Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)

Diunggah oleh

Lipika Gayen0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

114 tayangan1 halamanThis

Judul Asli

4_6021560431213020225

Hak Cipta

© © All Rights Reserved

Format Tersedia

XLS, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai XLS, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

114 tayangan1 halamanWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)

Diunggah oleh

Lipika GayenThis

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai XLS, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

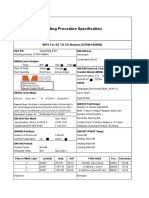

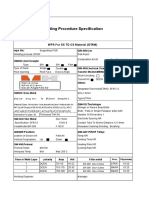

Welding Procedure Specification

WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)

wps No: Supporting PQR: QW-408:Gas

Welding process: GTAW+SMAW Gas:Argon

Composition:99.95 Flow Rate:6-12Lit/min

QW402:Joint Desighn

Type: BW SW Fillet

Type of Weld: Single Double QW-409:Electrical Characterist

Transfer Mode(GMAW):

Short-Circuiting Glubular Spray

Current:AC DCEN DCEP

Other:

Tangestan Electrode(GTAW): SFA5.12

QW403: Base Metal Size:1.6mm

[P,S] no:6 Group No:1 Type:ETWH

Material Spec: TYPE410 , F6a , F6b QW410:Technique

Stringer or Weave Bead:Both

Multi - Pass or Single Pass(per side) both

Thickness:All Number Of Electrodes: 1

QW-404:Filler Metal Dia=2.4mm Electrode Spacing:NA

Specification: SFA5.9 +SFA5.13 A NO 8+8 Contact Tube To Worke Distance:12-14mm

Classificatin:ER-309+ECOCR F NO:6+8 Interpass Cleaning:Grinding , Brushing

QW405:Position QW-407:PWHT Temp:

position of Groove:Flat Fillet: Temp:NR

Vertical Progression: Up Down Holding Time:NR

QW-406:Preheat Heating Rate:NR

Preheat Temp: Min:NA Cooling Rate:NR

Interpass Temp: Min: Max:200 C

Pass or Weld Layer polarity Amp Volt Filler metal Proc. TV(cm/min)

1 DCEN 70-110 18-22 ER-309 Dia =2mm GTAW 10-20

2 DCEP 110-170 20-30 ECOCR Dia =2.5mm SMAW 10-20

n DCEP 150-200 25-35 ECOCR Dia =2.5mm SMAW 10-20

inspector: Manager:

Anda mungkin juga menyukai

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- Gta+sma PQRDokumen3 halamanGta+sma PQRRahul MoottolikandyBelum ada peringkat

- WPS for SS to CS WeldingDokumen1 halamanWPS for SS to CS WeldingLipika GayenBelum ada peringkat

- DefectDokumen2 halamanDefectanon_90890103100% (1)

- PT Kuwera Karya Me: PanduDokumen2 halamanPT Kuwera Karya Me: PanduGalang Pratama PutraBelum ada peringkat

- Multi Process Welding Procedures QW200.4 (ASME IX)Dokumen1 halamanMulti Process Welding Procedures QW200.4 (ASME IX)HoangBelum ada peringkat

- ITP For Drum Screen InspectionDokumen1 halamanITP For Drum Screen InspectionkapsarcBelum ada peringkat

- Welder ID Card BRE KarahaDokumen5 halamanWelder ID Card BRE KarahaHerruSetiawan100% (1)

- QW 442 A Number PDFDokumen1 halamanQW 442 A Number PDFMadidj_2014Belum ada peringkat

- WQT Form (ASME) 04-23Dokumen1 halamanWQT Form (ASME) 04-23hanz bermejoBelum ada peringkat

- WPS Resrvoire Sous Pression Smaw SawDokumen6 halamanWPS Resrvoire Sous Pression Smaw SawDanem HalasBelum ada peringkat

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDokumen11 halamanEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaBelum ada peringkat

- OC-1-1-FCAW-1 Rev 0 PDFDokumen4 halamanOC-1-1-FCAW-1 Rev 0 PDFDario100% (1)

- Utoc Preliminary Wps Shell Project 270807 PDFDokumen55 halamanUtoc Preliminary Wps Shell Project 270807 PDFErick HoganBelum ada peringkat

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDokumen2 halamanASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaBelum ada peringkat

- Fermi Lab Orbital Welding ProcedureDokumen2 halamanFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- STS QAC SOP 006 Repair Procedure For Stainless SteelDokumen5 halamanSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriBelum ada peringkat

- OCS Engineering & Construction Visual Inspection ReportDokumen1 halamanOCS Engineering & Construction Visual Inspection ReportvinothBelum ada peringkat

