifiers leading to the filters should also be kept

clean and free of algae. Any floating material should be removed.

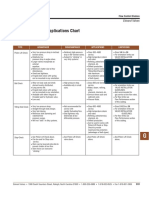

Operation and maintenance requirements for sedimentation processes Problems that may be experienced with Troubleshooting for sedimentation processes

Where typically Advantages and

Operational

Maintenance

sedimentation processes and suggested remedies

Sedimentation process Description Design parameters parameters and

employed disadvantages

aspects

requirements or actions Notes Possible Actions

Horizontal-flow Rectangular basin Applied to treat • Retention time Advantages: • Flow velocity • Regular desludging ROUND TANKS

sedimentation in which turbid raw coagulated / • Horizontal flow • Tolerant to hydraulic monitoring • Leak detection and Sedimentation Potential Possible Suggested

that has been flocculated raw velocity and quality variations • Effluent quality repair 1 Is the bridge rotating? For the sedimentation process to work the The process controller must check that the

coagulated & water characterised • Surface loading • Unskilled operator and (turbidity)

process problems causes remedies/actions bridge must rotate slowly allowing settling wheel alignment is correct and that the

flocculated flows by medium to high rate does not require monitoring both Horizontal-flow • Poor settling of • Incorrect (higher) • Correct (lower) flow to occur. In this respect the wheel bridge is moving. Any concerns must be

Is the wheel alignment in the

horizontal and suspended solids • Weir overflow rate operator presence all visual and sedimentation flocs, hence flow velocity; velocity; 2 centre of the running surface? alignment must be in the centre of the reported to the supervisor or the

allows flocs to settle and turbidity the time analytical effluent turbidity • poor chemical • optimise chemical running surface. maintenance personnel.

at the inclined • Lower construction not suitable for dosing/ dosing, coagulation

filtration coagulation/floccu and flocculation The process controller must inspect the

bottom costs & permits

lation; processes; weirs and report any loose or broken weir

oversizing The overflow weir plates may occasionally

• excessive sludge • desludge Are the overflow weir plates plates to the supervisor or maintenance

• Scales up well 3 maintained?

break off and sludge/scum accumulation

personnel. The process controller must

Disadvantages: accumulation sedimentation tank, may occur.

• Poor sludge • poor chemical • optimise chemical regularly brush the weir plates to remove

• Large land

Up-flow type (Conical blanket dosing/ dosing / coagulation / any sludge/scum accumulation.

requirements

Basin with a Applied to treat • Up-flow flow Advantages: • Flow velocity • Regular desludging settlers including sludge formation coagulation/ flocculation and / or Is the desludging mechanism

blanket settlers) leading to floc flocculation and/or • correct upflow 4 working? Desludging is important for the optimum

Up-flow type (Conical circular, square or coagulated raw velocity < 1 .5 m/h; • Efficient removal of monitoring • Leak detection and The process controller must visually

overflows; • incorrect upflow velocity working of the WTW, to ensure that

settlers including sludge rectangular surface water characterised sludge • Effluent quality repair Is the desludging valve in inspect the desludging mechanism and

blanket settlers) area with conical by stable turbidity • Desludging can be (turbidity) inability to velocities; 5 working order?

accumulated sludge does not become re-

report any malfunctions to the supervisor

empty sludge suspended and carried over to the next

bottoms in which done without taking unit monitoring both Is the rate of desludging or maintenance personnel.

cones 6 process if it is not removed.

water flows out of operation visual and adequate?

upwards and • compact design analytical Batch sedimentation • Poor settling of • Inadequate • Optimise chemical

flocs within chemical dosing / dosing and RECTANGULAR TANKS

settleable solids are suitable when space is

desired and/or rapid coagulation process The process controller must visually

returned by gravity limited, hence attractive Uneven flow over the weirs may indicate

retention time or mixing • Increase retention Is there even flow over the inspect the weirs to ensure that flow is

for package or modular

long retention • High turbidity times

7 outlet weir?

that there are blockages along the top of

even, and if not must brush the weirs to

type plant designs the weir.

times to achieve supernatant remove any build-up.

