Altronic Ignition-Systems PDF

Diunggah oleh

Nabeel AhmadJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Altronic Ignition-Systems PDF

Diunggah oleh

Nabeel AhmadHak Cipta:

Format Tersedia

Ignition Systems

for Industrial Engines

Altronic Ignition Systems

CONTENTS

Altronic Ignition Systems Overview and Guide

Contents and Introduction................................................................................. 2

Application Guide............................................................................................. 3

Solid-State/Mechanical Ignition Systems

Theory and Overview......................................................................................... 4

Altronic I, II, III, and V...................................................................................... 5

Disc-Triggered Digital Ignition Systems

Theory and Overview......................................................................................... 6

CD1, CD200, CD200D, DISN............................................................................ 7

Crankshaft-Referenced Digital Ignition Systems

Theory and Overview......................................................................................... 8

CPU-95, CPU-2000.......................................................................................... 9

Ignition Coils . ................................................................................................. 10

Flashguard® Spark Plugs and Secondary Leads,

24V Alternator Systems ................................................................................. 11

Pushing the Performance Envelope: Altronic Ignition Systems and Accessories

Girard, Ohio-based Altronic, Inc. has spent much of the last 40 Browsing through these pages will give you a good overview of

years defining and redefining the state-of-the-art when it comes both the evolution of the Altronic ignition and ignition accessory

to ignition systems and accessories for industrial natural gas- product line, as well as a good idea about the system options

fueled engines. As a result of this constant attention to product available for your specific make and model of engine.

development and manufacturing excellence, engine manufactu-

rers and end users alike from around the world continue to turn

to Altronic first for technically-advanced, high-quality ignition

systems and components.

All rights reserved

© ALTRONIC, INC 2009 2

AIS-C 9-09

Altronic Ignition Systems Application Guide

No. CD1 CPU- CPU- No. CD1 CPU- CPU-

Engine Manufacturer I III V DISN Engine Manufacturer I III V DISN

Cyls. CD200 95 2000 Cyls. CD200 95 2000

AJAX 1-2 R O O JENBACHER 6-8 O O R R

3 R R O O 12-16 O R R

4 R O O 18-20 O R

ALCO 6-16 O R KUBOTA 1 R

ALLIS-CHALMERS 4-6 O R LISTER 2-3 R R

ARIEL 1-2 R O LORAIN 1 R

ARROW 1 R LUFKIN 2 R O

2 R O MAN 6-12 R R

BELL 1 R MAN

6-18 O R

(BRONS-CROSSLEY)

BUDA 6-8 O R

M.E.P. 4-12 O O R O

CATERPILLAR 4-6 O O O R R R

MINNEAPOLIS-MOLINE 4-6 O O R

8-16 O R R

MITSUBISHI 6-18 R R

CHICAGO PNEUMATIC 8-10 R

MWM (DEUZ) 6-16 O R

CLARK 1-2 R

NIIGATA 6-18 R

3-8 O O R R

NORDBERG 6-16 R

10-12 O R

OILWELL (WHITE) 1-2 R

16-20 R

PERKINS 6-16 R

CLIMAX 6-12 O R

ROLLS-ROYCE (BERGEN) 6-18 R

CONTINENTAL 3-6 O O R

ROILINE 6-12 O R

CONTINENTAL-EMSCO 1-2 R O

RUSTON 6-12 R O

COOPER-BESSEMER 1-2 R

SACM 6-16 O R

3-8 O O R R

SCANIA 6 R R

10-12 O R

SUPERIOR 6-16 O O R O

16-20 R

VALMET (SISU) 3-6 R R

CUMMINS 4-6 O O O R R

WAUKESHA 4-6 O R R O

12-16 O R R

6-16 O R R

DE LAVAL 6-16 R

WORTHINGTON 3-10 O O R

DEUTZ 2-6 O O R R

12-20 R

8-16 O R

R = Recommended system for application. O = Optional system for application.

DORMAN 3-6 R O R

6-16 O R

FAIRBANKS MORSE 1 R

FORD 4-6 O R

8 R O

GEMINI 1-2 R

GUASCOR 6-16 O R R CERTIFIED FOR USE IN

HAZARDOUS LOCATIONS

HERCULES (WHITE) 4-6 O O R NOTE: Most, but not all, Altronic ignition

INGERSOLL RAND 1-2 R systems and accessories in this catalog

are CSA certified and compliant with the

4-16 O O R R appropriate CE/ATEX regulations. Check

each product listing for certification and

INTERNATIONAL 4-6 O R

hazardous area classification.

IVECO 6-12 R R

All rights reserved

© ALTRONIC, INC 2009 3

AIS-C 9-09

Solid-State/Mechanical Systems

Altronic solid-state ignition systems con-

sist of a self-powered ignition unit, a wir-

ing harness and an appropriate number of

ignition coils. Operating power is provided

by a self-contained, multi-pole perma

nent magnet alternator that charges an

energy storage capacitor. Pick-up coils,

triggered magnetically, provide the timing

pulses to discharge the capacitor in timed

sequence. These low-tension discharges

are routed by a distribution system, com-

posed of a rotating magnet and solid state

switching components, to the ignition

coil of the proper cylinder. Electronics

are mounted on easy to replace plug-in

modules.

