Design Guide For Customer-Owned Transformer Vaults: 1.0 Index

Diunggah oleh

Lee ChorneyJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Design Guide For Customer-Owned Transformer Vaults: 1.0 Index

Diunggah oleh

Lee ChorneyHak Cipta:

Format Tersedia

DESIGN GUIDE FOR CUSTOMER-OWNED

TRANSFORMER VAULTS

1.0 INDEX

1.0 INDEX

2.0 PURPOSE

3.0 GENERAL

4.0 LOCATION OF INSTALLATION

5.0 VENTILATION

6.0 VAULTS IN STREETS AND RIGHTS-OF-WAY

7.0 CUSTOMER BUILDING VAULTS

8.0 SECONDARY TERMINATION AT TRANSFORMERS

9.0 METERING

10.0 REFERENCES

11.0 VAULT DETAILS/DRAWINGS

2.0 PURPOSE

This standard represents SPPC's basic design criterion for customer-owned transformer vaults.

Customer owned vaults must follow NEC Article 450-C.

3.0 GENERAL

The requirements in this standard may be in addition to the requirements in NEC, and all

Local Codes. The customer is responsible for providing a complete vault structure.

Vaults may be either installed underground, with access and ventilation through an opening

in the top section, furnished by the customer within his premises, or as an attachment with

access through a door in one of the vault walls and/or a hatch in the roof of the vault.

4.0 LOCATION OF INSTALLATION

4.1 When furnished by the customer and installed on his premises, the vault must be so

located as to be accessible at all times by SPPC crews and hoisting equipment.

Future expansion plans by the customer must not affect accessibility. Customer shall

furnish dimensioned plan and elevation views of the entire project showing the vault

location in relation to surrounding structural parts. Two sets of drawings clearly

showing the vault must be submitted to the appropriate SPPC Customer Services

Engineering Dept. (for Reno, MC: R77CSE), P.O. Box 10100, Reno Nevada

ENGINEERING & CONSTRUCTION STANDARD SHEET 35 OF 4 6

DESIGN GUIDE FOR VOLUME 17

DRAWN DESIGN SUPR DATE REV CUSTOMER OWNED DRAWING NUMBER

JL MB DA 07/05 4 TRANSFORMER VAULTS VB0100U

89520, and for districts outside of Reno, submit to your local district office. The

elevational view will be checked for vault elevation and its ventilating system in relation to

the levels of streets, water mains, sewer lines, storm-drains, and other discharge facilities

that, when ruptured or overflowing, could flood the vault. No such piping is permitted to

enter or pass through a transformer vault (NEC 450-47).

4.2 Vaults shall be located where they can be ventilated to the outside air whenever

practicable (NEC 450-41).

4.3 Underground vaults with openings at or below street level must be considered as

subject to flooding. A means to eliminate or reduce the degree of flooding is to raise

the vault’s top section above its surroundings where possible on customer’s property.

5.0 VENTILATION

5.1 The vault can be provided with ventilation directly to the utside air of total net area as

shown below in 5.2. Ventilation may be incorporated into the design of the door, cover,

hatches, etc. Net area means after deducting area taken by grates, mesh, louers, etc. Vault

ambient temperatures shall not exceed 40°C and the average ambient emperatrure for any

24 hour period shall not exceed 30°C. Forced ventilation thermostatically controlled (5.3)

can be utilized if necessary and approved by SPPC. Forced air inlets shall be near the floor

and exhaust near the ceiling of the vault. Both inlet and exhaust ducts shall be fire proofed

including fire damperers.

5.2 Natural Air Circulation: The size of opening is determined by NEC Article 450-45(c) as

follows: Net Area in square inches > 3 x kVA rating.

Example:

For a 50 kVA transformer, net ventilation area = 3 x 50 = 150 sq. in.

Note: 1 sq. ft. is the minimum net area also for any transformer under 50 kVA.

When determining the size of the opening, all obstructions, such as the grate, must

be added to the net area. Two openings at opposite vault ends are more effective

than one center opening of the same total net area.

5.3 Forced Air Circulation:

A. The accurate calculation of the minimum required quality of cooling air,

expressed in cubic-foot per minute (CFM), should be made. The flow of the air

must be such that the transformer is cooled.

