BIOREACTOR

Diunggah oleh

upenderJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

BIOREACTOR

Diunggah oleh

upenderHak Cipta:

Format Tersedia

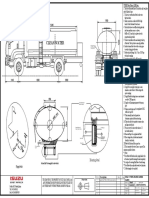

Item Name High Pressure high temperature reactor for Biodiesel production

a) Size & M.O.C 5 Ltr. net filling capacity made from SS 316 solid bar stock (no welding) & all wetted parts

of SS-316.

b) Design Pressure Up to 350 bar. Digital Pressure Indicator

c) Max Working 400 to 500 deg. C. Digital temperature indicator in flame proof enclosure.

Temperature

d) Heating External electrical ceramic band heater with insulation and high temperature steel cladding

& provision to connect heater temperature sensor. It shall have insulated heater plate to

prevent thermal shock to operator and SS Control Panel with Microprocessor based

Programmable P.I.D temperature controller (Make: PPI, Model: Neuro 102a/102ac,

Programs: 16 ramp/soak with OSIH over shoot inhibit parameter to control overshoot

with standby mode to cut off heating & cooling) with high temperature alarm system

mounted on it with temperature sensor. The panel shall be Screwless design with push

lock enclosure, PVC Cable tray for internal wiring, safe & rugged metal clad military grade

lockable plug sockets for all the sensors, heaters & motors (for tight connection & safety).

e) Nozzles & Fittings i) External Fittings : Pressure gauge, vent valve, Safety rupture disc (Inconel)(Certified by

original manufacturer), gas inlet- valve & liquid sampling valve mounted on common dip

tube,

ii) Internal Fittings : Ball valve for liquid inlet, cooling coil, thermowell, dip tube.

f) Body & Head Sealing PTFE Gasket with split clamp type quick opening system with clamp bolts. Body clamps

shall be with clit / latches to prevent flying off of clamps in case of over pressure.

g) Head Mounting Style Removable head & vessel design.

h) SS Pr. Regulator with self-venting for releasing the pressure, pressure gauge & 4m long flexible hose pipe with

NRV O/P pressure for H2 gas & adaptor for N2, O2 or air cylinder.

i) Flush Bottom Valve of MOC. SS-316.

j) Auto-cooling System with Flame Proof Group II C Motor (for Hydrogenation) with water pump, SS tank

& hose pipes for exothermic reaction & faster cooling.

k) Water Pump and 5Ltr. Tank with tubing for circulating water to cool the pressure sensor etc.

l) SS Trolley with all 4 lockable wheels for easy & smooth movements

m) Pressure relief valve of MOC SS- 316 ( Max. working temp. 400 Deg.C)

n) Digital pressure indicator in bar & psi with SS-316 Pr. transmitter (Non-FLP) & high pressure alarm in addition to

analog pressure gauge with high pressure safety heater cut off.

o) SCADA Software with RS232 connector for online display trends, data logging & remote set points of

temperature, pressure alarm & rpm w.r.t. time on PC. (Digital Pressure Indicator also to be ordered). Note: Cable

length shall be 10m from PC to panel unless specified.

p) High Pressure Liquid / Catalyst Slurry / Gas charging system for injecting liquids / Gas / Catalyst during the

reaction under pressure. ( It should consists of a high pressure SS-316 pot, inlet & outlet valves, pressure gauge,

high pr. Hose pipe, NRV (Viton ‘o’ Ring) & Pressure relief Valve) (Upto 350 Bar).

Anda mungkin juga menyukai

- MF7203-Dec 16 THEORY-OF-METAL-FORMINGDokumen3 halamanMF7203-Dec 16 THEORY-OF-METAL-FORMINGupender100% (1)

- Crystal ModelsDokumen6 halamanCrystal ModelsupenderBelum ada peringkat

- Pages From CH 3Dokumen6 halamanPages From CH 3upenderBelum ada peringkat

- Pages From CH 3Dokumen6 halamanPages From CH 3upenderBelum ada peringkat

- (WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Forming Sample Paper 3 PDFDokumen2 halaman(WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Forming Sample Paper 3 PDFupenderBelum ada peringkat

