Hardware Installation Guide: Imanager Neteco V600R008C10

Diunggah oleh

Nagaraju ThangellaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hardware Installation Guide: Imanager Neteco V600R008C10

Diunggah oleh

Nagaraju ThangellaHak Cipta:

Format Tersedia

iManager NetEco

V600R008C10

Hardware Installation Guide

Issue 04

Date 2018-03-07

HUAWEI TECHNOLOGIES CO., LTD.

Copyright © Huawei Technologies Co., Ltd. 2018. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior written

consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and the

customer. All or part of the products, services and features described in this document may not be within the

purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information,

and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://e.huawei.com

Issue 04 (2018-03-07) Huawei Proprietary and Confidential i

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide About This Document

About This Document

Overview

Describes how to install the hardware components of the RH2288H V3/RH5885 V3 server,

the precautions of the installation, and how to check the installation.

Product Version

The following table lists the product version related to this document.

Product Name Product Version

NetEco V600R008C10

Intended Audience

This document is intended for network management engineers.

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in previous issues.

04 (2018-03-07)

This issue is the fourth official release for iManager NetEco V600R008C10. Compared with

03 (2017-10-20), this issue includes the following changes.

Navigation Tree Change Description

Installing Devices 5.8 Installing the SMS Modem

Issue 04 (2018-03-07) Huawei Proprietary and Confidential ii

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide About This Document

03 (2017-10-20)

This issue is the third official release for iManager NetEco V600R008C10. Compared with 02

(2017-06-30), this issue includes the following changes.

Navigation Tree Change Description

Connecting Server Signal Cables Added the Server Interface Description

and descriptions about the server signal

cable connections in southbound and

northbound network isolation scenarios in

the following pages:

l 7.1 Connecting Signal Cables (IP

Networking)

l 7.2 Connecting Signal Cables (Entire

E1 Networking)

l 7.3 Connecting Signal Cables (Partial

E1 Networking)

02 (2017-06-30)

This issue is the second official release for iManager NetEco V600R008C10. Compared with

01 (2017-02-28), this issue includes the following changes.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential iii

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide About This Document

Navigation Tree Change Description

NetEco Hardware Installation Guide Deleted descriptions relevant to the RH2288

(RH2288H V3/RH5885 V3) V2 and RH2288H V2 servers in the

following sections because the two servers

are not delivered with the NetEco:

l 1 Installation Process

l 5.1 Cabinet Configuration

l 5.3 Installing RH2288H V3/RH5885

V3 Server

l 6.1 Power Distribution Chart of a

Cabinet

l 6.2 Connecting the Power Cables of

Devices

l 7.1 Connecting Signal Cables (IP

Networking)

l 7.2 Connecting Signal Cables (Entire

E1 Networking)

l 7.3 Connecting Signal Cables (Partial

E1 Networking)

l 9.1 Main Device Parameters

01 (2017-02-28)

This issue is the first official release for iManager NetEco V600R008C10. Compared with

Draft A (2016-11-07), this issue has no changes.

Draft A (2016-11-07)

This issue is the first release of the iManager NetEco V600R008C10 beta version.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential iv

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide Contents

Contents

About This Document.....................................................................................................................ii

1 Installation Process....................................................................................................................... 1

2 Installation Preparations.............................................................................................................. 3

3 Installing Cabinets........................................................................................................................ 5

4 Installing Power Cables and PGND Cables of Cabinets.......................................................7

5 Installing Devices........................................................................................................................ 10

5.1 Cabinet Configuration.................................................................................................................................................. 10

5.2 Installing Floating Nuts................................................................................................................................................ 13

5.3 Installing RH2288H V3/RH5885 V3 Server................................................................................................................13

5.4 Installing a KVM.......................................................................................................................................................... 15

5.5 Installing LAN Switches.............................................................................................................................................. 16

5.6 Installing a TD-6200RM-4U........................................................................................................................................ 17

5.7 Installing a TD-6032 or TD-6310.................................................................................................................................18

5.8 Installing the SMS Modem...........................................................................................................................................19

6 Connecting Internal Power Cables of a Cabinet................................................................... 22

6.1 Power Distribution Chart of a Cabinet......................................................................................................................... 22

6.2 Connecting the Power Cables of Devices.....................................................................................................................24

7 Connecting Server Signal Cables............................................................................................. 28

7.1 Connecting Signal Cables (IP Networking)................................................................................................................. 28

7.2 Connecting Signal Cables (Entire E1 Networking)......................................................................................................32

7.3 Connecting Signal Cables (Partial E1 Networking)..................................................................................................... 37

8 Checking the Installation...........................................................................................................43

8.1 Checking the Installation of the Cabinet...................................................................................................................... 43

8.2 Checking the Installation of Components in the Cabinet............................................................................................. 44

8.3 Checking the Installation of Power Cables and Ground Cables...................................................................................44

8.4 Checking the Connection of Signal Cables.................................................................................................................. 45

9 Appendixes................................................................................................................................... 47

9.1 Main Device Parameters...............................................................................................................................................47

9.2 Installation Specifications.............................................................................................................................................49

9.2.1 Installation Specifications of Power Cables and PGND Cables in the Cabinet........................................................ 49

Issue 04 (2018-03-07) Huawei Proprietary and Confidential v

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide Contents

9.2.2 Installation Specifications of Signal Cables.............................................................................................................. 51

9.3 Preparing Power Cables and PGND Cables of the Cabinet......................................................................................... 59

Issue 04 (2018-03-07) Huawei Proprietary and Confidential vi

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 1 Installation Process

1 Installation Process

NOTE

l The operations highlighted in red are mandatory. The other operations are optional.

l The floating nuts have been installed on the mounting bars of each cabinet. If the model and position

of a floating nut is incorrect, reinstall it.

l TD type: bridge device.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 1

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 1 Installation Process

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 2

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 2 Installation Preparations

2 Installation Preparations

Unpacking and Acceptance

After cargoes are delivered onsite, check the following:

l Check whether the number of delivered cargoes is consistent with the number described

on the Packing List attached to each packing case and whether the arrival place is the

actual installation site.

l Check the cargoes against the packing lists. If shortage or miscarriage occurs, fill in the

Cargo Shortage and Miscarriage Report. If cargo damage occurs, fill in the Cargo

Replacement Application Form.

Installation Personnel Requirements

The following describes the requirements for the number of installation personnel and

required technical skills:

l The number of installation personnel varies depending on the project progress and the

installation environment. Typically, three to five persons are required.

l Only trained and qualified personnel are allowed to install and commission the

equipment.

Preparing Installation Tools

The following figure shows the tools to be prepared before you install the NetEco hardware.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 3

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 2 Installation Preparations

Figure 2-1 Installation tools

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 4

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 3 Installing Cabinets

3 Installing Cabinets

Procedure

Step 1 Install the N610E-22 cabinets by referring to the N610E Cabinet Installation Guide.