B. Air inlets and outlets shall be located at opposite ends of the vault, the inlet

positioned as close to the floor as possible (maximum of 18"), and the outlet as

close as possible to the roof of the vault. The farther apart inlet and outlet are

from each other within the given vault space, the more efficient the cooling of

the transformer(s) within it.

ENGINEERING & CONSTRUCTION STANDARD SHEET 36 OF 4 6

DESIGN GUIDE FOR VOLUME 17

DRAWN DESIGN SUPR DATE REV CUSTOMER OWNED DRAWING NUMBER

JL MB DA 07/05 4 TRANSFORMER VAULTS VB0100U

C. Transformer data for loss calculations will be 1.15% of nameplate for transformers

less than 750kva; 0.87% for 750/1000/1500 kva transformers and 0.77% for

transformers greater than 1500 kva.

D. Use 0.045 kw per 10 ft2 for heat transferred through the vault walls and roof, if

not exposed to the sun.

E. The volume of cooling air per minute will be calculated as follows:

1. CFM = 110CFM/KW net loss.

2. Net Loss KW = transformer losses minus vault heat transfers.

F. Fans will be less than 1750 RPM to reduce noise. Axial type fans capable

of continuous service are recommended. All fans require a manual "across the

line" starter and "overload" protection.

G. In vaults where continuous heavy loading does not occur, thermostatic control

of the fan may provide economic advantages by reducing power requirements

and fan maintenance. Thermostats will generally be set @85oF with a

differential of 15oF.

6.0 VAULTS IN STREET AND RIGHTS-OF-WAY

6.1 Vaults of this type are usually precast, selected from manufacturer’s catalogs, and

installed by the customer or in some cases by SPPC The following rules apply:

A. Opening(s) in the top section shall be large enough to install and remove

transformer(s) in their upright position with only the cover section of the vault

removed and without disturbing the pavement that extends over the remainder

of the vault.

B. The cover section(s) will have an opening covered by a grate to permit adequate

ventilation. All ventilation openings shall be covered with durable gratings,

screens, or louvers according to the treatment required in order to avoid unsafe

conditions.

C. Transformers and equipment in underground vaults shall be submersible or

partially submersible as the case may permit.

D. Vaults containing more than 100 kVA transformer capacity shall be provided

with a sump in the lowest part of the floor.

E. Ground rods, minimum of (2) 5/8" x 8', to be installed in the trench near opposite

corners of the vault. Grounding bus will be connected to the rods (grd inserts)

and will be continuous around the inside of the vault, consisting of #2/0 str

copper (min.). Aluminum not permitted.

7.0 CUSTOMER BUILDING VAULTS

7.1 The vault must conform to drawing on sheet 43 of this standard. The no-scale outline

on that drawing must be supplemented by a scaled drawing showing all installations

in their true relationship per 4.1.

ENGINEERING & CONSTRUCTION STANDARD SHEET 37 OF 4 6

DESIGN GUIDE FOR VOLUME 17

DRAWN DESIGN SUPR DATE REV CUSTOMER OWNED DRAWING NUMBER

JL MB DA 07/05 4 TRANSFORMER VAULTS VB0100U

7.2 Pulling irons are to be rated at least 20,000 lbs. working load. Two or more on each

wall, (if more than 2 transformers, 1 for each transformer), 24 inches from the wall,

the location to be determined by SPPC Customer Services Engineering. Each

pulling iron must be tied into the rebar in the wall and located approximately 18"

above the floor. One iron will be provided for cable pulling located in opposite wall,

same height as incoming primary conduits.

7.3 The walls and roof of vaults shall be constructed of materials which have adequate

structural strength for the conditions with a minimum fire resistance of three hours.

The floors of vaults in contact with the earth shall be of concrete not less than 4 inches

thick, but when the vault is constructed with a vacant space or other stories below it,

the floor shall have adequate structural strength for the loading imposed thereon (25,000

lbs for a 2500 kva) and a minimum fire resistance of three hours. The three - hour fire

resistance requirement may be reduced to one hour fire resistance if transformers are

protected with automatic carbon dioxide or halon systems. (NEC 450-42).

7.4 For doorways. See NEC 450-43.

Floor and bottom four inches of wall and doorway openings to be constructed and

sealed so as to contain any oil spill. Each doorway leading into a vault from the

building interior shall be provided with a tight - fitting door having a minimum fire

rating of three hours. The vault shall have at least two means of entrance/exit. The

doors shall swing out and be equipped with locksand hinges/latches that permit opening by

easy pressure or torque on the operating components. Door will be provided with a SPPC

key box.

