Sh1-Dhi-P0100-M-M01-Pid-5301 - Symbol and Legend 1 of 4 PDF

Diunggah oleh

Thanh SonJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Sh1-Dhi-P0100-M-M01-Pid-5301 - Symbol and Legend 1 of 4 PDF

Diunggah oleh

Thanh SonHak Cipta:

Format Tersedia

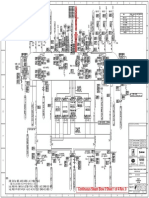

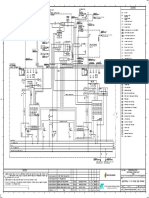

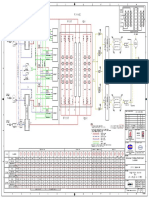

A B C D E F G H

SH1-DHI-P0100-M-M01-PID-5301 Drawing No.

EQUIPMENT EQUIPMENT (CONT) LINE VALVES VALVE STATUS SYMBOLS MISCELLANEOUS (CONT)

KNIFE GATE

1 1

PIPE CLASS CHANGE

TURBINE G GATE

SILO STEAM LEAKOFF

HBD GBD

SINGLE DOUBLE GENERATOR VACUUM PRIMING VALVE

FLOW FLOW

M WS

CONVEYOR WATER SEAL

HORIZONTAL MOTOR OPERATED VALVE

CENTRIFUGAL PUMP INSIDE OUTSIDE BUILDING PENETRATION

M

PRESSURE BALANCE

MOV WITH INTEGRAL MOV

M EXTERNAL PIPE

CHUTE

WITH SMALL VALVE

VERTICAL PUMP

M

MOTOR OPERATED VALVE EJECTOR OR EDUCTOR

SUMP SUBMERSIBLE WET PIT CANNED OPEN DURING NORMAL

WITH SMALL ISOLATION VALVE

OPERATION

ON SLIDING GATE

EXHAUST HOOD

BARREL CASING GAS SCRUBBER

CENTRIFUGAL PUMP GLOBE(OPEN) LO

LOCKED OPEN

V

PIPING HIGH POINT VENT ( V )

2 GLOBE(CLOSED) 2

POSITIVE DISPLACEMENT CLOSED DURING NORMAL OPERATION

PUMP SLIDE GATE

Y-PATTERN GLOBE

DESUPERHEATER

SCREW TYPE RECIPROCATING LC

LOCKED CLOSED

DOME VALVE

VIBRATING FEEDER SPRAY NOZZLE OR

L THROTTLE SPARGER (SHOWN WITH

HAND PUMP BALL (USED WHEN LOCKED IN THROTTLE UPWARD FLOW)

POSITION)

DWG.(TYP.)

VS

HOOD ANGLE VACUUM SEAL X-XX-XXX

D-1 LINE BREAK OR RESUMPTION POINT

DRUM PUMP

ZONE(TYP.)

THREE-WAY

TRIPPER FURNISHED WITH SUPPLIER EQUIPMENT

VACUUM PUMP MISCELLANEOUS

FURNISHED WITH TURBINE

FOUR-WAY GENERATOR EQUIPMENT

3 RECIPROCATING 3

AIR COMPRESSOR

(INSTR. AND SERVICE)

PROCESS PIPING SPECTACLE BLIND FURNISHED WITH STEAM

NEEDLE GENERATOR EQUIPMENT

PLUG IDENTIFICATION OF PIPING

MAIN PROCESS FLOW PIPING 4 CONNECTION AT CONDENSER

ROTARY SCREW COMPRESSOR CIRCULAR OR HAMMER BLIND

2-WAY 3-WAY 4-WAY

SECONDARY PROCESS FLOW PIPING IDENTIFICATION OF PIPING

DIAPHRAGM VALVE 1 CONNECTION AT TURBINE GENERATOR

M SIMPLEX BASKET STRAINER

BUTTERFLY(OPEN)

CONCENTRIC REDUCER

MIXER INCREASER

NC FURNISHED BY CONSTRUCTOR

BUTTERFLY(CLOSED)

