Stainless Steel 422 Round Bar

Diunggah oleh

Arun KumarHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Stainless Steel 422 Round Bar

Diunggah oleh

Arun KumarHak Cipta:

Format Tersedia

STAINLESS STEEL 422 / S42200 / 1.

4935 / 616

Alloy 422 is a hardenable stainless steel designed for use at temperatures of up to 1200ºF (649ºC). Alloy 422 has good

resistance to scaling and oxidation. Through heat treatment, high mechanical properties can be developed. Alloy 422 is used in

applications such as compressors or steam turbines and also in aircraft parts, valves, high temperature bolting etc.

General Properties

With better strength at higher temperatures, Type 422 (S42200) is an appealing alternative to Type 403. Type 422 is a

hardenable martensitic stainless steel which is being widely used for high temperatures up to 1200°F. It is capable of being heat

treated to various high strength levels. It is often used in aircraft and power industries who require high strength/weight ratios

from room temperature to 1200°F.

Applications:

• Aircraft parts

• Steam and gas turbine components

• High heat components

• Rotors

Standards:

• UNS: ASTM/ASTE 42200

• DIN: 1.4935

Specifications

UNS - S42200

AISI - 616

AMS - 5655

ASTM A 565

GRD 616

DOD F 24669/7

MIL S 861

Chemical Composition Limits

Weig

C P Si Ni V Fe Mn S Cr Mo W

ht %

Alloy 0.20- 0.040 1.0 0.50- 0.20- 0.030 11.5- 0.75- 0.75-

Bal 1.0

422 0.25 max max 1.0 0.50 max 13.5 1.25 1.25

Availability :

Alloy 422 is available as round / flat / sheet / hexagonal / plate/ square / coil / pipe & fittings.

Availability

Alloy 422 is available as Bar (Round, Shapes)

Typical Mechanical Properties (Room Temperature)

Alloy 422

Test Yield Strength Ultimate Tensile % % Reduction

Temperature 0.2%MPa Strength MPa Elongation of Area

Alloy 422 862 1027 18.5 52

Mechanical properties

AISI Type 422 (DIN 1.4935) Mechanical properties,Our production completely according to the AISI Type 422 (DIN 1.4935)

standards to meet the AISI Type 422 (DIN 1.4935) mechanical performance, can also according to the customer request, to

meet the requirements of customers of AISI Type 422 (DIN 1.4935) mechanical properties.

Heat treatment

AISI Type 422 (DIN 1.4935) Heat treatment,Our production completely according to the AISI Type 422 (DIN 1.4935) standards

to meet the AISI Type 422 (DIN 1.4935) Heat treatment, can also according to the customer request, to meet the requirements

of customers of AISI Type 422 (DIN 1.4935) Heat treatment.

Welding performance

AISI Type 422 (DIN 1.4935) Welding performance,Our production completely according to the AISI Type 422 (DIN 1.4935)

standards to meet the AISI Type 422 (DIN 1.4935) Welding performance, can also according to the customer request, to meet

the requirements of customers of AISI Type 422 (DIN 1.4935) Welding performance.

Machineability

• Comparable to 18-8 but easier to machine

• Help avoid galling with sharply ground tools

• Maintain consistent speed and feed

• Turning tools: 8-14° side rake

• Drilling: 140° point

• Threading: grind tools with 10-15° back rake

• Cobalt high-speed tools: turn at 90-120 sfpm, drill at 40-75 sfpm, mill at 70-120 sfpm, ream at 20-60 sfpm, roughing and

finishing at 200-400 sfpm

Workability

• Initial forging and rolling at 2100° to 2150°F (1149° to 1177°C)

• 1700°F (927°C) minimum to hot work

Anda mungkin juga menyukai

- Stone Retaining Wall DesignDokumen25 halamanStone Retaining Wall DesignSafi Zabihullah Safi81% (16)

- AISI 1020 Low Carbon/Low Tensile Steel: Element ContentDokumen4 halamanAISI 1020 Low Carbon/Low Tensile Steel: Element ContentRatno WijayaBelum ada peringkat

- AMS-2404-G - Electroless Nickel CoatingDokumen9 halamanAMS-2404-G - Electroless Nickel CoatingaadmaadmBelum ada peringkat