- Gupta 2007Dokumen18 halamanGupta 2007upenderBelum ada peringkat

- Siemens Articles On SN Crve Fatigue and Stress StrainDokumen37 halamanSiemens Articles On SN Crve Fatigue and Stress StrainupenderBelum ada peringkat

- Papet ID (IE507) : Roll No. ......................... (Total No. of Pages: 02Dokumen2 halamanPapet ID (IE507) : Roll No. ......................... (Total No. of Pages: 02upenderBelum ada peringkat

- Anna UniversityDokumen3 halamanAnna UniversityupenderBelum ada peringkat

- Siemens Articles On SN Crve Fatigue and Stress StrainDokumen37 halamanSiemens Articles On SN Crve Fatigue and Stress StrainupenderBelum ada peringkat

- Papet ID (IE507) : Roll No. ......................... (Total No. of Pages: 02Dokumen2 halamanPapet ID (IE507) : Roll No. ......................... (Total No. of Pages: 02upenderBelum ada peringkat

- Intellectual Property Rights: CSCI 327 Social Implications of ComputingDokumen22 halamanIntellectual Property Rights: CSCI 327 Social Implications of ComputingupenderBelum ada peringkat

- 6 PDFDokumen3 halaman6 PDFupenderBelum ada peringkat

- Creep Strength: Definitions: Creep Is The Tendency of A Solid Material To Move Slowly or Deform Permanently UnderDokumen13 halamanCreep Strength: Definitions: Creep Is The Tendency of A Solid Material To Move Slowly or Deform Permanently UnderupenderBelum ada peringkat

- Different Types of PlagiarismDokumen4 halamanDifferent Types of Plagiarismupender100% (1)

- Research MethodologyDokumen41 halamanResearch MethodologyRomit Machado83% (6)

- 28annexure XVI LL.M. (IPR) FoLDokumen16 halaman28annexure XVI LL.M. (IPR) FoLupenderBelum ada peringkat

- Research Lecture 1Dokumen15 halamanResearch Lecture 1upenderBelum ada peringkat

- Research Lecture 2Dokumen17 halamanResearch Lecture 2upenderBelum ada peringkat

- 2 The Four Main ApproachesDokumen4 halaman2 The Four Main ApproachesSukhdeep Kaur MaanBelum ada peringkat

- RM SyllabusDokumen1 halamanRM SyllabusupenderBelum ada peringkat

- RM SyllabusDokumen1 halamanRM SyllabusupenderBelum ada peringkat

- Formulating Research Problem 103506 - Chapter - 6 - Kumar5eDokumen23 halamanFormulating Research Problem 103506 - Chapter - 6 - Kumar5eupenderBelum ada peringkat

- Research Approach: Deductive Research Approach Inductive Research Approach Abductive Research ApproachDokumen10 halamanResearch Approach: Deductive Research Approach Inductive Research Approach Abductive Research ApproachupenderBelum ada peringkat

- Examination Schedule For B.Tech 1 & 5 Semester and M.Tech 1 Semester (Regular & Backlog) December, 2018Dokumen3 halamanExamination Schedule For B.Tech 1 & 5 Semester and M.Tech 1 Semester (Regular & Backlog) December, 2018upenderBelum ada peringkat

- I. Types and ContentDokumen4 halamanI. Types and ContentupenderBelum ada peringkat

- The Research Problem and ObjectivesDokumen23 halamanThe Research Problem and ObjectivesDeepika NetamBelum ada peringkat

- 2 The Four Main ApproachesDokumen4 halaman2 The Four Main ApproachesSukhdeep Kaur MaanBelum ada peringkat

- RM SyllabusDokumen1 halamanRM SyllabusupenderBelum ada peringkat

- 28annexure XVI LL.M. (IPR) FoLDokumen16 halaman28annexure XVI LL.M. (IPR) FoLupenderBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Autostroke (AST-200-V2) : For Use With The Autobox Product LineDokumen28 halamanAutostroke (AST-200-V2) : For Use With The Autobox Product LineLuiz PauloBelum ada peringkat

- BL Micro NXP Microcontroller Overview3Dokumen2 halamanBL Micro NXP Microcontroller Overview3Balaji PotnuriBelum ada peringkat