7.5 If the customer cannot guarantee that the vault is safe from entry of water, all

equipment must be at least partially submersible and installations such as electrical

outlets and lights must be vapor tight. (NEC 450-46).

7.6 Vault floors shall slope to a sump of 12" diameter, (or one (1) foot square), with 12"

minimum depth. A grated cover will be required.

7.7 The customer must provide a continuous grounding bus ring consisting of a minimum of

#2/0 str copper wire and shall be tied to the structural steel of the building at two or

more points and be run around the inside walls of the vault at 12" above the floor. Grounding

connections shall be cadweld or equivalent. The grounding bus will be used for equipment

grounding. Aluminum is not permitted (NEC 250-92(a)).

7.8 Vault lighting and wall outlets will be provided by the custome and shall be connected to

the customers emergency power supply when applicable. As a rule, lighting, approximately

2 watts per square foot (25 foot candles) of floor space, shall be provided from at least two

ENGINEERING & CONSTRUCTION STANDARD SHEET 38 OF 4 6

DESIGN GUIDE FOR VOLUME 17

DRAWN DESIGN SUPR DATE REV CUSTOMER OWNED DRAWING NUMBER

JL MB DA 07/05 4 TRANSFORMER VAULTS VB0100U

overhead fixtures with a control switchmounted close to the personnel access entrance into

the vault. 120V wall outlets consisting of duplex receptacles, minimum rating 20 amps,

shall be provided so that no point on a wall is more that ten feet away from an outlet.

7.9 Primary cables will not be be laid on the vault floor. Wall racking or ceiling supports will be

provided by the customer. Any support structures shall be constructed such that a minimum

of 9' of clearance exists from the bottom of the cable rack to the vault floor. Any metal

racking will be bonded to the vault ground system. (NEC 450-10).

7.10 Any pipe or duct system foreign to the electrical installation shall not enter or pass

through a transformer vault. Piping or other facilities provided for fire protection, or for

transformer operation shall not be considered foreign to the electrical system. (NEC 450-

47).

7.11 Transformer vault area shall not be used for storage. NEC 450-48.

7.12 A telephone is required to be installed in the vault room. This requirement does not

apply to outside underground vaults where access to a radio is available. (

7.13 No customer equipment is allowed in the transformer vault area with the exception of his

secondary bus. The bus shall be designed and located such that it will not block the primary

cable installation.

7.14 Each vault, through the roof access, must have a permanently attached ladder. A light

switch must be near the top of the ladder. The ladder must be installed so as not to

interfere with vault's equipment opening.

8.0 SECONDARY TERMINATION AT TRANSFORMERS

8.1 The customer shall provide a secondary cable support system. Any metal racking will be

bonded to the vault ground system. The support system shall be arranged to provide a

maximum unobstructed passageway for personnel.

8.2 For the installation of the bus duct, see SPPC Standard SB0001M, in Section 8.

8.3 The bus duct will be terminated to the transformer using an 18" or 24" flexible copper

braid connector rated at 1000 amps each. SPPC stock #25-2802/25-2804.

8.4 For general information see Drawings on Sheets 43 & 44 of this Standard.

ENGINEERING & CONSTRUCTION STANDARD SHEET 39 OF 4 6

DESIGN GUIDE FOR VOLUME 17

DRAWN DESIGN SUPR DATE REV CUSTOMER OWNED DRAWING NUMBER

JL MB DA 07/05 4 TRANSFORMER VAULTS VB0100U

9.0 METERING

The customer's main switch and metering panel shall be located outside of and adjacent to the

vault. Space at the metering panel shall be provided for the meter(s) and metering instrument

transformers which SPPC shall provide. Metering equipment and switchgear must be approved

by SPPC metering dept. prior to installation.

10.0 REFERENCES

10.1 SPPC Engineering and Construction Standard: Volume 5, DES 05U, “ Large Under

ground Commercial Distribution Service Planning Guide”.

10.2 SPPC: TRS10X “Three- Phase Subway/Vault - Type Distribution Transformer

Specification”.

