RS 007 July 2014 (Welder Test Run Sheet M. Wardi)

Diunggah oleh

Muhammad Fitransyah Syamsuar PutraHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

RS 007 July 2014 (Welder Test Run Sheet M. Wardi)

Diunggah oleh

Muhammad Fitransyah Syamsuar PutraHak Cipta:

Format Tersedia

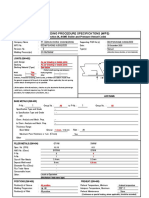

PT.

ZUG INDUSTRY INDONESIA

RUN SHEET

Run Sheet No. : : 008/VII/RS/2014 WPS No. : 018/WPS/GMAW R.0 Welding Process : GMAW Position : 3G Weld Date : 15 July 2014 Others Information

SOP No. : - Base Metal : SA 516 Gr. 70 Coupon No. : 002 Page : 1 of 1

Consumable Used Heating Electrical Parameter Unit : mm

No Process Welder ID Layer No Weld Time Total Filler Flux Gas (Average) Heat Input Wire feet speed Travel speed

Diameter Spec/SFA Class Brand Spec Class Brand Type % Mix Preheat (°C) Interpass (°C) Voltage Amphere AC DC Transfer Mode (mm/min) (mm/min)

1 GWAW Indra root 7 min 1.2 5.18 ER 70S-6 HTW 50 N.A N.A N.A Argon 99 32 - 20 75 - EP Short Circuiting 2250 40 -

fill 5 min 1.2 5.18 ER 70S-6 HTW 50 N.A N.A N.A Argon 99 32 102 20 109 - EP Short Circuiting 2616 50 -

fill 7 min 1.2 5.18 ER 70S-6 HTW 50 N.A N.A N.A Argon 99 32 103 20 102 - EP Short Circuiting 2040 60 -

cap 9 min 1.2 5.18 ER 70S-6 HTW 50 N.A N.A N.A Argon 99 32 110 20 115 - EP Short Circuiting 2760 50 -

Note :

- Calculating Heat Input using formula in QW-409.1 (a)

- Flow rate : 10 - 15 Ltr/min

- Pressure : 20 - 25 Bar

1. Visual Examination 2. Non Destractive Examination

Defect Type Welding Area Examined by Approved by Type of Test : Radiography Test Tested by Approved by

Location Size (mm) Test Result : ACC

- - - Ade Ruhiyat Welding Engineer Abdul Djalal Welding Engineer

SEE ATTACHMENT

Report No. : 20 WQT/VII/ZII/QC-RT/14

Visual Examination ACC

3. Destructive Examination

TENSILE TEST CHARPHY TEST BEND TEST

Speciment No Size Area Load Tensile Stress Speciment Defect Remarks

Speciment No Location No Energy

Width (mm) Thicness (mm) (mm2) (kgf) (kgf/mm) (Mpa) (PSI) No Type Size

- - - - - - - - - - - - - - - - - - -

SEE ATTACHMENT - - - - - - SEE ATTACHMENT

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

4. Judgement

PASS RE-TEST FAIL

Supervised by Accepted by Approved by

(QC Inspector) (QC. Engineer) (Welding Engineer)

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Tanda TerimaDokumen2 halamanTanda TerimaMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Program K3 2023Dokumen2 halamanProgram K3 2023Muhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Employee Hours Worked Last Three YearsDokumen1 halamanEmployee Hours Worked Last Three YearsMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Transmittal FormDokumen90 halamanTransmittal FormMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT BridonDokumen1 halamanPT BridonMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Manufacturing Data Record IndexDokumen2 halamanManufacturing Data Record IndexMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Laporan PiketDokumen12 halamanLaporan PiketMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Design Intermittent WeldingDokumen5 halamanDesign Intermittent WeldingMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT DjabesmenDokumen1 halamanPT DjabesmenMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Method Statement For Prediction Weld Shrinkage On StructuralDokumen4 halamanMethod Statement For Prediction Weld Shrinkage On StructuralMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PQR PT Bse WPS 07Dokumen2 halamanPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT DjabesmenDokumen1 halamanPT DjabesmenMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Lifting Lug Calculation G1-5Dokumen3 halamanLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Dokumen3 halamanLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- 7 Inspection and Repair: 3 Api S 2BDokumen1 halaman7 Inspection and Repair: 3 Api S 2BMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Annex C Residual Stress Profiles: Fitnet Mk7Dokumen62 halamanAnnex C Residual Stress Profiles: Fitnet Mk7Muhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Wps - Asme Ix - Gtaw - PipaDokumen5 halamanWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Wps - Asme Ix - Gtaw - Plat SteDokumen6 halamanWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- AMH Magz Vol 9Dokumen40 halamanAMH Magz Vol 9Muhammad Fitransyah Syamsuar Putra0% (1)