CERTIFIED

Drive couplings are furnished in synthetic

CLASS 1, DIV. 2,

elastomer materials for low wear and long GROUP D

life. They also serve to dampen part of

the engine drive train vibration. Com- Application Data

bined with the smooth rotational cycle IGNITION SYSTEM POWER SOURCE CYLINDERS APPLICATIONS

Small in-line engines

of the Altronic alternator, these features Altronic I Self-powered 1-6

Horizontal 1-3 cyl. engines

contribute to the long mechanical life de- Altronic II Self-powered 3-20 Large bore, slow speed engines

signed into Altronic solid-state systems. Altronic III Self-powered 2-16 Medium-sized industrial engines

Small in-line engines

Alternator powered Altronic V Self-powered 1-6

Horizontal 1-3 cyl. engines

Capacitor discharge ignition

Replaces magneto, breaker points TYPICAL CYLINDER BORE SIZE (MM)

and impulse coupling 100 125 150 175 200 225 250 275 300 325 350 375 400 425

High output at engine cranking RPM Altronic I *

Altronic II

Extended spark life

Altronic III

Easy to service with plug-in modules

Altronic V *

* Also applies to larger bore, horizontal 1-3 cylinder engines

All rights reserved

© ALTRONIC, INC 2009 4

AIS-C 9-09

Solid-State/Mechanical Systems

Altronic I for Small Engines, able back cover, which contains all the

1-6 cylinder In-Line and system electronics.

1-3 cylinder Horizontal Other options include a choice of stan-

Altronic I, first introduced in 1966, dard or long spark duration coils in both

brought the advantages of capacitor dis- unshielded and shielded versions. Altronic

charge ignition to industrial gas engines. III can also be upgraded to the benefits

It consists of a small permanent magnet of crankshaft-referenced, electronically-

breaker-point ignition systems. Altronic

alternator with a plug-in electronic controlled timing — refer to the Altronic

II can be used on engines with either

module attached. Timing is set by one or III-CPU system.

one or two spark plugs per cylinder.

more remote mounted pick-up sensing

With an operating base of thousands of

magnets refer- Altronic V for Small In-Line Engines,

units, Altronic II has a proven record for

enced to the en- 1-6 cylinder

reliability. Users can also easily upgrade

gine crankshaft. Altronic V offers the same design fea-

to the Altronic II-CPU system while re-

On horizontal tures, installation ease, dependability

taining the Altronic II alternator section

engines, these

to supply system power requirements.

are typically

mounted on

the flywheel; Altronic III for Medium-Sized Engines,

on in-line engines, a magnet disc is 2-16 cylinders

used. The alternator performs no timing With over 40,000 units in the field,

function and can thus be either belt- or Altronic III has become the industry

coupling-driven. The only moving part is standard system for medium-sized

the alternator’s sealed, underloaded ball stationary gas engines. Altronic III is of-

bearing. fered with seven mounting variations and and serviceability that are built into

Over 60,000 Altronic I systems have six internal gear ratios to fit virtually any Altronic III, but in a smaller package. Six

been sold. The system’s simplicity and mounting variations and a dual-position

long record of field reliability have made electronic timing option are additional

it the ignition of choice for operators of features.

low-horsepower industrial engines. Altronic V affords small engine users a

cost-effective replacement for obsolete

Altronic II for Large Gas Engines, and maintenance-intensive breaker-point

3-20 cylinders magneto systems.

Altronic II provides a self-powered, ca-

pacitor discharge system for large-bore,

application in its class. Three types of

slow-speed gas engines. With four dif-

electronic timing control are also offered:

ferent internal gear ratios, base or flange

dual timing settings, timing vs. RPM and

mounting, and three drive coupling

timing vs. 4-20 milliamp signal. Ease

choices, Altronic II can be readily speci-

of service is assured by the replace-

fied to replace most older magneto or

All rights reserved

© ALTRONIC, INC 2009 5

AIS-C 9-09

Disc-Triggered Digital Ignition Systems

The Altronic disc-triggered digital ignition

systems consist of an ignition unit, a

magnetic or Hall-effect pickup, a timing

disc mounted to the engine crankshaft or

camshaft, wiring harnesses, and an ap-

propriate number of ignition coils. These

systems employ a cylinder position sens-

ing design, typically using a single pickup

and one trigger event per cylinder, which

may be derived from an Altronic timing

disc or holes/protrusions in the engine

flywheel or camshaft gear. The pickup and

timing disc provide accurate timing refer-

ence signals to the ignition unit, which

calculates the correct ignition timing

point. The systems feature high-energy,

capacitor-discharge output supplying

over 40KV with spark duration up to 600

microseconds.