ECCENTRIC REDUCER

INCREASER HOSE DUPLEX BASKET STRAINER DOOSAN

U-TUBE HEAT EXCHANGER

SUPPLIER INTERFACE

WELDED CAP PINCH OTHERS DRAWING SUBMISSION STATUS :

Y-TYPE STRAINER (SHOWN FOR CONSTRUCTION

WITHOUT BLOWOFF VALVE)

4 SCREWED CAP TANDEM BLOW DOWN 4

SHELL & TUBE TYPE

HEAT EXCHANGER PIPING & DUCTWORK

-

SPECIALTY IDENTIFICATION

HOSE CONNECTION T-TYPE STRAINER (SHOWN

CHECK WITHOUT BLOWOFF VALVE)

QUICK DISCONNECT

PLATE TYPE HEAT EXCHANGER FOOT

TEMPORARY STARTUP

0 04.02.2016 FOR CONSTRUCTION Y.H.CHO H.W.NAM J.HWANGBO

REMOVABLE SPOOL STRAINER VENDOR SCOPE WITHIN THE BOX

FLOW LIMITING REV DATE DESCRIPTION DRWN CHKD APPD

(OR EXCESS FLOW) CHECK

OWNER OWNER'S CONSULTANT

FLANGE

SCREEN TYPE STRAINER

STRAIGHT TUBE HEAT NON RETURN POWER ACTUATED

EXCHANGER (SINGLE PASS) BLIND FLANGE

INSULATING FLANGE (IF) BACKFLOW PREVENTER

OR DIELECTRIC UNION (DU) FICHTNER GmbH & Co. KG PV ENGINEERING

IF/DU (SHOWN) F FILTER WHITE : NEW VIETNAM OIL AND GAS GROUP

STOP CHECK

BLACK : EXISTING (PVN)

STRAIGHT TUBE HEAT BREATHER CAP EPC CONTRACTOR EPC CONTRACTOR'S CONSULTANT

EXCHANGER (TWO PASS)

ANGLE CHECK

5 LOOP SEAL CO2 CO2 ABSORBER

SEAL PIT

5

PRESSURE VESSELS VERITICAL COMBINED AIR RELEASE VALVE

(SHOWN) OR HORIZONTAL

(TANKS, RECEIVERS, DRYERS, PROCESS DATA POINT VIETNAM MACHINERY

DOWNWARD SLOPE TOKYO ELECTRIC POWER SERVICES

SEPARATORS, ETC.)

G

ACTUATOR T-TYPE STRAINER 3 IDENTIFICATION INSTALLATION CORPORATION COMPANY LIMITED - TEPSCO

(ON FLOW DIAGRAM) (LILAMA)

G = GEAR (SHOWN)

UPWARD SLOPE PROJECT TITLE

A = AIR WRENCH

C = CHAIN

CONE ROOF TANK X = EXTENSION STEM DRAIN LEG WITH WELDED CAP SONG HAU 1 THERMAL POWER PLANT

B = WITH INTEGRAL BYPASS

VALVE

EXPANSION JOINT 2 x 600MW

OR VENT

D = DEEP STUFFING BOX AND

LANTERN GLAND PULSATION DAMPER

FLOATING TOP TANK

T = TAP IN BOTTOM OF BODY CONTRACT NO.

(FOR ASME TEST) FLEXIBLE CONNECTION

BURIED PIPE

CALIBRATION COLUMN

250515 / LILAMA-DHI

AFTERCOOLER DRAWING TITLE

HEAT TRACING TRAP P&I DIAGRAM

E E

E = ELECTRICALLY TRACED SYSTEM INTERFACE BOUNDARY _T

ST = STEAM TRAP SAFETY SHOWER AND EYE WASH SYMBOL AND LEGNED (1/4)

