API 2003 4.5.2 Inciso B

Diunggah oleh

Leonardo Ramirez GuzmanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

API 2003 4.5.2 Inciso B

Diunggah oleh

Leonardo Ramirez GuzmanHak Cipta:

Format Tersedia

16 API RECOMMENDED PRACTICE 2003

and Terminals, provides speciÞc guidance related to static (3 feet per second) during this period, since lower velocities

hazards in all facets of marine operations (including loading, can result in settling out of water at low points of piping. Sub-

unloading, sampling, gauging, tank cleaning, etc.) and should sequent re-entrainment when the velocity is increased could

be followed. signiÞcantly raise the productÕs charging tendency.

c. Where the material is a static accumulator and contains a

4.5 STORAGE TANKS dispersed phase, such as entrained water droplets, the inlet ßow

4.5.1 General velocity should be restricted to 1 meter per second (3 feet per

second) throughout the Þlling operation, (see 4.2.5.5).

For a discussion of ignition due to static electricity, spark d. Provide a minimum 30-second residence time downstream

promoters, and ßammable vapor-air mixtures, see 4.1.2, of micropore Þlters. (See 4.2.5.2 and 4.2.5.6.)

4.1.3, and 4.1.4, respectively. For a discussion of precautions

e. Check for ungrounded loose or ßoating objects in the tank

relating to internal coatings, and Þlters and relaxation cham-

and remove them. (i.e., loose gauge ßoats and sample cans).

bers, see 4.6.6, and 4.6.3, respectively.

The following discussion pertains only to conductive f. Avoid pumping substantial amounts of air or other

(metallic) storage tanks. Nonconductive tanks are discussed entrained gas into the tank through the liquid. In particular, the

in 4.5.8. practice of clearing Þll lines by air-blowing should be prohib-

ited when the material is a ßammable liquid or a combustible

liquid heated to within 8.5¡C (15¡F) of its ßash point.

4.5.2 Control of Electrostatic Charge Generation

g. To minimize charge generation, some operators limit the

The possibility of a static discharge between the liquid sur- maximum Þll rate after the initial Þll rate is complete. A max-

face and the tank shell, roof supports, or other appurtenances imum Þll rate between 7 meters per second and 10 meters per

is related to the static-generating qualities of the liquid in the second (23 feet per second and 33 feet per second) is com-

tank. The generation rate is also inßuenced by the degree of monly used.

turbulence in the liquid and by the settling of minute quanti- If the vapor space in a tank is at or above the lower ßam-

ties of Þnely divided materials, such as water droplets, parti- mable limit because of the previously stored product and the

cles of iron scale, and sediment. The possibility of a spark is tank is to be Þlled with a low vapor pressure static accumulat-

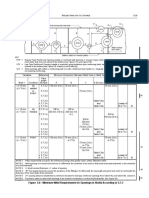

greater in the presence of a spark promoter (see 4.1.3 and Fig- ing liquid, the precautions outlined above should be followed.

ures 1A and 1B). An alternative is to purge or ventilate the tank to a safe vapor

ReÞned petroleum products that tend to retain static concentration prior to Þlling (see Appendix A.8.6).

charges can introduce a greater risk of static ignition unless

The protective measures described above apply to ßoat-

they are handled properly. When the vapor space in a storage

ing-roof tanks only until the roof is ßoating. After the roof is

tank is likely to contain ßammable mixturesÑintermediate

ßoating, these precautions (except for item f) are unnecessary

vapor pressure products, low vapor pressure products con-

because the liquid surface is grounded by the ßoating roof

taminated with high vapor pressure liquids, low vapor pres-

and the absence of a signiÞcant vapor space. Care must be

sure products that contain dissolved hydrogen or light

taken, however, to ensure that ßoating roofs are in metallic

hydrocarbon from the treating process, or switch loadingÑ

contact with the shell. Following the recommendations

protective measures should be used:

described in 5.4.2.2 for lightning protection will also provide

a. Avoid splash Þlling and upward spraying. The Þll-pipe static protection. Some types of ßoating covers, though non-

outlet should discharge near the bottom of the tank, with min- conducting, are constructed with isolated metallic clips,

imum agitation of the water and sediment on the tank bottom. which if not bonded, can become charge accumulators and

