Snubbers Fronek Anchor PDF

Diunggah oleh

JOHN0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

7 tayangan8 halamanJudul Asli

SNUBBERS FRONEK ANCHOR.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

7 tayangan8 halamanSnubbers Fronek Anchor PDF

Diunggah oleh

JOHNHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 8

rronexanciononnnceremnsts nc, HYDRAULIC AND RIGID RESTRAINTS)

HYDRAULIC AND RIGID RESTRAINTS

FRONEK ANCHOR/DARLING ENTERPRISES, INC.

‘86 DORIS RAY COURT

LACONIA, NH 03246

INFO@FRONEKGRP.COM

PH: 713-731-0030

FAX: 713-731-8640

PAGES.

HYDRAULIC SNUBBERS......... sevens RARE

SWAY STRUT ASSEMBLIES... eo RE-RE

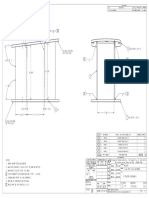

The style "AD" Hydraulic Shock Arrestor is a

manifold dasign hydraulic component consisting of a high

pressure main cylinder, @ flow conirol secon which

‘contains dual stage velocity senstive poppet vaives, and a

sping energze reservar.

Bee

sy i

_—

ca)

AZCoKNENDD APELLEATION

Used for the control and protection of piping and

‘equipment subject to shock ( pulse ) loading and seismic

(cycic) conditions Its use transfers anyimposed forces on

the piping oF equipment directy to the building stucture at

the inetant of chock occurrence, while at all other times

allowing free unresricted movement trough Its. normal

‘operating range.

BASIC OPERATION

The piston rod is fies to mave in elthar direction

witty no restictions 10 the fluc flow ‘or all piston velocities

Up to the activation velocity. At activation velocity the

Poppet valve, internal to tne snubber, loses. Closure of the

poppet in cither tension or compression greatly reduces the

fluid flow through grooves in the poppet at rated design

‘capacity of the unit's termed the * bieed rate”. When the:

applied velocity of the unit becomes zaro the poppet valve

‘opens once again, allowing free piston movement.

STANDARD DESIGN FEATURES

~ Piping and/or oquipmont movement is controlled by

tamperproof dual stage flow control poppels designed wit

sel-cleaning orfices,

= Furnished as a complete, compact and eficient unt,

ready forimmeciate use.

= Manifold configuration requirhg no external piping,

= Spharical, sel-aligning ball bushings allow for 5° of

angular motion or misalignment.

Stable premium grade, antiwear hydraulic fluid

= Pressutized hydraulic reservoir allows mounting in any

‘patil orientation

~ Virtually no resistance to normal thermal movements,

ofthe piping

~ Large restraining forces compared to size.

= Functions in restraining tension and compression

loads.

= Designed for continuous operation up to 200°F with

brief tranciente to a maximum of 300°F.

= Stroke posttion is measured from 2 machined groove

located atthe piston rod wrench fats,

~ Fluid Level in the unit, thereby eliminating estimate of

reserve fuid level

OPTIONAL DESIGN FEATURES

= Remote Reservoir Mounting - The snubbers

pressurized reservoir can be emotely mounted for

inaccessible locations.

“Integral Relief Valve. A non-adjistable valve, whichis

factory preset at 193%, or 200% of mated load.

= Protective Boot- Installed over piston rod forprotection

against corrosive or outdoor environments.

Rigid Stud Application- When no thermal growth is

antcipated atter lacc-up, an optional poppet vaive, without

bleed, can be furnished, Must be erdered with oational

integral reliof valve.

SIZE RANGE

Seven sizes with cyinder bores of 1 %" to8" and

with normal load retinge fFem 3000 to 130,000 pounds. All

arg mace with iegral pressurized reservors in 6 12° ot

18" strokes,

SIZE SELECTION

The selection of size depencs on the anticipated

force and themmal movement of the protected piping or

‘equipment. It is recommended that the soleded cylinder

stfoke be a minimum of the anticipated therma’ movement,

pus 20%,

FACTORY PRE-SET

‘The units are shipped from the factory complete,

tested, reservoir lled to capacity end piston rod preset to

‘mate with pin to pin inetallation dimeneion.

