Cera Grout 40

Diunggah oleh

Anwar HussainDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cera Grout 40

Diunggah oleh

Anwar HussainHak Cipta:

Format Tersedia

CERA GROUT 40

High strength, non-shrink, free flowing grout

An ISO 9001:2015 Company

CERA GROUT 40 is a high strength non-shrink, pourable / pumpable grout for industrial

applications. Premixed, selectively graded components result in a dense, homogenous mix,

with excellent strength and dimensional stability.

ADVANTAGES:

Excellent fluidity for easy placements

Accessibility to remote parts of structure

One-step grout, Ready to use

High early strength and uniform set, minimizes downtime for repairs and

maintenance, allows earlier loading

Dimensionally stable, needs no special treatment at open ends, capping or edges

No bleeding / segregation

Densification of material decreases permeability, increases wear resistance

Resistant to oils, chemicals etc

No efflorescence

FUNCTION: RECOMMENDED METHOD OF

APPLICATION:

CERA GROUT 40 develops a slight, but

controlled expansion, beginning at the Surface Preparation: All areas to be

time of placement, resulting in excellent grouted shall be clean and free of laitance,

dimensional stability. It ensures that no grease, dirt and contaminants. All loose

major voids are left even in areas that are material shall be removed. In case of

remotely accessible. Because of its non- repair, the concrete must be hacked back

shrink characteristics, it remains stable in until a sound surface is obtained. All

place without cracking, crumbling or metal components shall be de-rusted and

delamination. made free of paints or oils.

USES: The prepared concrete surface should be

saturated before application, with clean

CERA GROUT 40 can be used for water. Remove excess water from voids

grouting of precast structural members and holes prior to grouting.

and to joints, dowels, rail posts and sealing

bolts, powerline stanchions etc. Form Work:

CERA GROUT 40 compensates for the For machine and column bases, firm form

normal shrinkage of concrete and mortar, work should be provided which will allow

absorbs, and minimizes the effects of for rapid and continuous placement of the

vibration on foundation. grout and complete filling of space to be

grouted.

CERA GROUT 40 can be used in

machinery bases, structural columns, Support elements should be anchored so

pumps and accessory bases, anchor bolts, that no movement is possible. Removal

bearing plates, floor grids, crane tracks etc. of formwork should be done only after

CERA GROUT 40 has hardened

CERA GROUT 40 is an excellent properly.

material for structural concrete repairs.

Mixing:

The dry grout should be mixed with surfaces where thickness is more than

recommended amount of water - typically 50mm.

3 – 3.5 liters per bag of 25kg. The grout

shall be added to the water in a container. Curing:

For flowing grout, water content may be Protection against drying winds and direct

increased slightly. Quantities which can sunlight is essential. Use wet hessian cloth

be placed in about 15-20 minutes only or ponding water. If a damp hessian is

should be mixed at a time. Use mechanical used, curing for atleast 7 days is necessary.

mixer to obtain a consistent mix. Note: The initial strength of Cera Grout

40 will be less at 24 hours when the air or

Placing and Compacting: contact temperature is less than 100C

For getting best results, the grouting during the setting of the grout. This is

operation shall be carried out when the due to a delay in the setting and hardening

atmospheric temperature is below 300C. process. In such cases, warm water (300C

Where the ambient temperature during to 400C) shall be used for mixing.

the day is very high, it is recommended Further,

that the grouting is carried out either early the demoulding shall be done only after a

morning or late evening. The grout should minimum duration of 36hours.

be placed only from one side of the For actual site conditions we recommend

opening to avoid trapping of air. Use site trials.

chains, rods or tamping devices to

compact grout tightly, for completely PROPERTIES:

removing air voids. Vibration is Supply form : Powder

acceptable but should not exceed limits so Specific gravity : 2.00

as to cause segregation and bleeding. Chloride content : Nil

Water-binder ratio : 0.135

Restraint:

Adequate restraint should be maintained SHELF LIFE:

on all sides so that the desired shrinkage 12 months in tightly sealed bags.

compensation is obtained. Providing PACKAGING:

reinforcement will help in case of exposed 25 & 50 kg HDPE bags.

COMPRESSIVE AND FLEXURAL STRENGTH:

Age Flexural Free Expansion (%)

in Compressive Strength Early age Hardened Yield / bag

Grout Days Strength(N/mm2) (N/mm2) state (M3)

1 36.0 4.0

Ceragrout 3 55.0 9.0 0.013 (25kgs)

40 7 68.0 10.0 0.8 0.03 0.026 (50kgs)

28 80.0 11.0

Please consult Cera - Chem. technical cell for further details.