Where the outlet of the Þll line is attached to a Òdowncomer,Ó spark promoters.

the siphon breakers that permit air or vapor to enter the down-

comer should not be used. Avoid discharging the product 4.5.3 Grounding

from a nozzle that is elevated above the liquid level.

b. Limit the Þll line and discharge velocity of the incoming Storage tanks on grade-level foundations are considered

liquid stream to 1 meter per second (3 feet per second) until inherently grounded for dissipation of electrostatic charges,

the Þll pipe is submerged either two pipe diameters or 61 cm regardless of the type of foundation (i.e., concrete, sand,

(2 ft), whichever is less. In the case of a ßoating-roof (internal asphalt). For elevated tanks, the resistance to ground can be as

or open-top) tank, observe the 1-meter-per-second (3-feet- high as 1 megohm (1 million ohms), and the tank can still be

per-second) velocity limitation until the roof becomes buoy- considered adequately grounded for dissipation of electro-

ant. During the initial stages of tank Þlling, more opportunity static charges.

exists for the incoming stream to produce agitation or turbu- The addition of grounding rods and similar grounding sys-

lence, hence, the need to limit the inlet velocity. However, the tems will not reduce the hazard associated with electrostatic

productÕs ßow rate should be kept close to 1 meter per second charges in the ßuid. However, additional grounding may be

COPYRIGHT 2000 American Petroleum Institute

Information Handling Services, 2000

Anda mungkin juga menyukai

- 2 Static ElectricityDokumen14 halaman2 Static Electricitylam dinhBelum ada peringkat

- ToxicityDokumen13 halamanToxicityNavin DipaliBelum ada peringkat

- Pre Exam Review 21 653 TanksDokumen6 halamanPre Exam Review 21 653 TanksBassam AbdelazeemBelum ada peringkat

- UL-142 R912 Installation InstructionsDokumen4 halamanUL-142 R912 Installation InstructionsRodrigoBelum ada peringkat

- Sti R912Dokumen4 halamanSti R912Mauricio AdameBelum ada peringkat

- Npga412 94Dokumen7 halamanNpga412 94Conifer YuBelum ada peringkat

- Failure of Inert GasDokumen3 halamanFailure of Inert GasVarun Agrawal100% (2)

- 800 Fire and Safety DesignDokumen31 halaman800 Fire and Safety Designjhon smith100% (1)

- 800 - Fire and Safety DesignDokumen32 halaman800 - Fire and Safety DesignShinji46Belum ada peringkat

- Deck SealDokumen7 halamanDeck SealAlamin Siddique100% (1)

- Above Ground Storage TankDokumen6 halamanAbove Ground Storage TankBasil OguakaBelum ada peringkat

- Iptc 14475 MSDokumen19 halamanIptc 14475 MSElizabeth Vicente MedranoBelum ada peringkat

- Onshore Knockout Drum GuidanceDokumen2 halamanOnshore Knockout Drum Guidanceneil_nhBelum ada peringkat

- Process Vessels 93851 - 18ADokumen21 halamanProcess Vessels 93851 - 18Aakarcz6731Belum ada peringkat

- HPHT Drill & Well ControlDokumen40 halamanHPHT Drill & Well ControlanilkumarBelum ada peringkat

- Sti p3 InstallationDokumen6 halamanSti p3 InstallationnjkasdncjkdBelum ada peringkat

- KATALCO 33-1 DischargeDokumen1 halamanKATALCO 33-1 Dischargekuros2711Belum ada peringkat

- Installation in Process Systems: 6.1. Design Considerations With Respect To Other System ComponentsDokumen8 halamanInstallation in Process Systems: 6.1. Design Considerations With Respect To Other System ComponentsJosé LuísBelum ada peringkat

