Ultrasonic Testing Thickness Measurement Report: Component Description

Diunggah oleh

Pand AemonaEonJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ultrasonic Testing Thickness Measurement Report: Component Description

Diunggah oleh

Pand AemonaEonHak Cipta:

Format Tersedia

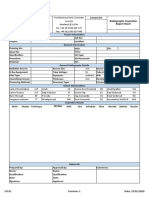

ULTRASONIC TESTING THICKNESS MEASUREMENT REPORT

PREVIOUS EXAMINATION

PLANT :COGEN :05/03/2016

DATE

CURRENT EXAMINATION

TAG NO : E1-2103F :05/03/2019

DATE

DESCRIPTION : CONDENSATE COOLER F DOSH REG NO (if any): :PMT-127801

MATERIAL OF CONSTRUCTION : CARBON STEEL INSTRUMENT TYPE/BRAND :OLYMPUS

SEARCH UNIT SIZE :10mm INSTRUMENT MODEL :38DL PLUS

SEARCH UNIT TYPE :TWIN CRYSTAL COUPLANT TYPE :WALLPAPER PASTE

SEARCH UNIT FREQUENCY :5MHz CALIBRATION BLOCK :STEP WEDGE

□ High temp couplant & search unit

□ Hot plates

SURFACE TEMPERATURE :AMBIENT CORRECTIVE PROCEDURE □ Temperature Correction Factor

□ No corrective procedure required

COMPONENT DESCRIPTION:

NOMINAL MINIMUM PREVIOUS CURRENT CORRECTED

REF. PRBI THICKNESS

DESCRIPTION THICKNESS THICKNESS PRBI MEASURED THICKNESS

POINT (mm)

(mm) (mm) THICKNESS THICKNESS (mm)

(mm) (mm)

HA01 HEAD 16.00 16.41 16.10

HA02 HEAD 16.00 16.54 16.32

HA03 HEAD 16.00 16.70 16.51

HA04 HEAD 16.00 16.50 16.32

HA05 HEAD 16.00 16.35 16.10

HA06 HEAD 25.00 25.50 24.79

HA07 HEAD 25.00 25.90 24.88

HA08 HEAD 16.00 16.40 16.31

HA09 HEAD 16.00 16.31 16.43

HA10 HEAD 16.00 16.39 16.31

HA11 HEAD 16.00 16.28 16.13

HA12 HEAD 16.00 16.12 16.17

HA13 HEAD 16.00 16.05 16.19

NA01 NOZZLE 10.97 10.91 10.50

NB01 NOZZLE 10.97 10.81 10.75

HB01 HEAD 12.00 12.62 12.65

HB02 HEAD 12.00 12.57 12.32

HB03 HEAD 12.00 12.60 12.61

HB04 HEAD 25.00 25.85 25.48

HB05 HEAD 25.00 25.85 25.32

HB06 HEAD 12.00 12.58 12.38

HB07 HEAD 12.00 12.40 12.32

HB08 HEAD 12.00 12.38 12.15

NA02 NOZZLE 8.75 7.81 8.21

NB02 NOZZLE 8.75 8.60 8.55

Reviewed By : _____________. Approved By : _____________.

Position: Position:

Examined By : MUHAMAD HAFIZI □ Risk Based Inspection Engineer

□ Inspection Engineer

□ Inspection Technician □ Corrosion Engineer

Date : 05.03.2019.

Date:______________. Date:______________.

FORM NO : OeXMS-06.01.02 L3 UTTM/F05 REVISION NO : 3 DATE :

PAGE NO : 1 OF 1 TITLE : ULTRASONIC TESTING THICKNESS MEASUREMENT REPORT

Anda mungkin juga menyukai

- Ut Report-1 PDFDokumen1 halamanUt Report-1 PDFsureshrathod2Belum ada peringkat

- Report 1 Paut Sts 409Dokumen12 halamanReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- Marine Ultrasonic Testing ReportDokumen1 halamanMarine Ultrasonic Testing ReportRonanki RaviBelum ada peringkat

- UT ASME Report FormatDokumen2 halamanUT ASME Report Formatrifa100% (1)