Whilst any information and / or specification contained herein is to the best of our knowledge true and accurate, no

warranty is given or implied in connection with any recommendation or suggestions made by us, our Representatives,

Agents or Distributors, as the conditions of use of any labour involved are beyond our control.

Cera-Chem Private Limited Edition: Aug 2015

SUPERIOR CONSTRUCTION CHEMICALS

No. 6, Park Street, Kilpauk Garden Colony, Chennai - 600010

Ph: 044-26441013, 26453498/4792, 26460844

Fax: 044-26446104

Email: corporate@cerachemindia.com

www.cerachemindia.com

Anda mungkin juga menyukai

- Cementitious-Grout MasterFlow 718Dokumen2 halamanCementitious-Grout MasterFlow 718Abhi MitraBelum ada peringkat

- Mix Design For Concrete Grade M 42Dokumen4 halamanMix Design For Concrete Grade M 42NaveenkumarBelum ada peringkat

- Concrete Admixtures: For Durable & Sustainable ConstructionDokumen11 halamanConcrete Admixtures: For Durable & Sustainable ConstructionShridhar VaidyaBelum ada peringkat

- ECMAS Terrace Waterproofing SolutionsDokumen8 halamanECMAS Terrace Waterproofing SolutionsLokesh DvBelum ada peringkat

- Concure WBDokumen2 halamanConcure WBR.ThangarajBelum ada peringkat

- SAAOA - Handbook 2012Dokumen38 halamanSAAOA - Handbook 2012Teluguvilan HaHaBelum ada peringkat

- About Fosroc International: Fosroc Product Guide ForDokumen2 halamanAbout Fosroc International: Fosroc Product Guide ForMital DamaniBelum ada peringkat

- Concrete Mix Design C 30 For KamoaDokumen9 halamanConcrete Mix Design C 30 For Kamoamitendra singhBelum ada peringkat

- Self Curing MixDokumen60 halamanSelf Curing MixnhulugallaBelum ada peringkat

- Shobha DevelopersDokumen212 halamanShobha DevelopersJames TownsendBelum ada peringkat

- Nitoflor BrochureDokumen13 halamanNitoflor BrochureMaha MuflehBelum ada peringkat

- Lab Equipment ListDokumen17 halamanLab Equipment ListPalla Bhaskara RaoBelum ada peringkat

- Brick CalculationsDokumen13 halamanBrick CalculationsMirza Mustansir BaigBelum ada peringkat

- Sik A Green Streak Presentation 2Dokumen34 halamanSik A Green Streak Presentation 2hahaerBelum ada peringkat

- Concrete: Various Terms Used / Steps For Concreting Operation A) BatchingDokumen5 halamanConcrete: Various Terms Used / Steps For Concreting Operation A) BatchingDARK KnightBelum ada peringkat

- Sun PU GardDokumen2 halamanSun PU GardUmeshchandra PatilBelum ada peringkat

- Shutter MAINDokumen22 halamanShutter MAINOvais MunshiBelum ada peringkat

- Civil Engineering Material: Lab ManualDokumen16 halamanCivil Engineering Material: Lab ManualSahar Gul100% (2)

- BOQ - Rate AnalysisDokumen9 halamanBOQ - Rate AnalysisKeyur GajjarBelum ada peringkat

- 3 TekniFloor LDPDokumen2 halaman3 TekniFloor LDPAndy100% (1)

- Concrete Mix Design Calculations - Water Cement Ratio and Optimum Cement Content and Ideal Aggregate PropotionsDokumen6 halamanConcrete Mix Design Calculations - Water Cement Ratio and Optimum Cement Content and Ideal Aggregate PropotionsGemunu WilsonBelum ada peringkat

- Concrete Pour Card by Tremie MethodDokumen1 halamanConcrete Pour Card by Tremie MethodBiplab dattaBelum ada peringkat

- 6.self Curing ConcreteDokumen4 halaman6.self Curing ConcreteBhanu Chandar KBelum ada peringkat

- Comprehensive Development Plan 2021 SecoDokumen308 halamanComprehensive Development Plan 2021 SecoVenu GopalBelum ada peringkat

- 072-73rate AnalysisKTMDokumen388 halaman072-73rate AnalysisKTMAmok BajracharyaBelum ada peringkat

- Dr. C. D. Modhera - Day 3 - Session 1Dokumen93 halamanDr. C. D. Modhera - Day 3 - Session 1mbgfknjhgfBelum ada peringkat