NOTE

l The N610E Cabinet Installation Guide is delivered with the cabinets. For details about the main

parameters of N610E-22 cabinets, seeMain Device Parameters in the NetEco Hardware

Installation Guide(RH2288 V2/RH2288H V2/RH2288H V3/RH5885 V3) .

l N610E-22 cabinets provide 19-inch mechanical structure (IEC 60297-1). N610E-22 cabinets do not

support anti-seismic reconstructions. If the customer requires anti-seismic design, contact Huawei

technical support.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 5

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 3 Installing Cabinets

Figure 3-1 N610E-22

----End

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 6

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 4 Installing Power Cables and PGND Cables of Cabinets

4 Installing Power Cables and PGND Cables

of Cabinets

Prerequisites

l The power cables and PGND cables of cabinets are ready for use. For details about how

to prepare the power cables and PGND cables, see 9.3 Preparing Power Cables and

PGND Cables of the Cabinet.

l The switch of the power distribution cabinet (PDC) in the equipment room is OFF.

Procedure

l Install the power cables and PGND cables of cabinets in overhead cabling mode.

NOTE

l The power distribution box (PDB) is installed on the top of the cabinet and provides two-

way input (1+1 backup). You are advised to use different power supplies or connect the PDB

to different uninterruptible power supply (UPS) devices.

l You must remove the rear cover plate of the PDB before installing the power cables and

install the rear cover plate again after the power cables are installed.

l A power cable is composed of three wires. The brown one is the live wire; the blue one is

the neutral wire; the yellowish green one is the ground cable. The following labels are

attached on the cable connection ports of the PDB: L (live wire), N (neutral wire), and PE

(ground cable).

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 7

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 4 Installing Power Cables and PGND Cables of Cabinets

Figure 4-1 Installing the power cables and PGND cables of cabinets in overhead cabling

mode

l Install the power cables and PGND cables of cabinets in underfloor cabling mode.

In underfloor cabling mode, you can route the power cables and PGND cables through

the cable trough in the middle of the cabinet in rope lifting mode, as shown in Figure

4-2.

Figure 4-2 Routing the power cables and PGND cables in rope lifting mode

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 8

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 4 Installing Power Cables and PGND Cables of Cabinets

NOTE

l The power distribution box (PDB) is installed on the top of the cabinet and provides two-

way input (1+1 backup). You are advised to use different power supplies or connect the PDB

to different uninterruptible power supply (UPS) devices.

l You must remove the rear cover plate of the PDB before installing the power cables and

install the rear cover plate again after the power cables are installed.

l A power cable is composed of three wires. The brown one is the live wire; the blue one is

the neutral wire; the yellowish green one is the ground cable. The following labels are

attached on the cable connection ports of the PDB: L (live wire), N (neutral wire), and PE

(ground cable).

Figure 4-3 Installing the power cables and PGND cables of cabinets in underfloor

cabling mode

----End

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 9

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

5 Installing Devices

About This Chapter

5.1 Cabinet Configuration

5.2 Installing Floating Nuts

5.3 Installing RH2288H V3/RH5885 V3 Server

5.4 Installing a KVM

5.5 Installing LAN Switches

5.6 Installing a TD-6200RM-4U

5.7 Installing a TD-6032 or TD-6310

5.8 Installing the SMS Modem

5.1 Cabinet Configuration

Cabinet Configuration Rules

l During installation, you can adjust the positions of devices as required. The sum of

device powers in each cabinet cannot exceed 6000 W. The cabinets must meet the

requirements of the equipment room on heat emission and weight.

l If the number of a type of devices is smaller than the number of installation positions

specified for the device type in the cabinet configuration chart, the devices of this type

can be installed in any of the specified positions. Usually, the positions at the bottom of

the cabinet are preferentially used.

l If a position is specified for multiple devices, the space of the position is sufficient for

installing those devices. If the required space of a device is less than that specified in the

cabinet configuration chart, install the device at the bottom of the space, and install filler

panels in the free space above the device.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 10

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

Cabinet Configuration Chart

NOTICE

This section describes the installation positions of devices in a cabinet. You can adjust the

installation positions based on the cabinet configuration rules.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 11

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

Figure 5-1 Cabinet configuration chart

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 12

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

5.2 Installing Floating Nuts

Procedure

Step 1 Use the flat-head screwdriver to install floating nuts.

NOTE

l Different device components require different types of floating nuts. Select the appropriate types of

floating nuts. If inappropriate floating nuts are used, the device components cannot be fixed. When

this occurs, you need to remove the floating nuts and the device components and reinstall them.

l The mounting hole for a floating nut is 9.5 mm x 9.5 mm. Therefore, the size of the flat-head

screwdriver must be smaller than 9.5 mm x 9.5 mm.

Figure 5-2 Installing floating nuts

----End

5.3 Installing RH2288H V3/RH5885 V3 Server

Procedure

Step 1 Push the server into the cabinet and secure the server to the mounting bar in the front of the

cabinet.

NOTE

When installing the RH2288H V3 or RH5885 V3 server in the N610E-22 cabinet, you are not advised to

install the guide rails or cable coiler delivered with the server. If you install them, server ports may be

damaged during the maintenance of the server. If the guide rails and cable coiler are required onsite,

install them by referring to the installation guides delivered with the server.

l Installing RH2288H V3 Server

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 13

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

Figure 5-3 Installing the RH2288H V3 Server

l Installing RH5885 V3 Server

Figure 5-4 Install guide rails

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 14

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

Figure 5-5 Secure the server

----End

5.4 Installing a KVM

Procedure

Step 1 Place the KVM tilt in the cabinet and secure the mounting ears of the KVM to the front and

rear mounting bars of the cabinet, as shown in Figure 5-6.

NOTE

If the floating nuts for securing rear mounting ears are blocked by cables on the mounting bar at the rear

of the cabinet, remove the cable ties and adjust the position of the cables. After securing the rear

mounting ears of the KVM and installing the KVM, bind the cables again.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 15

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

Figure 5-6 Installing a KVM

----End

5.5 Installing LAN Switches

Procedure

Step 1 Determine the collector mounting holes in the server cabinet according to the engineering

drawing. Secure two floating nuts to each rack rail of the cabinet by using a floating nut

mounting bar, as shown in Figure 5-7. Ensure that the floating nuts are at the same level.

Figure 5-7 Installing a floating nut

Step 2 Install the mounting ears of a LAN switch and secure the LAN switch to the mounting bar in

the front of the cabinet, as shown in Figure 5-8.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 16

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

Figure 5-8 Installing a LAN switch

----End

5.6 Installing a TD-6200RM-4U

Procedure

Step 1 Install the mounting ears of a TD-6200RM-4U and secure the TD-6200RM-4U to the

mounting bar in the front of the cabinet, as shown in Figure 5-9.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 17

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

Figure 5-9 Installing a TD-6200RM-4U

----End

5.7 Installing a TD-6032 or TD-6310

Context

This section describes how to install a TD-6032 or TD-6310. The method for installing the

TD-6032 and TD-6310 are the same. You can install them by referring to this section.

