4650 and 4850 Section 30

Diunggah oleh

josephmw0308Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

4650 and 4850 Section 30

Diunggah oleh

josephmw0308Hak Cipta:

Format Tersedia

Section

FUEL AND AIR SYSTEMS REPAI

CONTENTS

REPAIR INFORMATION GROUP 10 - ACQUIRE ACCESS TO DIESEL FUEL

SVSTEM

For complete repair information on the 6466 John

Deere engine, component technical manual CTM-1 is About This Group 90-10-01

also required. Bleed Fuel System g0-i0-02

Remove Fuel Tank 90-10-02

Use the component manual in conjunction with this .

Install Fuel Tank 90-10-04

machine manual.

GROUP 15 . SPEED CONTROL LINKAGE

See the component manual for instructions on the

engine, fuel system, and engine accessory items: Remove and Install Control Linkage ... .. g0-1S-01

Theory of operation Remove Foot Throttle Linkage g0-1S-02

Diagnostic and testing procedures Linkage

Install Foot Throttle g0-1S-09

Disassembly

lnspection

Repair

Assembly

See this machine manual for removal and installation

instructions.

GROUP 05 . ACQUIRE ACCESS TO AIR INTAKE

SYSTEM

About This Group 30-05-01

Removing Air Cleaner Elements 30-05-01

Cleaning Element 30-05-02

Washing Element 30-05-03

Inspecting Element 30-05-03

Service Ether Starting Aid . 30-05-04

u30;030c0N Ax4 180q87

Litho in U.S.A. TM-1354

Litho in U.S.A.

Groud 05

ACQUIRE ACCESS TO AIR INTAKE SYS

Acquire Access to Air lntake System

Remove secondary element (A) ONLY if

It is to be replaced. Do not attempt to

clean secondary element.

lf secondary element ls replaced, install

new element lmmediately to prevent dust

from entering alr intake system.

APr;RW6825 Uo};SEXI 13 100582

ELEMENT

sides of element gently (A) to loosen dirt. Do not tap

against a hard surface.

2.( a John Deere AR62g77 Dry Element Cleaner Gun

(B), element with compressed air. Hold nozzle next

to ir surface, and move up and down pleats.

ANT: Do not direct air against outslde of ele-

ment, as it mlght force dlrt through to

inside.

step 1 and 2 to remove additional dirt.

element before reinstalling.

30-05-02 TM-1354 (Sep-85)

lu8;3o0501 u0965

Acquire Access to Air lntake System

Acquire Access to Air lntake System

VICE ETHER STARTING AID

CAUTION: Starting fluid is highly flammable. Do

not use near fire, sparks, or flames. Read the

cautionary information on the container. Protect

container against damage.

I ANT: To avoid drawing dust into engine, always

keep a starting fluid can in position.

1. safety cap and plastic spray nozzle from new

can.

2. LQosen canister to remove old can (A).

3. lristall new can and tighten canister.

4. Tpst starting aid as instructed in Accessory Circuits,

Section 240,TM-1259.

IMPQRTANT: To avoid drawing dust into engine, always

keep a starting fluid can in position, or

clean bottom of canister and install bot-

tom side up (B).

AD8;RW1027 8,RWr027 9 U30;030005 BX4 090784

starting aid does not operate properly, disconnect

line (A) and remove spray nozzle (B) from manifold.

6. 1 compressed air to blow nozzle clean. Reinstall and

test proper operation. Do not use sealing compound on

joints.

ANT: Be sure nozzle is secure in adapter. lf

nozzle should come loose, engine may be

seriously damaged. However, care

should be taken as too much force when

tightening will cause nozzle to break off

just above threads.

AD8;RW7714 U30;030005 CXA 17oba2

Litho lin U.S.A. 30-05-04 TM-1354 (Sep-87)

1u8:300504 180987

Group

ACQUIRE ACCESS TO DIESEL FUEL SY

ABOUT THIS GROUP

This group contains infomation on servicing fuel filters,

bleeding fuel system and removing fuel tank. Refer to

CTM-1, 6466 Engines for information on injection puffip,

nozzles and aneroid.

u30;030015 Ax4

BLEED THE FUEL SYSTEM

GAUTION: Escaplng dlesel tuel under pressure

can have sufflcient force to penetrate the skln,

causing serlous personal Infury. Before discon.

necting lines be sure to relleve all pressure.