- Welding TrainingDokumen87 halamanWelding Trainingeswar100% (1)

- Stone Cladding Fixings Technical StandardsDokumen6 halamanStone Cladding Fixings Technical StandardsvtalexBelum ada peringkat

- Machine Design Board ExamDokumen13 halamanMachine Design Board ExamMico Castillo CampoBelum ada peringkat

- 422 Steel DatasheetDokumen2 halaman422 Steel DatasheetKashif MohiuddinBelum ada peringkat

- Section 2.0 Alloy SteelsDokumen10 halamanSection 2.0 Alloy SteelsAloísio NascimentoBelum ada peringkat

- Our Products: About Us What We Do About Us What We Do About Us What We Do About Us What We DoDokumen4 halamanOur Products: About Us What We Do About Us What We Do About Us What We Do About Us What We DoThaw Zin HtayBelum ada peringkat

- Alloy Steels 8620: Chemistry DataDokumen6 halamanAlloy Steels 8620: Chemistry DataVijay PalBelum ada peringkat

- Aalco Metals LTD Stainless Steel 14021 Bar 311Dokumen2 halamanAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaBelum ada peringkat

- 431 Stainless SteelDokumen2 halaman431 Stainless Steeldeden ibnuBelum ada peringkat

- Din 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnDokumen3 halamanDin 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnairkadBelum ada peringkat

- Aisi 4340 Alloy Steel (Uns g43400)Dokumen3 halamanAisi 4340 Alloy Steel (Uns g43400)detriwiatnoBelum ada peringkat

- 17 4 PHDokumen2 halaman17 4 PHzaranrajputBelum ada peringkat

- S7 Tool Steel: What Is ?Dokumen3 halamanS7 Tool Steel: What Is ?Sama UmateBelum ada peringkat

- Etchant Test On CastingsDokumen2 halamanEtchant Test On CastingsHarshaVeeragandhamBelum ada peringkat

- Minfm35152 en 10111 Grade Dd11 Hot RolledDokumen3 halamanMinfm35152 en 10111 Grade Dd11 Hot Rolledmelvin ekboteBelum ada peringkat

- EN19 Alloy Steel Properties GuideDokumen5 halamanEN19 Alloy Steel Properties GuideNaiduBelum ada peringkat

- Difference Between y Block and Other Xmas TreeDokumen6 halamanDifference Between y Block and Other Xmas TreeMOHAMED FAISALKHANBelum ada peringkat

- Stainless Steel 420 Material Chemical CompositionDokumen3 halamanStainless Steel 420 Material Chemical Compositionr arumugamBelum ada peringkat

- Stainless Steel 202 Material Chemical CompositionDokumen3 halamanStainless Steel 202 Material Chemical CompositionLelka2000Belum ada peringkat

- Stainless Steel 420 Material Chemical CompositionDokumen2 halamanStainless Steel 420 Material Chemical CompositionAHMED FATHIBelum ada peringkat

- Supply Range of AISI M42 Tool Steel High SpeedDokumen4 halamanSupply Range of AISI M42 Tool Steel High SpeedSama UmateBelum ada peringkat

- 440C DS CarpenterDokumen5 halaman440C DS CarpenterdaymonBelum ada peringkat

- Tooling Materials&Heat TreatmentDokumen13 halamanTooling Materials&Heat TreatmentVinod MadireddyBelum ada peringkat

- Welding Product Programme: Duplex and Super Duplex Stainless SteelDokumen6 halamanWelding Product Programme: Duplex and Super Duplex Stainless SteelFERNANDO MIRANDABelum ada peringkat

- 25CR20NIDokumen2 halaman25CR20NIShariq KhanBelum ada peringkat

- Nickel Alloys Monel 400 N04400Dokumen4 halamanNickel Alloys Monel 400 N04400David Balboa VillenasBelum ada peringkat

- Amie Material Science Notes PDFDokumen276 halamanAmie Material Science Notes PDFAlok KulkarniBelum ada peringkat

- JIS G4051 Grade S45C: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDokumen4 halamanJIS G4051 Grade S45C: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearALEX MURPHYBelum ada peringkat

- Aisi 4140 En8 En19Dokumen1 halamanAisi 4140 En8 En19Jose KurianBelum ada peringkat