Procedure

Step 1 Install the mounting ears of a device and secure the device to the mounting bar in the front of

the cabinet, as shown in Figure 5-10.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 18

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

Figure 5-10 Installing a TD-6032 or TD-6310

----End

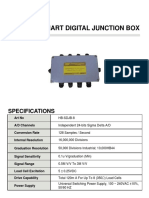

5.8 Installing the SMS Modem

Prerequisites

An idle serial port is available on the server.

Context

SMS modem needs to be installed on the server. Figure 5-11 shows SMS Modem Interface.

Figure 5-11 SMS Modem Interface

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 19

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

No. Interface

1 Connecting to the SIM card

2 Connecting to the antenna

3 Connecting to the power cable

4 Serial port

Procedure

Step 1 Insert a SIM card into the SMS modem.

Use a tool such as the small screwdriver to press the yellow key. Put the SIM card on the

ejected tray, and insert the tray into the SMS modem.

Step 2 Connect the antenna to the antenna connector.

Step 3 Connect the serial port cable.

One end of the cable connects the SMS modem and the other end connects an idle serial port

on the server, serial port on the server see 7 Connecting Server Signal Cables.

NOTE

l For details, see the user manual delivered with the SMS modem.

l Use the connector convertor delivered with the SMS modem if the connector of the serial cable does not

match the serial port on the server.

Step 4 Connect the power cable.

Use the power adapter with the SMS modem.

l Connect one end of the power adapter to the SMS modem, for details, see the

specifications delivered with the SMS modem.

l Connect the other end of the power adapter to the 220V power.

After the power cable is connected, switch on the power. Normally, the indicator of the SMS

modem blinks regularly. Table 5-1 shows how the indicator indicates the work status of the

SMS modem.

Table 5-1 Relations between the status of the indicator and the SMS modem

Indicator Modem

On The SMS modem is activated and is not registered with the

network.

Blinks slowly The SMS modem is connected to the network and is in idle

mode.

Blinks quickly The SMS modem is in transmission mode.

Off The SMS modem is deactivated.

Step 5 Install the SMS modem driver.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 20

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 5 Installing Devices

NOTE

l You need to install the driver only when the installation of the driver is required in the specifications

delivered with the SMS modem.

l To install the SMS modem driver, see the specifications delivered with the SMS modem.

----End

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 21

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 6 Connecting Internal Power Cables of a Cabinet

6 Connecting Internal Power Cables of a

Cabinet

About This Chapter

6.1 Power Distribution Chart of a Cabinet

6.2 Connecting the Power Cables of Devices

6.1 Power Distribution Chart of a Cabinet

l Each internal power cable in a cabinet is labeled and placed in a fixed position. You need

to find the power cables of a device in the positions specified for the device when

connecting power cables.

l If the number of power cables required for the devices in the power distribution chart is

less than the number of power cables shown in the chart, for example, 3 and 4 provide

two power channels while only one power channels are required, connect either 3 or 4.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 22

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 6 Connecting Internal Power Cables of a Cabinet

Figure 6-1 Power distribution chart of a cabinet

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 23

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 6 Connecting Internal Power Cables of a Cabinet

6.2 Connecting the Power Cables of Devices

Procedure

l Connect the power cables of a LAN switch. The input voltage of the LAN switch is 100

V to 240 V and the power consumption is 20 W.

Figure 6-2 Connecting the power cables of a LAN switch

l Connect the power cables of a KVM. The input voltage of the KVM is 90 V to 264 V,

and the power consumption is 46 W.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 24

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 6 Connecting Internal Power Cables of a Cabinet

Figure 6-3 Connecting the power cables of a KVM

l Connect the power cables of a RH2288H V3/RH5885 V3 server. The input voltage of

the RH2288H V3 is 100 V to 240 V, and the power consumption is 460 W. The input

voltage of the RH5885 V3 is 90 V to 264 V and the power consumption is 1200 W.

Figure 6-4 Connecting the power cables of a RH2288H V3 server

Figure 6-5 Connecting the power cables of a RH5885 V3 server

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 25

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 6 Connecting Internal Power Cables of a Cabinet

l Connect the power cables of the TD-6200. The input voltage of TD-6200 is 200 V to 240

V and the power consumption is 50 W.

Figure 6-6 Connecting the power cables of the TD-6200

l Connect the power cables of the TD-6340. The input voltage of the TD-6340 is 200 V to

240 V and the power consumption is 5 W.

Figure 6-7 Connecting the power cables of the TD-6340

l Connect the power cables of the TD-6310. The input voltage of the TD-6010 is 200 V to

240 V and the power consumption is 5 W.

Figure 6-8 Connecting the power cables of the TD-6310

l Connect the power cables of the TD-6032. The input voltage of TD-6032 is 200 V to 240

V and the power consumption is 15 W.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 26

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 6 Connecting Internal Power Cables of a Cabinet

Figure 6-9 Connecting the power cables of the TD-6032

----End

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 27

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

7 Connecting Server Signal Cables

About This Chapter

7.1 Connecting Signal Cables (IP Networking)

7.2 Connecting Signal Cables (Entire E1 Networking)

7.3 Connecting Signal Cables (Partial E1 Networking)

7.1 Connecting Signal Cables (IP Networking)

Server Interface Description

Figure 7-1 shows the RH2288H V3 server interfaces and Table 7-1 describes the interfaces.

Figure 7-1 RH2288H V3 server interface diagram

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 28

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Table 7-1 RH2288H V3 server interface description

No. Interface Function

Type

1 eth0 GE Used for connecting to the LAN switch. eth0 and eth1

interface comprise a bond, which is used for providing external

services.

2 eth1 GE

l If southbound and northbound network isolation is

interface

not adopted, only eth0 or eth1 is required.

3 eth2 GE l If southbound and northbound network isolation is

interface adopted, both eth0 (or eth1) and eth2 (eth3) are

required.

4 eth3 GE eth0 (or eth1) is used for providing southbound

interface services while eth2 (or eth3) is used for providing

northbound services.

5 USB interface Used for connecting to the KVM.

6 iBMC Used for connecting to the PC computer to manage the

management RH2288H V3 server.

interface

7 VGA interface Used for connecting to the monitor or KVM.

8 Server serial Used for Connecting to the SMS modem or

interface commissioning.

Figure 7-2 shows the RH5885 V3 server interfaces and Table 7-2 describes the interfaces.

Figure 7-2 RH5885 V3 server interface diagram

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 29

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Table 7-2 RH5885 V3 server interface description

No. Interface Function

Type

1 eth0 GE Used for connecting to the LAN switch. eth0 and eth1

interface comprise a bond , which is used for providing external

services.

2 eth1 GE

l If southbound and northbound network isolation is

interface

not adopted, only eth0 or eth1 is required.