Before apptying pressure to the system, be sure

all connections are ilght and that llnes, plpes

and hosee are not damaged. Fuel escaplngfrom

a very small hole can be almost Invlslble. Uee a

plece of cardboard or wood, rather than your

hands, to search for suspected leaks.

lf injured by eecaplng fuel, see a doctor at once.

Serlous infectlon or reacllon can develop lf

proper medlcal treatment ls not admlnlstered

lmmedlately.

Whenever the fuel system has been opened up for service

(lines disconnected or filters removed), it will be necessary

to bleed air from the system.

A84;X98U Sr1r0408 AC

1. Loosen the bleed ptug (A).

AE4;RGr400 Stt;0408 AD

Litho in U.S.A. 30-10-01 TM-l354

Acquire Access to Diesel Fuel System

2.L rscrew hand primer knurled knob (A) on fuel supply

pun >. Loosen knob until it can be pulled by hand.

3.( perate the hand primer until a smooth flow of fuel comes

out rf the filter plug hole.

4.S multaneously stroke the hand primmer down and close

the rcrt plug. This prevents air from entering the system.

Tigt :en plug securely.

5.t rck hand primer in position.

NO 'E: lf the engine will not start, it may be necessary to

loosen the fuel pipes at the iniection nozles to bleed

air from system. Put the hand throttle in slow idle

position. Push the engine fuel shut-off control knob

all the way in. Turn the engine with the starter until

fuel without air, flows from the loose fuel pipe

connections. Tighten the connections.

Ag: SuffG AF l0r2&

RI /E FUEL TANK

1. ve hood and grille screens.

2. fuel from tank and disconnect tuel lin9.

3. rnect fuel sender (A).

AD9;RW6,16 U30;0r0015 EX4 170682

in U.S.A. 30-10-02 TM-1354 (Sep-85)

1U8;r01002 u0985

Acquire Access to Diesel Fuel System

10. Disconnect left-side horn bracket (A) and rear fuel tank

mounting cap screws (8, one each side).

Litho in U.S.A. 30-10-03

Acquire Access to Diesel Fuel System

11. ?move two front tank attaching cap screws (A) from

und ride of tractor.

': Photo is

NO as viewed from under side of tractar.

12. rstall a suitable lifting fixture to top of tank using nut

wel rd to tank.

13. rarefully lift tank from tractor using chain hoisl

14. ake care to prevent damaging hydraulic oil lines (A)

wht lifting tank.

AD9;RW5794 U30;0300I5 JX4 1706A2

lNr TALL FUEL TANK

1. rstall fuel tank in reverse of removal.

2. fter tank is installed check radiator and fan shroud

alig tment as instructed in Remove/lnstall Cooling System,

Se jon 20.

u30;030015 KX4 170682

in U.S.A. 30-10-04 TM-1354 (Sep-85)

1U8:301004 170985

----

Group 15

CONTROL LINKA E

REMOVE AND INSTALL HAND THROTTLE

LINKAGE

1. Remove cover from side of console.

2. Disconnect control arm (A).

3. Remove spring-loaded attaching cap screw and remove

lever assembly.

4. Inspect condition of friction disks, and replace as

necessary.

5. Install in reverse of removal.

AEURW6250 U30;030025 AX4

6, Remove cotter pin and washer (A) from linkage under

floor of cab.

7. Remove cap screw and clamp (B).

8. Remove right side rear side shield and disconnect cable

from turnbuckle just ahead of cab bulkhead.

9. Remove cable and inspect for damage. Replace as

necessary.

AEURW7716 U30;030025 BX4

10. Reassemble and install in reverse of removal.

11. Adjust speed control linkage as instructed in speed

control linkage, Section 230, TM-1259.

Litho in U.S.A. 30-15-01 TM-1354

Control Linkage

FO9T THROTTLE L|NKAGE

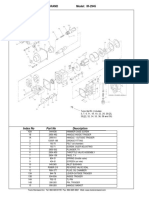

AFVertical Control Rod D-lnner Arm F-Shaft Arm H-Pedal

BFOuter Arm E-Arm Shaft G-Spring l-Fedal Arm

Gl-Rear Control Rod J-Support Bracket

AE1;RW1260 9 U30;030015 DX4 150987

FOOT THROTTLE LINKAGE

1. RBmove the floor mat, floor pane. and foot rest panel.

2. Qisconnect the vertical control rod (A) from outer arm (B).

Rer{ove rear control rod (C). Disconnect the control cable

or rdd from inner arm (D).