These innovative and reliable systems can

CERTIFIED

be applied to a variety of engines, includ-

CLASS 1, DIV. 2,

ing heavy-duty vehicular applications as GROUP D

well as engines incorporating lean-burn NOTE: Hazardous

area certifications

technology. Timing discs are manufac-

do not include the

tured to an accuracy of 0.1 degree, thus CD1 or non-shielded

eliminating variations caused by drilling CD200 systems.

timing holes in the field.

Application Data

Single pickup operation

IGNITION SYSTEM POWER SOURCE CYLINDERS SPECIAL FEATURES

Precision-machined timing disc

12-24Vdc or Universal, low cost CD200 system available in shielded

accurate to 0.1 degree CD1/CD200 1-8

DC alternator and CSA certified versions

Incremental manual timing switches 12-24Vdc or

CD200D 4-16 General purpose, unshielded industrial system

for known adjustments DC alternator

12-24Vdc or

LED diagnostics for power, pickup, DISN 800C

DC alternator

4-16 Unshielded or shielded industrial system, CSA certified

application faults

Suitable for lean-burn engines TYPICAL CYLINDER BORE SIZE (MM)

12-24Vdc powered 100 125 150 175 200 225 250 275 300 325 350 375 400 425

Full output at engine cranking RPM CD1/CD200

CD200D

DISN 800C

All rights reserved

© ALTRONIC, INC 2009 6

AIS-C 9-09

Disc-Triggered Digital Ignition Systems

CD1/CD200 Family for flexibility through the use of an advanced, It is also capable of accepting an engine

Small Engines to 8-cylinders ModBus RTU-driven, Windows™-based position signal from either a magnetic

The Altronic CD1 Digital Ignition System terminal program. Performance enhance- or Hall-effect pickup. The CD200D is

has been developed for application on ment features resident in the CD200 designed as the successor to the widely-

small, stationary industrial engines up include adjustable output energy and used Altronic DISN system.

to 8 cylinders. This moderately-priced, automatic timing adjustment curves.

DISN 800C for Medium-Sized

easily installed system utilizes a low- Diagnostics associated with system opera-

Industrial Engines

cost magnetic pickup sensing drilled tion, as well as the primary and secondary

The DISN is a full-featured industrial

holes (usually in the engine flywheel) to discharge functions, are communicated

ignition system for small- to medium-sized

determine the angular position of the via on-board LEDs as well as through

stationary engines up to 16 cylinders. The

crankshaft. LED indicators give diagnos- the terminal program. Integral overspeed

DISN system is intended for compression-

tic signals regarding input power, the shutdown protection is also included.

stroke firing

pickup signal, and correct ignition unit

and usually

operation. Individual coils or economical Two versions of the CD200 system are

uses a single

multi-cylinder coil modules can be used available. The standard CD200 systems

pickup sens-

in conjunction with the CD1 system. (791070-X) are used with unshielded

ing, precision-

system components and ignition coils. For

machined

Beyond the CD1, substantial capabil- applications requiring service in hazard-

timing disc

ity for this same class/ ous areas (Class I, Division 2, Groups C

rotating at

size of industrial gas and D), a special, CSA-certified series of

engine cam-

engine is avaliable in CD200 systems is available (791080-X).

shaft speed.

the CD200 Universal This latter version utilizes shielded pri-

If crankshaft-referenced timing is desired,

Small Engine Digital Ignition mary input and output harnesses as well

two pickups are used: one sensing firing

System. These innova- as CSA-certified ignition coils (shielded

magnets placed in the engine flywheel and

tive designs employ and integral-style). Both the unshielded

the second sensing a single index magnet

micropro- and CSA-certified versions are available

rotating at camshaft speed. DISN offers

cessor in 6 and 8-output configurations.

up to eight firing patterns in a common

tech-

unit and is available in 8, 12 or 16-output

nology CD200D

models, each with multiple applications.

and The Altronic CD200D is suitable for both

The DISN systems also incorporate four

are unshielded and shielded systems on en-

advanced timing control options: manual

fully config- gines up to 16-cylinders. Housed in the

16-position timing switch, one-step timing

urable for a traditional DISN enclosure, this advanced

change, remote potentiometer timing con-

range of suitable digital ignition system incorporates all of

trol or control from a 4-20 milliamp analog

1-8 cylinder engine the same capabilities and functionality

signal. Three LED diagnostic indicators

models and firing patterns. resident in the standard CD200 prod-

give an instant indication of the basic

While using the same single pickup ar- uct, including adjustable output energy,

incoming power and pickup signals. The

rangement employed in the CD1 system, primary and secondary discharge diagnos-

cast housing offers superior protection in

the CD200 features complete application tics, automatic timing adjustment curves,

harsh environments.

and ModBus RTU communications.

All rights reserved

© ALTRONIC, INC 2009 7

AIS-C 9-09

Crankshaft-Referenced Digital Ignition Systems

The Altronic CPU crankshaft-referenced

systems consist of an ignition unit, two

magnetic pickups and cables, a primary

wiring harness and an ignition coil for

each spark plug. They employ a con-

tinuous crankshaft-sensing design. One

magnetic pickup inputs signals from the

engine ring-gear or holes drilled in the

flywheel; the second pickup senses a

revolution/reset event giving precise infor-

mation on the location of the crankshaft.