3 eth2 GE l If southbound and northbound network isolation is

interface adopted, both eth0 (or eth1) and eth2 (eth3) are

required.

4 eth3 GE eth0 (or eth1) is used for providing southbound

interface services while eth2 (or eth3) is used for providing

northbound services.

5 Server serial Used for Connecting to the SMS modem or

interface commissioning.

6 VGA interface Used for connecting to the monitor or KVM.

7 USB interface Used for connecting to the KVM.

8 iMana Used for connecting to the PC to manage the RH5885

management V3 server.

network

interface

Server Signal Cable Connection Description

Figure 7-3 and Figure 7-4 show how signal cables are connected without southbound and

northbound network isolation. Figure 7-5 and Figure 7-6 show how signal cables are

connected with southbound and northbound network isolation.

NOTE

For details on southbound and northbound network isolation, see the Overview of Southbound and

Northbound Network Isolation in NetEco Software Installation and Commissioning Guide.

Figure 7-3 Signal cable connection diagram of the RH2288H V3 server (without southbound

and northbound network isolation)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 30

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Figure 7-4 Signal cable connection diagram of the RH5885 V3 server (without southbound

and northbound network isolation)

Figure 7-5 Signal cable connection diagram of the RH2288H V3 server (with southbound and

northbound network isolation)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 31

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Figure 7-6 Signal cable connection diagram of the RH5885 V3 server (with southbound and

northbound network isolation)

7.2 Connecting Signal Cables (Entire E1 Networking)

Server Interface Description

Figure 7-7 shows the RH2288H V3 server interfaces and Table 7-3 describes the interfaces.

Figure 7-7 RH2288H V3 server interface diagram

Table 7-3 RH2288H V3 server interface description

No. Interface Function

Type

1 eth0 GE Used for connecting to the LAN switch. eth0 and eth1

interface comprise a bond, which is used for providing external

services.

2 eth1 GE

l If southbound and northbound network isolation is

interface

not adopted, only eth0 or eth1 is required.

3 eth2 GE

interface

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 32

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

No. Interface Function

Type

4 eth3 GE l If southbound and northbound network isolation is

interface adopted, both eth0 (or eth1) and eth2 (eth3) are

required.

eth0 (or eth1) is used for providing southbound

services while eth2 (or eth3) is used for providing

northbound services.

5 USB interface Used for connecting to the KVM.

6 iBMC Used for connecting to the PC computer to manage the

management RH2288H V3 server.

interface

7 VGA interface Used for connecting to the monitor or KVM.

8 Server serial Used for Connecting to the SMS modem or

interface commissioning.

Figure 7-8 shows the RH5885 V3 server interfaces and Table 7-4 describes the interfaces.

Figure 7-8 RH5885 V3 server interface diagram

Table 7-4 RH5885 V3 server interface description

No. Interface Function

Type

1 eth0 GE Used for connecting to the LAN switch. eth0 and eth1

interface comprise a bond , which is used for providing external

services.

2 eth1 GE

l If southbound and northbound network isolation is

interface

not adopted, only eth0 or eth1 is required.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 33

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

No. Interface Function

Type

3 eth2 GE l If southbound and northbound network isolation is

interface adopted, both eth0 (or eth1) and eth2 (eth3) are

required.

4 eth3 GE eth0 (or eth1) is used for providing southbound

interface services while eth2 (or eth3) is used for providing

northbound services.

5 Server serial Used for Connecting to the SMS modem or

interface commissioning.

6 VGA interface Used for connecting to the monitor or KVM.

7 USB interface Used for connecting to the KVM.

8 iMana Used for connecting to the PC to manage the RH5885

management V3 server.

network

interface

Server Signal Cable Connection Description

Figure 7-9 and Figure 7-10 show how signal cables are connected without southbound and

northbound network isolation. Figure 7-11 and Figure 7-12 show how signal cables are

connected with southbound and northbound network isolation.

NOTE

For details on southbound and northbound network isolation, see the Overview of Southbound and

Northbound Network Isolation in NetEco Software Installation and Commissioning Guide.

Figure 7-9 Signal cable connection diagram of the RH2288H V3 server (without southbound

and northbound network isolation)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 34

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Figure 7-10 Signal cable connection diagram of the RH5885 V3 server (without southbound

and northbound network isolation)

Figure 7-11 Signal cable connection diagram of the RH2288H V3 server (with southbound

and northbound network isolation)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 35

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Figure 7-12 Signal cable connection diagram of the RH5885 V3 server (with southbound and

northbound network isolation)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 36

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Connecting to the E1 Network

Figure 7-13 Connection diagram between E1 devices and the E1 network

7.3 Connecting Signal Cables (Partial E1 Networking)

Server Interface Description

Figure 7-14 shows the RH2288H V3 server interfaces and Table 7-5 describes the interfaces.

Figure 7-14 RH2288H V3 server interface diagram

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 37

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Table 7-5 RH2288H V3 server interface description

No. Interface Function

Type

1 eth0 GE Used for connecting to the LAN switch. eth0 and eth1

interface comprise a bond, which is used for providing external

services.

2 eth1 GE

l If southbound and northbound network isolation is

interface

not adopted, only eth0 or eth1 is required.

3 eth2 GE l If southbound and northbound network isolation is

interface adopted, both eth0 (or eth1) and eth2 (eth3) are

required.

4 eth3 GE eth0 (or eth1) is used for providing southbound

interface services while eth2 (or eth3) is used for providing

northbound services.

5 USB interface Used for connecting to the KVM.

6 iBMC Used for connecting to the PC computer to manage the

management RH2288H V3 server.

interface

7 VGA interface Used for connecting to the monitor or KVM.

8 Server serial Used for Connecting to the SMS modem or

interface commissioning.

Figure 7-15 shows the RH5885 V3 server interfaces and Table 7-6 describes the interfaces.

Figure 7-15 RH5885 V3 server interface diagram

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 38

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Table 7-6 RH5885 V3 server interface description

No. Interface Function

Type

1 eth0 GE Used for connecting to the LAN switch. eth0 and eth1

interface comprise a bond , which is used for providing external

services.

2 eth1 GE

l If southbound and northbound network isolation is

interface

not adopted, only eth0 or eth1 is required.

3 eth2 GE l If southbound and northbound network isolation is

interface adopted, both eth0 (or eth1) and eth2 (eth3) are

required.

4 eth3 GE eth0 (or eth1) is used for providing southbound

interface services while eth2 (or eth3) is used for providing

northbound services.

5 Server serial Used for Connecting to the SMS modem or

interface commissioning.

6 VGA interface Used for connecting to the monitor or KVM.

7 USB interface Used for connecting to the KVM.

8 iMana Used for connecting to the PC to manage the RH5885

management V3 server.

network

interface

Server Signal Cable Connection Description

Figure 7-16 and Figure 7-17 show how signal cables are connected without southbound and

northbound network isolation. Figure 7-18 and Figure 7-19 show how signal cables are

connected with southbound and northbound network isolation.

