Vigas de Concreto - Astm C78

Diunggah oleh

Fer QuijanoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Vigas de Concreto - Astm C78

Diunggah oleh

Fer QuijanoHak Cipta:

Format Tersedia

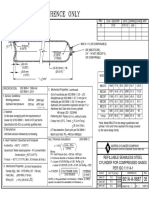

VELOCIDADES DE CARCA APROXIMADAS SEGÚN NORMAS ASTM PARA COMPRESION AXIAL DE

ESPECIMENES DE CONCRETO Y SUELO CEMENTO

CILINDRO DE CONCRETO - ASTM C39

7.5 Rate of Loading—Apply the load continuously and without shock.

7.5.1 The load shall be applied at a rate of movement (platen to crosshead measurement) corresponding to a

stress rate on the specimen of 0.25 ± 0.05 MPa/s [35 ± 7 psi/s] (See Note 11). The designated rate of

movement shall be maintained at least during the latter half of the anticipated loading phase.

CILINDRO CILINDRO CILINDRO CILINDRO CILINDRO CILINDRO

DE DE DE DE DE DE

ASTM C 39 ф = 15.0 cm ф = 15.1 cm ф = 15.2 cm ф = 15.3 cm ф = 15.4 cm ф = 15.5 cm

RAZON DE RAZON DE RAZON DE RAZON DE RAZON DE RAZON DE RAZON DE RAZON DE RAZON DE

CARGA CARGA CARGA CARGA CARGA CARGA CARGA CARGA CARGA

(PSI/S) (KG/CM2/S) (KG/CM2/MIN) (KG/MIN) (KG/MIN) (KG/MIN) (KG/MIN) (KG/MIN) (KG/MIN)

28 1.97 118.2 20887.7 21167.1 21448.4 21731.5 22016.5 22303.4

35 2.46 147.6 26083.1 26432.0 26783.3 27136.8 27492.7 27850.9

42 2.95 177.0 31278.5 31696.9 32118.1 32542.1 32968.9 33398.5

VIGAS DE CONCRETO - ASTM C78

6.3 Load the specimen continuously and without shock. The load shall be applied at a constant rate to the

breaking point. Apply the load at a rate that constantly increases the máximum stress on the tension face

between 0.9 and 1.2 MPa/min [125 and 175 psi/min] until rupture occurs. The loading rate is calculated using

the following equation:

r = Sbd2

L

where:

r = loading rate, N/min [lb/min],

S = rate of increase in maximum stress on the tension face,

MPa/min [psi/min],

b = average width of the specimen as oriented for testing,

mm [in.],

d = average depth of the specimen as oriented for testing,

mm [in.], and

L = span length, mm [in.]

PERALTE PERALTE PERALTE PERALTE

ASTM C 78 15.0 cm 15.1 cm 15.2 cm 15.3 cm

RAZON DE RAZON DE 𝑆 ∗ 𝑏 ∗ 𝑑2

CARGA CARGA 𝑟=

(KG/CM2/MIN) 𝐿

(PSI/MIN)

125 8.79 659.25 672.52 685.97 699.60

150 10.55 791.25 807.18 823.32 839.68

175 12.3 922.5 941.07 959.89 978.96

ESPECIMENES DE SUELO CEMENTO - ASTM D1633

7.2 Apply the load continuously and without shock. A screw power testing machine, with the moving

head operating at approximately 0.05 in. (1 mm)/min when the machine is running idle, may be used.

With hydraulic machines, adjust the loading to a constant rate within the limits of 20 ± 10 psi (140 ± 70

kPa)/s, depending upon the strength of the specimen. Record the total load at failure of the test specimen

to the nearest 10 lbf (40 N).