AT = AIR TRAP

SAMPLE COOLER DT = DRAIN TRAP

6 PIPING BY VENDOR RT = RESIN TRAP 6

THIS SYMBOL REPRESENTS INTERFACES

BETWEEN SYSTEM/PLANTS AND SUB-CONTRACTOR FUNCTION NAME SIGN DATE

MESH SCREEN

STEAM CONVERTER VENT LINE IN DRAINAGE SYSTEM VIEW GLASS

SUBSYSTEMS/PLANT SECTIONS. DRWN Y.H.CHO 26.06.2015

0 CHKD H.W.NAM 26.06.2015

TO DRAINAGE SYSTEM APPD J.HWANGBO 26.06.2015

PRESSURIZED GAS BOTTLE INSULATED PIPE LINE

D DRAWING No. SHEET No. SCALE REV

THIS SYMBOL REPRESENTS INTERFACES

BETWEEN PIPING SUBSYSTEM. SH1-DHI-P0100-M-M01-PID-5301 1 OF 1 N/A 0

A B C D E F G H A3 (420x297)

Anda mungkin juga menyukai

- Diagram PLTA SLJDokumen4 halamanDiagram PLTA SLJMEi Cuiet Luph-LuPhBelum ada peringkat

- VA1 NHI 00100 M M1C MAN 1001 Rev0 MGS4766 Double Inlet and Double Outlet Coal Mill Instruction (Dextral)Dokumen5 halamanVA1 NHI 00100 M M1C MAN 1001 Rev0 MGS4766 Double Inlet and Double Outlet Coal Mill Instruction (Dextral)hoangduythanhqbBelum ada peringkat

- Civil Works Guide Line For SMC: Braskem-Idesa CodeDokumen92 halamanCivil Works Guide Line For SMC: Braskem-Idesa CodeDaniel EsparzaBelum ada peringkat

- Minera Spence S.A Sgo Project Graphic Displays Drawings Plant OverviewDokumen12 halamanMinera Spence S.A Sgo Project Graphic Displays Drawings Plant Overviewrodrigo betancurBelum ada peringkat

- Continuous Steam Blow 3 Sheet 1 of 4 Rev. 0Dokumen4 halamanContinuous Steam Blow 3 Sheet 1 of 4 Rev. 0Anonymous JtYvKt5XEBelum ada peringkat

- Eil Job No.: A545: OwnerDokumen35 halamanEil Job No.: A545: OwnerSandip SurBelum ada peringkat

- SKETCH 022 Tripping MatrixDokumen6 halamanSKETCH 022 Tripping MatrixÖzgür Özdemir100% (1)

- Cable Schedule TemplateDokumen1 halamanCable Schedule TemplatevarunBelum ada peringkat

- F+CTJB: 3 5 6 2 0 0 6 1 3 6 8 File Name:-Ytpsd1Dokumen4 halamanF+CTJB: 3 5 6 2 0 0 6 1 3 6 8 File Name:-Ytpsd1Appalaraju RokallaBelum ada peringkat

- Fiala PDFDokumen52 halamanFiala PDFRinjumon RinjuBelum ada peringkat

- Motor Selection FoliosDokumen26 halamanMotor Selection Folios8085roBelum ada peringkat

- Catalogo Rev FDokumen44 halamanCatalogo Rev FtelephonicaBelum ada peringkat

- Accesorios UnistrutDokumen76 halamanAccesorios UnistrutLuisxMiguelBelum ada peringkat

- Switch MaterialDokumen46 halamanSwitch Materialvivek savaliyaBelum ada peringkat

- Control TranformerDokumen1 halamanControl TranformerRAM SHANMUGAMBelum ada peringkat

- Manual Valve (NT2-L1-M-HAL.56-209130 - Rev - 00) PDFDokumen81 halamanManual Valve (NT2-L1-M-HAL.56-209130 - Rev - 00) PDFlele862014Belum ada peringkat

- SSG Ed 100 Ele SLD 0002 - 2Dokumen2 halamanSSG Ed 100 Ele SLD 0002 - 2Hanugroho AjiBelum ada peringkat

- ML:LT Ji 0 : Vinh Tan Power Plant ProjectDokumen7 halamanML:LT Ji 0 : Vinh Tan Power Plant ProjectMinh Tien DangBelum ada peringkat

- R1 - 100701492-Pro-004 - Uf P&idDokumen1 halamanR1 - 100701492-Pro-004 - Uf P&idPrashant HuddarBelum ada peringkat