- NRG 200Dokumen64 halamanNRG 200Rahul LavandBelum ada peringkat

- Flare SystemsDokumen10 halamanFlare SystemsMahboob Ur-RahmanBelum ada peringkat

- Understanding Atmospheric Storage Tanks: Printer-Friendly PageDokumen6 halamanUnderstanding Atmospheric Storage Tanks: Printer-Friendly PageEvert AlexBelum ada peringkat

- Advantages of Membrane TechnologyDokumen5 halamanAdvantages of Membrane TechnologyGopalBelum ada peringkat

- Process Vessels 93851 - 18 PDFDokumen19 halamanProcess Vessels 93851 - 18 PDFNector Jr. GuevarraBelum ada peringkat

- Numerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaDokumen8 halamanNumerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaAlexander ProkhorenkoBelum ada peringkat

- Liquid Seal Water Seal DrumDokumen6 halamanLiquid Seal Water Seal Drumhk168Belum ada peringkat

- Seismic Isolation of Liquefied Natural Gas Tanks: A Comparative AssessmentDokumen16 halamanSeismic Isolation of Liquefied Natural Gas Tanks: A Comparative AssessmentTelemachos PanagiotakosBelum ada peringkat

- Flare and Vent Disposal SystemsDokumen17 halamanFlare and Vent Disposal Systemsganeshdhage100% (1)

- Nitrogen Handling PurgingDokumen9 halamanNitrogen Handling PurgingJeet Singh100% (1)

- Standard Procedures For Tank CleaningDokumen7 halamanStandard Procedures For Tank CleaningDhitya Agil Harnowo100% (1)

- Specific Gravity and Absorption of Aggregate by Volumetric Immersion MethodDokumen9 halamanSpecific Gravity and Absorption of Aggregate by Volumetric Immersion MethodWaleed AhmedBelum ada peringkat

- Tank FailuresDokumen65 halamanTank FailuresAnonymous GfPSYi4n100% (1)

- R912 Installation Instructions - July 2022Dokumen6 halamanR912 Installation Instructions - July 2022Franklin Mata LayaBelum ada peringkat

- Boiler PRESERVATION PROCEDUREDokumen18 halamanBoiler PRESERVATION PROCEDUREasirul_meBelum ada peringkat

- Optimising Digestion Flash Tank Design For The Alumina IndustryDokumen5 halamanOptimising Digestion Flash Tank Design For The Alumina IndustryJuan Manuel ChavarríaBelum ada peringkat

- Optimising Nitrogen Utilisation in Refinery OperationsDokumen7 halamanOptimising Nitrogen Utilisation in Refinery Operationsamir.alishahi.hsn24Belum ada peringkat

- Failure Scenarios For VesselsDokumen24 halamanFailure Scenarios For VesselsJim WesnorBelum ada peringkat

- Experience With In-Field Assessment of Water Contamination ofDokumen19 halamanExperience With In-Field Assessment of Water Contamination ofmayur3dhandeBelum ada peringkat

- Hydrocarbon Processing TOV Offer Advantages in Emergency Services PDFDokumen4 halamanHydrocarbon Processing TOV Offer Advantages in Emergency Services PDFSu KaBelum ada peringkat

- What Is Deck Water Seal On Tanker and Its Types in DetailDokumen5 halamanWhat Is Deck Water Seal On Tanker and Its Types in DetailRose AriantiBelum ada peringkat

- P3 Air Pipe Closing Devices P3Dokumen5 halamanP3 Air Pipe Closing Devices P3Anonymous HPlNDhM6ejBelum ada peringkat

- Pilot Operated Tank Blanketing Valve, 2": ProtectoDokumen8 halamanPilot Operated Tank Blanketing Valve, 2": ProtectoTimBelum ada peringkat

