Heizer, J. H. y Render, B. (1999) PDF

Diunggah oleh

Pilar Fuentes0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

76 tayangan34 halamanJudul Asli

04. Heizer, J. H. y Render, B. (1999)..pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

76 tayangan34 halamanHeizer, J. H. y Render, B. (1999) PDF

Diunggah oleh

Pilar FuentesHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 34

04) Heizer, Jay H. & Render, Barry. (1999). “Forecasting” en Principles of operations

management. USA: Prentice Hall, pp. 139 - 172.

LEARNING

OBJECTIVES

When you complete

CHAPTER OUTLINE

GLOBAL COMPANY PROFLE: Standard Error ofthe Estimate the depter you

TUPPERWARE CORPORATION (Cotraluran’Coalhciates for should be able to:

WHATIS FORECASTING? Repression Unes \dertty or Define:

Forecasting Tine Horizons Maile Regression Anahi Forecasting

Tho influence of Product LifeCyele MONITORING AND CONTROLLING Types of forecasts

‘TYPES OF FORECASTS Se, = oe

THE STRATEGIC IMPORTANCE OF laptive Smoc iui to

FORECASTING Focus Forecasting ari

Human Resources The Computer'soleinroreatiog Pl oesene oe tele:

Capacty FORECASTING INTHE SERVICE a

‘Supply-Chain Management. SECTOR ee eee

‘SEVEN STEPS IN THE FORECASTING ‘SUMMARY

svsTeM EY TERMS a

FORECASTING APPROACHES USING POM FoR WINDOWS IN ia ec

Overview of Gustave Methods FORECASTING Regresion and

Overview of Quantitative Methods USING EXCEL SPREADSHEETS IN ee as

TWwESEHES FORECASTING RECAST) soe

eS

Se DISCUSSION QUESTIONS

el (CRITICAL THINKING EXERCISE

Exponential Smoothing cases

Exponential Smoothing with Trend. DATABASE AE DCATION)

genes ‘CASE STUDIES: NORTH-SOUTH AIRUNE;

ee ‘AKRON ZOOLOGICAL PARK

Seasonal Variations in Data INTERNET CASEiSTUOY

BIBLIOGRAPHY

CAUSAL FORECASTING METHODS:

REGRESSION AND CORRELATION INTERNET RESOURCES

ANALYSIS

Using Regression Analysis to Forecast

139

‘Material compilado confines académicos, se prohibe Su reproduccién total oparclal sin la autorizacion de cada autor.

Suinless tet alos mols, each requiring over 1,000 hows of killed

‘anderafing, ave the hear ofthe manufacturing proces. Each mold creates the

cevaet shape of new product: Molds cost an average of Stoo.oo0 nd can weigh

Wren most people think of Tup-

ppeeware, they envision plastic food-

Storage containers sold through

home partes. However, Tupperware

happens to be a successful global

manufacturer, with more than 85% of

its $1.2 bilion in sales outside the

United States. A household name in

nearly 100 countries, the firm has 15

plants located around the world: one

in South Carolina, four in Latin Armer-

ica, one in Aria, five in Europe, and

four in Asia. Throughout the world,

Tupperware stands for quality, pro-

viding a lifetime warranty that each

140

‘up 10 § tons. When a specific product ix scheduled fora production run, its med

is carefully placed, as we see inthe photo, imo an injection molding machine.

‘of its 400 plastic products will not

chip, crack, break, or peel

Forecasting demand at Tupper-

‘ware is a critical, never-ending

process. Each ofits 50 profit centers

round the world is responsible for

‘computerized monthly, quarterly,

and 12-month sales projections.

‘These are aggregated by region and

then globally at Tupperware’s World

Headquarters in Orlando, Florida.

‘These forecasts drive production at

each plant.

‘The variety of statistical forecast-

ing models used at Tupperware in-

cludes every technique discussed in

this chapter, including moving aver

ages, exponential smoothing, and

regression analysis. At world head-

‘quarters, huge databases are main-

tained to map the sales of each

‘product, the test-market results of

‘each new product (20% of the firm's

sales come from products less than

two years old), end the stage of each

product in its own life cycle.

