900 KW, Tier 2, Chilled Water, 16100 FT: Reference Design 5)

Diunggah oleh

dexiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

900 KW, Tier 2, Chilled Water, 16100 FT: Reference Design 5)

Diunggah oleh

dexiHak Cipta:

Format Tersedia

[Reference Design 5]

2

900 kW, Tier 2, Chilled Water, 16100 ft

DESIGN OVERVIEW INTRODUCTION

The planning process of most projects can be iterative and thereby

Data Center IT Capacity

expensive. Data center projects are burdened with these challenges and can

900 kW

benefit greatly from simplification and time savings. Schneider Electric’s data

Adaptable from 200 kW to 2700 kW

center reference designs help customers optimize the planning process by

providing them with validated, proven, and documented data center physical

Target Availability

infrastructure designs. The use of these designs has a positive impact on not

Tier 2 just the project itself, but also on the performance, reliability, and efficiency of

the data center over its lifetime.

Annualized PUE at 100% Load

1.50 in Miami, FL USA

1.34 in Montreal, Canada Reference Design 5 includes design information for three spaces: IT space,

1.41 in St. Louis, MO USA facility power, and facility cooling. Combined together, they comprise the

integrated power, cooling and structural systems required to meet the

design’s specifications published in this overview document.

Total Racks and Average Density

318 racks at 2.8 kW/rack

IT & Facility Floor Space

2

16100 ft

Regional Voltage and Frequency

480V, 60Hz

ABOUT THIS DESIGN

Water-cooled chiller with cooling

tower architecture

Integrated row-based air

distribution

Energy savings through water-

side economizer during favorable

outdoor conditions

Highly scalable and adaptable

[Reference Design 5] 2

Facility Power

The facility power system supplies power to all of the critical and non-critical

components within the data center. The architecture used in this electrical

design is a single path with N+1 UPS and a generator. Switching between

generator power and utility is achieved using a programmable logic controller

(PLC). A 3200 amp bus feeds PZ4 electrical and mechanical switchboards. In

the electrical room, UPSs are configured down-stream of the switchboards. A

Symmetra MW configured to N+1 redundancy provides 1200 kW of critical

power to the IT room with 6 minutes of runtime. Valve regulated lead acid

(VRLA) batteries are housed in an isolated battery room. A Galaxy 5000 UPS

provides 72 kW of power to the pumps in the facility cooling system. Additional

DESIGN OPTIONS

low-voltage transformers are included in the design to support lighting and other

This reference design can be modified as

building loads. The power distribution architecture from the electrical room to

follows without a significant effect on the the IT space utilizes a combination of LV panels and InfraStruxure power

design’s performance attributes: distribution units (PDUs). The facility power system is designed to support

additional peripheral devices like fire panels, access control systems, and

Add StruxureWare Power Monitoring environmental monitoring and control devices. Power meters in the electrical

Expert path monitor power quality and allow for predictive maintenance & diagnostics of

Provision for load bank the system. These meters also integrate with StruxureWare Power Monitoring

Change UPS batteries Expert.

Add/change standby generator options: Every component in this design is built and tested to the applicable ANSI,

Location NEMA, UL or IEEE standards.

Tank size Further design details and schematics are available in the engineering package.

Fuel type

FACILITY POWER BLOCK DIAGRAM

FACILITY POWER ATTRIBUTES

Utility

AC G

Name Value Unit

3200A, 480V, 65kA Total amps (main bus) 3200 A

Input voltage (main bus) 480 V

2000A, 480V, 65kA Switchboard kAIC 65 kA

Power path Single

72 kW 1200kW (N+1)

Galaxy Symmetra SSW Generator redundancy N

5000 MW 1400kW

400A, IT space UPS capacity 1200 kW

480V, LOAD

65kA BANK 2000A, 480V, 65kA IT space UPS redundancy N+1

© 2013 Schneider Electric. All rights reserved.

IT space UPS runtime @ rated load 6 minutes

IT space UPS output voltage 480 V

Facility cooling UPS capacity 72 kW

14x PDU Feeds

4x CHW Pumps

to IT Space Facility cooling UPS redundancy N

Facility cooling UPS runtime @ rated load 12 minutes

1200A, 480V, 65kA

4x Mech.

Cooling Cooling

Chiller Chiller Cond. Panel

Tower Tower

Water (CRAHs,

Pump AHUs)

Schneider Electric www.schneider-electric.com

Document Number RD05DS Revision 2

[Reference Design 5] 3

Facility Cooling

The mechanical design utilizes chilled water as the primary medium for heat

dissipation. The architecture consists of a single chilled water loop. The cooling

system contains two 1196 kW water-cooled chillers in an N+1 redundant

configuration with N+1 pumps. Water-side economization is achieved with a

plate & frame heat exchanger to save energy during favorable outdoor

conditions.

In order to extend availability of chilled water during a power outage, a 7000

gallon water storage tank provides 6 minutes of continuous cooling.

The piping architecture of the mechanical system feeds row-based InRow RC

CRAHs in the IT space. It also feeds room-based CRAHs in the electrical and

battery rooms. More information on the cooling configuration is provided in the

DESIGN OPTIONS IT space section of this document.

This design is instrumented to work with StruxureWare Cooling Monitoring

This reference design can be modified as Expert.

follows without a significant effect on the

Further design details such as dimensions, equipment placement, temperature

design’s performance attributes:

set points, pipe sizing, flow rates, and pressure drops are available in the

Add StruxureWare Cooling engineering package.

Monitoring Expert

FACILITY COOLING ATTRIBUTES

FACILITY COOLING BLOCK DIAGRAM

Name Value Unit

Piping detail inside IT space

Total cooling capacity 1196 kW

Input voltage 480 V

Heat rejection medium Chilled water

InRow InRow

RC RC

… 98 units...