On 4-cycle engines, a reference signal at

engine camshaft speed is used to deter-

mine the compression cycle. A replace-

able memory chip, programmed with the

engine’s application data, operates with

the CPU’s digital circuitry to output pre-

cise firing pulses to the ignition coils.

Altronic CPU systems eliminate mechani-

cal wearing parts — gears, chains, cou-

plings, etc. Ignition timing is precise in

all cylinders due to crankshaft-referenced

timing. All CPU systems feature manual

timing adjustment, one-step timing capa-

bility and electronic timing control from a CERTIFIED

CLASS 1, DIV. 2,

4-20 milliamp signal.

GROUP D

Single pickup operation

Precision-machined timing disc Application Data

accurate to 0.1 degree IGNITION SYSTEM POWER SOURCE CYLINDERS SPECIAL FEATURES

Incremental manual timing switches CPU-95

12-24Vdc or

3-18

Adds display of operational and primary/secondary

DC alternator diagnostic features

for known adjustments

Adds operational and diagnostic displays:

LED diagnostics for power, pickup, CPU-2000 24Vdc 3-30

multi-strike feature

application faults

Suitable for lean-burn engines TYPICAL CYLINDER BORE SIZE (MM)

12-24Vdc powered 100 125 150 175 200 225 250 275 300 325 350 375 400 425

Full output at engine cranking RPM CPU-95

CPU-2000

All rights reserved

© ALTRONIC, INC 2009 8

AIS-C 9-09

Crankshaft-Referenced Digital Ignition Systems

Altronic CPU-95 for Medium addition of special ignition coils or high This second-generation digital crank-

Stationary Engines voltage probes. Special CPU-95 models: shaft-referenced system also integrates

The Altronic CPU-95 is a DC-powered, CPU-95C — Developed for use on sophisticated combustion enhancement

capacitive discharge digital ignition SI Controller-equipped Caterpillar tools and communications capabilities.

system for medium-sized industrial gas 3500-series engines, the CPU-95C The quad-strike function (four full-energy

engines to 20 cylinders. The Display system replaces both the existing strikes), present in the CPU-2000, is

Module, typically mounted in the engine Altronic III unit and AIB box. Its highly effective in igniting lean mix-

control panel, gives the user convenient installation allows for full access to tures for lower exhaust emissions, and

access to critical operating information the critical operational and diagnostic improved fuel economy on engines that

such as ignition system mode, engine information and enhanced spark suffer from poor air/fuel mixing and scav-

speed, system diagnostics and setup characteristic control resident in enging. An on-board RS-485 serial port

functions, and the value of the 4–20mA standard CPU-95 systems. with MODBUS capability for integration

signal being used for automatic timing CPU-95 VariSpark™ — an innovative into planned or existing control systems is

control and the timing of the ignition variant which uses capacitive- also available.

system. State-of-the-art combustion discharge ignition technology to Comprehensive system diagnostics, with

enhancement tools, including multistrike deliver a long-duration spark, typical primary and secondary discharge monitor-

(two full-energy spark events), and au- of an inductive ignition system. This ing functions, are built into the CPU-

tomatic spark energy adjustment (incre- model is of particular interest to 2000 Diagnostic Module. This innovative

mentally raising required spark energy) operators of large bore, low-BMEP diagnostic method patented by Altronic

help to minimize engines that exhibit ignitability or requires no additional probes or special

misfire and thus combustion stability problems. ignition coils, yet offers users effective

improve fuel tools for monitoring spark plug wear and

economy and Altronic CPU-2000 for Large other ignition or combustion abnormali-

reduce exhaust Stationary Engines ties. This spark demand monitoring capa-

emissions. The DC-powered CPU-2000 system is bility can be used to automatically raise

Individual designed for application on all large-bore the delivered energy as the spark plugs

cylinder tim- stationary gas engines and can accommo- wear calling for higher voltage.

ing control date virtually any engine firing pattern. A

strategies single, universal CPU-2000 Logic Module

can also be can be used in conjunction with either a

incorporated. 16 or a 32-output Ignition Output Module

Proprietary thus minimizing the number and variety

diagnostic capabilities for monitoring of ignition components. A simple terminal

the system, as well as the primary and program allows one unit to fit all applica-

secondary discharge diagnostic func- tions, and a field-replaceable memory

tions, are built into the CPU-95. These minimizes overall engine downtime in the

patented diagnostics offer users a means event that the ignition system requires

of continually monitoring spark plug wear replacement.

and combustion stability without the

All rights reserved

© ALTRONIC, INC 2009 9

AIS-C 9-09

Ignition System Accessories

Ignition Coils Flange Mount Coils Integral Coils

The ignition coil is a final and most The same internal structure as Designed to mount directly

critical component in the ignition system the unshielded coil pack- to special threaded spark

performance chain. Available in several aged in the convenient plugs, integral coils have

electrical and physical configurations, Al- 3-bolt flange mount stainless steel housings

tronic coils are produced in a new, state- configuration. Flange and are CSA-certified

of-the-art facility — the most advanced mount coils are designed for Class I, Division

in the world dedicated solely to industrial to mount to the valve covers on a number 2, Group D areas.