- Steel Dynamics Bar Book Rev 2 New CoverDokumen194 halamanSteel Dynamics Bar Book Rev 2 New CoverNina LazuardiBelum ada peringkat

- 17 4 PHDokumen2 halaman17 4 PHParag NaikBelum ada peringkat

- Oxford Alloy 182 (ENiCrFe-3)Dokumen1 halamanOxford Alloy 182 (ENiCrFe-3)brunizzaBelum ada peringkat

- Aisi 200 SeriesDokumen19 halamanAisi 200 Seriessgupta_192494Belum ada peringkat

- Alloy Steel Round BarDokumen10 halamanAlloy Steel Round BarSingarao KattaBelum ada peringkat

- Monel® Alloy 400: C MN S Si Ni Cu FeDokumen2 halamanMonel® Alloy 400: C MN S Si Ni Cu FeD_D_76Belum ada peringkat

- MaterialData - Aço 1045Dokumen2 halamanMaterialData - Aço 1045Victhor AraujoBelum ada peringkat

- Essential Guide to Piping Materials SelectionDokumen60 halamanEssential Guide to Piping Materials SelectionEngr Arfan Ali DhamrahoBelum ada peringkat

- AISI 4130 Steel - 25CrMo4 - 1.7218 - 708A25 - SCM430 - Special SteelDokumen3 halamanAISI 4130 Steel - 25CrMo4 - 1.7218 - 708A25 - SCM430 - Special SteelGeorge LawrenceBelum ada peringkat

- Hardness HSS - SKD11Dokumen5 halamanHardness HSS - SKD11Antonius PrakosaBelum ada peringkat

- Stainless Steel - Grade 321 (UNS S32100)Dokumen4 halamanStainless Steel - Grade 321 (UNS S32100)mp87_ingBelum ada peringkat

- 02.CARBO - RC 3 Blau eDokumen1 halaman02.CARBO - RC 3 Blau eMario CastilloBelum ada peringkat

- High Quality Products For Welding and CladdingDokumen25 halamanHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- Chemical Formula Topics Covered: Table 1. Composition Ranges For 410 Grade Stainless SteelDokumen4 halamanChemical Formula Topics Covered: Table 1. Composition Ranges For 410 Grade Stainless Steelaryanscrews2329Belum ada peringkat

- 321 Stainless Steel Sheet SuppliersDokumen3 halaman321 Stainless Steel Sheet SuppliersSteel EmporiumBelum ada peringkat

- SAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDokumen4 halamanSAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearALEX MURPHYBelum ada peringkat

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDokumen2 halamanStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdBelum ada peringkat

- Stainless Steel Grade 410Dokumen5 halamanStainless Steel Grade 410Rajesh N Priya Gopinathan100% (1)

- AISI 4130 Alloy SteelDokumen2 halamanAISI 4130 Alloy SteelSantosh IngaleBelum ada peringkat

- AISI 4130 Alloy SteelDokumen2 halamanAISI 4130 Alloy SteelKandeepanBelum ada peringkat

- Steels For Oil - Gas - ExplorationDokumen16 halamanSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىBelum ada peringkat

- P20 Steel Plate Tool SteelDokumen4 halamanP20 Steel Plate Tool SteelSama UmateBelum ada peringkat

- Bar Basics and TerminologyDokumen24 halamanBar Basics and TerminologyEdwin MPBelum ada peringkat

- Norris Polished Rods (P004-V02-072208) - 1Dokumen5 halamanNorris Polished Rods (P004-V02-072208) - 1Rodrigo RuizBelum ada peringkat

- BUTTING Duplex 2018Dokumen20 halamanBUTTING Duplex 2018Benny PoBelum ada peringkat

- Spec 4140 & 4130Dokumen7 halamanSpec 4140 & 4130Nisa_nisheBelum ada peringkat

- Filler Wires PDFDokumen7 halamanFiller Wires PDFJayaram MVBelum ada peringkat

- Liquid NitridingDokumen7 halamanLiquid NitridingSenthil_kumar_palaniBelum ada peringkat

- 444 Data Sheet PDFDokumen2 halaman444 Data Sheet PDFamitavjhaBelum ada peringkat

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDari EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonBelum ada peringkat