300

mm

300

mm

Mechanical redundancy N+1

Water-cooled chiller

Outdoor heat exchange

with cooling tower

CW supply

Coolant supply temperature 46 F

CW return

Coolant return temperature 56 F

InRow

RC

InRow

RC

Storage tank size 7000 gallons

300 300

mm mm

Ride-through time 6 minutes

Economizer type Water-side

© 2013 Schneider Electric. All rights reserved.

Tower Tower

Secondary loop

pumps

VFD

Thermal Storage

CW supply

VFD to IT space

Primary loop pumps

System

VFD Dirt/air

Strainers bypass

separator

CW return

VFD Chiller from IT space

VFD

Expansion

City Water tank

VFD Chiller

Heat

Exchanger

Schneider Electric www.schneider-electric.com

Document Number RD05DS Revision 2

[Reference Design 5] 4

IT Space

The IT capacity of this design is 900 kW. The design is highly scalable and

adaptable; it can be configured to support IT loads within a range. Smaller

starting loads as low as 200 kW can be supported by making adjustments such

as reducing the number of IT pods or decreasing the quantity of UPS modules.

Likewise, this design can be used as a baseline for larger loads as high as 2700

kW by using a step and repeat approach to the design. This flexibility drives

efficiency and defers capital expenditure until needed.

The IT space design specifies all of the physical infrastructure systems, as well

as their physical arrangement/spacing, required to meet the overall design’s

performance attributes. This includes racks, PDUs, rack power distribution,

DESIGN OPTIONS cooling units, and airflow management systems.

This reference design can be modified as Each pair of rows (pod) within the IT space can be “stepped and repeated” in a

follows without a significant effect on the standardized and predictable manner. This enables right-sizing of power and

design’s performance attributes: cooling that scales with IT growth. Each pod supports an average power

density of 2.8 kW per rack. All the pods are outfitted with integrated power and

Add environmental and security cooling distribution.

management Each pod is powered by floor mount factory-configured power distribution units

Change rack options (tall, (PDUs). Every rack is configured with a metered rack-mount PDU to enable

wide, deep)

remote monitoring of the units for efficiency and capacity management.

Change power distribution options

Rack PDU type (basic, Each pod is cooled by N+1 redundant chilled water-based InRow RC CRAHs

switched) that control the supply of cool air by monitoring temperature variation at the rack

Add StruxureWare Data Center level.

Expert

The security of the room is maintained at multiple points. At the rack level,

access is controlled by a door lock and sensor. At the room level, security

cameras are utilized for monitoring.

Row A Row B

R R C R R R R C R R R R R C R R C R R R R R C R R R R C R R

R/A-2/Z1 R/A-3/Z1 C/ R/A-5/Z1 R/A-6/Z1 R/A-7/Z1 R/A-8/Z1 C/ R/A-10/Z1 R/A-11/Z1 R/A-12/Z1 R/A-13/Z1 R/A-14/Z1 C/ R/A-16/Z1 R/B-1/Z2 C/ R/B-3/Z2 R/B-4/Z2 R/B-5/Z2 R/B-6/Z2 R/B-7/Z2 C/ R/B-9/Z2 R/B-10/Z2 R/B-11/Z2 R/B-12/Z2 C/ R/B-14/Z2 R/B-15/Z2

A-4/ A-9/ A- B-2/ B-8/ B-

Z1 Z1 15/ Z2 Z2 13/

Z1 Z2

IT ROOM ATTRIBUTES

G

Gap

Row C Row D

R C R R R C R R R C R R R C R R C R R R C R R R C R R R C R

R/C-1/Z1 C/ R/C-3/Z1 R/C-4/Z1 R/C-5/Z1 C/ R/C-7/Z1 R/C-8/Z1 R/C-9/Z1 C/ R/C-11/Z1 R/C-12/Z1 R/C-13/Z1 C/ R/C-15/Z1 P P R/D-2/Z2 C/ R/D-4/Z2 R/D-5/Z2 R/D-6/Z2 C/ R/D-8/Z2 R/D-9/Z2 R/D-10/Z2 C/ R/D-12/Z2 R/D-13/Z2 R/D-14/Z2 C/ R/D-16/Z2