engine ignition coils. The plant incorpo- of popular, modern gas engines. Steel shell primary

rates advanced, customized equipment connectors are used

Shielded Coils

and manufacturing processes to assure to take the rough handling of industrial

Shielded versions are encased in stainless

consistent, high quality production of market applications.

steel housings and are CSA-

high voltage coils — a component very Note: To maintain the CSA system cer-

certified for Class I, Division

sensitive to process variations. tification, all coils (shielded or integral

2, Group D areas. Steel

For optimum performance and reliabil- types) and all primary and secondary

shell primary connectors

ity, the ignition coil must be properly components must be CSA-certified Al-

are used to take the

matched to the ignition system output tronic parts.

rough handling of in-

characteristics. Despite look-alike appear-

dustrial market applications.

ance, other sources of coils simply are

not the same internally, and don’t offer

comparable output and quality. A variety

of coils are offered to meet application

requirements. ALTRONIC I, III, V ALTRONIC II

CD1, CD200 II-CPU

COIL TYPE DURATION

Unshielded Round Case Coils CPU-90/95 CPU-2000

DISN D.I.S.

The standard for unshielded Standard 501061 —

Unshielded, round case

coils, the well-known Extended 591010 291001

Extended 591040 —

Altronic blue, red and Unshielded, square case

Extended 591050* —

black variations are used Standard 591018 —

Flange, 3-bolt

Extended 591012 —

in applications not requiring

Standard 501061-S —

hazardous area certifications. Shielded

Extended 591010-S 291001-S

Unshielded Square Case Coils Integral, 1"-20 x 5.6" 591007 591008

13/16"-20 x 6.1" 591011A —

Standard

An alternative to the round 13/16”-20 x 10.8” 591011B —

13/16”-20 x 11.3” 591011C —

case design, these coils

have extended spark

duration.

All rights reserved

© ALTRONIC, INC 2009 10

AIS-C 9-09

Ignition System Accessories

FLASHGUARD®, Shielded, and FLASHGUARD® Spark Plugs 24VDC Alternator Power Packages

Altronic offers a series of high quality The alternator power packages are

Safe-T-Lead™ Spark Plug Leads

spark plugs engineered and manufactured designed to deliver up to 70 watts of

Altronic offers a complete line of univer-

specifically for use in stationary gas en- DC power to users wishing to operate

sal and custom Flashguard® spark plug

gines. Incorporating a number of unique the latest DC-powered ignition systems,

leads. These premium secondary leads

design elements, the Altronic Flashguard® instrumentation, and control products, on

are designed with a 5,000-ohm integral

spark plugs are available with both installations lacking access to electrical

resistor and with tight-fitting silicone or

massive and precious metal electrodes service. To promote easy field retrofit,

Teflon® boots for reduced emitted RFI,

(including an iridium/platinum model), in the alternator units are designed to mate

minimized flashover, and improved spark

14mm, 18mm, and 7/8"-18 sizes, and in directly to various flange-mount magneto

plug life.

both shielded and unshielded configura- drive configurations. A belt-driven version

For those operating in Division 2 hazard- tions. All Flashguard spark plugs feature

®

is also available.

ous areas, Altronic offers two certified an extended ceramic insulator and pro- Two variations of the power package sys-

secondary lead styles designed for use prietary nose cone design for maximum tem are offered:

with shielded spark plugs. The traditional flashover resistance, and a high ohmic

braided stainless-steel lead is certified as Version I — Consists of an alternator,

internal resistor for reduced RFI and

safe for use in Class I, Division 2, Group voltage regulator, battery pack and

improved spark plug service life.

D hazardous areas. As an alternative, the cable. This system can furnish up

See the Altronic Ignition Accessories to 4 amps at 24Vdc for powering

Altronic Safe-T-Lead™ is a non-metallic

Catalog for further technical and applica- ignition, instrumentation and

lead designed for use in conjunction with

tion details. controls.

shielded ignition coils and spark plugs,

but eliminates the corrosion and spark Version II — Consists of an alternator,

plug life issues associated with traditional voltage regulator and cable optimized

metallic leads. The non-metallic nature of to make a self-powered ignition

the Safe-T-Lead™ lead also enables the system for the Altronic CPU-90 or

user to employ traditional diagnostic tools DISN. No battery is used with the

such as an ignition timing light Version II system.

in troubleshooting the ignition

system and the engine.

See the Altronic Industrial

Spark Plug and Ignition

Accessories catalog

for further details.

All rights reserved

© ALTRONIC, INC 2009 11

AIS-C 9-09

Altronic Inc – A Member of

the HOERBIGER Group

The HOERBIGER Group

HOERBIGER Compression Technology is a business unit of HOERBIGER Holding AG,

Zug / Switzerland. HOERBIGER is active throughout the world as a leading player in the fields

of compression technology, automation technology and drive technology. Its 6,400 employees

achieve sales of around 1 billion Euro. The focal points of its business activities include key

components and services for compressors, gas engines and turbomachines, hydraulic systems and

piezo technology for vehicles and machine tools, as well as components and systems for shift and

clutch operations in vehicle drive trains of all kinds. Through innovations in attractive technological

niche markets, the HOERBIGER Group sets standards and delivers cutting-edge solutions for the

benefit of its customers.