CILINDRO DE CILINDRO DE CILINDRO DE

ASTM D1633 ф = 10.0 cm ф = 10.1 cm ф = 10.2 cm

RAZON DE RAZON DE RAZON DE RAZON DE RAZON DE

RAZON DE

CARGA CARGA CARGA CARGA CARGA

CARGA (PSI/S)

(KG/CM2/S) (KG/CM2/MIN) (KG/MIN) (KG/MIN) (KG/MIN)

10 0.7 42 3298.7 3365.0 3431.9

20 1.41 84.6 6644.5 6778.0 6912.9

30 2.11 126.6 9943.1 10143.0 10344.8

ESPECIMENES DE CUBOS DE MORTERO – ASTM C109

10.6.3 Apply the load to specimen faces that were in contact with the true plane surfaces of the mold. Carefully

place the specimen in the testing machine below the center of the upper bearing block. Prior to the testing of

each cube, it shall be ascertained that the spherically seated block is free to tilt. Use no cushioning or bedding

materials. Bring the spherically seated block into uniform contact with the surface of the specimen. Apply the

load rate at a relative rate of movement between the upper and lower platens corresponding to a loading on the

specimen with the range of 200 to 400 lbs/s [900 to 1800 N/s]. Obtain this designated rate of movement of the

platen during the first half of the anticipated maximum load and make no adjustment in the rate of movement

of the platen in the latter half of the loading especially while the cube is yielding before failure.

ASTM C

109

RAZON DE RAZON DE RAZON DE

CARGA CARGA CARGA

(LBS/S) (KG/S) (KG/MIN)

200 90.72 5443.2

300 136.08 8164.8

400 181.44 10886.4

ESPECIMENES DE MRBC – ASTM D4832

11.2 Rate of Loading —Apply the load continuously and without shock. Apply the load at a constant rate such

that the cylinder will fail in not less than 2 min. Make no adjustment in the controls of the testing machine while

a specimen is yielding rapidly immediately before failure.

11.3 Apply the load until the specimen fails, and record the maximum load carried by the specimen during the

test. For about one out of every ten cylinders, continue the loading until the cylinder breaks enough to examine

the appearance of the interior of the specimen. Note any apparent segregation, lenses, pockets, and the like in

the specimen.

Anda mungkin juga menyukai

- REPORT ON VERTICAL PILE LOAD TESTDokumen8 halamanREPORT ON VERTICAL PILE LOAD TESTshaaz v s mBelum ada peringkat

- Initial Load Test ReportDokumen6 halamanInitial Load Test ReportRAHUL RAVINDRANBelum ada peringkat

- AASHTO Vs ASTMDokumen2 halamanAASHTO Vs ASTMFurqona A'yuninBelum ada peringkat

- 3233F390 TabelaDokumen1 halaman3233F390 TabelaOFFICE DANACBelum ada peringkat

- Compressive Strength TestDokumen8 halamanCompressive Strength TestBeaver CaraBelum ada peringkat

- Compressive Strength TestDokumen21 halamanCompressive Strength TestJommel GonzalesBelum ada peringkat

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Dokumen1 halamanRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhBelum ada peringkat

- Series: Full-Automatic Load-Cell System Rockwell Type Hardness TesterDokumen4 halamanSeries: Full-Automatic Load-Cell System Rockwell Type Hardness Testerchan channsreyrathBelum ada peringkat

- CT E BookDokumen107 halamanCT E BookKshitiz RawatBelum ada peringkat

- Los Angeles Abrasion Test AASHTO 96Dokumen4 halamanLos Angeles Abrasion Test AASHTO 96Lava HimawanBelum ada peringkat

- LOAD-CELL SYSTEM ROCKWELL HARDNESS TESTER <40Dokumen4 halamanLOAD-CELL SYSTEM ROCKWELL HARDNESS TESTER <40chan channsreyrathBelum ada peringkat

- Specific Gravity & Water Absorption Test (I S 2386 Iii/63)Dokumen11 halamanSpecific Gravity & Water Absorption Test (I S 2386 Iii/63)End EndBelum ada peringkat

- Mix Design ComplainceDokumen7 halamanMix Design Complainceraja qammar100% (2)

- 3230F250 DATA CatalogDokumen1 halaman3230F250 DATA CatalogLIONN TESTE2021Belum ada peringkat