NOTE

For details on southbound and northbound network isolation, see the Overview of Southbound and

Northbound Network Isolation in NetEco Software Installation and Commissioning Guide.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 39

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Figure 7-16 Signal cable connection diagram of the RH2288H V3 server (without

southbound and northbound network isolation)

Figure 7-17 Signal cable connection diagram of the RH5885 V3 server (without southbound

and northbound network isolation)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 40

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Figure 7-18 Signal cable connection diagram of the RH2288H V3 server (with southbound

and northbound network isolation)

Figure 7-19 Signal cable connection diagram of the RH5885 V3 server (with southbound and

northbound network isolation)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 41

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 7 Connecting Server Signal Cables

Connecting to the E1 Network

Figure 7-20 Connection diagram between E1 devices and the E1 network

NOTE

l Interconnection method for TD-6228 and TD-6032: TX interface is interconnected with RX

interface.

l Interconnection method for TD-6032 and TD-6310: TX interface is interconnected with OUT

interface; RX interface is interconnected with IN interface.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 42

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 8 Checking the Installation

8 Checking the Installation

About This Chapter

8.1 Checking the Installation of the Cabinet

8.2 Checking the Installation of Components in the Cabinet

8.3 Checking the Installation of Power Cables and Ground Cables

8.4 Checking the Connection of Signal Cables

8.1 Checking the Installation of the Cabinet

SN Check Item

1 The cabinet is placed as designed.

2 The rack is secure and reliable and meets the anti-seismic requirements. The

horizontal and vertical differences do not exceed 3 mm. You can use a horizontal

ruler and a lead ruler to measure the differences.

3 If the cabinet is placed on an ESD floor, all the expansion bolts of the supports are

secure with the floor; the installation sequence of the insulation washers, flat

washers, spring washers, and nuts (bolts) are correct; the installation holes of the

supports are secure with the expansion bolts. The supports are insulated from the

floor and guide rails. The resistance of all the insulated points between the supports

and cabinets measured by the MΩ level of the multimeter is greater than 5 MΩ.

4 All the screws are secure; a flat washer and a spring washer are installed for each

screw; the washers are properly placed.

5 The cabinets are arranged in order. The cabinet queue at both sides of the passage

are straight, and the difference does not exceed 5 mm.

6 The connecting plates are installed properly when two cabinets are deployed on one

site.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 43

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 8 Checking the Installation

SN Check Item

7 The front, side, and rear doors of the cabinets are installed. The front and rear doors

can be opened and closed. The door locks function normally.

8 The exteriors and interiors of the cabinets (including the front door, rear door, and

sides of each cabinet) are clean. No dirt, damage, or fingerprint is allowed.

9 All the outlets or inlets of the cabinets are sealed. The gap around a cover plate

does not exceed the width of the cover plate. If a bag is used, the opening of the

bag is tied up. The sizes of the outlets that use plastics are appropriate. You can use

other appropriate, insulated, or flame-resistant materials to seal the outlets.

10 There are excessive hair bands, lines, and other wastes.

11 All the configured filler panels are installed.

12 The ESD wrist strap is inserted into the ESD installation hole.

13 The cabinet labels are smooth and tidy.

8.2 Checking the Installation of Components in the

Cabinet

SN Check Item

1 The devices are installed in the correct positions as designed.

2 All the panel screws of the devices are installed and secure.

3 The panel and exterior of each device are not dirty, and the paint is not scraped off.

4 The labels (coating of the subrack, plate nameplate, transport label, and product

nameplate) of each device are not peeled off.

5 The bar code of each device is not peeled off.

6 The ejector lever of each board is placed in position.

7 The captive screws of each board are secure.

8 There is no vacant slot in the subrack, and filler panels are installed in vacant slots.

9 A protective cover is installed for the power module if the power module is

configured with a protective cover.

8.3 Checking the Installation of Power Cables and Ground

Cables

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 44

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 8 Checking the Installation

SN Check Item

1 All the power cables and ground cables are copper-core cables.

2 There are no solder joints or connectors in power cables and ground cables.

3 The extra length of power cables or ground cables is truncated and the cables are

not coiled.

4 There are no breaking equipment such as switches and fuses in the electrical

connection of the grounding system.

5 The ground bars and PGND bars are connected to one grounding conductor.

6 The OT terminals at both ends of the power cables or ground cables are crimped

securely.

7 The bare wires and OT terminals at the wiring terminals are tightly wrapped up

with PVC insulation tapes or heat shrink tubing.

8 The power cables and ground cables connecting the PDB with each device, and the

ground cables connecting each device with the PGND busbar of the cabinet are all

correctly installed and have good contact.

9 The front and rear doors are connected to the ground bolts on the lower enclosure

of the cabinet using 6 mm2 greenish yellow cables. Two such cables are used for

each door.

10 The power cables and ground cables are bound separately from other cables.

11 Labels are attached at both ends of the power cables and ground cables.

12 The plastic cover plate on the top of wiring terminals of the PDB is properly

installed.

8.4 Checking the Connection of Signal Cables

SN Check Item

1 There are no solder joints or connectors in signal cables. The signal cables are not

scratched or broken.

2 The connectors of signal cables are tight and secure.

3 Proper length of the cable is reserved at the connectors.

4 Proper length is reserved for signal cables at turning points. The turning radius

meets the requirement.

5 The optical fibers must be sheathed using corrugated pipes at outsides of cabinets.

Both ends of the pipes must be fastened. The edges are smooth or be processed for

cutting prevention.

6 No other cables are laid on optical fibers.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 45

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 8 Checking the Installation

SN Check Item

7 The extra optical cables are coiled on the cable coiler at the rear of the cabinet.

8 The signal cables connected to the left part of the subrack are led out of the subrack

from the left. Similarly, the signal cables connected to the right part of the subrack

are led out of the subrack from the right.

9 The signal cables are bound separately from the power cables. The signal cables are

bound and arranged neatly and closely. The cable ties are spaced evenly. The tips of

the cable ties point to the same direction.

10 The extra length of the cable ties must be cut and the cut surface must be smooth.

11 The cables whose connectors are far away from the cable entrance are arranged at

the external side of the cable bundle, while those near the entrance are arranged at

the internal side of the cable bundle. The trunk cables are laid out smoothly without

any tangling.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 46

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

9 Appendixes

About This Chapter

9.1 Main Device Parameters

9.2 Installation Specifications

9.3 Preparing Power Cables and PGND Cables of the Cabinet

9.1 Main Device Parameters

Main Cabinet Parameters

Table 9-1 describes the main cabinet parameters.

Table 9-1 Main cabinet parameters

Cabinet Model Cabinet Dimensions (Height x Weight

Interior Width x Depth)

Space

N610E-22 46 U 2200 mm x 600 mm x 1000 150 kg (factory

mm configuration)

87 in. x 24 in. x 39 in.