ALTRONIC INC ALTRONIC EUROPE BV Form AIS-C 9-09

712 Trumbull Avenue De Tienden 50A

Girard, Ohio 44420 USA 5674 TB Nuenen

P: 330-545-4045 The Netherlands

F: 330-545-9005 P: 011-31-40-2906270

F: 011-31-40-2838990

Anda mungkin juga menyukai

- 4 X3.6TAA G1 (35 40kVA) PDFDokumen4 halaman4 X3.6TAA G1 (35 40kVA) PDFCHETAN PRAJAPATI RDOBelum ada peringkat

- P222 Parts BookDokumen66 halamanP222 Parts BookMustafa A.WBelum ada peringkat

- 4008TAG2 Electro Unit PN2199Dokumen2 halaman4008TAG2 Electro Unit PN2199RioBelum ada peringkat

- ID FLX Lite 1 3 OperatorGuide ComapDokumen19 halamanID FLX Lite 1 3 OperatorGuide ComapMahesh MirajkarBelum ada peringkat

- 001a HM02316 - 00 Engine SpecificationsDokumen92 halaman001a HM02316 - 00 Engine SpecificationsBruno VenturaBelum ada peringkat

- Natural gas and biogas generator frequency and emissionsDokumen2 halamanNatural gas and biogas generator frequency and emissionsjosuelino2002Belum ada peringkat

- Installation Guide for FT-10 PowerCommand Control 2100 Genset Network Communications Module Kit 541–0770Dokumen5 halamanInstallation Guide for FT-10 PowerCommand Control 2100 Genset Network Communications Module Kit 541–0770Khaled KamelBelum ada peringkat

- Ecp-4083935oampmecpg PDFDokumen100 halamanEcp-4083935oampmecpg PDFP.p. Arul Ilancheeran100% (1)

- 6BT 5.9 C Hyundai ConstrutionDokumen139 halaman6BT 5.9 C Hyundai ConstrutionRitesh kumar100% (2)

- QSK19G PerformanceDokumen5 halamanQSK19G PerformancetroyBelum ada peringkat

- ACS Analogue Control Systems eDokumen12 halamanACS Analogue Control Systems eKhaled KamelBelum ada peringkat

- 4000 Series: 4008TAG2ADokumen5 halaman4000 Series: 4008TAG2ALopo LesmanaBelum ada peringkat

- G3512 SpecDokumen4 halamanG3512 SpecnunkpBelum ada peringkat

- Engine Data SheetEngine Data SheetEngine Data SheetEngine Data SheetDokumen3 halamanEngine Data SheetEngine Data SheetEngine Data SheetEngine Data SheetHumayun Nawaz100% (1)

- Engine Technical Specification SummaryDokumen8 halamanEngine Technical Specification SummarybaljeetjatBelum ada peringkat

- KTA 50 G3 1250 KVA Operation and Maintenance ProcedureDokumen20 halamanKTA 50 G3 1250 KVA Operation and Maintenance ProcedureWaruna Pasan100% (1)

- Mitsubishi Diesel Engine - S16R-Y2PTAW2Dokumen2 halamanMitsubishi Diesel Engine - S16R-Y2PTAW2Christian Rivera FloverBelum ada peringkat

- B2-Lehe4748-01 - Emcp3.3Dokumen8 halamanB2-Lehe4748-01 - Emcp3.3Ali H. Al-ZowayedBelum ada peringkat

- Systems Operation Testing and Adjusting: 4008-30 Industrial EngineDokumen42 halamanSystems Operation Testing and Adjusting: 4008-30 Industrial EngineAbood Sameer AlbaghdadiBelum ada peringkat

- QST30 G5Dokumen2 halamanQST30 G5Hoang Minh Hung75% (4)

- 4008tag2a DGBH6061Dokumen157 halaman4008tag2a DGBH6061MARCOBelum ada peringkat

- AGC200 DesignersReferenceHandbookDokumen239 halamanAGC200 DesignersReferenceHandbookMarcWorld0% (1)

- fr4212 KTA19-G4Dokumen4 halamanfr4212 KTA19-G4acere18Belum ada peringkat

- 3516B, 1600 kW-2000 kVA PDFDokumen6 halaman3516B, 1600 kW-2000 kVA PDFbambangBelum ada peringkat

- Parts Catalogue 6CTAA-8.3-G4Dokumen125 halamanParts Catalogue 6CTAA-8.3-G4Joko Irawanto100% (2)

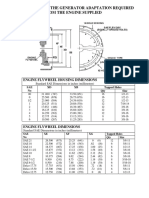

- Determining The Generator Adaptation Required From The Engine SuppliedDokumen2 halamanDetermining The Generator Adaptation Required From The Engine SuppliedolumideBelum ada peringkat