remove the speed control arm shaft (E), drive out the

pin securing inner arm to shaft. Drive out spring pin

ing speed shaft arm (F) to shaft. Remove arms from

and pull out shaft. Remove spring (G) to separate arms.

bushings.

foot pedal (H) from the control support by

ing round head bolt on pedal arm (l). Pull out pedal

support bracket (J). Remove two nylon bushings from

U30;030015 EX4 150987

Litho U.S.A. 30-15-02 TM-1354 (Sep-87)

1u8;301502 180987

Control Linkage

INSTALL FOOT THROTTLE LINKAGE

1. Insert shaft (E) into platform support, with end of shaft

having hole farthest from the end facing toward middle of

tractor. Position nylon bushings on shaft so that large

shoulder of bushing will be against the inner and outer arms.

2. Install inner arm (D) on shaft with large shoulder toward

the outside, and secure with spring pin. Install spring (G) on

outer arm (B) and shaft arm (F). Make sure that ends of

spring are in their respective notches.

3. Insert outer arm assembly into position and push shaft

through outer bushing and through the outer arm assembly.

Secure shaft arm to shaft with spring pin.

4. Install bushings in support bracket (J). Insert pedal

through bushings.

5. Position pedalarm (l) on pedal shaft. Fasten arm to pedal

shaft with bolt, flat washer, lock washer and nut.

6. lnstall the rear control rod (C). Yoke-end of rod connects

to bottom hole of inner arm, and is retained with a steel pin,

washer and cotter pin. Front end of rod is secured with a

retaining ring.

7. Connect control cable or rod (leading to turnbuckle) in

the upper hole of arm (D). lnstall cotter pin and washer or

retaining rings.

8. Place end of vertical control rod (A) in middle hole of outer

arm and retain with cotter pin.

9. Check the foot throttle linkage adjustment before com-

pleting the installation. (See TM-19S9, Section 230.)

10. Complete the installation by checking all connections

to see that they are secured, and installing floor panels and

floor mat.

u30;0300r5 FX4 1

TM-1354 (Sep-87)

Anda mungkin juga menyukai

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDari EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Supply Pump RemoveDokumen6 halamanSupply Pump Removeeshopmanual EnamBelum ada peringkat

- Electronic Unit Injector - Remove: Shutdown SIS Previous ScreenDokumen12 halamanElectronic Unit Injector - Remove: Shutdown SIS Previous ScreenOdai AlsaafinBelum ada peringkat

- Fuel Injection Pump - Remove: Shutdown SIS Previous ScreenDokumen7 halamanFuel Injection Pump - Remove: Shutdown SIS Previous ScreenOdai AlsaafinBelum ada peringkat

- Transmission Pressures - Test (SENR9159-10)Dokumen3 halamanTransmission Pressures - Test (SENR9159-10)Anderson Oliveira SilvaBelum ada peringkat

- Caterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U00001-00693)Dokumen28 halamanCaterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U00001-00693)rpoy9396615Belum ada peringkat

- Caterpillar Cat 247 MULTI TERRAIN LOADER (Prefix CML) Service Repair Manual (CML00001 and Up)Dokumen22 halamanCaterpillar Cat 247 MULTI TERRAIN LOADER (Prefix CML) Service Repair Manual (CML00001 and Up)rpoy93966150% (1)

- Group 25 Intake and Exhaust TroubleshootingDokumen10 halamanGroup 25 Intake and Exhaust TroubleshootingUNICARGAS SU, Lda.Belum ada peringkat

- John Deere PowerTech 10.5L Diesel Engines Level 6 Electronic Fuel Systems With Lucas EUIs Service Repair Manual (CTM188)Dokumen17 halamanJohn Deere PowerTech 10.5L Diesel Engines Level 6 Electronic Fuel Systems With Lucas EUIs Service Repair Manual (CTM188)laopaodunBelum ada peringkat

- Fuel Injection Pump - RemoveDokumen4 halamanFuel Injection Pump - RemovechanlinBelum ada peringkat

- 120g - Service ManualDokumen2.569 halaman120g - Service ManualFilipe Da Silva NascimentoBelum ada peringkat

- Ajuste de VentiladorDokumen9 halamanAjuste de VentiladorRobert Canchanya ProcilBelum ada peringkat