- Joints (Qw-402) DetailsDokumen3 halamanJoints (Qw-402) DetailsNaqqash SajidBelum ada peringkat

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDokumen3 halamanTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanBelum ada peringkat

- Report No. TA-V-1456Dokumen2 halamanReport No. TA-V-1456u04ajf3Belum ada peringkat

- Tüvis: AD 2000-MerkblattDokumen10 halamanTüvis: AD 2000-MerkblattUfuk ÇİMENBelum ada peringkat

- WPQR Welding Procedure QualificationDokumen3 halamanWPQR Welding Procedure QualificationThanasis KyrgiazoglouBelum ada peringkat

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokumen1 halamanQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Belum ada peringkat

- Repair Procedure For Super Heater Coil TubesDokumen2 halamanRepair Procedure For Super Heater Coil Tubesbehzad mohammadiBelum ada peringkat

- Sample Forms WPS PQRDokumen22 halamanSample Forms WPS PQRGMBelum ada peringkat

- PWHTDokumen103 halamanPWHTChetan B KapadiaBelum ada peringkat

- WELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTDokumen1 halamanWELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTAhmed LepdaBelum ada peringkat

- 004 Gtaw P5aDokumen16 halaman004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDokumen50 halamanASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANBelum ada peringkat

- Appendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Dokumen14 halamanAppendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Fadil WimalaBelum ada peringkat

- PL1083 - WHB 1 and 2 REPAIR PROCEDURE Rev 1 PDFDokumen4 halamanPL1083 - WHB 1 and 2 REPAIR PROCEDURE Rev 1 PDFsarsan nedumkuzhiBelum ada peringkat

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Dokumen17 halamanWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizBelum ada peringkat

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Dokumen4 halamanWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiBelum ada peringkat

- ASME 9 Multi Process Welding Procedures QW200Dokumen2 halamanASME 9 Multi Process Welding Procedures QW200Teodor EzaruBelum ada peringkat

- Review of ISO Standards for Welding Procedure SpecificationsDokumen9 halamanReview of ISO Standards for Welding Procedure SpecificationsYan FerizalBelum ada peringkat

- Welding Procedure Specification For Storage Tank & Piping SystemDokumen3 halamanWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadBelum ada peringkat

- Header Plug Seal Weld ProcedureDokumen3 halamanHeader Plug Seal Weld ProcedureMohd Shafuaaz Kassim100% (1)

- WPS for Welding SA-335 P11 to SA-234 WP11Dokumen3 halamanWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitBelum ada peringkat

- VP16 PDFDokumen13 halamanVP16 PDFKara WhiteBelum ada peringkat

- WOPQ Form English1Dokumen2 halamanWOPQ Form English1oaperuchenaBelum ada peringkat

- IX-10-08 QW-407.2 Procedure Qualification LimitsDokumen4 halamanIX-10-08 QW-407.2 Procedure Qualification LimitsPatrick DominguezBelum ada peringkat

- Note 6 - Welder Test RequirementDokumen29 halamanNote 6 - Welder Test RequirementMohamad Yusuf Helmi100% (1)

- Template BUTTDokumen1 halamanTemplate BUTTDylan TriggBelum ada peringkat

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDokumen2 halamanWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabBelum ada peringkat

- Welder Qualification CertificateDokumen2 halamanWelder Qualification CertificateNguyen Thanh BinhBelum ada peringkat

- SB410 (JIS) - Worldwide Equivalent Grades 11Dokumen1 halamanSB410 (JIS) - Worldwide Equivalent Grades 11valli raju100% (1)

- Welding Procedure Specifications for P91 Butt WeldsDokumen6 halamanWelding Procedure Specifications for P91 Butt WeldssrinivasanBelum ada peringkat

- Asme CCase 1987-2Dokumen2 halamanAsme CCase 1987-2ADAMJSRAOBelum ada peringkat

- Portfolio Storage&Drying Control ProcedureDokumen4 halamanPortfolio Storage&Drying Control Procedurelaz_kBelum ada peringkat

- 121 T BW FPDokumen4 halaman121 T BW FPA. ΒρατσισταBelum ada peringkat

- Welder Performance Qualification (WPQ) According To ASME IX Hassan HussienDokumen1 halamanWelder Performance Qualification (WPQ) According To ASME IX Hassan HussienMahmoud shawkyBelum ada peringkat

- B-Qac-Pro-210-391xx QCP Welding ControlDokumen22 halamanB-Qac-Pro-210-391xx QCP Welding ControlZaidiBelum ada peringkat