- Inspection Report Radiographic TestingDokumen1 halamanInspection Report Radiographic TestingJindarat Kasemsooksakul0% (1)

- Ultrasonic Testing Report Format Based On IACSDokumen1 halamanUltrasonic Testing Report Format Based On IACSDeepak100% (6)

- Pipe Wall Thickness - Report PDFDokumen1 halamanPipe Wall Thickness - Report PDFPetroBelum ada peringkat

- Ultrasonic Testing Report For PipingDokumen54 halamanUltrasonic Testing Report For Pipingeldobie3Belum ada peringkat

- RT ProcedureDokumen12 halamanRT ProcedurePRASHANTBelum ada peringkat

- Api Ut Thickness Procedure PDFDokumen7 halamanApi Ut Thickness Procedure PDFShreekanthKannath100% (1)

- UT Report FormDokumen1 halamanUT Report FormElisha NguyenBelum ada peringkat

- UT Thickness ProcedureDokumen8 halamanUT Thickness ProcedureManoj Balla100% (3)

- Vacuum Box Test Report of Tank T-8112 Bottom PlatesDokumen8 halamanVacuum Box Test Report of Tank T-8112 Bottom PlatesShalom LivingstonBelum ada peringkat

- PCN Examination and Training Fee StructureDokumen3 halamanPCN Examination and Training Fee StructureKarthik Karunanidhi67% (3)

- Automated Ultrasonic Report Sample PHASE ARRAYDokumen2 halamanAutomated Ultrasonic Report Sample PHASE ARRAYAzrul Hanif100% (2)

- Surface Preparation & Painting ReportDokumen1 halamanSurface Preparation & Painting ReportChethan100% (1)

- Ultrasonic Testing ReportDokumen3 halamanUltrasonic Testing ReportsingaduraipandianBelum ada peringkat

- Sample Magnetic Particle Inspection ReportDokumen3 halamanSample Magnetic Particle Inspection ReportOby100% (2)

- Ultrasonic Testing ReportDokumen2 halamanUltrasonic Testing ReportRonel John Rodriguez Custodio100% (1)

- RT Acceptance CriteriaDokumen3 halamanRT Acceptance CriteriaRanjan Kumar100% (2)

- Ut FormDokumen1 halamanUt FormTrung Tinh Ho100% (1)

- F-Liquid Penetran Exam ReportDokumen24 halamanF-Liquid Penetran Exam Reportzat572000Belum ada peringkat

- Wtm-046 RT Procedure Aws D 1.1 2010-V01Dokumen16 halamanWtm-046 RT Procedure Aws D 1.1 2010-V01Wisüttisäk Peäröön100% (2)

- Mpi Acceptance Criteria Aws D1.1ziuhjhdsbhdebhdbdDokumen2 halamanMpi Acceptance Criteria Aws D1.1ziuhjhdsbhdebhdbdsandeep100% (1)

- Welder Id Card DhavalDokumen18 halamanWelder Id Card DhavalDhaval engineeringBelum ada peringkat

- GE Mentor EM Weld BrochureDokumen6 halamanGE Mentor EM Weld BrochuredimachampionBelum ada peringkat

- P-001 Radiographic Testing Procedure For PipelineDokumen25 halamanP-001 Radiographic Testing Procedure For PipelineSaheb YadavBelum ada peringkat

- Hydrostatic Pressure Test ReportDokumen2 halamanHydrostatic Pressure Test Reportmaani7zero50% (10)

- Vacuum Box Test Report - Eff.170628Dokumen1 halamanVacuum Box Test Report - Eff.170628Jindarat KasemsooksakulBelum ada peringkat

- RT Report FormatDokumen1 halamanRT Report FormatRonanki RaviBelum ada peringkat

- D-p5-Bv-pd-012 - Rvi, Issue 01, Rev 00 - Remote Visual InspectionDokumen10 halamanD-p5-Bv-pd-012 - Rvi, Issue 01, Rev 00 - Remote Visual InspectionThinh Nguyen100% (1)

- Ultrasonic Thickness Measurement ProcedureDokumen8 halamanUltrasonic Thickness Measurement ProcedureAbdur Rahim100% (2)