Disadvantages:

• Sensitive to raw water acceptable despite adequate Is the desludging valve in

quality and changes in effluent quality chemical 8 working order? Desludging should be done at least once The process controller must record and

dosing/coagulatio per shift so it is important that the valves report any malfunctions to the supervisor

flow velocity; Is the rate of desludging

• Requires skilled n 9 adequate?

are maintained. or maintenance personnel.

supervision and daily Radial flow sedimentation • Poor settling of • Incorrect (higher) • Correct (lower) flow

MAINTENANCE

operator presence flocs, hence flow velocity; velocity;

effluent turbidity • poor chemical • optimise chemical Suitably qualified mechanics and artisans

Are suitably qualified

Operational not suitable for dosing / dosing, coagulation should always be available – they do not Ensure that a maintenance person is on

Where typically Advantages and Maintenance mechanics and artisans

Sedimentation process Description

employed )

Design parameters

disadvantages

parameters and

requirements

filtration coagulation/floccu and flocculation 10 available if maintenance is

have to be on site but should be available hand within a reasonable timeframe to

aspects lation; processes; to report to the WTW within a reasonable deal with any breakdowns.

required?

Batch sedimentation Operates Treats turbid water • Detention time Advantages: • Filling and • Removal of sludge • excessive sludge • desludge timeframe.

intermittently: tank for very small • Low O & M costs emptying tank • Removal of floating accumulation sedimentation tank, To ensure that maintenance occurs when The process controller must record and

filled with holdings where Disadvantages: • Chemical dosages objects Are all malfunctions recorded it is reported it is important to keep a report all malfunctions and must follow up

coagulated water, demand is not high Limited production • Effluent quality • Cleaning of inlet and 11 and reported? record of the malfunctions and date on with the supervisor if they are not

then allowed to monitoring outlet structures which they were reported. timeously dealt with.

stand for desired

ENVIRONMENTAL and SAFETY ISSUES

retention time and

then supernatant To comply with the OHSA PPE: overall,

water is withdrawn safety shoes, hard hat, gloves should be

Radial flow Circular tank in Treats turbid water • Retention time advantages: • Flow velocity • Regular desludging worn as required. It is important that a life Ensure that PPE is available on site and is

sedimentation which water to be for any capacity • Radial flow • Low O & M costs monitoring • Leak detection and

12 Is correct PPE worn?

jacket is worn when the process controller correctly worn.

clarified enters at velocity Disadvantages: • Effluent quality repair is on the sides of the tank cleaning the

the centre and flows • Surface loading • Sensitive to flow (turbidity) weirs.

through the radius rate velocity monitoring both The area around the sedimentation tanks

(radial)) towards • Weir overflow rate visual and must be kept clean to avoid contaminating The process controller must keep the area

launders located on analytical Is good housekeeping

its periphery

13 practiced around the tanks?

the water as well as accidents that may be clean and safely dispose of the sludge and

caused if sludge/scum removed is left scum.

lying around.

Anda mungkin juga menyukai

- Standard DWA-A 118E: German DWA Rules and StandardsDokumen37 halamanStandard DWA-A 118E: German DWA Rules and StandardsZoran Kostić100% (4)

- OPTIMISED DRILLING PRACTICES COURSE SECTION 6: HOLE CLEANINGDokumen56 halamanOPTIMISED DRILLING PRACTICES COURSE SECTION 6: HOLE CLEANINGWaleed Barakat Maria100% (1)

- Subsea Well Control PDFDokumen118 halamanSubsea Well Control PDFluciano_ferreira_80100% (2)

- A Review of Cuttings Transport in Directional-Well DrillingDokumen3 halamanA Review of Cuttings Transport in Directional-Well Drillingfaishal hafizhBelum ada peringkat

- Operation and Management of Wastewater Treatment Plants: Authors: Andrea Giordano Luigi PettaDokumen18 halamanOperation and Management of Wastewater Treatment Plants: Authors: Andrea Giordano Luigi PettaJack nguyenBelum ada peringkat

- Wastewater TreatmentDokumen66 halamanWastewater TreatmentDan NanyumbaBelum ada peringkat

- Lecture 2 - Rig ComponentsDokumen37 halamanLecture 2 - Rig Componentsasel.muratttBelum ada peringkat

- WILDWELL Snubbing OperationsDokumen134 halamanWILDWELL Snubbing OperationsJeffry Dhody Pratama100% (1)

- Thickeners and Clarifiers: Liquid / Solid SeparationDokumen6 halamanThickeners and Clarifiers: Liquid / Solid Separationyounes1980Belum ada peringkat

- Headbox Condition Testing - FlyerDokumen1 halamanHeadbox Condition Testing - FlyerAmmar MalikBelum ada peringkat

- Flowserve Pump Seal PlansDokumen56 halamanFlowserve Pump Seal PlansDDBelum ada peringkat