- 4650 and 4850 Section 20 PDFDokumen22 halaman4650 and 4850 Section 20 PDFjosephmw0308Belum ada peringkat

- 950H Valvula de LinhaDokumen8 halaman950H Valvula de LinhaAnderson OliveiraBelum ada peringkat

- Lineas Combustible D5GDokumen4 halamanLineas Combustible D5GjulianmatabajoyBelum ada peringkat

- Caterpillar Cat 232 SKID STEER LOADER (Prefix CAB) Service Repair Manual (CAB00001 and Up)Dokumen24 halamanCaterpillar Cat 232 SKID STEER LOADER (Prefix CAB) Service Repair Manual (CAB00001 and Up)rpoy9396615Belum ada peringkat

- SB Exlar Bleed VlaveDokumen5 halamanSB Exlar Bleed VlavemdoBelum ada peringkat

- Caterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00001-00288)Dokumen23 halamanCaterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00001-00288)rpoy9396615Belum ada peringkat

- Caterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BFA) Service Repair Manual (BFA00001 and Up) PDFDokumen22 halamanCaterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BFA) Service Repair Manual (BFA00001 and Up) PDFfkdmma0% (1)

- 3 Flow Control ValveDokumen5 halaman3 Flow Control ValvegwahyudinnBelum ada peringkat

- Caterpillar Cat 235C EXCAVATOR (Prefix 5AF) Service Repair Manual (5AF00001 and Up)Dokumen32 halamanCaterpillar Cat 235C EXCAVATOR (Prefix 5AF) Service Repair Manual (5AF00001 and Up)rpoy9396615Belum ada peringkat

- REHS1037 - Fuel Priming PumpDokumen13 halamanREHS1037 - Fuel Priming Pumpkman548Belum ada peringkat

- C6 Remove Fuel PumpDokumen7 halamanC6 Remove Fuel PumpHan100% (2)

- Accumulator Discharging and Charging ProceduresDokumen25 halamanAccumulator Discharging and Charging Proceduresbenjir shuvoBelum ada peringkat

- Electronic Unit Injector - Remove: C6.6 Industrial EngineDokumen12 halamanElectronic Unit Injector - Remove: C6.6 Industrial EngineBassieBelum ada peringkat

- Caterpillar Cat 235 EXCAVATOR (Prefix 81X) Service Repair Manual (81X00404 and Up)Dokumen22 halamanCaterpillar Cat 235 EXCAVATOR (Prefix 81X) Service Repair Manual (81X00404 and Up)rpoy9396615Belum ada peringkat

- Maytag Triple Lip and Bearing Kit Installation InstructionsDokumen8 halamanMaytag Triple Lip and Bearing Kit Installation InstructionsSamurai Appliance Repair ManBelum ada peringkat

- Installation Notes for Caterpillar D398 Gen Set PackageDokumen6 halamanInstallation Notes for Caterpillar D398 Gen Set PackageFardos OmarBelum ada peringkat

- Inlet and Exhaust Valves - Remove and Install: Shutdown SIS Previous ScreenDokumen5 halamanInlet and Exhaust Valves - Remove and Install: Shutdown SIS Previous ScreenbejoythomasBelum ada peringkat

- Fuel Injection Pump - RemoveDokumen6 halamanFuel Injection Pump - RemoveedwinBelum ada peringkat

- Caterpillar Cat 235 EXCAVATOR (Prefix 83X) Service Repair Manual (83X00444 and Up)Dokumen21 halamanCaterpillar Cat 235 EXCAVATOR (Prefix 83X) Service Repair Manual (83X00444 and Up)rpoy9396615Belum ada peringkat

- C4.4+HP+pump+removal+and+installationDokumen20 halamanC4.4+HP+pump+removal+and+installationDumitrescu emanuel victorBelum ada peringkat

- Lc320dxj Sfe1 LGDokumen8 halamanLc320dxj Sfe1 LGdreamyson1983Belum ada peringkat

- Kysor On/Off Rear Air Fan Drive: Installation - ServiceDokumen12 halamanKysor On/Off Rear Air Fan Drive: Installation - ServiceeloyabnerBelum ada peringkat

- Caterpillar Cat 235 EXCAVATOR (Prefix 64R) Service Repair Manual (64R00596-01257)Dokumen24 halamanCaterpillar Cat 235 EXCAVATOR (Prefix 64R) Service Repair Manual (64R00596-01257)rpoy9396615Belum ada peringkat