- PowerKit 6M26 Series Diesel Engine SpecsDokumen2 halamanPowerKit 6M26 Series Diesel Engine SpecsDuc Thao VuBelum ada peringkat

- DG 00 006-E 06-09 Pandaros IDokumen54 halamanDG 00 006-E 06-09 Pandaros Ibatavia elektroBelum ada peringkat

- Series 8000 Diesel Engines For Marine ApplicationsDokumen3 halamanSeries 8000 Diesel Engines For Marine ApplicationsMaurizioBelum ada peringkat

- Four Stroke Diesel Engine PresentationDokumen29 halamanFour Stroke Diesel Engine Presentationfaizan997Belum ada peringkat

- QSK60 Electrical SystemDokumen7 halamanQSK60 Electrical SystemagvassBelum ada peringkat

- Cummins Product SupportDokumen86 halamanCummins Product SupportVineet Garmella100% (2)

- 2206a-E13tag3 Electropak Pn1881Dokumen2 halaman2206a-E13tag3 Electropak Pn1881ibrahemBelum ada peringkat

- Technical Data: @perkinsDokumen6 halamanTechnical Data: @perkinsHendra SyalalaBelum ada peringkat

- IPD Gasket CatalogDokumen48 halamanIPD Gasket CatalogКонстантинBelum ada peringkat

- Cummins, Deutz, GM, Doosan engine part numbersDokumen8 halamanCummins, Deutz, GM, Doosan engine part numbersMetis100% (1)

- DV SeriesDokumen101 halamanDV SeriesManish KumarBelum ada peringkat

- KG 545 EmsDokumen32 halamanKG 545 EmsRoyston fernandes0% (2)

- SP275 50HZ Perkins Generator STAMFORDDokumen4 halamanSP275 50HZ Perkins Generator STAMFORDsunshinemachineryBelum ada peringkat

- Perkins 2800 Series: Diagnostic ManualDokumen156 halamanPerkins 2800 Series: Diagnostic ManualSajjad Hussain100% (1)

- Kta50 Gs8 (Advantage)Dokumen4 halamanKta50 Gs8 (Advantage)Ursula Johnson100% (1)

- Cristian Makes and ModelsDokumen54 halamanCristian Makes and ModelsIgnacio Real BuffelliBelum ada peringkat

- Kirloskar Engine EA10 & EA20Dokumen34 halamanKirloskar Engine EA10 & EA20Niten Gupta100% (1)

- EdisDokumen227 halamanEdisThong Chan100% (1)

- QSK60 G6 PDFDokumen2 halamanQSK60 G6 PDFShahzad Ali100% (2)

- Ecp ManualDokumen22 halamanEcp Manualகோவி கோபால் ஆர்ட்ஸ்100% (1)

- Ready Reckoner For Kits - DBUDokumen60 halamanReady Reckoner For Kits - DBUkhan khadarBelum ada peringkat

- Your Engine Overhaul. Your Custom SolutionDokumen5 halamanYour Engine Overhaul. Your Custom SolutionYasir JamilBelum ada peringkat

- Schematic125 170Dokumen4 halamanSchematic125 170agus haryono100% (1)

- 2000 Series Installation Manual TPD1615E1 PDFDokumen136 halaman2000 Series Installation Manual TPD1615E1 PDFMostifa Mastafa100% (1)

- HP5 - Caterpillar Generator Submittal As-BuiltDokumen80 halamanHP5 - Caterpillar Generator Submittal As-BuiltŁukasz AdamczakBelum ada peringkat

- QSB7-G5: EU Stage IIIA / EPA Tier 3Dokumen3 halamanQSB7-G5: EU Stage IIIA / EPA Tier 3V.ganese MoorthyBelum ada peringkat

- Catalog gaps page numbersDokumen58 halamanCatalog gaps page numbersArgee PadauanBelum ada peringkat

- Cummins CPLDokumen66 halamanCummins CPLYann LejardBelum ada peringkat

- Engines CPH v1.1 03.13.14 PDFDokumen41 halamanEngines CPH v1.1 03.13.14 PDFJulie Ann VeyraBelum ada peringkat

- Sara Gasket BrochureDokumen4 halamanSara Gasket BrochureSetyohdWBelum ada peringkat

- Denah Ruang Pat 2021Dokumen1 halamanDenah Ruang Pat 2021Mustain MustainBelum ada peringkat

- Schematic Volume 1 Document Electrical SchematicDokumen75 halamanSchematic Volume 1 Document Electrical SchematicCarlos Pabon SalomBelum ada peringkat

- Tr-144-En-Msi Lop May KeoDokumen2 halamanTr-144-En-Msi Lop May KeoKa KaBelum ada peringkat

- Catalogo PrasaCamisa-motor (Lerc)-slidepdf.com: Motor CamisasDokumen58 halamanCatalogo PrasaCamisa-motor (Lerc)-slidepdf.com: Motor CamisasJose Antonio Jareda ArreolaBelum ada peringkat