- Ur P3rev5Dokumen6 halamanUr P3rev5Eren HürcanBelum ada peringkat

- Surface Condenser HEIDokumen7 halamanSurface Condenser HEIJesús Santiago QuijadaBelum ada peringkat

- PART 2 of 2.01 INTERVIEW Вопросы-ответы v.2.01Dokumen30 halamanPART 2 of 2.01 INTERVIEW Вопросы-ответы v.2.01Максим Романов100% (1)

- 11 Preservation: Rabab Harweel Power PlantDokumen10 halaman11 Preservation: Rabab Harweel Power PlantPazhamalairajan KaliyaperumalBelum ada peringkat

- Standard Procedures For Tank Cleaning, Purging and Gas Free Operation For Oil TankersDokumen8 halamanStandard Procedures For Tank Cleaning, Purging and Gas Free Operation For Oil TankersGopu Thalikunnath100% (3)

- EarthingDokumen8 halamanEarthingbacabacabacaBelum ada peringkat

- Pilot Operated Tank Blanketing Valve: ProtectoDokumen8 halamanPilot Operated Tank Blanketing Valve: ProtectoHector Flores MarcosBelum ada peringkat

- ATM Storage TankDokumen10 halamanATM Storage TanksameerpecBelum ada peringkat

- Ui Ll11 Rev3Dokumen3 halamanUi Ll11 Rev3temp ovaryBelum ada peringkat

- 8 0 A P I P 2021: UblicationDokumen63 halaman8 0 A P I P 2021: UblicationgoncogenBelum ada peringkat

- Tank TrucksDokumen4 halamanTank Trucksram27_rajiBelum ada peringkat

- Article CFB Studies On The Operation of Loop Seal in Circulating Fluidized Bed Boilers-1Dokumen1 halamanArticle CFB Studies On The Operation of Loop Seal in Circulating Fluidized Bed Boilers-1nguyenhuutan91Belum ada peringkat

- Progress in Energy and Combustion Science Volume 6 Issue 2 1980 (Doi 10.1016/0360-1285 (80) 90002-7) F. Briscoe P. Shaw - Spread and Evaporation of LiquidDokumen14 halamanProgress in Energy and Combustion Science Volume 6 Issue 2 1980 (Doi 10.1016/0360-1285 (80) 90002-7) F. Briscoe P. Shaw - Spread and Evaporation of LiquidFarahatBelum ada peringkat

- Plastics and Insulating MaterialsDokumen1 halamanPlastics and Insulating MaterialsAngel GutierrezBelum ada peringkat

- Mass Transfer EquipmentsDokumen32 halamanMass Transfer EquipmentsAjaykumarBelum ada peringkat

- IG SysDokumen59 halamanIG SysSergioi Indurain100% (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDari EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingPenilaian: 5 dari 5 bintang5/5 (3)

- Scientific American Supplement, No. 470, January 3, 1885Dari EverandScientific American Supplement, No. 470, January 3, 1885Belum ada peringkat

- Intercambiador de CalorDokumen6 halamanIntercambiador de CalorLeonardo Ramirez GuzmanBelum ada peringkat

- PHDokumen4 halamanPHLeonardo Ramirez GuzmanBelum ada peringkat

- CorrosionDokumen2 halamanCorrosionLeonardo Ramirez GuzmanBelum ada peringkat

- Separacion de Boquilla Con SoldaduraDokumen1 halamanSeparacion de Boquilla Con SoldaduraLeonardo Ramirez GuzmanBelum ada peringkat

- CorrosionDokumen2 halamanCorrosionLeonardo Ramirez GuzmanBelum ada peringkat

- CimentacionDokumen1 halamanCimentacionLeonardo Ramirez GuzmanBelum ada peringkat

- PHDokumen4 halamanPHLeonardo Ramirez GuzmanBelum ada peringkat

- 7.3.2.2 Fillet Welds: 7-6 Api S 650Dokumen1 halaman7.3.2.2 Fillet Welds: 7-6 Api S 650Leonardo Ramirez GuzmanBelum ada peringkat