Main Device Parameters

Table 9-2 describes the main device parameters.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 47

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Table 9-2 Main device parameters

Device Short Dimensions Weight Power Input Voltage

Name Name (mm) (Height x (kg) Consum (V)

Width x Depth) ption

(W)

Tecal RH228 86.1×447×708 25.0 460 110 to 220

RH2288H V3 8H

V3(sma

ll scale)

RH228 86.1×447×708 26.0 460 110 to 220

8H

V3(med

ium

scale)

Tecal RH5885 RH588 175 x 447 x 790 70.0 1200 90 to 264

V3 5 V3

KVM - 42.5 x 447.4 x 15 46 90 to 264

594.1

Quidway S3328 43.6 x 442 x 220 2.5 20 100 to 240

S3328

(100Mbit/s

LAN Switch)

TD-6200RM- - 183 x 483 x 180 1.35 50 200 to 240

4U

TD-6310 - 44.5 x 430 x 203 2 5 200 to 240

TD-6032 - 44.5 x 260 x 440 5 15 200 to 240

TD-6340 - 44.5 x 430 x 203 2.3 5 200 to 240

PDB Parameters

Table 9-3 describes the power distribution box (PDB) parameters.

Table 9-3 Parameters for the APD63-2-24 AC PDB

Item KPI

Input Input Voltage 176 V AC to 276 V AC

Maximum Input 63 A

Current

Frequency 47 Hz to 63 Hz

Input Mode Two AC inputs (1+1 backup)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 48

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Item KPI

Output Output Voltage 176 V AC to 276 V AC

Output Shunt The 24 output shunts are divided into group A and

group B (each group has 12 output shunts).

l The output shunts support the short circuit

protection function. Group A and group B work in

active/standby mode. The maximum output

currents of the output shunts in each group are as

follows: 10 A (four output shunts) and 6 A (eight

output shunts).

l The rated output currents of output terminals L1,

L2, L3, and L4 are 10 A.

l The rated output currents of output terminals L5,

L6, L7, L8, L9, L10, L11, and L12 are 6 A.

Output The PDB supports the overcurrent protection

Protection function. The short circuit fault needs to be manually

rectified.

Environment Working -15ºC to +45ºC

Temperature

Storage -40ºC to +70ºC

Temperature

Relative 5% RH to 95% RH

Humidity

9.2 Installation Specifications

9.2.1 Installation Specifications of Power Cables and PGND

Cables in the Cabinet

Principles of Laying Power Cables and PGND Cables

l The power cables and PGND cables must be laid straight with smooth radian. Different

colors of cables must be separately straightened out and bound in bundles.

l When laying out power cables, you must measure the distance between the power

distribution cabinet terminal and the PDB terminal and reserve proper extra length.

During the layout of cables, if the length of a cable is insufficient, you must replace the

cable. Do not make a joint or solder joint within the cable.

l The excess of the power cables and ground cables are trimmed off, rather than being

coiled.

l When installing OT terminals of power cables and ground cables, install them in cross

connection. The bigger OT terminal is installed at the bottom, and the smaller one is

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 49

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

installed at the top. Alternatively, you can bend OT terminals at an angle of 45 or 90

degrees, as shown in Figure 9-1.

Figure 9-1 Installing OT terminals

l The power cables and PGND cables must be laid separately from signal cables. If the

power cables and PGND cables are laid parallel with signal cables, the distance cannot

be less than 100 mm, as shown in Figure 9-2.

Figure 9-2 Distance between the power cables and the signal cables

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 50

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

l When cables are turned, the bending radius must be greater than five times the diameter

of the cables.

l If the height difference between the cable ladder and the top of the cabinet is more than

800 mm in case of overhead cabling, a downward cable ladder is required to fix cables to

avoid damage to cables because of overexertion.

l In underfloor cabling mode, the height of cables below the ESD floor cannot exceed

three fourth of the headroom of the ESD floor.

l The cables are arranged closely without being crossed, tangled, and distorted.

Principles of Binding Power Cables and PGND Cables

l The power cables and PGND cables must be bound separately from signal cables.

l The power cables and PGND cables are bound at a distance of 200 mm.

l During the installation and layout of cables, ensure that the cables are not squeezed or

strained by rotating parts such as door. Do not bind cables cables at turns, as shown in

Figure 9-3.

Figure 9-3 Position of binding tapes at the cable turnings

l The specification of the cable ties can be 150 mm or 300 mm, subject to the diameter and

number of cables.

l The tips of the cable ties point to the same direction. The extra length of the cable ties

must be cut and the cut surface must be smooth.

9.2.2 Installation Specifications of Signal Cables

Cabling Areas in the Cabinet

Figure 9-4 shows the planform of the cabling areas in the cabinet.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 51

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Figure 9-4 Cabling areas in the cabinet

A Area for power cables B Area for network cables and SAS cables

C Front cabling area D Device installation area

E Cabling parts such as horizontal cable trough F Area for optical fibers, network cables, SAS

cables, and power cables

Description of each cabling area:

l Power cables are preferentially laid in area A, the inner side of the mounting bar in the

cabinet. If the number of power cables exceeds 40 and area A cannot accommodate all

the power cables, you can lay some power cables on the wire bushing in area F.

l The network cables laid in are B must be close to area F.

l If both power cables and signal cables are laid in area F, the distance between the power

cables and the signal cables must be greater than 100 mm.

Cabling Parts

l 1 U horizontal cable trough shown in Figure 9-5

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 52

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Figure 9-5 1 U horizontal cable trough

The 1 U horizontal cable trough is installed on the mounting bar at the rear of the cabinet

and is used to bind the power cables connecting the power distribution box (PDB) and

the signal cables connecting the rear transition module of the subrack. Generally, the

height of cables that are bound to the horizontal cable trough cannot exceed the height of

the horizontal cable trough. Figure 9-6 shows the installation effect.

Figure 9-6 Installation effect of the 1 U horizontal cable trough

l Side fiber management tray shown in Figure 9-7

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 53

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Figure 9-7 Side fiber management tray

The side fiber management tray is installed on the mounting bar at the rear of the cabinet

and is used for optical fiber winding. Each fiber management tray can manage a

maximum of 10 m redundant optical fibers.

l 1 U cable tray shown in Figure 9-8

Figure 9-8 1 U cable tray (1)

The 1 U cable tray installed near the LAN switch is used for cabling. The maximum

number of cables per tooth is 4. Figure 9-9 shows the installation effect.

NOTE

If the network cable is inserted into the Ethernet port on the LAN switch after being bent upwards

on the cable tray, the bending radius must be greater than 15 mm to avoid damage to the Ethernet

port.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 54

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Figure 9-9 1 U cable tray (2)

l Fiber binding tape

The fiber binding tape is used for binding optical fibers. The distance between two

places with fiber binding tapes is 200 mm, as shown in Figure 9-10.