- GMAWDokumen12 halamanGMAWsushant47Belum ada peringkat

- Welding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Dokumen1 halamanWelding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Lipika GayenBelum ada peringkat

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Dokumen1 halamanWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenBelum ada peringkat

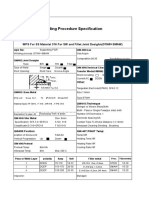

- Welding Procedure Specification: WPS For SS Material 316 For SW and Fillet Joint Desighn (GTAW+SMAW)Dokumen1 halamanWelding Procedure Specification: WPS For SS Material 316 For SW and Fillet Joint Desighn (GTAW+SMAW)Lipika GayenBelum ada peringkat

- Welding Procedure Specification for 316 Stainless Steel GTAW WeldsDokumen1 halamanWelding Procedure Specification for 316 Stainless Steel GTAW WeldsLipika GayenBelum ada peringkat

- WPS for Low Carbon Steel SMAW WeldingDokumen1 halamanWPS for Low Carbon Steel SMAW WeldingLipika GayenBelum ada peringkat

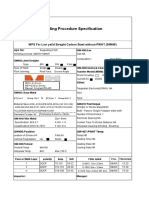

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Dokumen1 halamanWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Lipika GayenBelum ada peringkat

- Acceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Dokumen4 halamanAcceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Lipika Gayen100% (1)

- Table T-233.1 For RTDokumen1 halamanTable T-233.1 For RTLipika GayenBelum ada peringkat

- T-721 For MPTDokumen1 halamanT-721 For MPTLipika GayenBelum ada peringkat

- Table T-233.1 For RTDokumen1 halamanTable T-233.1 For RTLipika GayenBelum ada peringkat

- Quality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VDokumen1 halamanQuality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VLipika Gayen100% (1)

- Tee JointsDokumen1 halamanTee JointsLipika GayenBelum ada peringkat

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Dokumen1 halamanWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Lipika GayenBelum ada peringkat

- Ductile Pipe MFG ProcessDokumen1 halamanDuctile Pipe MFG ProcessLipika GayenBelum ada peringkat

- Impact Test Machine CalculationsDokumen6 halamanImpact Test Machine CalculationsSoumadipta SenBelum ada peringkat

- API 650 Tank Design CalculationDokumen8 halamanAPI 650 Tank Design Calculationmail_younes659283% (29)

- CompressorDokumen17 halamanCompressorLipika GayenBelum ada peringkat

- CompressorDokumen17 halamanCompressorLipika GayenBelum ada peringkat

- CompressorDokumen6 halamanCompressorLipika GayenBelum ada peringkat

- CompressorDokumen17 halamanCompressorLipika GayenBelum ada peringkat

- How Does A Steam Boiler Work?Dokumen11 halamanHow Does A Steam Boiler Work?Lipika GayenBelum ada peringkat

- Third Party Inspection For Reciprocating Compressor - ProcedureDokumen12 halamanThird Party Inspection For Reciprocating Compressor - ProcedureLipika GayenBelum ada peringkat

- Axial Flow For Industry 1Dokumen9 halamanAxial Flow For Industry 1Lipika GayenBelum ada peringkat

- API 650, 5.6.4, Calculation of Shell ThicknessDokumen31 halamanAPI 650, 5.6.4, Calculation of Shell ThicknessalokbdasBelum ada peringkat

- Test ConditionDokumen1 halamanTest ConditionLipika GayenBelum ada peringkat

- Test ConditionDokumen1 halamanTest ConditionLipika GayenBelum ada peringkat

- Technical Tank Inspection Report TemplateDokumen1 halamanTechnical Tank Inspection Report TemplateLipika GayenBelum ada peringkat

- Wa0000Dokumen9 halamanWa0000Lipika GayenBelum ada peringkat

- S.No. Hospital Code Hospital NameDokumen20 halamanS.No. Hospital Code Hospital NameLipika GayenBelum ada peringkat

- Work permit details for IPDC project constructionDokumen1 halamanWork permit details for IPDC project constructionLipika GayenBelum ada peringkat

- Flange Dimensions and Pressure Ratings ChartDokumen24 halamanFlange Dimensions and Pressure Ratings Chartgateauxboy100% (2)

- Tank Shell DesignDokumen4 halamanTank Shell Designgon972001Belum ada peringkat

- Code for Gas Welding Process and ParametersDokumen1 halamanCode for Gas Welding Process and ParametersLipika GayenBelum ada peringkat

- Tank Shell DesignDokumen4 halamanTank Shell Designgon972001Belum ada peringkat

- Standard Pipe Sizes and PropertiesDokumen64 halamanStandard Pipe Sizes and PropertiesLipika GayenBelum ada peringkat