- ET NDT Sample Test Report FormatDokumen1 halamanET NDT Sample Test Report Formatanas dwiBelum ada peringkat

- Vacuum Box Test PDFDokumen3 halamanVacuum Box Test PDFWilson RodriguezBelum ada peringkat

- Calibration Block As Per API 1104Dokumen2 halamanCalibration Block As Per API 1104Chandrashekhar Thiramdasu100% (1)

- Non Destructive Testing Procedure UT, RT, MT, PT (ASME)Dokumen63 halamanNon Destructive Testing Procedure UT, RT, MT, PT (ASME)Irvan Maruli100% (1)

- Radiographic Inspection Report SheetDokumen1 halamanRadiographic Inspection Report SheetMike BoyesBelum ada peringkat

- 11 Ut ProcedureDokumen11 halaman11 Ut ProcedureSajeesh KrishnanBelum ada peringkat

- 7.5CCEV-35-16-A15 Esp 12,5 MM 1 Grupo Index - 20 MM Raiz 40-60° COBRADokumen2 halaman7.5CCEV-35-16-A15 Esp 12,5 MM 1 Grupo Index - 20 MM Raiz 40-60° COBRAwilfran villegasBelum ada peringkat

- PENETRANT TEST REPORT - ContohDokumen2 halamanPENETRANT TEST REPORT - ContohSmksore Pas100% (1)

- Dye Penetrant ProcedureDokumen8 halamanDye Penetrant ProcedureTouil HoussemBelum ada peringkat

- DS 324 ManualDokumen44 halamanDS 324 ManualAshish Srivastava100% (1)

- Liquid Penetrant Test Report.Dokumen2 halamanLiquid Penetrant Test Report.mani kandan100% (1)

- 01-M115 Iss 2 (BS en 1290 - Electromagnet, (Fluorescent) )Dokumen3 halaman01-M115 Iss 2 (BS en 1290 - Electromagnet, (Fluorescent) )DeepakBelum ada peringkat

- RT Procedure 10.09.16Dokumen9 halamanRT Procedure 10.09.16mukeshsingh6Belum ada peringkat

- Miss Bee Anchor Chain CalibrationDokumen2 halamanMiss Bee Anchor Chain CalibrationFerdinandus Sihombing100% (5)

- Liquid Penetrant Examination ReportDokumen7 halamanLiquid Penetrant Examination ReportmizanBelum ada peringkat

- DPT Report - FormatDokumen1 halamanDPT Report - Formatskc0% (1)

- Mpi Report SampleDokumen6 halamanMpi Report SampleGowrisanthosh PalikaBelum ada peringkat

- Smaw PQR FinalDokumen3 halamanSmaw PQR Finalsheikmoin100% (1)

- ASME Sección V - Artículo 6Dokumen9 halamanASME Sección V - Artículo 6Jhonathan ST100% (1)

- Appointment Letter NDE LVL IIIDokumen2 halamanAppointment Letter NDE LVL IIIandreas sembiring100% (1)

- WPQR No. 2016 02Dokumen14 halamanWPQR No. 2016 02GANESH ABelum ada peringkat

- Gate WCB 900 RF Size 4 BR2023084Dokumen1 halamanGate WCB 900 RF Size 4 BR2023084Natthapong ApirattanapanBelum ada peringkat

- FPSO Motion Load - VerticalDokumen109 halamanFPSO Motion Load - VerticalSu Kil SungBelum ada peringkat

- Prathna Alloys WC6 Page-2Dokumen1 halamanPrathna Alloys WC6 Page-2Kishan ChauhanBelum ada peringkat

- PQR PDFDokumen2 halamanPQR PDFNjoku ChijiokeBelum ada peringkat

- SAMPLE Defect SheetDokumen2 halamanSAMPLE Defect SheetshafanyBelum ada peringkat

- Flow Element: Base Maximum Flow Normal Flow Property MethodDokumen1 halamanFlow Element: Base Maximum Flow Normal Flow Property MethodSureshBelum ada peringkat