- Topic: Identify The Front and Rear Panel Controls and Ports On A PC, Cases, Cooling, Cables and ConnectorsDokumen29 halamanTopic: Identify The Front and Rear Panel Controls and Ports On A PC, Cases, Cooling, Cables and ConnectorsKkr0% (1)

- Experiment 3 Power FactorDokumen8 halamanExperiment 3 Power FactorKyleBelum ada peringkat

- CSP-P Seismic Energy Source: Applied Acoustic Engineering LTDDokumen2 halamanCSP-P Seismic Energy Source: Applied Acoustic Engineering LTDDadang KurniaBelum ada peringkat

- SKT Series Set-Up Parameter (V08 - 20100826)Dokumen32 halamanSKT Series Set-Up Parameter (V08 - 20100826)medmedBelum ada peringkat

- 25 Serial Peripheral Interface (SPI)Dokumen53 halaman25 Serial Peripheral Interface (SPI)cansuBelum ada peringkat

- Emd645 Mi1740Dokumen16 halamanEmd645 Mi1740Alejandro Rivera Villa100% (2)

- HP 4520s Calpella Sclassintel10282pvrtllanDokumen62 halamanHP 4520s Calpella Sclassintel10282pvrtllanEl Mostafa MorauBelum ada peringkat

- Excitation System of Generator: Presented By: Niaz Akhtar Gte-ElectDokumen40 halamanExcitation System of Generator: Presented By: Niaz Akhtar Gte-Electrk250Belum ada peringkat

- Power at AC given by P = VI cosθDokumen4 halamanPower at AC given by P = VI cosθJohn Paul BaquiranBelum ada peringkat

- GTC 920901rev4 2003Dokumen2 halamanGTC 920901rev4 2003asim.karak001Belum ada peringkat

- Power SupplyDokumen15 halamanPower SupplyVelu SBelum ada peringkat

- Lect - 2 - 3 - Recent AdvancementDokumen76 halamanLect - 2 - 3 - Recent AdvancementAreeba talpurBelum ada peringkat

- VIPROS-255 Ver. 2 Parts List PDFDokumen468 halamanVIPROS-255 Ver. 2 Parts List PDFjcsantosr100% (1)

- Hydraulic Screen Changer (HSC) : FeaturesDokumen2 halamanHydraulic Screen Changer (HSC) : FeaturesdecBelum ada peringkat

- Manuals 7 3L Power Stroke ManualDokumen78 halamanManuals 7 3L Power Stroke ManualuriealBelum ada peringkat

- PV Mounting System GroundDokumen23 halamanPV Mounting System GroundFerdi BayuBelum ada peringkat

- 130 590031 315 - 32Dokumen176 halaman130 590031 315 - 32Jacob Jack Yosha100% (1)

- Copia de Precios Servidor HPDokumen2 halamanCopia de Precios Servidor HPKARINA FLORESBelum ada peringkat

- Riveted JointsDokumen7 halamanRiveted Jointsjimmy mlelwaBelum ada peringkat

- Voltronic Axpert MKSDokumen1 halamanVoltronic Axpert MKSMiguel CondoriBelum ada peringkat

- Clear-Com CC-300-400 Headset Datasheet PDFDokumen2 halamanClear-Com CC-300-400 Headset Datasheet PDFcarrlosalbertodossantossilvaBelum ada peringkat

- FVR90L WATER TANKER MAAIF-ModelDokumen1 halamanFVR90L WATER TANKER MAAIF-ModelAvi AtoBelum ada peringkat

- Error CodesDokumen24 halamanError CodesGustavo Rodriguez89% (47)

- Data Sheet For Oxygen Analyser (Hi Temp) : Project: North Karanpura 3 X 660Mw STPPDokumen19 halamanData Sheet For Oxygen Analyser (Hi Temp) : Project: North Karanpura 3 X 660Mw STPPvishnu ABelum ada peringkat

- Operationz ManualDokumen29 halamanOperationz Manualadnanshaikh09Belum ada peringkat

- Ict13a Nis21 JBMDokumen52 halamanIct13a Nis21 JBMjonathan100% (1)

- Eei Master Storage InverterDokumen4 halamanEei Master Storage Inverterpaohung linBelum ada peringkat

- CHP SopDokumen26 halamanCHP Sopkalyanm20351550% (2)