- 1035 Press Laminating Machine 1 - P61A-L42N V1.0 - ENGDokumen285 halaman1035 Press Laminating Machine 1 - P61A-L42N V1.0 - ENGHugo Enrique Ramirez RamirezBelum ada peringkat

- Power Transformer Testing & Maintenance: Special Course 2021Dokumen14 halamanPower Transformer Testing & Maintenance: Special Course 2021sherifmoussaBelum ada peringkat

- s10332300-3011 - 0 Process AnalyzerDokumen14 halamans10332300-3011 - 0 Process Analyzerappril26Belum ada peringkat

- SVP-43763-DWG-ELE-RSAB-008 - GA Capacitor Bank B - R02Dokumen12 halamanSVP-43763-DWG-ELE-RSAB-008 - GA Capacitor Bank B - R02septa ibnuBelum ada peringkat

- A ProcessDokumen41 halamanA ProcessjulioBelum ada peringkat

- A415 5120 1021 Enq Rev0Dokumen443 halamanA415 5120 1021 Enq Rev0Apoorv GoenkaBelum ada peringkat

- DN02 S09011 e XK 1004 01Dokumen64 halamanDN02 S09011 e XK 1004 01Konge ThethtunaungBelum ada peringkat

- Description Engg. Test Commi-Mainte - Dept. Dept. Ssioning NanceDokumen4 halamanDescription Engg. Test Commi-Mainte - Dept. Dept. Ssioning NanceVishal Kumar LaddhaBelum ada peringkat

- Manual Contactor Lc1dfk Lc1dgk Lc1dpk Lc1dwk (Conde.)Dokumen4 halamanManual Contactor Lc1dfk Lc1dgk Lc1dpk Lc1dwk (Conde.)joseBelum ada peringkat

- Kalpakka Chemical Cems Process Diagram-Model - PDF NewDokumen1 halamanKalpakka Chemical Cems Process Diagram-Model - PDF NewRajesh KumarBelum ada peringkat

- Generator and ProtectionsDokumen50 halamanGenerator and ProtectionsRakesh KiranBelum ada peringkat

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Dokumen2 halamanQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTOBelum ada peringkat

- Dehn Catalogue Safety EquipmentDokumen196 halamanDehn Catalogue Safety EquipmentIrfan AshrafBelum ada peringkat

- BE Engineering Guide VDC Air Cooled CondenserDokumen46 halamanBE Engineering Guide VDC Air Cooled Condensernauta007Belum ada peringkat

- Ash 13.8 em 411B - AsbuiltDokumen25 halamanAsh 13.8 em 411B - AsbuiltMr IlchamBelum ada peringkat

- NE1 Official Punch List - Condensate Polishing Plant 20220312Dokumen10 halamanNE1 Official Punch List - Condensate Polishing Plant 20220312FuqingliBelum ada peringkat

- One-Line Diagram - Overall SLD (Edit Mode) : Turbine PDC (33BBA, 33BBB, 33BBC, 33BBD)Dokumen2 halamanOne-Line Diagram - Overall SLD (Edit Mode) : Turbine PDC (33BBA, 33BBB, 33BBC, 33BBD)namakBelum ada peringkat

- AHS-KRS-30-BUB - DC-UPS2 - 00E652A3 - RedCorrex PDFDokumen24 halamanAHS-KRS-30-BUB - DC-UPS2 - 00E652A3 - RedCorrex PDFArchiford NdhlovuBelum ada peringkat

- T10107-YU03-P0HDE-520201 - Rev 0Dokumen41 halamanT10107-YU03-P0HDE-520201 - Rev 0stalin63Belum ada peringkat

- Control Panel Space OptimizationDokumen12 halamanControl Panel Space Optimizationyopy_yogieBelum ada peringkat

- LF Plant STG S.p.A. Main Control PanelDokumen98 halamanLF Plant STG S.p.A. Main Control Panelharetha all nassanBelum ada peringkat

- OSC - 2015 - Revised - Oct (Power Cables) PDFDokumen118 halamanOSC - 2015 - Revised - Oct (Power Cables) PDFIván P. MorenoBelum ada peringkat