- Rural MasonDokumen29 halamanRural Masonakumarao100% (1)

- AKHPL Concrete Mix Design Summary.Dokumen3 halamanAKHPL Concrete Mix Design Summary.dipl labBelum ada peringkat

- TDS - Bronco Cemgrout SP75Dokumen4 halamanTDS - Bronco Cemgrout SP75Jignessh JoshiBelum ada peringkat

- Expansion Joint Waterproofing Specs - SD Combiflex SG v2Dokumen5 halamanExpansion Joint Waterproofing Specs - SD Combiflex SG v2VIJAYTECH CONSULTANTS PVT. LTD.Belum ada peringkat

- Work Method Statement: ActivityDokumen5 halamanWork Method Statement: ActivityamolBelum ada peringkat

- Projectmodified Mix Design For ConcreteDokumen32 halamanProjectmodified Mix Design For ConcreteSagarBelum ada peringkat

- IRC-SP-100-2014 Cold MixDokumen7 halamanIRC-SP-100-2014 Cold MixVikas ThakarBelum ada peringkat

- Cico Bond Epo PDFDokumen2 halamanCico Bond Epo PDFPraveenk000Belum ada peringkat

- 2.hydroseeding by - BhoomiDokumen1 halaman2.hydroseeding by - BhoomiShivendra KumarBelum ada peringkat

- MoRTH Circular Value Engineering 22.02.2023 PDFDokumen2 halamanMoRTH Circular Value Engineering 22.02.2023 PDFHimanshu PatelBelum ada peringkat

- P5 - Rate Analysis - R3Dokumen169 halamanP5 - Rate Analysis - R3santosh yevvariBelum ada peringkat

- FixoblockDokumen2 halamanFixoblockRohan BagadiyaBelum ada peringkat

- Vista CatalogueDokumen10 halamanVista CataloguelaukuneBelum ada peringkat

- MTC For ThermocolDokumen2 halamanMTC For ThermocolhariprasadBelum ada peringkat

- TRK-CED-PL-CF05a, Plot Demarcation Application FormDokumen3 halamanTRK-CED-PL-CF05a, Plot Demarcation Application Formdubai eyeBelum ada peringkat

- Concord - July10Dokumen56 halamanConcord - July10iyappanthiagarajanBelum ada peringkat

- Marble Chips in ConcreteDokumen6 halamanMarble Chips in ConcreteMidhun JosephBelum ada peringkat

- Trucare-Wallputty (Exterior & Interior)Dokumen2 halamanTrucare-Wallputty (Exterior & Interior)Kishore Nayak kBelum ada peringkat

- 1.0 Technical Specification Structure180215Dokumen179 halaman1.0 Technical Specification Structure180215Shantanu SinghBelum ada peringkat

- Formwork Stripping TimeDokumen1 halamanFormwork Stripping TimeShimfeBelum ada peringkat

- Checklist For Weathering Course - Brick JellyDokumen1 halamanChecklist For Weathering Course - Brick JellyAarnav SinghBelum ada peringkat

- Xpert Cleanup: No. of Tank Underground/Overhead Tank Capacity Qty. PriceDokumen2 halamanXpert Cleanup: No. of Tank Underground/Overhead Tank Capacity Qty. PriceNacon WirelessBelum ada peringkat

- Material Particulars Unit Quantity Rate AmountDokumen4 halamanMaterial Particulars Unit Quantity Rate Amountsam_bhopBelum ada peringkat

- Analysis Book-2012Dokumen4.514 halamanAnalysis Book-2012Muhammad Danish KhanBelum ada peringkat

- Sikadur®-30 LP - PDS - 2014 GCCDokumen4 halamanSikadur®-30 LP - PDS - 2014 GCCameerBelum ada peringkat

- 03 SC-Clearance CertificateDokumen1 halaman03 SC-Clearance CertificateKannan GnanaprakasamBelum ada peringkat

- K102-2 - Final Account - BOQ - Reshaun Plumbing PDFDokumen4 halamanK102-2 - Final Account - BOQ - Reshaun Plumbing PDFSharon FarmerBelum ada peringkat

- BSR 2010Dokumen89 halamanBSR 2010B Ravindu Kasudul Cooray100% (2)

- Rate Analysis - Khulna - Barisal - GopalganjDokumen280 halamanRate Analysis - Khulna - Barisal - Gopalganjmd mohiuddinBelum ada peringkat

- Basf Masterflow 980 TdsDokumen4 halamanBasf Masterflow 980 Tdschopdekar1969_890124Belum ada peringkat