C-2/ C-6/ C- C- P/C-16/Z1 P/D-1/Z2 D-3/ D-7/ D- D-

Z1 Z1 10/ 14/ Z2 Z2 11/ 15/

Z1 Z1 Z2 Z2

Row E

R

R/E-2/Z12

R

R/E-3/Z12

C

C/

E-4/

Z12

R

R/E-5/Z12

R

R/E-6/Z12

R

R/E-7/Z12

R

R/E-8/Z12

C

C/

E-9/

Z12

R

R/E-10/

Z12

R

R/E-11/

Z12

R

R/E-12/

Z12

R

R/E-13/

Z12

R

R/E-14/Z12

C

C/

E-

15/

Z12

R

R/E-16/Z12

Row F

R

R/F-1/Z8

C

C/F-

2/

Z8

R

R/F-3/Z8

R

R/F-4/Z8

R

R/F-5/Z8

R

R/F-6/Z8

R

R/F-7/Z8

C

C/F-

8/

Z8

R

R/F-9/Z8

R

R/F-10/Z8

R

R/F-11/Z8

R

R/F-12/Z8

C

C/F-

13/

Z8

R

R/F-14/Z8

R

R/F-15/Z8 Name Value Unit

G

Gap

Row G

R

R/G-1/Z12

C

C/

G-2/

Z12

R

R/G-3/Z12

R

R/G-4/Z12

R

R/G-5/Z12

C

C/

G-6/

Z12

R

R/G-7/Z12

R

R/G-8/Z12

R

R/G-9/Z12

C

C/

G-

10/

R

R/G-11/

Z12

R

R/G-12/

Z12

R

R/G-13/

Z12

C

C/

G-

14/

R

R/G-15/

Z12

P

P/G-16/Z12

Row H

P

P/H-1/Z8

R

R/H-2/Z8

C

C/

H-3/

Z8

R

R/H-4/Z8

R

R/H-5/Z8

R

R/H-6/Z8

C

C/

H-7/

Z8

R

R/H-8/Z8

R

R/H-9/Z8

R

R/H-10/Z8

C

C/

H-

11/

R

R/H-12/Z8

R

R/H-13/Z8

R

R/H-14/Z8

C

C/

H-

15/

R

R/H-16/Z8

IT load 900 kW

Z12 Z12 Z8 Z8

Row J

R R C R R R R C R R R R R C R

Row K

R C R R R R R C R R R R C R R

Input voltage 480 V

R/J-2/Z11 R/J-3/Z11 C/J- R/J-5/Z11 R/J-6/Z11 R/J-7/Z11 R/J-8/Z11 C/J- R/J-10/ R/J-11/ R/J-12/ R/J-13/ R/J-14/Z11 C/J- R/J-16/Z11 R/K-1/Z9 C/ R/K-3/Z9 R/K-4/Z9 R/K-5/Z9 R/K-6/Z9 R/K-7/Z9 C/ R/K-9/Z9 R/K-10/Z9 R/K-11/Z9 R/K-12/Z9 C/ R/K-14/Z9 R/K-15/Z9

4/ 9/ Z11 Z11 Z11 Z11 15/ K-2/ K-8/ K-

Z11 Z11 Z11 Z9 Z9 13/

Z9

Row L

G

Gap

Row M

Supply voltage to IT 120 / 208 V

R C R R R C R R R C R R R C R R C R R R C R R R C R R R C R

R/L-1/Z11 C/L- R/L-3/Z11 R/L-4/Z11 R/L-5/Z11 C/L- R/L-7/Z11 R/L-8/Z11 R/L-9/Z11 C/L- R/L-11/ R/L-12/ R/L-13/ C/L- R/L-15/ P P R/M-2/Z9 C/ R/M-4/Z9 R/M-5/Z9 R/M-6/Z9 C/ R/M-8/Z9 R/M-9/Z9 R/M-10/Z9 C/ R/M-12/Z9 R/M-13/Z9 R/M-14/Z9 C/ R/M-16/Z9

2/ 6/ 10/ Z11 Z11 Z11 14/ Z11 P/L-16/Z11 P/M-1/Z9 M- M- M- M-

Z11 Z11 Z11 Z11 3/ 7/ 11/ 15/

Z9 Z9 Z9 Z9

Average density 2.8 kW/rack

Row N Row P

R R C R R R R C R R R R R C R R C R R R R R C R R R R C R R

Number of racks 318 racks

R/N-2/Z10 R/N-3/Z10 C/ R/N-5/Z10 R/N-6/Z10 R/N-7/Z10 R/N-8/Z10 C/ R/N-10/ R/N-11/ R/N-12/ R/N-13/ R/N-14/Z10 C/ R/N-16/Z10 R/P-1/Z7 C/ R/P-3/Z7 R/P-4/Z7 R/P-5/Z7 R/P-6/Z7 R/P-7/Z7 C/ R/P-9/Z7 R/P-10/Z7 R/P-11/Z7 R/P-12/Z7 C/ R/P-14/Z7 R/P-15/Z7

N-4/ N-9/ Z10 Z10 Z10 Z10 N- P-2/ P-8/ P-

Z10 Z10 15/ Z7 Z7 13/

Z10 Z7

G

Gap

Row Q Row R

R C R R R C R R R C R R R C R

P P

R C R R R C R R R C R R R C R

2

IT floor space 10800

R/Q-1/Z10 C/ R/Q-3/Z10 R/Q-4/Z10 R/Q-5/Z10 C/ R/Q-7/Z10 R/Q-8/Z10 R/Q-9/Z10 C/ R/Q-11/ R/Q-12/ R/Q-13/ C/ R/Q-15/ R/R-2/Z7 C/ R/R-4/Z7 R/R-5/Z7 R/R-6/Z7 C/ R/R-8/Z7 R/R-9/Z7 R/R-10/Z7 C/ R/R-12/Z7 R/R-13/Z7 R/R-14/Z7 C/ R/R-16/Z7

© 2013 Schneider Electric. All rights reserved.