- Goulds Model 3196 Power End Upgrades: A Revolution in Pump Performance and ReliabilityDokumen2 halamanGoulds Model 3196 Power End Upgrades: A Revolution in Pump Performance and ReliabilityFrank RodriguezBelum ada peringkat

- British Seagull Outboard-Start and StopDokumen1 halamanBritish Seagull Outboard-Start and StopMitchBelum ada peringkat

- PD SBL DSL 3rd 5 09Dokumen8 halamanPD SBL DSL 3rd 5 09Luis Fernando BravoBelum ada peringkat

- Hydra Rig HR 6100 Coiled Tubing Injector Data Sheet PDFDokumen2 halamanHydra Rig HR 6100 Coiled Tubing Injector Data Sheet PDFoswaldo58100% (1)

- File 6 ADokumen103 halamanFile 6 AHamiltonBelum ada peringkat

- RockShox 2011Dokumen26 halamanRockShox 2011mountainbikerusBelum ada peringkat

- Drive Shaft O&M April 2010Dokumen4 halamanDrive Shaft O&M April 2010elperrote3Belum ada peringkat

- 10V1600G70S - Motor TLY450Dokumen23 halaman10V1600G70S - Motor TLY450July E. Maldonado M.Belum ada peringkat

- 510 0366t Series - Owners - Manual 20190130webDokumen24 halaman510 0366t Series - Owners - Manual 20190130webfrancois lecomteBelum ada peringkat

- Form "F" Office of The Motor Registration Authority / Excise & Taxation Depatment Islamabad Capital TerritoryDokumen2 halamanForm "F" Office of The Motor Registration Authority / Excise & Taxation Depatment Islamabad Capital Territoryshozeb qureshi100% (1)

- 12H - 8MN (3306B)Dokumen1.392 halaman12H - 8MN (3306B)RODRIGOBelum ada peringkat

- Differences Between Highway and Airport Pavement DesignDokumen2 halamanDifferences Between Highway and Airport Pavement DesignAditya Ahirwar80% (5)

- ModeSix Jul - 08 - 2023 - 05 23 44 PMDokumen11 halamanModeSix Jul - 08 - 2023 - 05 23 44 PMKarina CardenasBelum ada peringkat

- 2019 Crf230F Specifications : EngineDokumen1 halaman2019 Crf230F Specifications : EngineEdwin WIlfredo Ttito AngelesBelum ada peringkat

- Cat Transmission 950F PDF - PDFDokumen43 halamanCat Transmission 950F PDF - PDFMehdi ChakrouneBelum ada peringkat

- CTImag 9 Punch PowertrainDokumen6 halamanCTImag 9 Punch Powertrainmhmd100% (1)

- Case Study 4 Toyota 65454Dokumen2 halamanCase Study 4 Toyota 65454Jude Mirth PukkaBelum ada peringkat

- Beside Jingyi Road Industry Area Generator ManualDokumen54 halamanBeside Jingyi Road Industry Area Generator ManualREINALDO GONZALEZBelum ada peringkat

- Bomag Bw141 151 154 Acad 4 Service TrainingDokumen20 halamanBomag Bw141 151 154 Acad 4 Service Trainingyvonne100% (40)

- Ancra Butoirs BumpersDokumen1 halamanAncra Butoirs BumpersSébastien DionBelum ada peringkat

- of GasekitDokumen18 halamanof GasekitsaurabhBelum ada peringkat

- Catalog PDFDokumen82 halamanCatalog PDFВалерий ГерасимовBelum ada peringkat

- Renault Kangoo Family and Mercedes Benz Citan Installation Manual Version 2 1 08 May 2015Dokumen136 halamanRenault Kangoo Family and Mercedes Benz Citan Installation Manual Version 2 1 08 May 2015BbgGabrielBelum ada peringkat

- Delphi Wide Range Oxygen Sensor: BenefitsDokumen2 halamanDelphi Wide Range Oxygen Sensor: BenefitsWang Zheng FengBelum ada peringkat

- Jeep Grand Cherokee 2" Suspension Lift Kit Installation Instructions 1999-2003 Kit# Jwj22Dokumen8 halamanJeep Grand Cherokee 2" Suspension Lift Kit Installation Instructions 1999-2003 Kit# Jwj22RASBelum ada peringkat

- Owner's Manual & Safety Instructions: InverterDokumen28 halamanOwner's Manual & Safety Instructions: InverterbowcoastieBelum ada peringkat

- Optimization of damper settings for URE05eDokumen42 halamanOptimization of damper settings for URE05eAnderson MoribeBelum ada peringkat

- Steel Fuel Supply Tube Installation InstructionsDokumen8 halamanSteel Fuel Supply Tube Installation InstructionsSean DuncanBelum ada peringkat

- VE Pressure Regulator RepairDokumen3 halamanVE Pressure Regulator RepairKiss Martin100% (1)

- ZOOMLION ZWL33G Wheel LoaderDokumen4 halamanZOOMLION ZWL33G Wheel Loadermohammed soaibul haque chowdhuryBelum ada peringkat