- Production - Problems and Field MonitoringDokumen73 halamanProduction - Problems and Field MonitoringadeebBelum ada peringkat

- Snubbing PDFDokumen134 halamanSnubbing PDFNavin SinghBelum ada peringkat

- Snubbing Operations GuideDokumen134 halamanSnubbing Operations Guidemjm_1365100% (1)

- Section 04 - Hole Cleaning PDFDokumen41 halamanSection 04 - Hole Cleaning PDFayhamBelum ada peringkat

- Apron Plate Replacement - FlyerDokumen1 halamanApron Plate Replacement - FlyerAmmar MalikBelum ada peringkat

- Drilling Fluid FunctionsDokumen28 halamanDrilling Fluid FunctionsChristian Olascoaga MoriBelum ada peringkat

- 06-Barite SagDokumen9 halaman06-Barite SagmarboudBelum ada peringkat

- Apron Replacement - FlyerDokumen1 halamanApron Replacement - FlyerAmmar MalikBelum ada peringkat

- Section 06 - Hole CleaningDokumen81 halamanSection 06 - Hole CleaningRicardo Villar100% (2)

- Pulsation Attenuator MaintenanceDokumen1 halamanPulsation Attenuator MaintenanceAmmar MalikBelum ada peringkat

- 1.1.1 AdvantagesDokumen8 halaman1.1.1 AdvantagesSarah KamilBelum ada peringkat

- SPE 35171 Review Reservoir Engineering Aspects ConformanceDokumen16 halamanSPE 35171 Review Reservoir Engineering Aspects ConformanceAngy Carolina Taborda VelasquezBelum ada peringkat

- Flow Performance ObjectivesDokumen18 halamanFlow Performance ObjectivesStanley EkechukwuBelum ada peringkat

- Apron Reconditioning - FlyerDokumen1 halamanApron Reconditioning - FlyerAmmar MalikBelum ada peringkat

- 20pst CI-JR 3Dokumen19 halaman20pst CI-JR 3Sergio PalmaBelum ada peringkat

- Online Streaming Current Monitor Usage - Theory and PracticeDokumen45 halamanOnline Streaming Current Monitor Usage - Theory and PracticeAna Carolina FrançaBelum ada peringkat

- Installation & Maintenance: 2.5.7 Tilt (Clearance)Dokumen2 halamanInstallation & Maintenance: 2.5.7 Tilt (Clearance)Depriwangga OMBelum ada peringkat

- 05 SeparatorDokumen5 halaman05 SeparatorNicolas Santana TijoBelum ada peringkat

- Belt Conveyor RT45-BDokumen2 halamanBelt Conveyor RT45-BMahmoud HanafyBelum ada peringkat

- 00 Hole CleaningDokumen159 halaman00 Hole CleaningMOH HAIDLER ALI SYAFIIBelum ada peringkat

- Small Flow Liquid Liquid Coalescers FLTR Purple EngineeringDokumen4 halamanSmall Flow Liquid Liquid Coalescers FLTR Purple EngineeringFLTR PURPLE E.Belum ada peringkat

- Operation & Maintenance Manual for 5700 Series Model 5701 PumpDokumen36 halamanOperation & Maintenance Manual for 5700 Series Model 5701 PumpGrabriel VallenteBelum ada peringkat

- Trouble Shooting Guide DM PlantDokumen20 halamanTrouble Shooting Guide DM Plantpuhazhr33% (3)

- Understanding Steam Turbine VibrationDokumen30 halamanUnderstanding Steam Turbine VibrationkatibraBelum ada peringkat

- At-Bit Inclination Measurements Improves Directional Drilling Efficiency and ControlDokumen7 halamanAt-Bit Inclination Measurements Improves Directional Drilling Efficiency and ControlddqylxgBelum ada peringkat

- Introduction To Smart Well Completion 1680670230Dokumen37 halamanIntroduction To Smart Well Completion 16806702306x4gmmkdb7Belum ada peringkat

- 05 Turbine Operation MaintenanceDokumen9 halaman05 Turbine Operation Maintenancesakera 88Belum ada peringkat

- 244 Hydraulic ActuatorsDokumen3 halaman244 Hydraulic ActuatorsjmezapBelum ada peringkat

- Ch02 Workover Oprnt and EquipmentsDokumen94 halamanCh02 Workover Oprnt and EquipmentsNIRAJ DUBEYBelum ada peringkat

- Check Valve SelectionDokumen1 halamanCheck Valve SelectionramkikkdBelum ada peringkat