- DSR Lab Note 7 DSR BBR and DTTDokumen8 halamanDSR Lab Note 7 DSR BBR and DTTEr. Piyush Kumar SinghBelum ada peringkat

- Concrete Canvas GCCM Specification19Dokumen6 halamanConcrete Canvas GCCM Specification19MeowMeowBelum ada peringkat

- ncs0111513 16Dokumen118 halamanncs0111513 16maximus2297Belum ada peringkat

- EN 341:2011 EN 12841:2006: Rope DiameterDokumen56 halamanEN 341:2011 EN 12841:2006: Rope Diameterfranzbecker100% (1)

- Lab Note 7 DSR BBR and DTTDokumen12 halamanLab Note 7 DSR BBR and DTTAKINMADE OLUWATOSINBelum ada peringkat

- Friction and wear study of Al, Brass and MSDokumen8 halamanFriction and wear study of Al, Brass and MSHrushikesh KhairnarBelum ada peringkat

- Design and Analysis of Continuous Stirred Tank Reactor (CSTRDokumen9 halamanDesign and Analysis of Continuous Stirred Tank Reactor (CSTRKushal KayalBelum ada peringkat

- D 2209 - 95 - RdiymdktukveDokumen4 halamanD 2209 - 95 - RdiymdktukvePabasara HerathBelum ada peringkat

- SAGDesign Mill Throughput Calculation ToolDokumen10 halamanSAGDesign Mill Throughput Calculation ToolBùi Hắc HảiBelum ada peringkat

- Measuring Pavement Skid Resistance with the British Pendulum MethodDokumen6 halamanMeasuring Pavement Skid Resistance with the British Pendulum MethodRhesty Putri ArishantyBelum ada peringkat

- Pin On Disc DryDokumen8 halamanPin On Disc DryHrushikesh KhairnarBelum ada peringkat

- AC - BC (Trial Compaction)Dokumen14 halamanAC - BC (Trial Compaction)anna damayantiBelum ada peringkat

- Concrete_UBC - 1778 WESBROOK CRES _Site ERA ENTERPRISE LTD _Site_20887_7_20170331Dokumen1 halamanConcrete_UBC - 1778 WESBROOK CRES _Site ERA ENTERPRISE LTD _Site_20887_7_20170331hbduzitBelum ada peringkat

- Material Testing LabDokumen7 halamanMaterial Testing Labjodoho3441Belum ada peringkat

- Fig. 1: Lab Vane Shear ApparatusDokumen2 halamanFig. 1: Lab Vane Shear ApparatusKishanBelum ada peringkat

- Everything you need to know about electric winchesDokumen20 halamanEverything you need to know about electric winchesthiricycBelum ada peringkat

- How To Use This Severity Chart: Example Fan 625 Um (25 Mils)Dokumen2 halamanHow To Use This Severity Chart: Example Fan 625 Um (25 Mils)dk4monjureBelum ada peringkat

- GRI-GM 28 Specification: Scrim Reinforced Chlorosulfonated Polyethylene (CSPE-R) GeomembranesDokumen27 halamanGRI-GM 28 Specification: Scrim Reinforced Chlorosulfonated Polyethylene (CSPE-R) GeomembranesГригорий ЛевашовBelum ada peringkat

- Oel TransDokumen19 halamanOel Transrazaain4305302Belum ada peringkat

- Rashmiranjan Si-716CE3008 (Group-7) TensileDokumen9 halamanRashmiranjan Si-716CE3008 (Group-7) TensileRASHMIRANJAN SIBelum ada peringkat

- Hgns / Aps / CNT / RST: (Porosity Tools)Dokumen13 halamanHgns / Aps / CNT / RST: (Porosity Tools)Wualdir Martin Vivas ChungaBelum ada peringkat

- DC 9/80 Performance Manual Chapter 05 - Flexible Takeoff Thrust ProcedureDokumen13 halamanDC 9/80 Performance Manual Chapter 05 - Flexible Takeoff Thrust ProcedurePapaFoxBelum ada peringkat