- Masterflow 980 TdsDokumen4 halamanMasterflow 980 Tdszhangjinlin132Belum ada peringkat

- Grout 100Dokumen5 halamanGrout 100salma karimahBelum ada peringkat

- Masterflow 980 Tds PDFDokumen4 halamanMasterflow 980 Tds PDFAdamo Absalome MulocheBelum ada peringkat

- TDS DC High Grout 210Dokumen4 halamanTDS DC High Grout 2104919404Belum ada peringkat

- File Number:EWB2/8/2020-LSGD-Part (1) Subject: LSGD - CMLRRP - District Level Technical Committee Honorarium and Guidelines Approval - RegDokumen1 halamanFile Number:EWB2/8/2020-LSGD-Part (1) Subject: LSGD - CMLRRP - District Level Technical Committee Honorarium and Guidelines Approval - RegAnwar HussainBelum ada peringkat

- Cera DampproofDokumen2 halamanCera DampproofAnwar HussainBelum ada peringkat

- ICI Update E Bulletin Jan Mar 2016 FinalDokumen35 halamanICI Update E Bulletin Jan Mar 2016 FinalAnwar HussainBelum ada peringkat

- GO (P) No 95-2017-Fin Dated 25-07-2017Dokumen10 halamanGO (P) No 95-2017-Fin Dated 25-07-2017Anwar Hussain100% (1)

- TrussDokumen1 halamanTrussAnwar HussainBelum ada peringkat

- Structural LW ConcreteDokumen24 halamanStructural LW ConcreteAnwar HussainBelum ada peringkat

- Association of Engineers Hand BookDokumen178 halamanAssociation of Engineers Hand BookAnwar HussainBelum ada peringkat

- Association of Engineers Membership ApplicationDokumen1 halamanAssociation of Engineers Membership ApplicationAnwar HussainBelum ada peringkat

- Ferrocement and Its Application To ConstructionDokumen5 halamanFerrocement and Its Application To ConstructionAnwar HussainBelum ada peringkat

- Re13 Eng WebDokumen68 halamanRe13 Eng WebBenjamin PeterBelum ada peringkat

- Electrocatalysis INREP Summer SchoolDokumen34 halamanElectrocatalysis INREP Summer SchoolEttystella Gonzalez PerezBelum ada peringkat

- Sae J122-2017Dokumen12 halamanSae J122-2017phan hoai nam PhanBelum ada peringkat

- Typical Roadway SectionDokumen1 halamanTypical Roadway SectionCarmela Ayessa PiguerraBelum ada peringkat

- Mcqs On HeatDokumen13 halamanMcqs On HeatParshantKumarBajajBelum ada peringkat

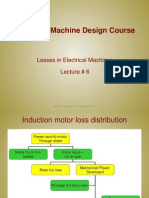

- Lecture6 - Losses in Electric MachinesDokumen24 halamanLecture6 - Losses in Electric Machinesthulasi_krishnaBelum ada peringkat

- Phase Rule Class 2ND Sem NotesDokumen6 halamanPhase Rule Class 2ND Sem NotesAmartya PraharajBelum ada peringkat

- Comparative Study On Direct Shear Behavior of Manufactured and Recycled Shredded Tyre Steel Fiber Reinforced Self-Consolidating ConcreteDokumen9 halamanComparative Study On Direct Shear Behavior of Manufactured and Recycled Shredded Tyre Steel Fiber Reinforced Self-Consolidating ConcreteDiego SukBelum ada peringkat

- En 13555 ReportDokumen16 halamanEn 13555 ReportTONBelum ada peringkat

- Design and Analysis of A Tapered Composite Leaf Spring K. Diwakar, N. Bhaskar, A. Surendra, Y. Uday Kumar & C. Srikar RaoDokumen11 halamanDesign and Analysis of A Tapered Composite Leaf Spring K. Diwakar, N. Bhaskar, A. Surendra, Y. Uday Kumar & C. Srikar RaoRôpíp PhanBelum ada peringkat

- Jis B 2291-1994Dokumen9 halamanJis B 2291-1994Ilka RaffaelliBelum ada peringkat

- 496 GDJGGJGFDokumen2 halaman496 GDJGGJGFRaluca FarcasBelum ada peringkat

- ETTV CalculationDokumen8 halamanETTV Calculationmeeng2014Belum ada peringkat

- Cupola Malleable Iron: Standard Specification ForDokumen4 halamanCupola Malleable Iron: Standard Specification ForHenriqueBelum ada peringkat