- fLOW 3265 PDFDokumen1 halamanfLOW 3265 PDFSureshBelum ada peringkat

- Scheme of Examination: Shell & Head SA516 Gr. 70Dokumen1 halamanScheme of Examination: Shell & Head SA516 Gr. 70Pand AemonaEonBelum ada peringkat

- Scheme of Examination: Shell & Head SA516 GR 60Dokumen1 halamanScheme of Examination: Shell & Head SA516 GR 60Pand AemonaEonBelum ada peringkat

- Scheme of Examination: Cylindrical Shell SA516 GR 60 SA516 GR 60 Elliptical HeadDokumen1 halamanScheme of Examination: Cylindrical Shell SA516 GR 60 SA516 GR 60 Elliptical HeadPand AemonaEonBelum ada peringkat

- Scheme of Examination: Shell & Head SA516 Gr. 70Dokumen1 halamanScheme of Examination: Shell & Head SA516 Gr. 70Pand AemonaEonBelum ada peringkat

- Scheme of Examination: Tubes SA179 Shell SA516 GR 70Dokumen1 halamanScheme of Examination: Tubes SA179 Shell SA516 GR 70Pand AemonaEonBelum ada peringkat

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDokumen2 halamanUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Scheme of Examination: 1E Medium HighDokumen5 halamanScheme of Examination: 1E Medium HighPand AemonaEonBelum ada peringkat

- Reliability EngineeringDokumen6 halamanReliability EngineeringPand AemonaEonBelum ada peringkat

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDokumen2 halamanUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDokumen2 halamanUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- The Frequency of Release From Piping: A Case-Study To Compare Approaches Quantifying Organizational and Managerial FactorsDokumen6 halamanThe Frequency of Release From Piping: A Case-Study To Compare Approaches Quantifying Organizational and Managerial FactorsPand AemonaEonBelum ada peringkat

- T Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Dokumen16 halamanT Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Pand AemonaEonBelum ada peringkat

- RJ GPP6Dokumen1.920 halamanRJ GPP6Pand AemonaEonBelum ada peringkat

- Analisis Item 1 Pertghn THN 2018Dokumen5 halamanAnalisis Item 1 Pertghn THN 2018Pand AemonaEonBelum ada peringkat

- C - 1531 RLDokumen11 halamanC - 1531 RLPand AemonaEonBelum ada peringkat

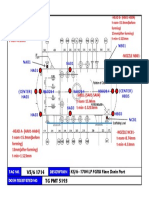

- Nozzle Na01-T-Nom 12.7mm T-Min 4.5mm - Nozzle Nb01 - T-Nom 12.7mm T-Min 4.5mmDokumen1 halamanNozzle Na01-T-Nom 12.7mm T-Min 4.5mm - Nozzle Nb01 - T-Nom 12.7mm T-Min 4.5mmPand AemonaEonBelum ada peringkat

- RJ Final Ta Gpp5 CogenDokumen1.349 halamanRJ Final Ta Gpp5 CogenPand AemonaEonBelum ada peringkat

- ASME VIII CalculationDokumen15 halamanASME VIII CalculationJoao Osmar Correa100% (1)

- 04 ElectricalDokumen223 halaman04 ElectricalductienssjBelum ada peringkat

- Chapter A DIN 931 ISO 4014 A2 STAINLESS PDFDokumen5 halamanChapter A DIN 931 ISO 4014 A2 STAINLESS PDFJonathan DouglasBelum ada peringkat

- Price Quotation Form: Technical Education & Skills Development AuthorityDokumen1 halamanPrice Quotation Form: Technical Education & Skills Development AuthorityKarl Juma JaclaBelum ada peringkat

- Classification of PolymersDokumen11 halamanClassification of Polymerssayon.ghosh1001Belum ada peringkat

- EME 109 Compressible Flow Nozzle Experiment: PreliminariesDokumen11 halamanEME 109 Compressible Flow Nozzle Experiment: PreliminariesSteelcover0% (1)

- The Construction (Design and Management) Regulations 2015 Brick Yard Farm Newtown Road Biddulph St8 7SwDokumen10 halamanThe Construction (Design and Management) Regulations 2015 Brick Yard Farm Newtown Road Biddulph St8 7SwDMK The DragonBelum ada peringkat