- CastableDokumen8 halamanCastableManindra SinghBelum ada peringkat

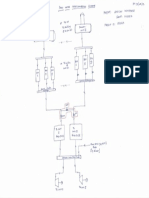

- Feed Water Inter Connection SchemeDokumen1 halamanFeed Water Inter Connection SchemeArun KumarBelum ada peringkat

- Fundamentals of Orifice Measurement Techwpaper PDFDokumen9 halamanFundamentals of Orifice Measurement Techwpaper PDFartletBelum ada peringkat

- Fan Sizing VENTILATIONDokumen1 halamanFan Sizing VENTILATIONArun KumarBelum ada peringkat

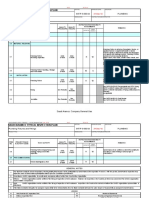

- Sno Service Pipe Material: 4. Non Ibr PipingsDokumen1 halamanSno Service Pipe Material: 4. Non Ibr PipingsArun KumarBelum ada peringkat

- Mathesh - Meaning - Baby Name Mathesh Meaning and AstrologyDokumen4 halamanMathesh - Meaning - Baby Name Mathesh Meaning and AstrologyArun KumarBelum ada peringkat

- Casting Material CF8M DATA SHEETDokumen9 halamanCasting Material CF8M DATA SHEETArun KumarBelum ada peringkat

- Revised TG Hall Layout for Client ReviewDokumen3 halamanRevised TG Hall Layout for Client ReviewArun KumarBelum ada peringkat

- Expansion JointsDokumen10 halamanExpansion JointsArun KumarBelum ada peringkat

- PID-0002 Heater SystemDokumen1 halamanPID-0002 Heater SystemArun KumarBelum ada peringkat

- Not For SaleDokumen1 halamanNot For SaleArun KumarBelum ada peringkat

- Chimney Sizing Calculation-R1Dokumen3 halamanChimney Sizing Calculation-R1Arun Kumar67% (3)

- IS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StorageDokumen98 halamanIS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StoragePankaj DhimanBelum ada peringkat

- Construction of Electric Plants - 2009Dokumen153 halamanConstruction of Electric Plants - 2009balwant singh negi100% (2)

- Chimney Sizing Calculation-R1Dokumen3 halamanChimney Sizing Calculation-R1Arun Kumar67% (3)

- HEI 2623 04 Standards For Power Plant Heat Ex Changers 4thDokumen88 halamanHEI 2623 04 Standards For Power Plant Heat Ex Changers 4thArun Kumar100% (2)

- Chimney Sizing Calculation-R1Dokumen3 halamanChimney Sizing Calculation-R1Arun Kumar67% (3)

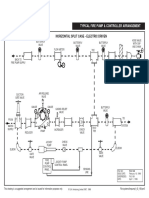

- ARM STRONG PUMP INTERLOCK HSC ElectricDokumen1 halamanARM STRONG PUMP INTERLOCK HSC ElectricArun KumarBelum ada peringkat

- Steam Conservation Guide 101Dokumen59 halamanSteam Conservation Guide 101Arun KumarBelum ada peringkat

- Modern Cement Plant Cold Start Up CurvesDokumen3 halamanModern Cement Plant Cold Start Up CurvesArun KumarBelum ada peringkat

- Route Map PDFDokumen1 halamanRoute Map PDFArun KumarBelum ada peringkat

- Underground Fire Supply GuideDokumen11 halamanUnderground Fire Supply GuideArun KumarBelum ada peringkat

- Flange Table ASME BS As ANSI DN200mmDokumen2 halamanFlange Table ASME BS As ANSI DN200mmArun KumarBelum ada peringkat

- Route MapDokumen1 halamanRoute MapArun KumarBelum ada peringkat

- 5822Dokumen16 halaman5822rambinodBelum ada peringkat

- Construction of Electric Plants - 2009Dokumen153 halamanConstruction of Electric Plants - 2009balwant singh negi100% (2)

- IS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StorageDokumen98 halamanIS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StoragePankaj DhimanBelum ada peringkat

- Is 10221Dokumen31 halamanIs 10221Vinoth P50% (2)

- BMW Center Show Room Final-01Dokumen43 halamanBMW Center Show Room Final-01QC MEPBelum ada peringkat