10.3 National Electrical Code (NEC): Articles 250 and 450.

10.4 ASTM Standard E119-75 “Construction Materials for 3 - Hour Fire Resistance”.

10.5 NFPA 251: “Fire Tests of Building Construction and Materials”.

10.6 NFPA 80 (ANSI): Standard for the Installation of Fire Doors and Windows”.

10.7 ANSI 42.1: “Methods of Fire Tests of Building and Materials”.

10.8 ANSI/UL 555: “Standard for Fire Dampers”.

10.9 California Administrative Code: Title 8 “Industrial Relations”.

ENGINEERING & CONSTRUCTION STANDARD SHEET 40 OF 4 6

DESIGN GUIDE FOR VOLUME 17

DRAWN DESIGN SUPR DATE REV CUSTOMER OWNED DRAWING NUMBER

JL MB DA 07/05 4 TRANSFORMER VAULTS VB0100U

11.0 VAULT DETAILS/DRAWINGS

ENGINEERING & CONSTRUCTION STANDARD SHEET 41 OF 4 6

DESIGN GUIDE FOR VOLUME 17

DRAWN DESIGN SUPR DATE REV CUSTOMER OWNED DRAWING NUMBER

JL MB DA 07/05 4 TRANSFORMER VAULTS VB0100U

CONSTRUCTION NOTES CUSTOMER NOTES

A. Be sure adequate concentric neutral wire 1. Customer is responsible for secondary

is provided for proper operation of separable buss duct and primary cable trays.

connectors.

2 Contact appropiate SPPC Planner for

B. Underground Cable identification tags to precise transformer measurements.

be used in accordance with CAB07U, Vol-

ume 5 and Volume 19, Operating proceedures 3. Dimensions shown are for 25KV 2500

Section 21. KVA transformer .

C. Fault indicators to be used in accordance 4. Buss duct will terminate with NEMA

with HDE02U, Volume 5. standard spacing (4 hole) see SB0001M.

D. Energized cables to be handled in accor-

dance with Volume 19, Underground Operat-

ing Proceedures, Section 20.

ENGINEERING & CONSTRUCTION STANDARD SHEET 42 OF 4 6

DESIGN GUIDE FOR VOLUME 17

DRAWN DESIGN SUPR DATE REV CUSTOMER OWNED DRAWING NUMBER

JL MB DA 07/05 4 TRANSFORMER VAULTS VB0100U

Anda mungkin juga menyukai

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDari Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsPenilaian: 4 dari 5 bintang4/5 (1)

- Customer Vault Design GuideDokumen8 halamanCustomer Vault Design GuidesauroBelum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- App027 Flue ApertureDokumen5 halamanApp027 Flue Aperturechong pak limBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- FF Mew Construction Specs FinalDokumen250 halamanFF Mew Construction Specs FinalmaheseeeBelum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- (B) 1 - Annexure: S # AADC Standard Requirement Compliance AADC ReviewDokumen2 halaman(B) 1 - Annexure: S # AADC Standard Requirement Compliance AADC ReviewBilal Hussein SousBelum ada peringkat

- SECTION 16460 Transformers (General Purpose)Dokumen4 halamanSECTION 16460 Transformers (General Purpose)no nameBelum ada peringkat

- (B) 1 - Annexure: S # AADC Standard Requirement Compliance AADC ReviewDokumen2 halaman(B) 1 - Annexure: S # AADC Standard Requirement Compliance AADC ReviewEng Islam HiBelum ada peringkat

- Substation Civil Design RequirementsDokumen3 halamanSubstation Civil Design Requirementsshaikhsajid242Belum ada peringkat

- Substation LayoutDokumen15 halamanSubstation LayoutSathiyanathan ManiBelum ada peringkat

- CEM PT HandbookDokumen44 halamanCEM PT Handbook翹翹九九100% (2)

- Outdoor Distribution Transformers Technical SpecDokumen21 halamanOutdoor Distribution Transformers Technical SpecPrashant NankarBelum ada peringkat

- Station Service TransformerDokumen13 halamanStation Service TransformerpvenkyBelum ada peringkat

- CEM PT HandbookDokumen44 halamanCEM PT HandbookThomas OrBelum ada peringkat

- DC Poweer Distribution Switch BoardDokumen9 halamanDC Poweer Distribution Switch BoardpvenkyBelum ada peringkat

- 630 KVA Distribution TransformerDokumen4 halaman630 KVA Distribution TransformerusmanaliBelum ada peringkat