ft

Q-2/ Q-6/ Q- Z10 Z10 Z10 Q- Z10 P/Q-16/Z10 P/R-1/Z7 R-3/ R-7/ R- R-

Z10 Z10 10/ 14/ Z7 Z7 11/ 15/

Z10 Z10 Z7 Z7

Row S Row T

R

R/S-2/Z4

R

R/S-3/Z4

C

C/

S-4/

Z4

R

R/S-5/Z4

R

R/S-6/Z4

R

R/S-7/Z4

R

R/S-8/Z4

C

C/

S-9/

Z4

R

R/S-10/Z4

R

R/S-11/Z4

R

R/S-12/Z4

R

R/S-13/Z4

R

R/S-14/Z4

C

C/

S-

15/

Z4

R

R/S-16/Z4

R

R/T-1/Z6

C

C/T-

2/

Z6

R

R/T-3/Z6

R

R/T-4/Z6

R

R/T-5/Z6

R

R/T-6/Z6

R

R/T-7/Z6

C

C/T-

8/

Z6

R

R/T-9/Z6

R

R/T-10/Z6

R

R/T-11/Z6

R

R/T-12/Z6

C

C/T-

13/

Z6

R

R/T-14/Z6

R

R/T-15/Z6

Single or dual cord Single

G

Gap

Row U Row V

R

R/U-1/Z4

C

C/

U-2/

Z4

R

R/U-3/Z4

R

R/U-4/Z4

R

R/U-5/Z4

C

C/

U-6/

Z4

R

R/U-7/Z4

R

R/U-8/Z4

R

R/U-9/Z4

C

C/

U-

10/

Z4

R

R/U-11/Z4

R

R/U-12/Z4

R

R/U-13/Z4

C

C/

U-

14/

Z4

R

R/U-15/Z4 P

P/U-16/Z4

P

P/V-1/Z6

R

R/V-2/Z6

C

C/

V-3/

Z6

R

R/V-4/Z6

R

R/V-5/Z6

R

R/V-6/Z6

C

C/

V-7/

Z6

R

R/V-8/Z6

R

R/V-9/Z6

R

R/V-10/Z6

C

C/

V-

11/

Z6

R

R/V-12/Z6

R

R/V-13/Z6

R

R/V-14/Z6

C

C/

V-

15/

Z6

R

R/V-16/Z6

Heat rejection medium Chilled water

Row 1

R

R/1-1/Z13

R

R/1-2/Z13

C

C/1-

3/

Z13

R

R/1-4/Z13

R

R/1-5/Z13

R

R/1-6/Z13

R

R/1-7/Z13

C

C/1-

8/

Z13

R

R/1-9/Z13

R

R/1-10/

Z13

R

R/1-11/

Z13

R

R/1-12/

Z13

R C

R/1-13/Z13 C/1-

14/

Z13

R

R/1-15/Z13

Row 2

R

R/2-1/Z14

C

C/2-

2/

Z14

R

R/2-3/Z14

R

R/2-4/Z14

R

R/2-5/Z14

R

R/2-6/Z14

R

R/2-7/Z14

C

C/2-

8/

Z14

R

R/2-9/Z14

R

R/2-10/

Z14

R

R/2-11/

Z14

R

R/2-12/

Z14

C

C/2-

13/

Z14

R

R/2-14/

Z14

R

R/2-15/Z14

CRAC/CRAH type Row-based CRAH

G

CRAC/CRAH redundancy N+1

Gap

Row 3 Row 4

R C R R R C R R R C R R R C R R C R R R C R R R C R R R C R

R/3-1/Z13 C/3- R/3-3/Z13 R/3-4/Z13 R/3-5/Z13 C/3- R/3-7/Z13 R/3-8/Z13 R/3-9/Z13 C/3- R/3-11/ R/3-12/ R/3-13/ C/3- R/3-15/ P P R/4-2/Z14 C/4- R/4-4/Z14 R/4-5/Z14 R/4-6/Z14 C/4- R/4-8/Z14 R/4-9/Z14 R/4-10/ C/4- R/4-12/ R/4-13/ R/4-14/ C/4- R/4-16/

2/ 6/ 10/ Z13 Z13 Z13 14/ Z13 P/3-16/Z13 P/4-1/Z14 3/ 7/ Z14 11/ Z14 Z14 Z14 15/ Z14

Z13 Z13 Z13 Z13 Z14 Z14 Z14 Z14

Row 5

R C R R R R C R R R R R R C R

Row 6

R R R C R R R C R R C R R

Containment type None

R/5-2/Z3 C/5- R/5-4/Z3 R/5-5/Z3 R/5-6/Z3 R/5-7/Z3 C/5- R/5-9/Z3 R/5-10/Z3 R/5-11/Z3 R/5-12/Z3 R/5-13/Z3 R/5-14/Z3 C/5- R/5-16/Z3 R/6-1/Z5 R/6-2/Z5 R/6-3/Z5 C/6- R/6-5/Z5 R/6-6/Z5 R/6-7/Z5 C/6- R/6-9/Z5 R/6-10/Z5 C/6- R/6-12/Z5 R/6-13/Z5

3/ 8/ 15/ 4/ 8/ 11/

Z3 Z3 Z3 Z5 Z5 Z5

G

Gap

Row 7 Row 8

R C R R R C R R R C R R C R R R R C R R R C R R C R R

R/7-1/Z3 C/7- R/7-3/Z3 R/7-4/Z3 R/7-5/Z3 C/7- R/7-7/Z3 R/7-8/Z3 R/7-9/Z3 C/7- R/7-11/Z3 R/7-12/Z3 C/7- R/7-14/Z3 R/7-15/Z3 P P R/8-2/Z5 R/8-3/Z5 C/8- R/8-5/Z5 R/8-6/Z5 R/8-7/Z5 C/8- R/8-9/Z5 R/8-10/Z5 C/8- R/8-12/Z5 R/8-13/Z5

2/ 6/ 10/ 13/ P/7-16/Z3 P/8-1/Z5 4/ 8/ 11/

Z3 Z3 Z3 Z3 Z5 Z5 Z5

Controller

Schneider Electric www.schneider-electric.com

Document Number RD05DS Revision 2

[Reference Design 5] 5

Design Attributes

OVERVIEW Value Unit

Target availability Tier 2 Tier

Annualized PUE at 100% load 1.50 / 1.34 / 1.41

Data center IT capacity 900 kW

2

IT & facility floor space 16100 ft

Average density 2.8 kW/rack

FACILITY POWER Value Unit

Total amps (main bus) 3200 A

Input voltage (main bus) 480 V

Switchboard kAIC 65 kA

Power path Single

Generator redundancy N

IT space UPS capacity 1200 kW

IT space UPS redundancy N+1

IT space UPS runtime @ rated load 6 minutes

IT space UPS output voltage 480 V

Facility cooling UPS capacity 72 kW

Facility cooling UPS redundancy N

Facility cooling UPS runtime @ rated load 12 minutes

FACILITY COOLING Value Unit

Total cooling capacity 1196 kW

Input voltage 480 V

Heat rejection medium Chilled water

Mechanical redundancy N+1

Outdoor heat exchange Water-cooled chiller with cooling tower

Coolant supply temperature 46 F

Coolant return temperature 56 F

Storage tank size 7000 gallons

Ride-through time 6 minutes

Economizer type Water-side

IT SPACE Value Unit

IT load 900 kW

Input voltage 480 V

Supply voltage to IT 120 / 208 V © 2013 Schneider Electric. All rights reserved.