- Caterpillar Cat 235B EXCAVATOR (Prefix 9PC) Service Repair Manual (9PC00001-UP)Dokumen23 halamanCaterpillar Cat 235B EXCAVATOR (Prefix 9PC) Service Repair Manual (9PC00001-UP)rpoy9396615Belum ada peringkat

- Torque Converter Lockup Clutch Pilot Pressure - Test and AdjustDokumen3 halamanTorque Converter Lockup Clutch Pilot Pressure - Test and AdjustBernabe Ruben Alayo RamosBelum ada peringkat

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Dokumen26 halamanCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduBelum ada peringkat

- Boom Drift Reduction ValveDokumen5 halamanBoom Drift Reduction ValveAbdellatef Bakr100% (1)

- Caterpillar Cat 235 EXCAVATOR (Prefix 83X) Service Repair Manual (83X00001-00443)Dokumen22 halamanCaterpillar Cat 235 EXCAVATOR (Prefix 83X) Service Repair Manual (83X00001-00443)rpoy9396615Belum ada peringkat

- Procedimento de retirada - 3054Dokumen6 halamanProcedimento de retirada - 3054carlos nogueiraBelum ada peringkat

- Engine Oil Pump - Disassemble: Shutdown SISDokumen4 halamanEngine Oil Pump - Disassemble: Shutdown SISOecox Cah DjadoelBelum ada peringkat

- 6 Relief Valve (Fuel)Dokumen4 halaman6 Relief Valve (Fuel)gwahyudinnBelum ada peringkat

- Installation and Operating Manual: Publication T1-728 Dated: April 15, 2002Dokumen10 halamanInstallation and Operating Manual: Publication T1-728 Dated: April 15, 2002Mauricio Ariel H. OrellanaBelum ada peringkat

- InyeccionDokumen5 halamanInyeccionWilsonStevBelum ada peringkat

- Transmission and Rear Differential - Remove: Shutdown SIS Previous ScreenDokumen5 halamanTransmission and Rear Differential - Remove: Shutdown SIS Previous ScreenToniGolBelum ada peringkat

- 972G Valvula PilotoDokumen2 halaman972G Valvula PilotodavidBelum ada peringkat

- SB 7-1-108Dokumen6 halamanSB 7-1-108jussmeeeBelum ada peringkat

- 330D-336D Testing and Adjusting (RENR9585-11) PDFDokumen176 halaman330D-336D Testing and Adjusting (RENR9585-11) PDFDiego Alonso Huaraca Baleriano100% (3)

- 777D Testing and Adjusting Service and Retarder Leakage-CheckDokumen10 halaman777D Testing and Adjusting Service and Retarder Leakage-Checkzawmoe aungBelum ada peringkat

- 5 Water Separator and Fuel FilterDokumen6 halaman5 Water Separator and Fuel FiltergwahyudinnBelum ada peringkat

- A3 2009 2.0L Cbfa CctaDokumen300 halamanA3 2009 2.0L Cbfa CctaJ VallejoBelum ada peringkat

- 3406c Fuel Pump-Governor DriveDokumen8 halaman3406c Fuel Pump-Governor Driveharikrishnanpd3327Belum ada peringkat

- Fuel Priming Pump - Remove and Install: Shutdown SISDokumen348 halamanFuel Priming Pump - Remove and Install: Shutdown SISjuan carlosBelum ada peringkat

- Pinion and Carrier Group - Disassemble - In-ChassisDokumen4 halamanPinion and Carrier Group - Disassemble - In-ChassisNidya Wardah JuhanaBelum ada peringkat

- Caterpillar Cat 235C FRONT SHOVEL (Prefix 4DG) Service Repair Manual (4DG00001 and Up)Dokumen23 halamanCaterpillar Cat 235C FRONT SHOVEL (Prefix 4DG) Service Repair Manual (4DG00001 and Up)rpoy9396615Belum ada peringkat

- Blowby SpecDokumen10 halamanBlowby Specbambang eengBelum ada peringkat

- SENR1013 Cнятие клапанов 3408ЕDokumen7 halamanSENR1013 Cнятие клапанов 3408ЕAminadavBelum ada peringkat

- Actuador de Válvula FlowserveDokumen8 halamanActuador de Válvula FlowserveemanuellesanchezBelum ada peringkat