- Distribution Transformer SpecificationDokumen23 halamanDistribution Transformer Specificationbalaeee123100% (1)

- 057521Dokumen20 halaman057521M.Senthil VelavanBelum ada peringkat

- SECTION 16460 DRY TYPE TRANSFORMERSDokumen6 halamanSECTION 16460 DRY TYPE TRANSFORMERSmiguel.peralta.etmBelum ada peringkat

- Raft Deepening AreaDokumen5 halamanRaft Deepening AreaRoyce AgabasBelum ada peringkat

- Wall Mount: Installation, OperationDokumen7 halamanWall Mount: Installation, OperationTradutor TécnicoBelum ada peringkat

- Code of Practice 101Dokumen48 halamanCode of Practice 101s0201228100% (1)

- Installation of Distribution-to-Utilization Voltage TransformersDokumen7 halamanInstallation of Distribution-to-Utilization Voltage TransformersadauBelum ada peringkat

- Transformers & Ring Main UnitsDokumen57 halamanTransformers & Ring Main Unitsoadipphone7031100% (1)

- Trafo Installed IndoorDokumen20 halamanTrafo Installed IndoorAtoelAcoBelum ada peringkat

- 11kV GIS Specification PDFDokumen44 halaman11kV GIS Specification PDFRiyazBelum ada peringkat

- Air Terminal SpecificationDokumen7 halamanAir Terminal Specificationadel rihanaBelum ada peringkat

- GuideToSupplyMetering - (v7) - Nov 2016 PDFDokumen25 halamanGuideToSupplyMetering - (v7) - Nov 2016 PDFLe'Novo FernandezBelum ada peringkat

- Pad Mounted TransformersDokumen8 halamanPad Mounted Transformersمدهش الاديبBelum ada peringkat

- TSS Building MethodDokumen7 halamanTSS Building MethodAnubhav Hem Kumar JainBelum ada peringkat

- 33KV CONTROL PANELDokumen27 halaman33KV CONTROL PANELkjfenBelum ada peringkat

- COP 101 Version 9.1 Document (Text) Jan 2006Dokumen41 halamanCOP 101 Version 9.1 Document (Text) Jan 2006MarcusBelum ada peringkat

- Section - Viii: Technical Specifications of TransformersDokumen21 halamanSection - Viii: Technical Specifications of TransformersSrini DuddupudiBelum ada peringkat

- Technical Specification 315 MVA 400/220KV AUTO Transformer FOR All Projects Except World Bank and Jbic ProjectsDokumen46 halamanTechnical Specification 315 MVA 400/220KV AUTO Transformer FOR All Projects Except World Bank and Jbic ProjectsanuragpugaliaBelum ada peringkat

- Power TransformerDokumen17 halamanPower TransformerANANDBelum ada peringkat

- Airport Terminal Hvac Design GuidelineDokumen10 halamanAirport Terminal Hvac Design GuidelineRahulBelum ada peringkat

- Technical SpecificationDokumen17 halamanTechnical Specificationmohan agasthiBelum ada peringkat

- COP 101 Version 12 Document (Text) June 2012Dokumen45 halamanCOP 101 Version 12 Document (Text) June 2012DFBelum ada peringkat

- Nicc802 Padmount Transformer BrochureDokumen8 halamanNicc802 Padmount Transformer Brochureparas99Belum ada peringkat

- Ts Vav Terminal BoxesDokumen2 halamanTs Vav Terminal BoxesAnkit JainBelum ada peringkat

- Vacuum Circuit BreakerDokumen7 halamanVacuum Circuit BreakerShiv Kumar VermaBelum ada peringkat

- HT SupplyDokumen9 halamanHT SupplyShiv Kumar VermaBelum ada peringkat

- 20 Mvar Capacitor BankDokumen9 halaman20 Mvar Capacitor BankTejaswi ShuklaBelum ada peringkat

- Appendix I - GuideToSupplyMetering - (v6) PDFDokumen24 halamanAppendix I - GuideToSupplyMetering - (v6) PDFAdrianSebastianDarmansyahBelum ada peringkat

- Honeywell Office, Gurgaon HVAC System: Particular Conditions & Technical SpecificationDokumen16 halamanHoneywell Office, Gurgaon HVAC System: Particular Conditions & Technical SpecificationAmitSamadiyaBelum ada peringkat