Average density 2.8 kW/rack

Number of racks 318 Racks

2

IT floor space 10800 ft

Single or dual cord Single

Heat rejection medium Chilled water

CRAC/CRAH type Row-based CRAH

CRAC/CRAH redundancy N+1

Containment type None

Schneider Electric www.schneider-electric.com

Document Number RD05DS Revision 2

[Reference Design 5] 6

Data center infrastructure management (DCIM)

Good design and quality construction alone do not ensure a highly available &

efficient data center. Data centers require on-going monitoring and management to

ensure the facility lives up to its design intent. StruxureWare for Data Centers is a

software management suite designed to collect and manage data about a data

center’s assets, resource use, and operational status throughout the life cycle of the

facility. This information is then distributed, integrated, and applied in ways that help

managers optimize the data center’s performance and meet IT, business, and

service-oriented goals. From IT assets to racks, rows, rooms and buildings,

StruxureWare for Data Centers delivers the right information to the right users at the

right time.

Control level: Experts, on site or remotely, can control process performance and

ensure business continuity in real time, while tracking energy consumption in a highly

critical and secure environment.

Operations level: Functional managers can optimize operations, energy, and assets

through smart analytical tools, often spanning multiple sites.

Enterprise level: C-level executives can drive their sustainability strategy efficiently,

choosing the best scenario that meets their business objective to conserve

enterprise-wide resources.

StruxureWare for Data Centers allows for flexibility when requirements and

implementation strategies change over time. StruxureWare software applications

and suites simplify integration time, improve reliability, enhance visibility to energy

information, and streamline operational efficiency.

>

© 2013 Schneider Electric. All rights reserved.

Demo:

Visit www.apc.com/software to learn more about StruxureWare for Data Centers!

Schneider Electric www.schneider-electric.com

Document Number RD05DS Revision 2

[Reference Design 5] 7

Get more information for this design:

Engineering Package

Every reference design is built with technical documentation

for engineers and project managers. This includes

engineering schematics (CAD, PDF), floor layouts,

equipment lists containing all the components used in the

design and 3D images showing real world illustrations of our

Floor layouts

reference designs.

3D spatial views

Documentation is available in multiple formats to suit the

needs of both engineers and managers working on data

center projects.

Bill of materials

One-line schematics

> Click here to register to receive the Engineering Package for this design, or email

ReferenceDesigns@Schneider-Electric.com.

Schneider Electric Life-Cycle Services

Team of over 7,000 trained specialists covering

every phase and system in the data center

© 2013 Schneider Electric. All rights reserved.

Standardized, documented, and validated

methodology leveraging automation tools and

repeatable processes developed over 45 years

Complete portfolio of services to solve your

technical or business challenge, simplify your

life, and reduce costs

Schneider Electric www.schneider-electric.com

Document Number RD05DS Revision 2

Anda mungkin juga menyukai

- Datasheet Powerpack2-5 AllDokumen2 halamanDatasheet Powerpack2-5 AllLorenzo67% (3)

- 3500 15 Power Supply 129767-01 Rev EDokumen22 halaman3500 15 Power Supply 129767-01 Rev EDenis JimenezBelum ada peringkat

- Iso 22301 Business Continuity Management PDFDokumen13 halamanIso 22301 Business Continuity Management PDFdexi100% (3)

- AN5516-06 Optical Line Terminal Equipment Installation GuideDokumen222 halamanAN5516-06 Optical Line Terminal Equipment Installation GuidebigdrsmithBelum ada peringkat

- Safety Checklist For Offices PDFDokumen4 halamanSafety Checklist For Offices PDFJINGO404Belum ada peringkat

- RD10DSR2Dokumen7 halamanRD10DSR2MarlonBelum ada peringkat

- 175 KW, Tier 2, Chilled Water, 4350 FT: Reference Design 2)Dokumen7 halaman175 KW, Tier 2, Chilled Water, 4350 FT: Reference Design 2)dexiBelum ada peringkat

- 170 KW, Tier 2, Chilled Water, 2650 FT: Reference Design 70)Dokumen7 halaman170 KW, Tier 2, Chilled Water, 2650 FT: Reference Design 70)dexiBelum ada peringkat

- RD21DSR1 PDFDokumen7 halamanRD21DSR1 PDFdexiBelum ada peringkat

- 1008 KW, Tier 3, Chilled Water, 15310 FT: Reference Design 82)Dokumen7 halaman1008 KW, Tier 3, Chilled Water, 15310 FT: Reference Design 82)dexiBelum ada peringkat

- 345 KW, Tier 2, Chilled Water, 3960 FT: Reference Design 72)Dokumen7 halaman345 KW, Tier 2, Chilled Water, 3960 FT: Reference Design 72)dexiBelum ada peringkat

- 520 KW, Tier 2, Chilled Water, 4823 FT: Reference Design 73)Dokumen7 halaman520 KW, Tier 2, Chilled Water, 4823 FT: Reference Design 73)dexiBelum ada peringkat

- 170 KW, Tier 1, Chilled Water, 2640 FT: Reference Design 69)Dokumen7 halaman170 KW, Tier 1, Chilled Water, 2640 FT: Reference Design 69)dexiBelum ada peringkat

- Semi-Prefabricated, 27762 FT: 1760 KW, Tier 3, Indirect Air EconomizerDokumen7 halamanSemi-Prefabricated, 27762 FT: 1760 KW, Tier 3, Indirect Air EconomizerdexiBelum ada peringkat

- 910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)Dokumen7 halaman910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)dexiBelum ada peringkat

- 490 KW, Tier III, Chilled Water, Prefabricated, 697 M: Reference Design 86)Dokumen7 halaman490 KW, Tier III, Chilled Water, Prefabricated, 697 M: Reference Design 86)dexiBelum ada peringkat

- 77 KW, Tier 2, Direct Expansion, 916 FT: Reference Design 41)Dokumen7 halaman77 KW, Tier 2, Direct Expansion, 916 FT: Reference Design 41)dexiBelum ada peringkat

- RD11 2.1 Facility Power Overview EN R0Dokumen1 halamanRD11 2.1 Facility Power Overview EN R0АндрейТрубниковBelum ada peringkat