- MRT-DN02-P2LBA-830001 (Commissioning Procedure) HP&IP&LP Steam System Rev.1Dokumen57 halamanMRT-DN02-P2LBA-830001 (Commissioning Procedure) HP&IP&LP Steam System Rev.1Alvin PanjaitanBelum ada peringkat

- 01+yn1m301719-Afb 1rtaDokumen53 halaman01+yn1m301719-Afb 1rtaNurul Islam FarukBelum ada peringkat

- DRAWINGDokumen44 halamanDRAWINGsugeng wahyudiBelum ada peringkat

- ABB - 4 Biggest MistakesDokumen7 halamanABB - 4 Biggest MistakesAnargha BhattacharyaBelum ada peringkat

- Inc MCC 400Dokumen14 halamanInc MCC 400Fatholla SalehiBelum ada peringkat

- Va1 Dec 00100 I M1D Pid 8701 PDFDokumen1 halamanVa1 Dec 00100 I M1D Pid 8701 PDFAnonymous JtYvKt5XEBelum ada peringkat

- 380910-EIA-0005-01 (0) SLD For PCC-04 - Temp PlantDokumen1 halaman380910-EIA-0005-01 (0) SLD For PCC-04 - Temp PlantNikhil Suthar100% (1)

- Calibration TablesDokumen32 halamanCalibration TablesDanielle BarkerBelum ada peringkat

- SOER Input Signals For Arar - Rev2 - 19may05Dokumen29 halamanSOER Input Signals For Arar - Rev2 - 19may05srigirisetty208Belum ada peringkat

- GA Drawing Deluge Valve System - R2Dokumen4 halamanGA Drawing Deluge Valve System - R2Keannu Radhika Putra WibowoBelum ada peringkat

- GE Synch Check RelayDokumen4 halamanGE Synch Check RelayVikrantBelum ada peringkat

- Cable Schedule - ST OXD - RP Rev 1Dokumen2 halamanCable Schedule - ST OXD - RP Rev 1mukesh_kht1Belum ada peringkat

- Feet Meter: Saudi Arabian Oil CompanyDokumen1 halamanFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesBelum ada peringkat

- Load Conduits Conductors Service Gland Type RUN Total QTY HP OR KVA Volts "FROM" END " TO " END FromDokumen1 halamanLoad Conduits Conductors Service Gland Type RUN Total QTY HP OR KVA Volts "FROM" END " TO " END FromJohn BuntalesBelum ada peringkat

- Feet Meter: Saudi Arabian Oil CompanyDokumen1 halamanFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesBelum ada peringkat

- Feet Meter: Saudi Arabian Oil CompanyDokumen1 halamanFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesBelum ada peringkat

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Dokumen1 halamanRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesBelum ada peringkat

- Feet MeterDokumen1 halamanFeet MeterThomas MathewBelum ada peringkat

- V121411002X00F2 CCSDokumen1 halamanV121411002X00F2 CCSEr M M KazimBelum ada peringkat

- (Elec) Generator & Auxiliary SystemsDokumen107 halaman(Elec) Generator & Auxiliary SystemsThanh Son100% (2)

- (Elec) Generator Excitation SystemDokumen51 halaman(Elec) Generator Excitation SystemThanh Son100% (1)

- (Elec) Generator ControlDokumen12 halaman(Elec) Generator ControlThanh SonBelum ada peringkat

- Section03 A4Dokumen1.644 halamanSection03 A4Thanh SonBelum ada peringkat

- Main Table of Contents Volume 1 Operation (Operators) ManualDokumen19 halamanMain Table of Contents Volume 1 Operation (Operators) ManualTrung ĐứcBelum ada peringkat

- VA1-TSB-00100-PM-M1B-TRN-0001 - Title BlockDokumen1 halamanVA1-TSB-00100-PM-M1B-TRN-0001 - Title BlockThanh SonBelum ada peringkat

- Operation & Manual of TSB TurbineDokumen14 halamanOperation & Manual of TSB TurbineTrung ĐứcBelum ada peringkat