- REACTOR - Rev-6Dokumen21 halamanREACTOR - Rev-6Anwar BegBelum ada peringkat

- MV Switchgear 11 KV VCB Rev-0Dokumen16 halamanMV Switchgear 11 KV VCB Rev-0ISHA SINGHBelum ada peringkat

- 33KV CONTROL PANEL SPECDokumen27 halaman33KV CONTROL PANEL SPECMohanathan VCBelum ada peringkat

- Solar PV 10 KW or LessDokumen6 halamanSolar PV 10 KW or LessKokoBelum ada peringkat

- 8 MVA 33/11 KV STEP DOWN TRANSFORMERSDokumen30 halaman8 MVA 33/11 KV STEP DOWN TRANSFORMERSHamayoun MurtazaBelum ada peringkat

- Specification of Distribution Transformer 33 KV Cap. 100 KVADokumen16 halamanSpecification of Distribution Transformer 33 KV Cap. 100 KVAzulryBelum ada peringkat

- Stack Maintenance Access Residential Dwellings July 2019Dokumen5 halamanStack Maintenance Access Residential Dwellings July 2019Moren AlfonsoBelum ada peringkat

- 30MVA 25MVA 16MVA, 88-132 - 33kV TransformersDokumen8 halaman30MVA 25MVA 16MVA, 88-132 - 33kV Transformersanuragpugalia100% (1)

- 1212.03 15kV Submersible Transformer SpecificationDokumen8 halaman1212.03 15kV Submersible Transformer SpecificationurramarianiBelum ada peringkat

- Earthing Transformer Technical SpecificationDokumen12 halamanEarthing Transformer Technical SpecificationVíctor CasadoBelum ada peringkat

- Specification TransformerDokumen33 halamanSpecification Transformeremartinez_bernal5989Belum ada peringkat

- Mounting Instructions and MaintenanceDokumen4 halamanMounting Instructions and MaintenanceKundzoBelum ada peringkat

- PEE 1560-ACMV SpecDokumen97 halamanPEE 1560-ACMV SpecjimiBelum ada peringkat

- Ex-Texas Cop Charged For Shooting Teen Eating HamburgerDokumen11 halamanEx-Texas Cop Charged For Shooting Teen Eating HamburgerLee ChorneyBelum ada peringkat

- Dramatic Elevator Footage Shows Model Assaulting Boyfriend Moments Before His Murder (Update)Dokumen10 halamanDramatic Elevator Footage Shows Model Assaulting Boyfriend Moments Before His Murder (Update)Lee ChorneyBelum ada peringkat

- Jill Biden Targeted in WSJ Op-Ed Asking Her To Drop - Dr. - From Her TitleDokumen8 halamanJill Biden Targeted in WSJ Op-Ed Asking Her To Drop - Dr. - From Her TitleLee ChorneyBelum ada peringkat

- President Donald Trump Performs Coin To... R Final Time As President at Army-NavyDokumen4 halamanPresident Donald Trump Performs Coin To... R Final Time As President at Army-NavyLee ChorneyBelum ada peringkat

- Hawkeye' Spoilers Say Fan-Favorite Marvel Villain Is Coming To The MCUDokumen5 halamanHawkeye' Spoilers Say Fan-Favorite Marvel Villain Is Coming To The MCULee ChorneyBelum ada peringkat

- Ecobox SemiActive StandardDokumen1 halamanEcobox SemiActive StandardLee ChorneyBelum ada peringkat

- A Huge Game of Thrones' Star Just Confirmed She's Joining The MCUDokumen5 halamanA Huge Game of Thrones' Star Just Confirmed She's Joining The MCULee ChorneyBelum ada peringkat

- Cuomo Impeachment Investigation Head Wa... Percussions - After Senior Aide - S TweetDokumen6 halamanCuomo Impeachment Investigation Head Wa... Percussions - After Senior Aide - S TweetLee ChorneyBelum ada peringkat

- A Healthcare Worker Who Was Hospitalize... Has Nearly $1 Million in Medical BillsDokumen4 halamanA Healthcare Worker Who Was Hospitalize... Has Nearly $1 Million in Medical BillsLee ChorneyBelum ada peringkat

- Britney Spears Poses Topless in Daisy Dukes For New Instagram PicDokumen6 halamanBritney Spears Poses Topless in Daisy Dukes For New Instagram PicLee ChorneyBelum ada peringkat