- 200 KW, Tier 3, Chilled Water, 5250 FT: Reference Design 4)Dokumen7 halaman200 KW, Tier 3, Chilled Water, 5250 FT: Reference Design 4)dexiBelum ada peringkat

- 790 KW, Tier 4, Chilled Water, 20000 FT: Reference Design 7)Dokumen7 halaman790 KW, Tier 4, Chilled Water, 20000 FT: Reference Design 7)dexiBelum ada peringkat

- 90 KW, Tier II, Direct Expansion, 142.1 M, All-In-One Prefab Data Center Module - Busway or PDUDokumen7 halaman90 KW, Tier II, Direct Expansion, 142.1 M, All-In-One Prefab Data Center Module - Busway or PDUahmadgce04Belum ada peringkat

- 1980 KW, Tier 2, Chilled Water, Prefabricated, 15125 FT: Reference Design 33)Dokumen7 halaman1980 KW, Tier 2, Chilled Water, Prefabricated, 15125 FT: Reference Design 33)dexiBelum ada peringkat

- RD11 5.1 Management Use Case en R0Dokumen25 halamanRD11 5.1 Management Use Case en R0АндрейТрубниковBelum ada peringkat

- 3300 KW, Tier 3, Chilled Water, 70,000 FT: Reference Design 22)Dokumen7 halaman3300 KW, Tier 3, Chilled Water, 70,000 FT: Reference Design 22)dexiBelum ada peringkat

- 48 KW, Pod-Based Build, Tier I, 646 FT: Design OverviewDokumen6 halaman48 KW, Pod-Based Build, Tier I, 646 FT: Design Overviewahmadgce04Belum ada peringkat

- 780 KW, Pod-Based Build, Tier I, 1873 FT: Design OverviewDokumen6 halaman780 KW, Pod-Based Build, Tier I, 1873 FT: Design Overviewahmadgce04Belum ada peringkat

- Secondary Skid Unit (SSU) : Solar Power Collection Application With Central InverterDokumen2 halamanSecondary Skid Unit (SSU) : Solar Power Collection Application With Central InverterhaBelum ada peringkat

- Smart-UPS SRT1-3kVA V2Dokumen13 halamanSmart-UPS SRT1-3kVA V2carlosBelum ada peringkat

- IS920 Product Information: Inverter System 48 V DC For TelecommunicationDokumen9 halamanIS920 Product Information: Inverter System 48 V DC For TelecommunicationOleg KuryanBelum ada peringkat

- ABB Industrial Drives: ACS880 Multidrive Modules, 1.5 To 3200 KWDokumen2 halamanABB Industrial Drives: ACS880 Multidrive Modules, 1.5 To 3200 KWDev ShahBelum ada peringkat

- Powerlink Intelligent Panelboards Brochure (Digital File) PDFDokumen16 halamanPowerlink Intelligent Panelboards Brochure (Digital File) PDFisaac oropezaBelum ada peringkat

- 9SX EaDokumen2 halaman9SX EaThanh Vinh NguyenBelum ada peringkat

- Components and Systems For Electric Vehicles (Hevs/Evs)Dokumen7 halamanComponents and Systems For Electric Vehicles (Hevs/Evs)NaniBelum ada peringkat

- Aula 1 An47 1Dokumen30 halamanAula 1 An47 1Alex cardoso CardosoBelum ada peringkat

- Delta Rpi m15 30a Inverter Data SheetDokumen4 halamanDelta Rpi m15 30a Inverter Data SheetDavid SaymonBelum ada peringkat

- Solar-Installer-Handbook IEC SchneiderDokumen52 halamanSolar-Installer-Handbook IEC SchneiderPutri Vardabella VeshiaBelum ada peringkat

- Power Meter Series 800: Powerlogic Power-Monitoring UnitsDokumen16 halamanPower Meter Series 800: Powerlogic Power-Monitoring UnitsFernandoCrespoMonBelum ada peringkat

- G55tupsm30hin enDokumen8 halamanG55tupsm30hin enDeepak VermaBelum ada peringkat

- Switchsync™ PWC600 Point-On-Wave ControllerDokumen4 halamanSwitchsync™ PWC600 Point-On-Wave Controllermic68hc11Belum ada peringkat

- A Review of Single-Phase Improved Power QualityDokumen20 halamanA Review of Single-Phase Improved Power QualityRajan M SBelum ada peringkat

- RM848HE Product Sheet 2022 8 9 22Dokumen2 halamanRM848HE Product Sheet 2022 8 9 22STC Hồng NgọcBelum ada peringkat

- Power+ A Parallel Redundant UPS - Uninterruptible Power SupplyDokumen8 halamanPower+ A Parallel Redundant UPS - Uninterruptible Power SupplyGamatronicBelum ada peringkat

- Attachment Technical Leaflet Charger, UPS and BatteryDokumen52 halamanAttachment Technical Leaflet Charger, UPS and BatteryWistaraBelum ada peringkat

- Symmetra PX: Scalable From 16 KW To 500 Kw. Parallel-Capable Up To 2,000 KWDokumen12 halamanSymmetra PX: Scalable From 16 KW To 500 Kw. Parallel-Capable Up To 2,000 KWcilok nangkaBelum ada peringkat

- Live Tank Circuit Breakers: Primary PlusDokumen20 halamanLive Tank Circuit Breakers: Primary PlusXuân Huy Nguyễn0% (1)

- Features, Value and Benefits of Digital Control For Power SuppliesDokumen10 halamanFeatures, Value and Benefits of Digital Control For Power Suppliestradingview9339Belum ada peringkat

- Netsure™: Itm With Esure™ Technology Row-Based, Scalable 48V DC UpsDokumen12 halamanNetsure™: Itm With Esure™ Technology Row-Based, Scalable 48V DC UpsALEX ALEXBelum ada peringkat

- 1500wlprot6002-000 PDFDokumen2 halaman1500wlprot6002-000 PDFsy_binh97Belum ada peringkat