Three factors are key in Tupper-

ware's sales forecasts: (1) the number

of registered "consultants" or sales

representatives, (2) the percentage

of currently “active” dealers (this

‘number changes each week and

month), and (3) sales per sctive

The plastic pellets tat are melted at

500 degrees ino Tunperware produets

‘are dropped through pipes from

second-floor bins into the mackine

Ihollng « mo. After being injected

ino warer-conled molds at a pressure

‘up 0 20.000 pounds per square incl,

the produet coals and is removed andl

inspected.

‘Material compllado confines académicos, se prohibe su reproduccion total o parcial sin a autrizacin de cada autor.

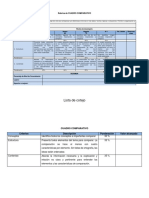

(2) Clear ptets

flow trough

(1) Ral car dalivers

40,000 bbs of pea size

pestc peters.

Tupperware's

Manufacturing Process

(8) Clea pots

are med

with eaored

= oe

ms =e

& =

a

UAT

Cieemeaeer Pree

eee teee tebe meee ener ar

incorporate historical data, recent

events, and promotional events

Tupperware maintains its edge

over strong competitors ike Rubber-

fine ite statistical forecasts: Althoug

inputs come from sales, marketing,

finance, and production, fina fore

casts are the consensus of all partici

Tupperwae’s version of the “jury of

executive opinion" described inthis,

chepter.

4

‘Material compitado confines académicos, se prohibe su reproduccién total o parcial sina autorizaion de cada autor.

Anda mungkin juga menyukai

- Plan de Acción Tutorial (PAT)Dokumen1 halamanPlan de Acción Tutorial (PAT)Pilar FuentesBelum ada peringkat

- 3.4.1 Actividades de Aprendizaje PlaneaciónDokumen1 halaman3.4.1 Actividades de Aprendizaje PlaneaciónPilar Fuentes57% (7)

- Carta de IntencionDokumen1 halamanCarta de IntencionPilar Fuentes0% (1)

- Actividades de Arpendizaje 3.5 EvaluaciónDokumen1 halamanActividades de Arpendizaje 3.5 EvaluaciónPilar FuentesBelum ada peringkat

- Plan de Acción Tutorial (PAT)Dokumen1 halamanPlan de Acción Tutorial (PAT)Pilar FuentesBelum ada peringkat

- 3.3.1 Formato Jerarquización.Dokumen3 halaman3.3.1 Formato Jerarquización.Pilar Fuentes0% (1)

- Diagnóstico GrupalDokumen14 halamanDiagnóstico GrupalPilar FuentesBelum ada peringkat

- Socializacion y Cultura PDFDokumen2 halamanSocializacion y Cultura PDFPilar FuentesBelum ada peringkat

- II. Rúbrica Módulo III Planeación de La Acción Tutorial - PDFDokumen1 halamanII. Rúbrica Módulo III Planeación de La Acción Tutorial - PDFPilar FuentesBelum ada peringkat

- Generatividad VS Estancamiento - ERIK ERIKSON PDFDokumen1 halamanGeneratividad VS Estancamiento - ERIK ERIKSON PDFPilar FuentesBelum ada peringkat

- 1.1.2 Tabla de Desarrollo Psicosocial de EricksonDokumen1 halaman1.1.2 Tabla de Desarrollo Psicosocial de EricksonPilar Fuentes100% (1)

- Evaluación DiagnósticaDokumen1 halamanEvaluación DiagnósticaPilar FuentesBelum ada peringkat

- Generatividad Vs EstancamientoDokumen1 halamanGeneratividad Vs EstancamientoPilar FuentesBelum ada peringkat

- Socializacion y Cultura PDFDokumen2 halamanSocializacion y Cultura PDFPilar FuentesBelum ada peringkat

- I.A. Dinamica Huella EcológicaDokumen3 halamanI.A. Dinamica Huella EcológicaPilar FuentesBelum ada peringkat

- Cuadro Comparativo BDokumen3 halamanCuadro Comparativo BPilar FuentesBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)