- 4650 and 4850 Section 15 PDFDokumen96 halaman4650 and 4850 Section 15 PDFjosephmw03080% (1)

- 4650 and 4850 ContentsDokumen14 halaman4650 and 4850 Contentsjosephmw03080% (1)

- 4650 and 4850 Section 55Dokumen100 halaman4650 and 4850 Section 55josephmw0308Belum ada peringkat

- PTO Gear Train Repair GuideDokumen100 halamanPTO Gear Train Repair Guidejosephmw0308100% (1)

- 4650 and 4850 Section 70Dokumen100 halaman4650 and 4850 Section 70josephmw0308Belum ada peringkat

- 4650 and 4850 Section 50Dokumen100 halaman4650 and 4850 Section 50josephmw0308Belum ada peringkat

- 4650 and 4850 Section 90Dokumen74 halaman4650 and 4850 Section 90josephmw0308Belum ada peringkat

- 4650 and 4850 Section 55Dokumen100 halaman4650 and 4850 Section 55josephmw0308Belum ada peringkat

- 4650 and 4850 Section 20 PDFDokumen22 halaman4650 and 4850 Section 20 PDFjosephmw0308Belum ada peringkat

- 4650 and 4850 Section 60Dokumen88 halaman4650 and 4850 Section 60josephmw0308Belum ada peringkat

- 4650 and 4850 Section 99Dokumen64 halaman4650 and 4850 Section 99josephmw0308Belum ada peringkat

- 4650 and 4850 Section 70Dokumen58 halaman4650 and 4850 Section 70josephmw0308Belum ada peringkat

- 4650 and 4850 Section 95Dokumen56 halaman4650 and 4850 Section 95josephmw0308Belum ada peringkat

- 4650 and 4850 Section 10 General PDFDokumen56 halaman4650 and 4850 Section 10 General PDFjosephmw0308Belum ada peringkat

- 4650 and 4850 Section 40Dokumen100 halaman4650 and 4850 Section 40josephmw0308100% (1)

- 4650 and 4850 Section 55Dokumen100 halaman4650 and 4850 Section 55josephmw0308Belum ada peringkat

- 4650 and 4850 Section 55Dokumen2 halaman4650 and 4850 Section 55josephmw0308Belum ada peringkat

- 4650 and 4850 Section 80Dokumen44 halaman4650 and 4850 Section 80josephmw0308Belum ada peringkat

- 4650 and 4850 Section 50Dokumen96 halaman4650 and 4850 Section 50josephmw0308100% (1)

- 4650 and 4850 Section 50Dokumen22 halaman4650 and 4850 Section 50josephmw0308Belum ada peringkat

- Esquema Cat 330Dokumen2 halamanEsquema Cat 330Francisco Iniesta67% (6)

- 4650 and 4850 Section 40Dokumen8 halaman4650 and 4850 Section 40josephmw0308Belum ada peringkat

- Use Labview For Research Quality of Polymer Coatings - NewDokumen4 halamanUse Labview For Research Quality of Polymer Coatings - Newjosephmw0308Belum ada peringkat

- Holly Truck Avenger ManDokumen14 halamanHolly Truck Avenger ManBryan HawkeBelum ada peringkat

- Esquema Cat 330Dokumen2 halamanEsquema Cat 330Francisco Iniesta67% (6)

- TRX Holiday Training PlanDokumen18 halamanTRX Holiday Training PlanRucsandra Avirvarei50% (2)

- Maintenance (Rotary Cutter) Repair Parts Catalog: Model: SectionDokumen14 halamanMaintenance (Rotary Cutter) Repair Parts Catalog: Model: Sectionjosephmw0308Belum ada peringkat

- Jaegersports Jband ManualDokumen16 halamanJaegersports Jband Manualjosephmw0308Belum ada peringkat

- LCD-TV Service Manual for LTM295W and LTM405W ModelsDokumen89 halamanLCD-TV Service Manual for LTM295W and LTM405W ModelsJose Evilio Perez ManzaneroBelum ada peringkat

- Coa, Com, Co Lam SyllabusDokumen4 halamanCoa, Com, Co Lam Syllabusnaga sitaram mBelum ada peringkat

- Linear PCM Recorder: Reference ManualDokumen116 halamanLinear PCM Recorder: Reference ManualpaulaazteixeiraBelum ada peringkat