- Elk-4 800 1HZC208015 202111 enDokumen16 halamanElk-4 800 1HZC208015 202111 ensameershukur17Belum ada peringkat

- 45 Integrated Power CenterDokumen20 halaman45 Integrated Power CenterGustavo GamezBelum ada peringkat

- PowerStore-Integrated-Flyer-4CAE000742-US LetterDokumen4 halamanPowerStore-Integrated-Flyer-4CAE000742-US LetterHector AgBelum ada peringkat

- Power Zone 4 Low Voltage Switchgear PDFDokumen6 halamanPower Zone 4 Low Voltage Switchgear PDFLuis PulidoBelum ada peringkat

- A Review of Single-Phase Improved Power Quality AC-DC ConvertersDokumen20 halamanA Review of Single-Phase Improved Power Quality AC-DC ConvertersRagunathan NarayananBelum ada peringkat

- IS920 Product Information: Inverter System 48 V DC For TelecommunicationDokumen10 halamanIS920 Product Information: Inverter System 48 V DC For TelecommunicationOleg KuryanBelum ada peringkat

- 998-1243569 Gma-Us BDokumen14 halaman998-1243569 Gma-Us BMuh Zaki NovriBelum ada peringkat

- Rectifier 1u 2u 3uDokumen16 halamanRectifier 1u 2u 3uSteve MartinezBelum ada peringkat

- Brochures - RC PDUDokumen11 halamanBrochures - RC PDUAGUNG SURYO ADI NUGROHOBelum ada peringkat

- Netsure501 A41 Netsure701 A41: Embedded High Frequency Switching Mode Power System SeriesDokumen2 halamanNetsure501 A41 Netsure701 A41: Embedded High Frequency Switching Mode Power System SeriesThuyaBelum ada peringkat

- MPPT Implementation of Ultra Capacitor Based DVR For Power Quality EnhancementDokumen9 halamanMPPT Implementation of Ultra Capacitor Based DVR For Power Quality EnhancementIJRASETPublicationsBelum ada peringkat

- Masterguard SIII UPSDokumen38 halamanMasterguard SIII UPSvayyikBelum ada peringkat

- Power Electronics Design Handbook: Low-Power Components and ApplicationsDari EverandPower Electronics Design Handbook: Low-Power Components and ApplicationsPenilaian: 4 dari 5 bintang4/5 (2)

- Practical Switching Power Supply DesignDari EverandPractical Switching Power Supply DesignPenilaian: 2 dari 5 bintang2/5 (1)

- 653B21 Time Server Netsilon PDFDokumen4 halaman653B21 Time Server Netsilon PDFdexiBelum ada peringkat

- Sigma C Master Clock Instructions PDFDokumen46 halamanSigma C Master Clock Instructions PDFdexiBelum ada peringkat

- User Manual Netsilon PDFDokumen74 halamanUser Manual Netsilon PDFdexiBelum ada peringkat

- Apc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsDokumen9 halamanApc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsdexiBelum ada peringkat

- Knuerr CoolFlex PDFDokumen6 halamanKnuerr CoolFlex PDFdexiBelum ada peringkat

- 643J31 Time Server SecureSyncDokumen4 halaman643J31 Time Server SecureSyncdexiBelum ada peringkat

- 643O41 Time Server Netsilon PDFDokumen4 halaman643O41 Time Server Netsilon PDFdexiBelum ada peringkat

- Airflow Uniformity Through Perforated Tiles in A Raised-Floor Data CenterDokumen11 halamanAirflow Uniformity Through Perforated Tiles in A Raised-Floor Data CenterdexiBelum ada peringkat

- Jnin-6n7srz R0 en PDFDokumen12 halamanJnin-6n7srz R0 en PDFdexiBelum ada peringkat

- Interpack2003-35282: Techniques For Controlling Airflow Distribution in Raised-Floor Data CentersDokumen8 halamanInterpack2003-35282: Techniques For Controlling Airflow Distribution in Raised-Floor Data CentersdexiBelum ada peringkat

- APC Application Note #69: Air Distribution Unit ApplicationDokumen4 halamanAPC Application Note #69: Air Distribution Unit ApplicationdexiBelum ada peringkat

- Ksih-6y6tlv R0 en 2 PDFDokumen9 halamanKsih-6y6tlv R0 en 2 PDFdexiBelum ada peringkat

- APC Application Note #69: Air Distribution Unit ApplicationDokumen4 halamanAPC Application Note #69: Air Distribution Unit ApplicationdexiBelum ada peringkat

- h14515 VNX Family Ds PDFDokumen6 halamanh14515 VNX Family Ds PDFdexiBelum ada peringkat

- Intel-Air-Cooled Data Centers PDFDokumen20 halamanIntel-Air-Cooled Data Centers PDFdexiBelum ada peringkat

- Impact of Hot and Cold Aisle Containment On Data Center Temperature and Efficiency PDFDokumen14 halamanImpact of Hot and Cold Aisle Containment On Data Center Temperature and Efficiency PDFdexiBelum ada peringkat

- Fulltext01 PDFDokumen64 halamanFulltext01 PDFdexiBelum ada peringkat

- Energy Efficient Electric Motor Selection PDFDokumen66 halamanEnergy Efficient Electric Motor Selection PDFdexiBelum ada peringkat

- IPack2005 73273 PDFDokumen8 halamanIPack2005 73273 PDFdexiBelum ada peringkat

- Effects of Doors On Airflow and Cooling WP PDFDokumen10 halamanEffects of Doors On Airflow and Cooling WP PDFdexiBelum ada peringkat

- Group Business Continuity Plan Summary 2018 PDFDokumen4 halamanGroup Business Continuity Plan Summary 2018 PDFdexiBelum ada peringkat

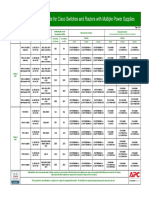

- APC (EMEA) Sizing Guide For Cisco Switches and Routers With Multiple Power SuppliesDokumen2 halamanAPC (EMEA) Sizing Guide For Cisco Switches and Routers With Multiple Power SuppliesdexiBelum ada peringkat