- Maintenance Schedule For BOP - 5131086 - 01Dokumen4 halamanMaintenance Schedule For BOP - 5131086 - 01franko guddiBelum ada peringkat

- Techo International Airport Ancillary Building Progress Meeting #045Dokumen24 halamanTecho International Airport Ancillary Building Progress Meeting #04536. Tengkea OuBelum ada peringkat

- Carboguard 893: Selection & Specification DataDokumen5 halamanCarboguard 893: Selection & Specification DataQuy RomBelum ada peringkat

- Comparative Study On Strength Properties of Concrete Made With River Sand and Dune Sand As Fine AggregateDokumen5 halamanComparative Study On Strength Properties of Concrete Made With River Sand and Dune Sand As Fine AggregateIOSRjournalBelum ada peringkat

- Renderoc LAXtraDokumen2 halamanRenderoc LAXtraMansoor Ali100% (1)

- Steel Floor Framing Solutions Complete Packages For Domestic Floors Decks and AdditionsDokumen12 halamanSteel Floor Framing Solutions Complete Packages For Domestic Floors Decks and AdditionsVaralakshmi SundarrajanBelum ada peringkat

- Aquamax Basecoat Series 500: Waterborne Basecoat For 2-3 Stage FinishesDokumen3 halamanAquamax Basecoat Series 500: Waterborne Basecoat For 2-3 Stage FinishesYoussef LfarissiBelum ada peringkat

- CIDECT 2 - Structural Stability of Hollow SectionsDokumen58 halamanCIDECT 2 - Structural Stability of Hollow SectionsClaudio AlvaradoBelum ada peringkat

- Valvula Compuerta NibcoDokumen1 halamanValvula Compuerta NibcoRobertoBelum ada peringkat

- Vdocuments - MX - Spreadsheet Esp Calculation FansDokumen36 halamanVdocuments - MX - Spreadsheet Esp Calculation FansraifaisalBelum ada peringkat

- Studies of Some Thermoplastic Resins Note - DR Akinsiku PDFDokumen12 halamanStudies of Some Thermoplastic Resins Note - DR Akinsiku PDFGlory Usoro100% (1)

- Process Specification For The Heat Treatment of Aluminum Alloys PDFDokumen8 halamanProcess Specification For The Heat Treatment of Aluminum Alloys PDFashokksamy100% (1)

- Blowdown Valves 6DB Series Rev 2 (MS-02-118)Dokumen2 halamanBlowdown Valves 6DB Series Rev 2 (MS-02-118)herysyam1980Belum ada peringkat

- Manual DometicDokumen52 halamanManual DometicCesar Alejandro Isaza RoldanBelum ada peringkat

- BS HC 100Dokumen44 halamanBS HC 100ashmita2k6Belum ada peringkat

- BN - 5687 Hexalobular Socket Pan Head Machine Screws Fully Threaded (A2)Dokumen3 halamanBN - 5687 Hexalobular Socket Pan Head Machine Screws Fully Threaded (A2)MSD ENGRBelum ada peringkat

- DsDokumen28 halamanDsArié WibowoBelum ada peringkat

- Rvs Procedure of Fema 154Dokumen12 halamanRvs Procedure of Fema 154Maksudur RahmanBelum ada peringkat

- Materials For Construction and Civil Engineering Science Processing and DesignDokumen839 halamanMaterials For Construction and Civil Engineering Science Processing and DesignDebendra Dev KhanalBelum ada peringkat

- ME 115 Lab Manual Winter 2013Dokumen29 halamanME 115 Lab Manual Winter 2013BobpoopBelum ada peringkat

- C-CVD Pyrosil Coatings: Sura Instruments GMBHDokumen22 halamanC-CVD Pyrosil Coatings: Sura Instruments GMBHThắm PhạmBelum ada peringkat

- Allround BrochureDokumen24 halamanAllround BrochureMs. ThuBelum ada peringkat

- Lexicon Host BrochureDokumen37 halamanLexicon Host BrochureMile FetahuBelum ada peringkat