- Medium Density FiberboardDokumen4 halamanMedium Density Fiberboardsabiha naazBelum ada peringkat

- Part 3 Chapter2Dokumen33 halamanPart 3 Chapter2Mahmoud AlnaserBelum ada peringkat

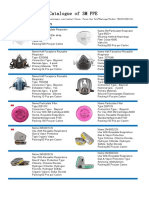

- Catalogue of 3M PPE and Safety EquipmentDokumen3 halamanCatalogue of 3M PPE and Safety EquipmentSothearaThengBelum ada peringkat

- Simplified Estimate by Max FajardoDokumen300 halamanSimplified Estimate by Max FajardoRyan David MacayanBelum ada peringkat

- Membrane Technology: Reverse Osmosis Ultrafiltration MicrofiltrationDokumen66 halamanMembrane Technology: Reverse Osmosis Ultrafiltration MicrofiltrationShivani MunishwarBelum ada peringkat

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDokumen2 halamanSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominBelum ada peringkat

- 5C1. Coal Ash Generation Process and Application FieldsDokumen2 halaman5C1. Coal Ash Generation Process and Application Fieldssrigirisetty208Belum ada peringkat

- Install Gantry SignsDokumen2 halamanInstall Gantry SignsNouman MohsinBelum ada peringkat

- P EBAA Mega Coupling Series 3800Dokumen4 halamanP EBAA Mega Coupling Series 3800Brandon HoltenBelum ada peringkat

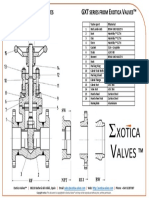

- Gate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimDokumen1 halamanGate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimGiovanni PetrizzoBelum ada peringkat

- Ultralight, Scalable, and High-Temperature, Resilient Ceramic Nanofiber SpongesDokumen4 halamanUltralight, Scalable, and High-Temperature, Resilient Ceramic Nanofiber SpongesCj Labadan100% (1)

- Mobil Dynagear Series Performance ProfileDokumen2 halamanMobil Dynagear Series Performance Profileanibal_rios_rivasBelum ada peringkat

- Brochure GC Fuji IX GP EXTRA PDFDokumen20 halamanBrochure GC Fuji IX GP EXTRA PDFRifqie al harisBelum ada peringkat

- Structural Specification - Titus.03Dokumen3 halamanStructural Specification - Titus.03Davie BancoroBelum ada peringkat

- JConservDent223216-4456049 122240Dokumen8 halamanJConservDent223216-4456049 122240AKSBelum ada peringkat

- Unit 6 - Chemical Reactions - Complete NotesDokumen57 halamanUnit 6 - Chemical Reactions - Complete Notesapi-508178584Belum ada peringkat

- 1999jan BldgTech (Final)Dokumen12 halaman1999jan BldgTech (Final)Pathy AmoresBelum ada peringkat

- Build Windows Doors Guide AA Tech UniversityDokumen49 halamanBuild Windows Doors Guide AA Tech UniversityAnonymous oUoJ4A8xBelum ada peringkat

- Basalt Fiber Properties and ApplicationsDokumen6 halamanBasalt Fiber Properties and ApplicationssrinilsukumarkhdBelum ada peringkat

- Chs - Chem - ch3 - Mass - Ratios - and - Law - of - Multiple - Proportions Mod4Dokumen22 halamanChs - Chem - ch3 - Mass - Ratios - and - Law - of - Multiple - Proportions Mod4Marvel Felicity Rosell ArmestoBelum ada peringkat

- CHAPTER 2 Classification of NanomaterialsDokumen45 halamanCHAPTER 2 Classification of NanomaterialsFarah Hanani ZulkifliBelum ada peringkat

- CodeDokumen13 halamanCodeKamlesh Steel industriesBelum ada peringkat

- Astm F1554Dokumen9 halamanAstm F1554CPA BTKBelum ada peringkat

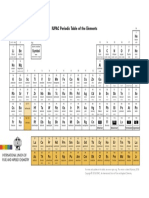

- IUPAC Periodic Table of The Elements: Ti CRDokumen1 halamanIUPAC Periodic Table of The Elements: Ti CRMargaux HidalgoBelum ada peringkat

- Alathon L5840Dokumen1 halamanAlathon L5840mohamed1303Belum ada peringkat