- Francisco Oringo, Sr. Elementary School: Cognitive DomainDokumen2 halamanFrancisco Oringo, Sr. Elementary School: Cognitive DomainPrecilla HalagoBelum ada peringkat

- Solutions For Heat Transfer Quiz-II: D. Height of The CylinderDokumen2 halamanSolutions For Heat Transfer Quiz-II: D. Height of The CylindermkvemulaBelum ada peringkat

- C0051-11 Standard Terminology Relating To Lime and Limestone (As Used by The IndustryDokumen5 halamanC0051-11 Standard Terminology Relating To Lime and Limestone (As Used by The IndustryAnonymous YwFJrk0yCBelum ada peringkat

- Heat, The Mechanical UniverseDokumen2 halamanHeat, The Mechanical UniversealadinsaneBelum ada peringkat

- Binary Phase DiagramsDokumen60 halamanBinary Phase DiagramsmaryzeenBelum ada peringkat

- KKS CodesDokumen39 halamanKKS Codeshamza shahzad100% (1)

- Practical Organic ChemistryDokumen368 halamanPractical Organic Chemistrycoincoin1Belum ada peringkat

- FlowMaster 07 Engineering ReferenceDokumen4 halamanFlowMaster 07 Engineering Referencejoseluis789Belum ada peringkat

- Paints and Varnishes - General Tests Methods - Vol 1.1 - IndexDokumen5 halamanPaints and Varnishes - General Tests Methods - Vol 1.1 - IndexGilberto ManhattanBelum ada peringkat

- Thermometry PDFDokumen49 halamanThermometry PDFYe YeoBelum ada peringkat

- Subjective Question SettlementDokumen6 halamanSubjective Question SettlementAden SitaraBelum ada peringkat

- AED Design Requirements:: Breaker and Conductor SizingDokumen4 halamanAED Design Requirements:: Breaker and Conductor SizingRicky Respondo TindocBelum ada peringkat

- BecherDokumen7 halamanBechervalholBelum ada peringkat

- 334 1982 PDFDokumen7 halaman334 1982 PDFतिप्लोकाची तिरुनचिपल्ली केरकेट्टाBelum ada peringkat

- MSDS For P19Dokumen3 halamanMSDS For P19Carlos Albán SalazarBelum ada peringkat

- (Tom Schanz) Experimental Unsaturated Soil MechaniDokumen490 halaman(Tom Schanz) Experimental Unsaturated Soil MechaniChristopher CarrilloBelum ada peringkat

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceDari EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceBelum ada peringkat

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Dari EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Belum ada peringkat

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDari EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionPenilaian: 4.5 dari 5 bintang4.5/5 (543)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDari EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tPenilaian: 4.5 dari 5 bintang4.5/5 (27)

- A Mind at Play: How Claude Shannon Invented the Information AgeDari EverandA Mind at Play: How Claude Shannon Invented the Information AgePenilaian: 4 dari 5 bintang4/5 (53)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDari EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgePenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Power System Control and ProtectionDari EverandPower System Control and ProtectionB. Don RussellPenilaian: 4 dari 5 bintang4/5 (11)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDari Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersPenilaian: 5 dari 5 bintang5/5 (1)

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Dari EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Penilaian: 4 dari 5 bintang4/5 (2)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDari EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesPenilaian: 5 dari 5 bintang5/5 (1)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDari EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDari EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonPenilaian: 5 dari 5 bintang5/5 (2)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDari EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Digital Transformation: Survive and Thrive in an Era of Mass ExtinctionDari EverandDigital Transformation: Survive and Thrive in an Era of Mass ExtinctionPenilaian: 4.5 dari 5 bintang4.5/5 (9)

- Schaum's Outline of Basic Electricity, Second EditionDari EverandSchaum's Outline of Basic Electricity, Second EditionPenilaian: 5 dari 5 bintang5/5 (14)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsDari EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsBelum ada peringkat

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDari EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionPenilaian: 4 dari 5 bintang4/5 (331)

- Teach Yourself Electricity and Electronics, 6th EditionDari EverandTeach Yourself Electricity and Electronics, 6th EditionPenilaian: 3.5 dari 5 bintang3.5/5 (15)

- Build Your Own Electronics WorkshopDari EverandBuild Your Own Electronics WorkshopPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- DIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesDari EverandDIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignDari EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignBelum ada peringkat

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldDari EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldPenilaian: 4 dari 5 bintang4/5 (87)