- (Mech) Major Parts of The Steam TurbineDokumen38 halaman(Mech) Major Parts of The Steam TurbineThanh Son100% (1)

- Sh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Dokumen1 halamanSh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Thanh SonBelum ada peringkat

- C&I - TSI System For Steam TurbineDokumen42 halamanC&I - TSI System For Steam TurbineThanh Son100% (2)

- C&I - Hardware OverviewDokumen27 halamanC&I - Hardware OverviewThanh SonBelum ada peringkat

- (Mech) Operation LimitationDokumen25 halaman(Mech) Operation LimitationThanh SonBelum ada peringkat

- C&I IES OverviewDokumen21 halamanC&I IES OverviewThanh SonBelum ada peringkat

- System Configuration and ArchitectureDokumen11 halamanSystem Configuration and ArchitectureThanh SonBelum ada peringkat

- (Mech) Mismatch ChartDokumen8 halaman(Mech) Mismatch ChartThanh Son50% (2)

- C&I - Control Logic ConfigurationDokumen43 halamanC&I - Control Logic ConfigurationThanh SonBelum ada peringkat

- (Mech) Gland Steam SystemDokumen7 halaman(Mech) Gland Steam SystemThanh Son100% (1)

- Smart-UPS On-Line SRT 2.2kVA - 10kVA Brochure 230V ModelsDokumen12 halamanSmart-UPS On-Line SRT 2.2kVA - 10kVA Brochure 230V ModelsThanh SonBelum ada peringkat

- Power Station Electrical Protection: A B C A B C CTDokumen64 halamanPower Station Electrical Protection: A B C A B C CTpriyanka236Belum ada peringkat

- Sh1 Dhi p0100 M m01 Pid 5303 - Symbol and Legend 3 of 4Dokumen1 halamanSh1 Dhi p0100 M m01 Pid 5303 - Symbol and Legend 3 of 4Thanh SonBelum ada peringkat

- BoilerDokumen1 halamanBoilerThanh SonBelum ada peringkat

- Bao Ve Role Va Tu Dong Hoa He Thong DienDokumen329 halamanBao Ve Role Va Tu Dong Hoa He Thong Dienth037100% (3)

- Sh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Dokumen1 halamanSh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Thanh SonBelum ada peringkat

- Dhi LLM M01 Eng T10873Dokumen1 halamanDhi LLM M01 Eng T10873Thanh SonBelum ada peringkat

- Testing MethoDs BaAn HDPE Flexible Pipe BFPDokumen1 halamanTesting MethoDs BaAn HDPE Flexible Pipe BFPThanh SonBelum ada peringkat

- SH1.RFP - P4 OTR - Ch13 General Technical Requirements - 140530Dokumen54 halamanSH1.RFP - P4 OTR - Ch13 General Technical Requirements - 140530Thanh SonBelum ada peringkat

- SH1-DHI-P1HAC-M-M01-PFD-5302 Boiler Flow Diagram For Water & Steam System - Rev2Dokumen1 halamanSH1-DHI-P1HAC-M-M01-PFD-5302 Boiler Flow Diagram For Water & Steam System - Rev2Thanh SonBelum ada peringkat

- SH1 Dhi P1PCB M M01 Pid 5325Dokumen1 halamanSH1 Dhi P1PCB M M01 Pid 5325Thanh SonBelum ada peringkat

- (CNTTQN - Com) 34 Ke Sach Kinhh Doanh Lam GiauDokumen109 halaman(CNTTQN - Com) 34 Ke Sach Kinhh Doanh Lam GiauThanh SonBelum ada peringkat

- Dewatering Solutions: A Guide To Our Centrifugal and Piston Pump RangeDokumen16 halamanDewatering Solutions: A Guide To Our Centrifugal and Piston Pump RangeMhenni OUFELLABelum ada peringkat

- RDP Reciprocating Plunger Pump Brochure enDokumen8 halamanRDP Reciprocating Plunger Pump Brochure enJavierAlvarezBelum ada peringkat

- Curvas Bombas FranklinDokumen20 halamanCurvas Bombas Franklinagvega69109Belum ada peringkat