- Marshall Method Mix DesignDokumen26 halamanMarshall Method Mix DesignChing TrangiaBelum ada peringkat

- CC - GCCM Data SheetDokumen2 halamanCC - GCCM Data SheetLarizza TesicoBelum ada peringkat

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDokumen1 halamanCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiBelum ada peringkat

- S04 - Basic Parameters and Design of Cast in Situ Box GirderDokumen71 halamanS04 - Basic Parameters and Design of Cast in Situ Box GirderSMR STPBelum ada peringkat

- Abutment Design ExampleDokumen56 halamanAbutment Design Examplezrilek1Belum ada peringkat

- Cleanphase Well Test Separator: Reduce Cleanup Time, Improve Safety, and Minimize Environmental RiskDokumen2 halamanCleanphase Well Test Separator: Reduce Cleanup Time, Improve Safety, and Minimize Environmental RiskMohammed. LouyBelum ada peringkat

- Machine Elements 3-Spur Gears 3Dokumen26 halamanMachine Elements 3-Spur Gears 3Prayogi FajarBelum ada peringkat

- Geocomposite Tn300 English 170220171841Dokumen1 halamanGeocomposite Tn300 English 170220171841AminulIslamBelum ada peringkat

- 5 Mechanical Properties of Local Concrete by DR Ray Su PDFDokumen47 halaman5 Mechanical Properties of Local Concrete by DR Ray Su PDFNandeesh M PanchapeetBelum ada peringkat

- Stainless Steel (SUS304 T x38W) Bellow: Siam Steel Works Co., LTDDokumen10 halamanStainless Steel (SUS304 T x38W) Bellow: Siam Steel Works Co., LTDสราวุฒิ เอี๊ยบเจริญBelum ada peringkat

- Tech Data Sheet Smooth GeomembraneDokumen1 halamanTech Data Sheet Smooth GeomembraneNasasira DerrickBelum ada peringkat

- PVC Geomembrane Material SpecificationDokumen9 halamanPVC Geomembrane Material SpecificationEduardo Rojas ArayaBelum ada peringkat

- 53e PDFDokumen12 halaman53e PDFarthymanicBelum ada peringkat

- FSA standard test method for gasket loading constantsDokumen16 halamanFSA standard test method for gasket loading constantsmansurudinBelum ada peringkat

- Cement Testing ReportsDokumen29 halamanCement Testing ReportstejakandulaBelum ada peringkat

- All Sheets ConcreteDokumen72 halamanAll Sheets ConcreteSulaiman Mohsin AbdulAziz100% (1)

- GRI-GM30 Specification Coated Tape Polymeric BarriersDokumen28 halamanGRI-GM30 Specification Coated Tape Polymeric BarriersГригорий ЛевашовBelum ada peringkat

- Mooring Winch Tests1Dokumen7 halamanMooring Winch Tests1RachitBelum ada peringkat

- 6.75in Hemidril MotorDokumen2 halaman6.75in Hemidril Motorerdal aydinBelum ada peringkat

- KES T-L461A 1995 Test Method of Lnteram Mat For AutomobileDokumen8 halamanKES T-L461A 1995 Test Method of Lnteram Mat For Automobiles_omeone4usBelum ada peringkat

- 10 MM Gradation Test PDFDokumen4 halaman10 MM Gradation Test PDFsyed sulemanBelum ada peringkat

- BridgeGirdersRegionalSpecsAB MB SK TG 2013 04 EDokumen23 halamanBridgeGirdersRegionalSpecsAB MB SK TG 2013 04 Esilvereyes18Belum ada peringkat

- BTS3900 GSM Site Maintenance Terminal User Guide - (V300R008 - 06)Dokumen160 halamanBTS3900 GSM Site Maintenance Terminal User Guide - (V300R008 - 06)engrvinzzBelum ada peringkat

- Volvo FMX: Product Guide - Euro 3-5Dokumen24 halamanVolvo FMX: Product Guide - Euro 3-5HiT Dayat100% (2)

- Summit Archive 1569863860Dokumen50 halamanSummit Archive 1569863860mangelchavezBelum ada peringkat