- In-Building Telecommunication Network: Specification Manual Guidelines For FTTX in New BuildingsDokumen63 halamanIn-Building Telecommunication Network: Specification Manual Guidelines For FTTX in New BuildingsdexiBelum ada peringkat

- Guide To BCM Third Edition ProtivitiDokumen66 halamanGuide To BCM Third Edition ProtivitiaalfonsopBelum ada peringkat

- AXIS P3375-LVE Network Camera: Classic, Outdoor-Ready HDTV 1080p Fixed Dome For Any Light ConditionsDokumen3 halamanAXIS P3375-LVE Network Camera: Classic, Outdoor-Ready HDTV 1080p Fixed Dome For Any Light ConditionsdexiBelum ada peringkat

- Enclosure Heat Load PDFDokumen55 halamanEnclosure Heat Load PDFdexiBelum ada peringkat

- SMP100 v2.0 W UserGuide EN 20170630Dokumen68 halamanSMP100 v2.0 W UserGuide EN 20170630RobertBelum ada peringkat

- Manual de Netbotz 750Dokumen24 halamanManual de Netbotz 750Victhor CondorBelum ada peringkat

- Yokogawa Terminal BoardsDokumen4 halamanYokogawa Terminal BoardsMohammed Abd El RazekBelum ada peringkat

- Instarack™ Lan: Ready-To-Assemble Network CabinetDokumen2 halamanInstarack™ Lan: Ready-To-Assemble Network CabinetNoel CastroBelum ada peringkat

- MC2018110593 ApplicationDokumen226 halamanMC2018110593 ApplicationcamaferBelum ada peringkat

- Harris IntegratorSeriesRacks1 - S - L - 25-8401Dokumen2 halamanHarris IntegratorSeriesRacks1 - S - L - 25-8401skustarzBelum ada peringkat

- Powervault tl2000 tl4000 Usersguide3en-Us PDFDokumen288 halamanPowervault tl2000 tl4000 Usersguide3en-Us PDFTom KielyBelum ada peringkat

- Manual For 7750Dokumen232 halamanManual For 7750cooldude_82Belum ada peringkat

- 2011 - 11 - 04 Manual de Servicio Horno Rosticero Marca Frijado Modelo STG - STWDokumen66 halaman2011 - 11 - 04 Manual de Servicio Horno Rosticero Marca Frijado Modelo STG - STWcristobalxst100% (2)

- Bike Rack InstructionsDokumen2 halamanBike Rack InstructionsmoremattersBelum ada peringkat

- SMT3000RMI2UC DATASHEET IE en-GBDokumen4 halamanSMT3000RMI2UC DATASHEET IE en-GBAbdul HameedBelum ada peringkat

- Smart-UPS On-Line - SRT3000RMXLADokumen4 halamanSmart-UPS On-Line - SRT3000RMXLAsqv64035Belum ada peringkat

- Hitachi Virtual Storage Platform G1000 Product OverviewDokumen56 halamanHitachi Virtual Storage Platform G1000 Product OverviewRobin LiBelum ada peringkat

- Hitachi DF700 Parts CatalogDokumen41 halamanHitachi DF700 Parts CatalogcymryshenBelum ada peringkat

- Installation Manual For Dacf710a CEL MakeDokumen134 halamanInstallation Manual For Dacf710a CEL MakeVikas SrivastavBelum ada peringkat

- DC Products ECatalog NA 2016 SSDokumen33 halamanDC Products ECatalog NA 2016 SSPhạm NamBelum ada peringkat

- LN SATA Series - Standalone DVR User's Manual (20080507)Dokumen121 halamanLN SATA Series - Standalone DVR User's Manual (20080507)Kulik MonicaBelum ada peringkat

- Install Guide: Fortigate-300A Fortios 3.0 Mr6Dokumen56 halamanInstall Guide: Fortigate-300A Fortios 3.0 Mr6Amarjeet.SinghBelum ada peringkat

- GCC OTSSMB Global Offer Q1 2014 Final Ed3.2Dokumen55 halamanGCC OTSSMB Global Offer Q1 2014 Final Ed3.2Diogo VillodreBelum ada peringkat

- Rack Stack ChecklistDokumen2 halamanRack Stack ChecklistJuller Efren Zabarburu MasBelum ada peringkat

- CSIII Model4310B User's Guide DS50003057Dokumen49 halamanCSIII Model4310B User's Guide DS50003057Daniel MestradoUNBBelum ada peringkat

- HP 10000 G2 Series Rack Options Installation Guide: Part Number: 489899-006 October 2013 Edition: 6Dokumen129 halamanHP 10000 G2 Series Rack Options Installation Guide: Part Number: 489899-006 October 2013 Edition: 6Sam Davendran A.Belum ada peringkat

- PowerSYSTIMAX® PowerSUM and GigaSPEED® XL Cabling Design GuidelinesSUM GigaSPEED XL Design GuidelinesDokumen37 halamanPowerSYSTIMAX® PowerSUM and GigaSPEED® XL Cabling Design GuidelinesSUM GigaSPEED XL Design Guidelinessarangan00720009986Belum ada peringkat

- Catalogue Ramblock English 2012 PDFDokumen411 halamanCatalogue Ramblock English 2012 PDFAbdelRhman ElfkyBelum ada peringkat

- Data Sheet 42U FS 600 X 800Dokumen6 halamanData Sheet 42U FS 600 X 800Sugunthan SelvarasuBelum ada peringkat

- Opcode Studio 5 Manual 1997Dokumen65 halamanOpcode Studio 5 Manual 1997nifnifnafnafBelum ada peringkat

- Installation Guide: Layer 2 Ethernet SwitchDokumen48 halamanInstallation Guide: Layer 2 Ethernet SwitchwpertuzpantojaBelum ada peringkat