- Fluid Mechanics and Machinery - 2 Marks - All 5 UnitsDokumen24 halamanFluid Mechanics and Machinery - 2 Marks - All 5 UnitsMohan Prasad.M94% (18)

- Unit 3 & 4 PDFDokumen5 halamanUnit 3 & 4 PDFPavithran JBelum ada peringkat

- DESMI Centrifugal Pump: Modular HDokumen17 halamanDESMI Centrifugal Pump: Modular HИгорьBelum ada peringkat

- KSB Fire PumpDokumen39 halamanKSB Fire Pumpmaqsood ahmedBelum ada peringkat

- Folleto SRH-SRC Series PDFDokumen4 halamanFolleto SRH-SRC Series PDFMargarita Rivera SegoviaBelum ada peringkat

- Plumbing 2Dokumen24 halamanPlumbing 2freanne_0527100% (1)

- Specification For PumpsDokumen29 halamanSpecification For PumpsEmad Rakat100% (1)

- Write Up On PumpsDokumen74 halamanWrite Up On PumpsGopal Reddy100% (1)

- WiloDokumen40 halamanWilovn_hung3137Belum ada peringkat

- Chapter 2 Pumps-NotesDokumen69 halamanChapter 2 Pumps-Notesdheepak manickavelanBelum ada peringkat

- Mech Engg CVDokumen5 halamanMech Engg CVShams TabrezBelum ada peringkat

- Termofluid Lab PDFDokumen28 halamanTermofluid Lab PDFSolomon GirmaBelum ada peringkat

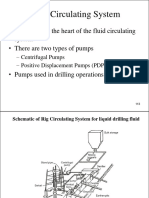

- Fluid Circulating System: - Mud Pump Is The Heart of The Fluid Circulating System - There Are Two Types of PumpsDokumen46 halamanFluid Circulating System: - Mud Pump Is The Heart of The Fluid Circulating System - There Are Two Types of PumpsFreddy Mendoza CoronelBelum ada peringkat

- Presentation On - : Horizontal Centrifugal PumpDokumen78 halamanPresentation On - : Horizontal Centrifugal Pumplifemillion2847100% (1)

- tutorial-CENTRIFUGAL PUMP SYSTEMSDokumen9 halamantutorial-CENTRIFUGAL PUMP SYSTEMSmmemhdBelum ada peringkat

- KSB Prirucnik - Odabir PumpeDokumen92 halamanKSB Prirucnik - Odabir PumpeНебојша РадићBelum ada peringkat

- 0906 3U 3UB TechDokumen32 halaman0906 3U 3UB TechVictor KrisnaBelum ada peringkat

- PDFDokumen17 halamanPDFDelovan CheikhoBelum ada peringkat

- EN NM TD 50HzDokumen72 halamanEN NM TD 50Hzlee marvin BilongBelum ada peringkat

- 4.16 Clear Water High Lift Pump HouseDokumen4 halaman4.16 Clear Water High Lift Pump HousePrasenjit DeyBelum ada peringkat

- Chapter 7 - Engine Fuel SystemsDokumen126 halamanChapter 7 - Engine Fuel SystemsKim RioverosBelum ada peringkat

- Balance LineDokumen0 halamanBalance Linewsjouri2510Belum ada peringkat

- Verifical Can TYPE Centrifugal Pump PDFDokumen1 halamanVerifical Can TYPE Centrifugal Pump PDFnecio77Belum ada peringkat

- Effect of Bearing Housing On Centrifugal Pump RotordynamicDokumen6 halamanEffect of Bearing Housing On Centrifugal Pump Rotordynamicmsh16000Belum ada peringkat

- Chapter 10: Pumps For Water SupplyDokumen29 halamanChapter 10: Pumps For Water SupplyJasleneDimarananBelum ada peringkat

- Jabsco Flexible Impeller PumpsDokumen46 halamanJabsco Flexible Impeller PumpsstratoschaBelum ada peringkat

- 2 PumpsDokumen105 halaman2 PumpsehabwardaBelum ada peringkat