- WPQTDokumen18 halamanWPQTMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Astm A 484 - A 484Dokumen13 halamanAstm A 484 - A 484Alvaro HernandezBelum ada peringkat

- Case Study: CrankshaftsDokumen12 halamanCase Study: CrankshaftsDHRUV SINGHALBelum ada peringkat

- (B0638) Zhuyao Zhang, R. A. Farrar - Atlas of Continuous Cooling Transformation (CCT) Diagrams Applicable To Low Carbon Low Alloy Weld Metals (Matsci-Maney Materials Science (1995)Dokumen101 halaman(B0638) Zhuyao Zhang, R. A. Farrar - Atlas of Continuous Cooling Transformation (CCT) Diagrams Applicable To Low Carbon Low Alloy Weld Metals (Matsci-Maney Materials Science (1995)Julio Hernandez MartinezBelum ada peringkat

- Fang Met Trans PaperDokumen12 halamanFang Met Trans PaperSubham NayakBelum ada peringkat

- Dv08pub5 e Cl-1 ScriptDokumen15 halamanDv08pub5 e Cl-1 Scriptwulfgang66Belum ada peringkat

- Module 2Dokumen10 halamanModule 2Mahadev MetriBelum ada peringkat

- A Review of Postweld Heat Treatment Code ExemptionDokumen46 halamanA Review of Postweld Heat Treatment Code ExemptionReza GhavamiBelum ada peringkat

- ASTM A270-98ae1Dokumen5 halamanASTM A270-98ae1NadhiraBelum ada peringkat

- Sample - Global Niobium Market (2016-2026) - Mordor Intelligence1621280011177Dokumen38 halamanSample - Global Niobium Market (2016-2026) - Mordor Intelligence1621280011177Mahmoud BakryBelum ada peringkat

- Is 6911 1992Dokumen18 halamanIs 6911 1992RINJUBelum ada peringkat

- Turner Question and Answer Bank 2014Dokumen88 halamanTurner Question and Answer Bank 2014bijukumarg93% (30)

- Is.814.2004 16Dokumen1 halamanIs.814.2004 16Anonymous vwbLPTpjBelum ada peringkat

- Sfa-5 01 PDFDokumen10 halamanSfa-5 01 PDFMahesh DeshmukhBelum ada peringkat

- Common Abbreviations in The Valve IndustryDokumen10 halamanCommon Abbreviations in The Valve IndustryNath BoyapatiBelum ada peringkat

- GP-03!12!01 Valve SelectionDokumen30 halamanGP-03!12!01 Valve SelectionabenitechBelum ada peringkat

- Corrosion Science: Eriko Yamaki, Kevin Ginestar, Laure MartinelliDokumen11 halamanCorrosion Science: Eriko Yamaki, Kevin Ginestar, Laure MartinellisureshjeevaBelum ada peringkat

- 02070-GEN-PNG-SPE-004 - 04 Soportes PDFDokumen234 halaman02070-GEN-PNG-SPE-004 - 04 Soportes PDFJose C. MelendezBelum ada peringkat

- Iron Through The Ages: Alan W. PenseDokumen11 halamanIron Through The Ages: Alan W. PenseMohamed IsmailBelum ada peringkat

- Carbon Equivalent EquationDokumen6 halamanCarbon Equivalent Equationrasnowmah2012Belum ada peringkat

- Lecture 7Dokumen27 halamanLecture 7Hijau Auliya Keramat Al-qadiryBelum ada peringkat

- Lesson Plan SMAW 12Dokumen8 halamanLesson Plan SMAW 12Jymaer GeromoBelum ada peringkat

- Machined Springs Vs Wire Springs PDFDokumen22 halamanMachined Springs Vs Wire Springs PDFsaranBelum ada peringkat

- F568M - Tiêu Chuẩn Để Tính Diện Tích Kháng Cắt Của Bu LôngDokumen8 halamanF568M - Tiêu Chuẩn Để Tính Diện Tích Kháng Cắt Của Bu Lôngdongngo0% (1)

- Drill TAP Series (EM)Dokumen44 halamanDrill TAP Series (EM)Beto MenaldoBelum ada peringkat

- Jceceb D2D 2021 Previous Year Question PaperDokumen51 halamanJceceb D2D 2021 Previous Year Question PaperDhasu Mna NeyazBelum ada peringkat

- Kellogg International CorporationDokumen1 halamanKellogg International Corporationqc_531040655Belum ada peringkat

- Appendix GeankoplisDokumen11 halamanAppendix Geankoplisv dBelum ada peringkat

- Asme Section IX - NewDokumen70 halamanAsme Section IX - NewAnaswarps100% (2)

- Datasheet Sanicro 72hpDokumen2 halamanDatasheet Sanicro 72hpphillipskincaidBelum ada peringkat

- Brittle Fracture TWIDokumen13 halamanBrittle Fracture TWIHouman Hatamian100% (1)