Figure 9-10 Fiber binding tape

Installation Principles of Signal Cables

l Principles of Laying Signal Cables

– The continuity test must be conducted for each signal cable before installation, and

both ends of a signal cable must be marked or attached with engineering labels that

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 55

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

identify the devices to be connected to ensure proper cable sequence. The labels

must be specified based on the specifications and be attached orderly and securely.

– There are no solder joints or connectors in signal cables. The signal cables are not

scratched or broken.

– The upward and downward cables are laid between the middle standing pillar and

the rear mounting bar. The horizontal cables should be laid along the wire bushing

and be bound to the wire bushing.

– Signal cables cannot be laid on cooling holes. Otherwise, the cooling of the cabinet

is affected and the lifetime of signal cables is shortened.

– When routing power cables and signal cables in the cable trough, ensure that the

distance between power cables and signal cables is greater than 100 mm. Do not

bind them together.

– Signal cables must be laid horizontally, vertically, and smoothly without tangling

(tangling is allowed within one meter out of the cabinet) and folding.

– The connectors of the signal cables must be tight and have favorable contact.

– The pins of signal cable connectors cannot be broken, twisted, or distorted.

l Principles of Binding Signal Cables

– In case of inter-subrack binding, the binding tape at the top of each subrack is

bound to the two ends of the turning and fixed by the standing pillar.

– The signal cables are bound and arranged evenly, neatly, and properly. The tips of

the cable tapes point to the same direction. You are advised to use one cable tape at

a distance of 200 mm outside the cabinet. The distance between two places with

cable tapes inside the cabinet must be less than 200 mm.

– The extra length of the cable tapes must be cut and the cut surface must be smooth.

– Different types of cables such as power cables, signal cables, and ground cables

must be laid and bound separately. Inside the cabinet, power cables and ground

cables are bound along the cable trough on the inner side, and signal cables are

bound along the wire bushing on the outer side.

– The same type of cables for different blades cannot be bound together or tangled.

– The cables in the cabinet that needs a side panel cannot affect the installation of the

side panel.

– The places that are bound by optical fibers must be protected by fiber binding tapes.

The distance between two places with fiber binding tapes is 200 mm. The fibers

near support beams must be fixed properly by binding tapes without being

scratched.

l Principles of Bending Signal Cables

– Signal cables cannot be excessively bent at the turnings so that the cable cores are

not damaged. You are advised to take necessary protective measures when signal

cables are fixed by mechanical parts with edges and corners.

– Generally, the curvature radius is equal to or greater than two times the diameter of

the signal cable when a signal cable is bent, and the curvature radius at the egress of

the connector is greater than four to six times the diameter of the signal cable.

– When the feeder tube or feeder line of a cable is bent, the curvature radius is equal

to or greater than seven times the diameter of the cable.

– Generally, the curvature radius of a radio frequency (RF) cable is equal to or greater

than 15 times the diameter of the RF cable when it is bent. In the extreme case, the

curvature radius is equal to or greater than ten times the diameter of the cable.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 56

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

– The curvature radius of optical fibers is equal to or greater than 40 mm when they

are bent.

– Binding tapes cannot be used at the turnings of signal cables, and proper length of

cables must be reserved at the turnings, as shown in Figure 9-11.

Figure 9-11 Position of binding tapes at the signal cable turnings

l Overhead Cabling Principles

Each of the eight corners at the top and bottom of the cabinet near the position for the

side panel has a rectangular cable-through hole, as shown in Figure 9-12.

Figure 9-12 Position of cable-through holes on the cabinet

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 57

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

The signal cables passing through device cabinets adopt the rear cabling mode. The

ingoing cabling mode is as follows:

– The signal cables go into a cabinet through the two cable-through holes at the top

rear of the cabinet and are laid along the space between the middle standing pillars

on the two sides of the cabinet and the rear mounting bar until they reach the

devices, as shown in Figure 9-13.

Figure 9-13 Overhead cabling mode

– If the cable tray is used, the signal cables must be bound to the beam of the cable

tray neatly in rectangular shape (single-core cables can be bound in round shape). If

the height difference between the cable tray and the top of the cabinet is more than

0.8 m, a downward cable ladder is required to fix cables to avoid damage to cables

because of overexertion.

l Underfloor Cabling Principles

– The signal cables go into a cabinet through the two cable-through holes at the

bottom rear of the cabinet and are laid along the cable trough between the middle

standing pillar and the rear mounting bar until they reach the devices. The

underfloor cabling mode is applicable to the scenario that the ESD floor is already

laid, as shown in Figure 9-14.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 58

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Figure 9-14 Underfloor cabling mode

– In underfloor cabling mode, the height of cables below the ESD floor cannot exceed

three fourth of the headroom of the ESD floor.

9.3 Preparing Power Cables and PGND Cables of the

Cabinet

Context

l Power cables of the cabinet are black-jacket three-core cables (cable cores: blue, brown,

and yellowish green). If some power cables need to be purchased by field engineers, the

power cables must meet the specifications described in Table 9-4.

Table 9-4 Specifications of power cables for the cabinet

Type 60227 IEC 10(BVV)

Color Black jacket (cable cores: blue, brown, and yellowish green)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 59

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Voltage- 300 V

Resistan

ce Level

Maximu 36 A

m

Current

Conduct 6 mm2

or

Cross-

Sectiona

l Area

l The PGND cables of the cabinet are yellow or green. If some PGND cables need to be

purchased by field engineers, the PGND cables must meet the specifications described in

Table 9-5.

Table 9-5 Specifications of PGND cables for the cabinet

Type 60227 IEC 02(RV)

Color Yellow or green

Voltage- 450 V/750 V

Resistan

ce Level

Maximu 110 A

m

Current

Conduct 25 mm2

or

Cross-

Sectiona

l Area

Procedure

l Prepare PGND cables.

a. Take a proper length of PGND cables based on the distance between the cabinet and

the power distribution cabinet (PDC) in the equipment room. Note that a proper

length of PGND cables must be reserved.

b. Use the cable cutter to cut the PGND cables and put the PGND cables that are cut

down flat and straight on the installation site.

c. Strip a section of power cable insulator C based on the conductor cross-sectional

area of the power cable so that L1 power cable conductor D is exposed, as shown in

Figure 9-15. Table 9-6 describes the recommended L1.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 60

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Figure 9-15 Stripping the insulator (OT terminal)

NOTE

Do not scratch the metal conductor of power cables when stripping the insulator of power

cables.