- API 650 Datasheet 1Dokumen16 halamanAPI 650 Datasheet 1alwacsBelum ada peringkat

- General Specifications: Detail ADokumen1 halamanGeneral Specifications: Detail AJeniel PascualBelum ada peringkat

- Executive Order 000Dokumen2 halamanExecutive Order 000Randell ManjarresBelum ada peringkat

- Abortion and UtilitarianismDokumen4 halamanAbortion and UtilitarianismBrent Harvey Soriano JimenezBelum ada peringkat

- Parasitology Lecture Hosts, Symbiosis & TransmissionDokumen10 halamanParasitology Lecture Hosts, Symbiosis & TransmissionPatricia Ann JoseBelum ada peringkat

- Comm Part For A320Dokumen1 halamanComm Part For A320ODOSBelum ada peringkat

- Chapter 4Dokumen26 halamanChapter 4Lana AlakhrasBelum ada peringkat

- Canada's Health Care SystemDokumen11 halamanCanada's Health Care SystemHuffy27100% (2)

- Bentel J408Dokumen64 halamanBentel J408Bojan MarkovicBelum ada peringkat

- 2 English Course BDokumen8 halaman2 English Course BAnjana27Belum ada peringkat

- Quiz EmbryologyDokumen41 halamanQuiz EmbryologyMedShare90% (67)

- of Types of Nuclear ReactorDokumen33 halamanof Types of Nuclear Reactormandhir67% (3)

- Module A Specimen Questions January2020 PDFDokumen5 halamanModule A Specimen Questions January2020 PDFShashi Bhusan SinghBelum ada peringkat

- Nursing Diagnosis TemplateDokumen6 halamanNursing Diagnosis Templatesdk6972Belum ada peringkat

- VIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhDokumen3 halamanVIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhÝ Nguyễn NhưBelum ada peringkat

- Theories of Motivation and Child Moral DevelopmentDokumen5 halamanTheories of Motivation and Child Moral DevelopmentPamela mirandaBelum ada peringkat

- 3-Step Mindset Reset: Overcome Self-Doubt with Mel Robbins' TrainingDokumen11 halaman3-Step Mindset Reset: Overcome Self-Doubt with Mel Robbins' TrainingBožana RadošBelum ada peringkat

- Q4 Module 8Dokumen14 halamanQ4 Module 8DerickBelum ada peringkat

- Lease Practice QuestionsDokumen4 halamanLease Practice QuestionsAbdul SamiBelum ada peringkat

- Ucg200 12Dokumen3 halamanUcg200 12ArielBelum ada peringkat

- RA8485 Animal Welfare Act (Carabao Slaughter)Dokumen2 halamanRA8485 Animal Welfare Act (Carabao Slaughter)Jazreth Gaile100% (1)

- Nursing Plan of Care Concept Map - Immobility - Hip FractureDokumen2 halamanNursing Plan of Care Concept Map - Immobility - Hip Fracturedarhuynh67% (6)

- UNICESS KR Consmetics Maeteria Nunssupjara 01apr23Dokumen44 halamanUNICESS KR Consmetics Maeteria Nunssupjara 01apr23ZB ChuaBelum ada peringkat

- MEDICO-LEGAL ASPECTS OF ASPHYXIADokumen76 halamanMEDICO-LEGAL ASPECTS OF ASPHYXIAAl Giorgio SyBelum ada peringkat

- How To Become A Coffee Aficionado: Tips & Tricks: Kate Macdonnell Brewing Updated: Feb 06 2023Dokumen17 halamanHow To Become A Coffee Aficionado: Tips & Tricks: Kate Macdonnell Brewing Updated: Feb 06 2023sadenaikeBelum ada peringkat

- TA-Ingles IX - UAPDokumen10 halamanTA-Ingles IX - UAPmanuel brennerBelum ada peringkat

- EO On Ban of Fireworks (Integrated)Dokumen2 halamanEO On Ban of Fireworks (Integrated)Mario Roldan Jr.Belum ada peringkat

- Marketing-Aspect 4Dokumen10 halamanMarketing-Aspect 4Leiren RingorBelum ada peringkat

- Jounce Therapeutics Company Events and Start DatesDokumen48 halamanJounce Therapeutics Company Events and Start DatesEquity NestBelum ada peringkat

- Abstract - Tropen Tag 2011 PDFDokumen634 halamanAbstract - Tropen Tag 2011 PDFzmoghesBelum ada peringkat

- Hydrogeological Characterization of Karst Areas in NW VietnamDokumen152 halamanHydrogeological Characterization of Karst Areas in NW VietnamCae Martins100% (1)