- FE Exam Formatted ProblemsDokumen12 halamanFE Exam Formatted ProblemsCarlo Galicia100% (1)

- Challenges Faced by PET ConvertorDokumen35 halamanChallenges Faced by PET ConvertorRakeshjha75Belum ada peringkat

- IC EngineDokumen2 halamanIC EnginePrince SethiBelum ada peringkat

- 11 - Desain, Prototipe Dan KonstruksiDokumen46 halaman11 - Desain, Prototipe Dan KonstruksiUtari Via VivianBelum ada peringkat

- Process Capability AnalysisDokumen37 halamanProcess Capability Analysisabishank09100% (1)

- Terumo BCT Trima Accel Blood Collection System - Service ManualDokumen340 halamanTerumo BCT Trima Accel Blood Collection System - Service Manualmorton1472Belum ada peringkat

- Quiz 12Dokumen3 halamanQuiz 12mwende faiyuuBelum ada peringkat

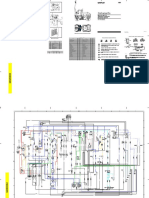

- Electric Schematic CB113 114 QENR2003 PDFDokumen2 halamanElectric Schematic CB113 114 QENR2003 PDFHipac TapicuBelum ada peringkat

- Planning of Electrical NetworksDokumen32 halamanPlanning of Electrical NetworksSerge RINAUDOBelum ada peringkat

- IES 2012 Exam Civil Engineering Paper II Solved With Answer KeyDokumen21 halamanIES 2012 Exam Civil Engineering Paper II Solved With Answer KeyPratik Nayak0% (2)

- VAS5054ADokumen3 halamanVAS5054AKarim ElmahrokyBelum ada peringkat

- Galvanic CorrosionDokumen35 halamanGalvanic CorrosionSyarief NahdiBelum ada peringkat

- Verdi TCL TrainingDokumen24 halamanVerdi TCL TrainingPratyush ShrotriyaBelum ada peringkat

- ISA SymbolsDokumen2 halamanISA Symbolsmahesh009Belum ada peringkat

- A320-25-1BPK R01 Dt. 25.05.21Dokumen39 halamanA320-25-1BPK R01 Dt. 25.05.21Pradeep K sBelum ada peringkat

- Management GurusDokumen44 halamanManagement GurusRouben ParmanumBelum ada peringkat

- Revue Des Études Juives. 1880. Volumes 71-73.Dokumen706 halamanRevue Des Études Juives. 1880. Volumes 71-73.Patrologia Latina, Graeca et OrientalisBelum ada peringkat

- D Screenplay DialoguesDokumen75 halamanD Screenplay DialoguesReza GhalibBelum ada peringkat

- Stampingjournal20130102 DLDokumen36 halamanStampingjournal20130102 DLWaqar MansoorBelum ada peringkat

- Banner Printing Set UpDokumen21 halamanBanner Printing Set UpAsanka ChandimaBelum ada peringkat

- Inventory Items DestinyDokumen11 halamanInventory Items DestinyManish NautiyalBelum ada peringkat

- Process VariableDokumen51 halamanProcess VariableLance HernandezBelum ada peringkat

- LV SWBDQualityInspectionGuideDokumen72 halamanLV SWBDQualityInspectionGuiderajap2737Belum ada peringkat

- Senior Aerospace Defense Engineer in Orlando FL Resume Ken WebbDokumen3 halamanSenior Aerospace Defense Engineer in Orlando FL Resume Ken WebbKenWebbBelum ada peringkat

- 6338d1285569848 Task Alfa 300ci SB Toner PDFDokumen3 halaman6338d1285569848 Task Alfa 300ci SB Toner PDFjosealcudiacastellas100% (1)

- Instrument and Control Requirements for Packaged EquipmentDokumen20 halamanInstrument and Control Requirements for Packaged EquipmentJithuRajBelum ada peringkat

- N248J ManualDokumen13 halamanN248J ManualChit KhunBelum ada peringkat