Table 9-6 Reference table of the cross-sectional area of the PGND cable conductor

and the removed insulator length L1

Cross- Removed Cross-Sectional Removed

Sectional Insulator Length Area of the Insulator Length

Area of the L1 (mm) Power Cable L1 (mm)

Power Conductor (mm2)

Cable

Conductor

(mm2)

1 7 10 11

1.5 7 16 13

2.5 7 25 14

4 8 35 16

6 9 50 16

d. Enclose the power cable with heat shrink tubing A and enclose the exposed power

cable conductor with OT terminal B, as shown in Figure 9-16.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 61

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Figure 9-16 Enclosing the power cable with the heat shrink tubing and enclosing

the exposed power cable conductor with the OT terminal

NOTE

l The OT terminal must be close to insulator C of the power cable.

l After the exposed power cable conductor is enclosed with the OT terminal, the length of

the exposed bare crimping terminal L2 of the power cable cannot be greater than 1 mm.

e. Use the hydraulic pliers to press and weld the contact part between the end of the

bare crimping terminal and the power cable conductor, as shown in Figure 9-17.

NOTE

The end face shape after crimping is subject to the crimping mold and may be different from

the end face shape shown in Figure 9-17.

Figure 9-17 Pressing and welding the contact part between the end of the bare

crimping terminal and the power cable conductor

f. Push heat shrink tubing A in the direction of the connector body until the heat

shrink tubing covers the crimping area between the OT terminal and the power

cable conductor. Then, use the heat gun to shrink the heat shrink tubing to complete

the assembly of the OT terminal and power cable, as shown in Figure 9-18.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 62

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Figure 9-18 Blowing the heat shrink tubing (OT terminal)

NOTE

The time for shrinking the heat shrink tubing by using the heat gun cannot be too long to

avoid the insulator to be burned. Stop shrinking the tube after the tube is tightly attached to

the connector.

l Prepare power cables.

a. Take a proper length of power cables based on the distance between the cabinet and

the PDB in the equipment room. Note that a proper length of power cables must be

reserved.

b. Use the cable cutter to cut the power cables and put the power cables that are cut

down flatly and straightly on the installation site.

c. Strip a section of power cable insulator B based on the conductor cross-sectional

area of the power cable so that L1 power cable conductor C is exposed, as shown in

Figure 9-19. Table 9-7 describes the recommended L1.

NOTE

l Power cables are black-jacket three-core cables (cable cores: blue, brown, yellowish

green). You need to remove the black jacket before removing the insulator of power

cables.

l Do not scratch the metal conductor of power cables when stripping the insulator of

power cables.

Figure 9-19 Stripping the insulator of power cables (bare crimping terminal)

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 63

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Table 9-7 Reference table of the cross-sectional area of the power cable conductor

and the removed insulator length L1

Cross-Sectional Removed Cross-Sectional Removed

Area of the Insulator Area of the Insulator Length

Power Cable Length L1 Power Cable L1 (mm)

Conductor (mm) Conductor

(mm2) (mm2)

1 8 10 15

1.5 10 16 15

2.5 10 25 18

4 12 35 19

6 14 50 26

d. Enclose the exposed power cable conductor with bare crimping terminal A and

enable the end face of the bare crimping terminal to be level with the end face of the

power cable conductor, as shown in Figure 9-20.

NOTE

After the exposed power cable conductor is enclosed with the bare crimping terminal, the

length of the exposed bare crimping terminal of the power cable cannot be greater than 1

mm.

Figure 9-20 Enclosing the exposed power cable conductor with the bare crimping

terminal

e. Use the hydraulic pliers to press and weld the contact part between the head of the

bare crimping terminal and the power cable conductor, as shown in Figure 9-21.

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 64

Copyright © Huawei Technologies Co., Ltd.

iManager NetEco

Hardware Installation Guide 9 Appendixes

Figure 9-21 Pressing and welding the contact part between the head of the bare

crimping terminal and the power cable conductor

f. After the terminal crimping, check the maximum width of the terminal. The width

of the tubular terminal W1 after crimping must be smaller than the width specified

in Table 9-8.

Table 9-8 Maximum width of the tubular terminal after crimping

Cross-Sectional Maximum Cross-Sectional Maximum

Area of the Width of the Area of the Width of the

Tubular Terminal W1 Tubular Terminal W1

Terminal (mm2) After Crimping Terminal (mm2) After Crimping

(mm) (mm)

0.25 1 4 3.1

0.5 1 6 4

1.0 1.5 10 5.3

1.5 1.5 16 6

2.5 2.4 25 8.7

----End

Issue 04 (2018-03-07) Huawei Proprietary and Confidential 65

Copyright © Huawei Technologies Co., Ltd.

Anda mungkin juga menyukai

- Nuvoton 8051 ISP by COM Port: User ManualDokumen18 halamanNuvoton 8051 ISP by COM Port: User ManualCharu SrivastavaBelum ada peringkat

- Configuration Guide (V100R006C001 02)Dokumen618 halamanConfiguration Guide (V100R006C001 02)saadyusr2003100% (6)

- SingleRAN WiMAX LTE Network Impact Report (V100R001C00 - Draft A) 20110805 A 1.0Dokumen22 halamanSingleRAN WiMAX LTE Network Impact Report (V100R001C00 - Draft A) 20110805 A 1.0CésarAntonioPérezCoronelBelum ada peringkat

- Huawei U2000Dokumen616 halamanHuawei U2000MeyisawKassa100% (2)

- RTL8723BS: Combo NGFF1216 User 'S ManualDokumen17 halamanRTL8723BS: Combo NGFF1216 User 'S ManualEnmanuel OrdoñezBelum ada peringkat

- Huawei DBS3900 LTE Network Commissioning v1.1Dokumen77 halamanHuawei DBS3900 LTE Network Commissioning v1.1Efosa AigbeBelum ada peringkat

- Configuration Guide - IP Routing (V600R003C00 - 02)Dokumen835 halamanConfiguration Guide - IP Routing (V600R003C00 - 02)okie11Belum ada peringkat

- Handbook On Electronic Interlocking Maintenance Instruction Series I PDFDokumen38 halamanHandbook On Electronic Interlocking Maintenance Instruction Series I PDFMatthew Carroll100% (2)

- Exaquantum Engineering Guide Vol 2Dokumen174 halamanExaquantum Engineering Guide Vol 2IlgizBelum ada peringkat

- Release NotesDokumen30 halamanRelease NotesARTURO CÉSAR ANDREW GONZÁLEZ ÁLVAREZBelum ada peringkat

- WAVENCE18 Installation & Comm - RN88294 - C - 1800 - V1.0 - SG - Ed1 - CEDokumen172 halamanWAVENCE18 Installation & Comm - RN88294 - C - 1800 - V1.0 - SG - Ed1 - CEDia nur100% (3)

- OMCDokumen587 halamanOMCOmer KhalidBelum ada peringkat

- Huawei DBS3900 LTE Network Commissioning v1.1 ENODEBDokumen77 halamanHuawei DBS3900 LTE Network Commissioning v1.1 ENODEBbexandyBelum ada peringkat

- A O IEEE 802.21: M - I H S: N Verview of Edia Ndependent Andover ErvicesDokumen8 halamanA O IEEE 802.21: M - I H S: N Verview of Edia Ndependent Andover ErvicesAline Oliveira ValenteBelum ada peringkat