- Under Fire For Strong-Arm Tactics, DeSa... at Former Data Scientist Rebekah JonesDokumen5 halamanUnder Fire For Strong-Arm Tactics, DeSa... at Former Data Scientist Rebekah JonesLee ChorneyBelum ada peringkat

- Utah State Game Canceled After Players ... Omments About Interim Coach - S ReligionDokumen5 halamanUtah State Game Canceled After Players ... Omments About Interim Coach - S ReligionLee ChorneyBelum ada peringkat

- ADC Green Book 5thDokumen32 halamanADC Green Book 5thbradalbiBelum ada peringkat

- Atlanta Mayor Keisha Lance Bottoms Repo... Being Offered A Bahamas AmbassadorshipDokumen4 halamanAtlanta Mayor Keisha Lance Bottoms Repo... Being Offered A Bahamas AmbassadorshipLee ChorneyBelum ada peringkat

- CERTIFIED PERFORMANCE DATA FOR CIRCULAR ELBOW NO-MEDIA HIGH VELOCITY SILENCERSDokumen10 halamanCERTIFIED PERFORMANCE DATA FOR CIRCULAR ELBOW NO-MEDIA HIGH VELOCITY SILENCERSLee ChorneyBelum ada peringkat

- Flexmaster U.S.A.® Quick Release LS Series Clamp: Submittal DataDokumen1 halamanFlexmaster U.S.A.® Quick Release LS Series Clamp: Submittal DataLee ChorneyBelum ada peringkat

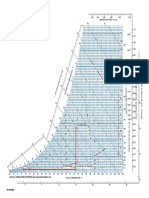

- State Point & Process Report: Psychrometric Chart Psychrometric ChartDokumen1 halamanState Point & Process Report: Psychrometric Chart Psychrometric ChartLee ChorneyBelum ada peringkat

- Flexmaster U.S.A.® 4NI: Submittal DataDokumen1 halamanFlexmaster U.S.A.® 4NI: Submittal DataLee ChorneyBelum ada peringkat

- (McQuay Incorporated) Geothermal Heat Pump Design ManualDokumen70 halaman(McQuay Incorporated) Geothermal Heat Pump Design Manualtpqnhat100% (1)

- TECH ABHi 19Dokumen8 halamanTECH ABHi 19Lee ChorneyBelum ada peringkat

- F 3500 Insertion Magmeter ManualDokumen28 halamanF 3500 Insertion Magmeter ManualLee ChorneyBelum ada peringkat

- 101 83 - DE - 4300 - 4380 - withIVSDrive - Quick - Installation - GuideDokumen4 halaman101 83 - DE - 4300 - 4380 - withIVSDrive - Quick - Installation - GuideLee ChorneyBelum ada peringkat

- FL TZDokumen1 halamanFL TZLee ChorneyBelum ada peringkat

- Spec SS NC 18aDokumen28 halamanSpec SS NC 18aLee ChorneyBelum ada peringkat

- FL-TZ SubmittalDokumen4 halamanFL-TZ SubmittalLee ChorneyBelum ada peringkat

- Fiancee of Late Aaron Hernandez Speaks Out On His Sexuality After DocuseriesDokumen4 halamanFiancee of Late Aaron Hernandez Speaks Out On His Sexuality After DocuseriesLee ChorneyBelum ada peringkat

- High efficiency commercial heating RTC seriesDokumen8 halamanHigh efficiency commercial heating RTC seriesLee ChorneyBelum ada peringkat

- FormulasDokumen1 halamanFormulasLee ChorneyBelum ada peringkat

- DM 2015 10 Labcontrol de en WebDokumen68 halamanDM 2015 10 Labcontrol de en WebtamaraBelum ada peringkat

- Blue ForgeDokumen3 halamanBlue ForgeLee ChorneyBelum ada peringkat

- Cooling Tower PDFDokumen3 halamanCooling Tower PDFmaimslapBelum ada peringkat

- 2.ARC - ARC Binh Duong ASRS - Quotation For PK2 - Panel and Refrigeration System - Phase 2 - 2020 10 28Dokumen12 halaman2.ARC - ARC Binh Duong ASRS - Quotation For PK2 - Panel and Refrigeration System - Phase 2 - 2020 10 28vu nguyen ngocBelum ada peringkat