- AWWA CertificationDokumen6 halamanAWWA CertificationLeonardo Ramirez GuzmanBelum ada peringkat

- Capacidad de Trabajo en Tanques APIDokumen1 halamanCapacidad de Trabajo en Tanques APILeonardo Ramirez GuzmanBelum ada peringkat

- Workbook: Case (Main) : Material StreamsDokumen9 halamanWorkbook: Case (Main) : Material StreamsLeonardo Ramirez GuzmanBelum ada peringkat

- Std-Apiipetro STD B53-Engl O B 2 6 7 4 9 T 4 4 111Dokumen1 halamanStd-Apiipetro STD B53-Engl O B 2 6 7 4 9 T 4 4 111Leonardo Ramirez GuzmanBelum ada peringkat

- Api 650 Apartado 5.8.11.2Dokumen1 halamanApi 650 Apartado 5.8.11.2Leonardo Ramirez GuzmanBelum ada peringkat

- Capacidad de Trabajo en Tanques APIDokumen1 halamanCapacidad de Trabajo en Tanques APILeonardo Ramirez GuzmanBelum ada peringkat

- FIXED ROOF TANK CALCULATION (AP-42: Chapter 7 Method) Basic Input DataDokumen1 halamanFIXED ROOF TANK CALCULATION (AP-42: Chapter 7 Method) Basic Input DataLeonardo Ramirez GuzmanBelum ada peringkat

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDokumen20 halamanExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsLeonardo Ramirez GuzmanBelum ada peringkat

- Summarry of Depressuring Caclculations For Dry Flare TABLEDokumen2 halamanSummarry of Depressuring Caclculations For Dry Flare TABLELeonardo Ramirez GuzmanBelum ada peringkat

- Gas HC Water: Input DataDokumen2 halamanGas HC Water: Input DataLeonardo Ramirez GuzmanBelum ada peringkat

- Viscosity Curves B31Dokumen2 halamanViscosity Curves B31Leonardo Ramirez GuzmanBelum ada peringkat

- Insulation Thickness CalculationDokumen2 halamanInsulation Thickness Calculationrajpal14667% (6)

- Control Valve CalculationDokumen18 halamanControl Valve CalculationLeonardo Ramirez Guzman100% (1)

- SeparatorDokumen23 halamanSeparatorLeonardo Ramirez GuzmanBelum ada peringkat

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDokumen1 halamanEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersLeonardo Ramirez GuzmanBelum ada peringkat

- Knockout DrumDokumen9 halamanKnockout Drumgautam_96948069Belum ada peringkat

- Modeling and Control of Three-Phase Gravity Separators in Oil Production FacilitiesDokumen7 halamanModeling and Control of Three-Phase Gravity Separators in Oil Production FacilitiesadilulloBelum ada peringkat

- Separator CalculationsDokumen18 halamanSeparator CalculationsLeonardo Ramirez GuzmanBelum ada peringkat

- Resume NDokumen2 halamanResume NLeonardo Ramirez GuzmanBelum ada peringkat

- Retention TimeDokumen10 halamanRetention TimealexnomitaBelum ada peringkat

- Viscosity Curves B31Dokumen2 halamanViscosity Curves B31Leonardo Ramirez GuzmanBelum ada peringkat

- Week 10 02411940000179 D Muhammad Ardhan AnshariDokumen5 halamanWeek 10 02411940000179 D Muhammad Ardhan AnsharianshariBelum ada peringkat

- Vibration Analysis of An Alstom Typhoon Gas Turbine Power Plant Related To Iran Oil IndustryDokumen8 halamanVibration Analysis of An Alstom Typhoon Gas Turbine Power Plant Related To Iran Oil IndustryFajar HidayatBelum ada peringkat

- MC Ka 2006 02Dokumen32 halamanMC Ka 2006 02GeeBelum ada peringkat

- Machine FoundationDokumen4 halamanMachine Foundationp kishorBelum ada peringkat