- Variable Geometry Turbo ChargerDokumen15 halamanVariable Geometry Turbo Chargernamrata chokakkarBelum ada peringkat

- Owner's Manual: Panel DescriptionsDokumen1 halamanOwner's Manual: Panel Descriptionsljputman09Belum ada peringkat

- IR 2945 PartsListDokumen2 halamanIR 2945 PartsListezeizabarrenaBelum ada peringkat

- Chamberlain WhisperDrive 8200CDokumen80 halamanChamberlain WhisperDrive 8200CalexologBelum ada peringkat

- Siemslvbh3610 SpecDokumen66 halamanSiemslvbh3610 SpecLD Jr FrancisBelum ada peringkat

- BU1-DC2 - DC Voltage Relay: Fig. 1: Front PlateDokumen4 halamanBU1-DC2 - DC Voltage Relay: Fig. 1: Front PlateLászló MártonBelum ada peringkat

- PS2 Pic16f887Dokumen4 halamanPS2 Pic16f887chau0105_btBelum ada peringkat

- REN RC310xxA DST 20230531Dokumen67 halamanREN RC310xxA DST 20230531杉澤 佑樹Belum ada peringkat

- Saybrook: Pull-Down Filtered Kitchen FaucetDokumen2 halamanSaybrook: Pull-Down Filtered Kitchen FaucetCasper John Nanas MuñozBelum ada peringkat

- Instruction Manual FAA Types L-880 and L-881 Precision Approach Path Indicator Systems 88XA2X-X-XXPAPI DOCUMENT 2438Dokumen73 halamanInstruction Manual FAA Types L-880 and L-881 Precision Approach Path Indicator Systems 88XA2X-X-XXPAPI DOCUMENT 2438Jose Manuel Restrepo Ruiz100% (2)

- Tellabs 8605 Installation GuideDokumen20 halamanTellabs 8605 Installation Guidekala-majka0% (1)

- A1753037 48 Conveyor Parts Manual CON 203 1 J1349Dokumen19 halamanA1753037 48 Conveyor Parts Manual CON 203 1 J1349waltergvBelum ada peringkat

- Master Slave Flip FlopDokumen3 halamanMaster Slave Flip FloplakshmiraniBelum ada peringkat

- Briggs Stratton Motor Kosilice - DeloviDokumen20 halamanBriggs Stratton Motor Kosilice - Delovicetojevic@hotmail.comBelum ada peringkat

- Lexus NX 200tDokumen28 halamanLexus NX 200tSopheak LimBelum ada peringkat

- An 4137SCDokumen13 halamanAn 4137SCYung SangBelum ada peringkat

- Index: GD251221-en 1 1 7Dokumen7 halamanIndex: GD251221-en 1 1 7'PeRsona NoUn GraTa'Belum ada peringkat

- The Intel 4004 Microprocessor, Which Was Introduced in 1971 Was The First MicroprocessorDokumen21 halamanThe Intel 4004 Microprocessor, Which Was Introduced in 1971 Was The First MicroprocessorPraise PhillipsBelum ada peringkat

- Hico SF Gas Circuit Breaker: Power Systems PUDokumen6 halamanHico SF Gas Circuit Breaker: Power Systems PUSubir ChattopadhyayBelum ada peringkat

- Spare Parts ListDokumen29 halamanSpare Parts ListRonaldBelum ada peringkat

- Pic18f IntroDokumen25 halamanPic18f IntroElena Gilbert100% (1)

- UTC 8156 Cmos: 8 Functions Xmas Light ControlDokumen3 halamanUTC 8156 Cmos: 8 Functions Xmas Light Controltantra_lover2005Belum ada peringkat

- Single Line Diagram of 220Kv Gis, Turavoor: Colour Code Voltage LevelDokumen1 halamanSingle Line Diagram of 220Kv Gis, Turavoor: Colour Code Voltage LevelmidhunvarBelum ada peringkat

- NUSTDokumen23 halamanNUSTcuami100% (2)

- AMF Panel Control WiringDokumen43 halamanAMF Panel Control WiringAnthony Robert XBelum ada peringkat

- Stepper Motor ControlDokumen5 halamanStepper Motor ControlSahilBelum ada peringkat

- Mazda 6 CY VM4290A PDFDokumen9 halamanMazda 6 CY VM4290A PDFJulian RuizBelum ada peringkat