- Effect of Crystallinity On Electrical Properties of ElectronDokumen4 halamanEffect of Crystallinity On Electrical Properties of Electronapi-3837841Belum ada peringkat

- Nuclear ReactorsDokumen45 halamanNuclear ReactorsAtul100% (3)

- Quality Criterion of Road Lighting Measurement and ExploringDokumen96 halamanQuality Criterion of Road Lighting Measurement and ExploringNitin UpadhyayBelum ada peringkat

- EMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat ProvningslaboratoriumDokumen13 halamanEMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat Provningslaboratoriumiogdfgkldf iodflgdfBelum ada peringkat

- Lab 3 - Series and Parallel CircuitsDokumen7 halamanLab 3 - Series and Parallel CircuitsHảo PhùngBelum ada peringkat

- CS20 Instruction Manual: Inverted Vertical Turning CellDokumen83 halamanCS20 Instruction Manual: Inverted Vertical Turning CellHenryBelum ada peringkat

- Ecdis-W: Warship Electronic Chart Display and Information SystemDokumen2 halamanEcdis-W: Warship Electronic Chart Display and Information SystemEngr Muhammad SalmanBelum ada peringkat

- 02 - Heat ExchangersDokumen88 halaman02 - Heat ExchangerssanjaysyBelum ada peringkat

- Sound AttenuatorsDokumen24 halamanSound Attenuatorsadeel_akhtarBelum ada peringkat

- Acopos User's ManualDokumen171 halamanAcopos User's ManualKonstantin Gavrilov100% (1)

- Thomson VTH 7090 VCR ManualDokumen33 halamanThomson VTH 7090 VCR ManualTrickyDicky2Belum ada peringkat

- Reduce Drum Pitch, Yarn Tension and Cradle LoadDokumen16 halamanReduce Drum Pitch, Yarn Tension and Cradle LoadJigneshSaradavaBelum ada peringkat

- Xtrons - TD609 User ManualDokumen16 halamanXtrons - TD609 User ManualadrianBelum ada peringkat

- Netsys NVF-200EKIT User Guide 1.0.6Dokumen19 halamanNetsys NVF-200EKIT User Guide 1.0.6pkramellaBelum ada peringkat

- R12 Period-End Procedures For Oracle Financials E-Business Suite Document 961285Dokumen3 halamanR12 Period-End Procedures For Oracle Financials E-Business Suite Document 961285Ravi BirhmanBelum ada peringkat

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesDokumen7 halamanMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94Belum ada peringkat

- Wastewater Treatment Plant Operator Certification TrainingDokumen69 halamanWastewater Treatment Plant Operator Certification Trainingkokushkin02Belum ada peringkat

- High Efficiency in Cementitious WaterproofingDokumen12 halamanHigh Efficiency in Cementitious WaterproofingMumtazBelum ada peringkat

- USBN Bahasa Inggris 2021Dokumen6 halamanUSBN Bahasa Inggris 2021Indah timorentiBelum ada peringkat

- 92v Parts List ViperDokumen194 halaman92v Parts List Viperreltih18Belum ada peringkat

- BYG Опросный лист на режущую кромкуDokumen51 halamanBYG Опросный лист на режущую кромкуMMM-MMMBelum ada peringkat

- Mount EFS Across VPCs and Availability ZonesDokumen12 halamanMount EFS Across VPCs and Availability Zonesbiswajit patrasecBelum ada peringkat

- ANSI-IsA 77.13.01-1999 Fossil Fuel Power Plant Steam Turbine Bypass SystemDokumen42 halamanANSI-IsA 77.13.01-1999 Fossil Fuel Power Plant Steam Turbine Bypass SystemArzu AkarBelum ada peringkat

- Indigo Assessment - Cynthia Nieto VargasDokumen14 halamanIndigo Assessment - Cynthia Nieto Vargasapi-506651646Belum ada peringkat

- Q7 Running GearDokumen54 halamanQ7 Running GearJoseph MorantBelum ada peringkat

- Char-Lynn (Eaton) - 158-2925-001 - Motion IndustriesDokumen2 halamanChar-Lynn (Eaton) - 158-2925-001 - Motion Industriesgeovane cardosoBelum ada peringkat

- CRI PumpsDokumen13 halamanCRI Pumpscrigroups0% (1)

- HVDC Grid Feasibility StudyDokumen189 halamanHVDC Grid Feasibility StudyDeoudrafBelum ada peringkat