- CBLM Use Hand ToolsDokumen55 halamanCBLM Use Hand ToolsJon Snow75% (12)

- Different Types of Vibrators Used in Construction IndustryDokumen29 halamanDifferent Types of Vibrators Used in Construction Industryramya_an2411Belum ada peringkat

- TM9-1765B Ordnance Maintenance Bomb Truck M6 PDFDokumen363 halamanTM9-1765B Ordnance Maintenance Bomb Truck M6 PDFdieudecafeBelum ada peringkat

- PanX Installguide RevaDokumen67 halamanPanX Installguide Revaalpharepair0% (1)

- Eendv 110001 - dv11 EngineDokumen178 halamanEendv 110001 - dv11 EnginenpachecorecabarrenBelum ada peringkat

- Sublimation Heat Press Settings - Quick Reference GuideDokumen1 halamanSublimation Heat Press Settings - Quick Reference GuidecherBelum ada peringkat

- Motor Protection and Control - Catalogue - 2012Dokumen392 halamanMotor Protection and Control - Catalogue - 2012Jigyesh SharmaBelum ada peringkat

- Laminar Vertical Cabinet: Basic CharacteristicsDokumen2 halamanLaminar Vertical Cabinet: Basic CharacteristicsBoris KozjanBelum ada peringkat

- MercerizationDokumen7 halamanMercerizationRahadian Noor MadanyBelum ada peringkat

- Zoom Pet Upright: User GuideDokumen26 halamanZoom Pet Upright: User GuideUKBelum ada peringkat

- Atlas Copco Oil-Injected Rotary Screw Compressors MAS (+) GA30+-90Dokumen16 halamanAtlas Copco Oil-Injected Rotary Screw Compressors MAS (+) GA30+-90mahdiBelum ada peringkat

- Green and Light Weight Vehicles Power Transmission System Design and DevelopmentDokumen8 halamanGreen and Light Weight Vehicles Power Transmission System Design and DevelopmentEditor IJTSRDBelum ada peringkat

- Pamantasan NG CabuyaoDokumen15 halamanPamantasan NG CabuyaoJudithRavelloBelum ada peringkat

- PFI HFB High Flow Pleated Bag Filter CartridgeDokumen2 halamanPFI HFB High Flow Pleated Bag Filter Cartridgebennypartono407Belum ada peringkat

- Api and British Standard Trim DesignationsDokumen1 halamanApi and British Standard Trim DesignationsPOTDARBelum ada peringkat

- Stone Stomper Compactor ManualDokumen98 halamanStone Stomper Compactor Manualgroomerz6612Belum ada peringkat

- 2.5-V Integrated Reference Circuit: FeaturesDokumen24 halaman2.5-V Integrated Reference Circuit: FeaturesAnderson BorgesBelum ada peringkat

- Laboratory Manual For HardnesstestDokumen12 halamanLaboratory Manual For Hardnesstest15 Saad HassanBelum ada peringkat

- Maintenance Repair ManualDokumen48 halamanMaintenance Repair ManualEngine Tuning UpBelum ada peringkat

- Conveyor IdlersDokumen255 halamanConveyor IdlersEd AceBelum ada peringkat

- Test Materials Engineering and ProcessingDokumen142 halamanTest Materials Engineering and Processinglarla SinghalBelum ada peringkat

- AFT Trolley 50-02Dokumen2 halamanAFT Trolley 50-02Forum PompieriiBelum ada peringkat

- HilmaDokumen4 halamanHilmaHaris ĐulićBelum ada peringkat

- CBLM Rmo Core 5Dokumen26 halamanCBLM Rmo Core 5Valcy Madz100% (1)

- JotamTechnologies ProfileDokumen12 halamanJotamTechnologies ProfileProjecte2Belum ada peringkat

- รายการคำนวณถังน้ำมันกลมIKEA PDFDokumen3 halamanรายการคำนวณถังน้ำมันกลมIKEA PDFGooddayBybs0% (1)