- Continuous Catalyst Regeneration Reforming Unit: Axens Octanizing ProcessDokumen2 halamanContinuous Catalyst Regeneration Reforming Unit: Axens Octanizing ProcessAnonymous GO6JVW9WudBelum ada peringkat

- Cap08&09 Ensaios OffshoreDokumen50 halamanCap08&09 Ensaios OffshoreThalles Giangiarulo de AguiarBelum ada peringkat

- Week 10 - Introduction of Environmental Engineering Concrete StructuresDokumen26 halamanWeek 10 - Introduction of Environmental Engineering Concrete StructuresRefaldi PrayitnoBelum ada peringkat

- Drilling Fluid Functions: Removing Cuttings from the WellDokumen11 halamanDrilling Fluid Functions: Removing Cuttings from the Wellb4rfBelum ada peringkat

- Belt Conveyor RFBE-B1800 X 9.7Dokumen2 halamanBelt Conveyor RFBE-B1800 X 9.7Mahmoud HanafyBelum ada peringkat

- Evoqua - Jet Tech SBR SystemsDokumen8 halamanEvoqua - Jet Tech SBR SystemsMohamed Ma'mounBelum ada peringkat

- Orbit Valves Brochure PDFDokumen28 halamanOrbit Valves Brochure PDFHendi RofiansyahBelum ada peringkat

- Diversion Considerations: Diversion Agents. Presented By: Production Technology Team Ss & W Functional ExcellenceDokumen7 halamanDiversion Considerations: Diversion Agents. Presented By: Production Technology Team Ss & W Functional ExcellenceWillianBelum ada peringkat

- Section 07 - Hole CleaningDokumen82 halamanSection 07 - Hole CleaningRobert MorauskasBelum ada peringkat

- ZI-CHEM Mining Capabilities Antiscalant 09Dokumen1 halamanZI-CHEM Mining Capabilities Antiscalant 09Ari WijayaBelum ada peringkat

- Top Slice Vertical Movement Reconditioning - FlyerDokumen1 halamanTop Slice Vertical Movement Reconditioning - FlyerAmmar MalikBelum ada peringkat

- 1 s2.0 S0262176201803965 MainDokumen3 halaman1 s2.0 S0262176201803965 MainLauriene UFPIBelum ada peringkat

- Flyer ROTOCAV - Hydrodynamic CavitatorDokumen2 halamanFlyer ROTOCAV - Hydrodynamic Cavitatorfsilassie8012Belum ada peringkat

- Approach Flow System Study - FlyerDokumen1 halamanApproach Flow System Study - FlyernotengofffBelum ada peringkat

- Swing Check Valves (S) - Rev 02-05-2019Dokumen2 halamanSwing Check Valves (S) - Rev 02-05-2019arjun 11Belum ada peringkat

- Swing Check Valve: Unique FeaturesDokumen2 halamanSwing Check Valve: Unique FeaturesshehanBelum ada peringkat

- Brines and Workover Fluids GuideDokumen90 halamanBrines and Workover Fluids Guideqazim786100% (4)

- Overview of HEC RAS-UnsteadyDokumen7 halamanOverview of HEC RAS-UnsteadyAnonymous nlgHmx1rhBelum ada peringkat

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsDari Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsPenilaian: 1 dari 5 bintang1/5 (1)

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsDari EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsPenilaian: 5 dari 5 bintang5/5 (1)

- Steam TablesDokumen6 halamanSteam TablesRichard Olawoyin100% (1)

- Poster 8 Daily TasksDokumen1 halamanPoster 8 Daily TasksRamco33Belum ada peringkat

- Plant Engineering 2006sepDokumen5 halamanPlant Engineering 2006sepRamco33Belum ada peringkat

- Poster 3 Problems (A3)Dokumen1 halamanPoster 3 Problems (A3)Ramco33Belum ada peringkat

- Graphene Super Strong MaterialDokumen1 halamanGraphene Super Strong MaterialRamco33Belum ada peringkat

- Poster 7 Operational Information Sheet 1 (A3)Dokumen1 halamanPoster 7 Operational Information Sheet 1 (A3)Ramco33Belum ada peringkat

- Calculation The Optimum Alum Dosages Used in Several DrinkingDokumen11 halamanCalculation The Optimum Alum Dosages Used in Several DrinkingRyanBelum ada peringkat

- PRIMARY TREATMENT OF SEWAGEDokumen95 halamanPRIMARY TREATMENT OF SEWAGErangaBelum ada peringkat