To determine factory pre-set dimension perform

the following caleulations,

(COMPRESSION STROKE:

Preset

He Hina + (

Preset =

prose: = Preset 4 ( LuiodueSioka Thana.

n= vmn, + ( Se sinke Themataes, )

RI

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Huber Gear BoxDokumen2 halamanHuber Gear BoxJOHN0% (1)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 1a PDFDokumen1 halaman1a PDFJOHNBelum ada peringkat

- ARE YOU PROPERLY SPECIFYING MATERIALS? 2 of 3Dokumen4 halamanARE YOU PROPERLY SPECIFYING MATERIALS? 2 of 3vBelum ada peringkat

- Installation of Geosynthetic Clay Liners: Standard Guide ForDokumen5 halamanInstallation of Geosynthetic Clay Liners: Standard Guide ForJOHNBelum ada peringkat

- API 600 Trim InformationDokumen1 halamanAPI 600 Trim Informationccie33639756Belum ada peringkat

- Lab LiftDokumen4 halamanLab LiftJOHNBelum ada peringkat

- TVM0102 PDFDokumen1 halamanTVM0102 PDFJOHNBelum ada peringkat

- 4996T General Assembly Drawing PDFDokumen1 halaman4996T General Assembly Drawing PDFJOHNBelum ada peringkat

- D 3535 - 00 - Rdm1mzuDokumen5 halamanD 3535 - 00 - Rdm1mzuJOHNBelum ada peringkat

- D 5656 - 01 - Rdu2ntytmdeDokumen6 halamanD 5656 - 01 - Rdu2ntytmdeJOHNBelum ada peringkat

- Engineering Example CalculationDokumen78 halamanEngineering Example Calculationkae kaeBelum ada peringkat

- Determination of The Coefficient of Friction of Lubricants Using The Four-Ball Wear Test MachineDokumen5 halamanDetermination of The Coefficient of Friction of Lubricants Using The Four-Ball Wear Test MachineJOHNBelum ada peringkat

- Speed Controlers JSU - JNU - Pisco PDFDokumen5 halamanSpeed Controlers JSU - JNU - Pisco PDFJOHNBelum ada peringkat

- D 3164 - 03 - RDMXNJQ - PDFDokumen4 halamanD 3164 - 03 - RDMXNJQ - PDFJOHNBelum ada peringkat

- 4996T Radome Base Frame Assy Drawing PDFDokumen1 halaman4996T Radome Base Frame Assy Drawing PDFJOHNBelum ada peringkat

- Connection Chart Ods Sizes 1.125" 1.625" 2.125" 2.625" 3.125" GPM 1-10 11-35 36-75 76-120 121 &Dokumen1 halamanConnection Chart Ods Sizes 1.125" 1.625" 2.125" 2.625" 3.125" GPM 1-10 11-35 36-75 76-120 121 &JOHNBelum ada peringkat

- SpiralWound PDFDokumen1 halamanSpiralWound PDFJOHNBelum ada peringkat

- TVM21 PDFDokumen1 halamanTVM21 PDFJOHNBelum ada peringkat

- Connection Chart Ods Sizes 1.125" 1.625" 2.125" 2.625" 3.125" GPM 1-10 11-35 36-75 76-120 121 &Dokumen1 halamanConnection Chart Ods Sizes 1.125" 1.625" 2.125" 2.625" 3.125" GPM 1-10 11-35 36-75 76-120 121 &JOHNBelum ada peringkat

- Winkel BearingsDokumen4 halamanWinkel BearingsJOHNBelum ada peringkat

- TVM1702 PDFDokumen1 halamanTVM1702 PDFJOHNBelum ada peringkat

- Avr 005-009.r7 PDFDokumen1 halamanAvr 005-009.r7 PDFJOHNBelum ada peringkat

- WINKEL MonorailDokumen12 halamanWINKEL MonorailJOHNBelum ada peringkat

- Ø 7/8" Mounting Hole, Typ 4 PL: Avr 190-216 Double WideDokumen1 halamanØ 7/8" Mounting Hole, Typ 4 PL: Avr 190-216 Double WideJOHNBelum ada peringkat

- Winkel ForksDokumen10 halamanWinkel ForksJOHNBelum ada peringkat

- GDC PDFDokumen129 halamanGDC PDFJOHNBelum ada peringkat

- AutoCAD P&ID 2010 Getting - StartedDokumen114 halamanAutoCAD P&ID 2010 Getting - StartedJanuar RahmatBelum ada peringkat

- Modelling of Road Profiles Using Roughness Indicators: Pär Johannesson Igor RychlikDokumen31 halamanModelling of Road Profiles Using Roughness Indicators: Pär Johannesson Igor RychlikJOHNBelum ada peringkat

- GDC PDFDokumen129 halamanGDC PDFJOHNBelum ada peringkat

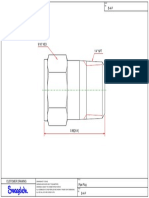

- B-4-P - SwagelokDokumen1 halamanB-4-P - SwagelokJOHNBelum ada peringkat