- Jurnal Pengaruh Biofilter Bermedia Botol Plastik Bekas Dengan Luas Permukaan Berbeda Dalam Menurunkan Kadar Tss Dan Tds Pada Limbah Cair LaundryDokumen9 halamanJurnal Pengaruh Biofilter Bermedia Botol Plastik Bekas Dengan Luas Permukaan Berbeda Dalam Menurunkan Kadar Tss Dan Tds Pada Limbah Cair LaundryPranawa Sri HapsaraBelum ada peringkat

- 150 KLD Quotation Chouhan JiDokumen8 halaman150 KLD Quotation Chouhan JiTech Monger100% (1)

- Palintest Sewage Effluent Kit InstructionsDokumen4 halamanPalintest Sewage Effluent Kit InstructionssvirkomartinkoBelum ada peringkat

- Brief of AWWDA NCRP Projects 01022021Dokumen17 halamanBrief of AWWDA NCRP Projects 01022021KennyBelum ada peringkat

- BIOGAS PRODUCTION FROM PALM OIL MILL EFFLUENTDokumen5 halamanBIOGAS PRODUCTION FROM PALM OIL MILL EFFLUENTNiegleBelum ada peringkat

- Analisis Kadar Padatan Tersuspensi Total (TSS) Dan Logam Krom Total (CR) Pada Limbah Tekstil Di Dinas Lingkungan Hidup SukoharjoDokumen10 halamanAnalisis Kadar Padatan Tersuspensi Total (TSS) Dan Logam Krom Total (CR) Pada Limbah Tekstil Di Dinas Lingkungan Hidup SukoharjoAkmal HernandiBelum ada peringkat

- Areading 11Dokumen3 halamanAreading 11IVy ViOlet ThOrnBelum ada peringkat

- Waterchar IwasteDokumen8 halamanWaterchar IwasteCharisma CabanogBelum ada peringkat

- Water Quality Aspects in and Around Dhaka CityDokumen4 halamanWater Quality Aspects in and Around Dhaka CityEmdad YusufBelum ada peringkat

- Project PresentationDokumen38 halamanProject PresentationThe AnonymousBelum ada peringkat

- Lohas Wastewater p4Dokumen1 halamanLohas Wastewater p4Dwinix John CabañeroBelum ada peringkat

- Template Tugas CompendiumDokumen8 halamanTemplate Tugas CompendiumannisyaBelum ada peringkat

- Sewage System DesignDokumen7 halamanSewage System DesignSajjad HussainBelum ada peringkat

- Unit 2 DrainageDokumen62 halamanUnit 2 DrainagekarunyaBelum ada peringkat

- Global Installation Records Sewerage SystemsDokumen9 halamanGlobal Installation Records Sewerage SystemsJulio TovarBelum ada peringkat

- Aquatic Ecosystem Threat from Human WasteDokumen1 halamanAquatic Ecosystem Threat from Human WasteLyndonn SantosBelum ada peringkat

- MBR Membranes for Wastewater TreatmentDokumen14 halamanMBR Membranes for Wastewater TreatmentTre LeminhBelum ada peringkat

- Question Bank - EeDokumen18 halamanQuestion Bank - EeShyamala GuruBelum ada peringkat

- Complete and Simple Solutions For Industrial Process Water and Wastewater TreatmentDokumen3 halamanComplete and Simple Solutions For Industrial Process Water and Wastewater TreatmentElena GilBelum ada peringkat

- Activated Sludge Aeration Tank CalculationsDokumen2 halamanActivated Sludge Aeration Tank CalculationsChun Jie GohBelum ada peringkat

- Ordinance of Davao City."Dokumen12 halamanOrdinance of Davao City."Jan kristel100% (1)

- Lab Volatile Suspended Solids (EC2206C4A)Dokumen9 halamanLab Volatile Suspended Solids (EC2206C4A)zahir asaharBelum ada peringkat

- SPT SPTDokumen7 halamanSPT SPTRadoNounBelum ada peringkat

- Secondary Wastewater TreatmentDokumen18 halamanSecondary Wastewater TreatmentSumaiya Rashid100% (1)

- Floating Floc Issues in Raw Water ClarifierDokumen1 halamanFloating Floc Issues in Raw Water Clarifierja23gonzBelum ada peringkat

- Community Managed DEWATS in NepalDokumen9 halamanCommunity Managed DEWATS in NepalOswar MungkasaBelum ada peringkat

- Septic Tank Leaching Chamber PDFDokumen7 halamanSeptic Tank Leaching Chamber PDFJohan Shane CarsidoBelum ada peringkat