Principles of Concrete Mix Design ACC

Diunggah oleh

Sunil ReddyDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Principles of Concrete Mix Design ACC

Diunggah oleh

Sunil ReddyHak Cipta:

Format Tersedia

PERFORMA FOR SUBMITTING THE MIX DESIGN REPORT TO RDSO

A) GENERAL DETAILS

1 RAILWAY

2 NAME OF PLANT

3 LOCATION

4 YEAR OF COMMISSIONING

5 EXISTING APPROVAL OF MIX DESIGN

(GIVE REFERENCE & DETAIL OF EARLIER APPROVED MIX

DESIGN)

6 MODIFICATION /NEW MIX DESIGN

7 GRADE OF CONCRETE

8 PURPOSE (MBC/TURNOUT/SPECIAL)

9 SPECIFICATION (IRS T-39/IRS T-45)

B) MATERIAL

1. CEMENT

1 GRADE OF CEMENT

2 MAKE OF CEMENT

3 SPECIFICATION

4 TEST REPORT ATTACHED AT ANNEXURE……….

1 a. ABSTRACT OF TEST RESULTS OF CEMENT

S.N. DESCRIPTION VALUE AS PER

TEST REPORT

1 Ratio of percentage of lime to percentage of silica, alumina and

iron oxide as per IRS T-40-1985

2 Ratio of percentage of alumina to that of iron oxide.

3 Insoluble residue

4 Magnesia(MgO) percentage by mass

5 Total sulphur content calculated as sulphuric anhydride(SO3)

percentage by mass

6 Total Loss on ignition

7 C3A content

8 C3S content

9 Fineness

10 Soundness

11 Initial Setting Time

12 Final Setting Time

13 Compressive Strength

Signature of Zonal Railway Official Signature of Firm’s Official

2. COARSE AGGREGATE

1 SOURCE OF AGGREGATE

2 TEST REPORT OF 20 MM AGGREGATE ANNEXURE………

ATTACHED AS

3 TEST REPORT OF 10 MM AGGREGATE ANNEXURE………

ATTACHED AT

A. SIEVE ANALYSIS OF 20 MM

Sieve 20 mm. aggregate (Sample taken as …….gm)

Size Wt. Ret % Wet. Ret. Cum. % of Wet. % of passing Limit as per

Ret. IS: 383(%)

20 mm 85-100

10 mm 0-20

4.75 mm 0-5

pan

B. SIEVE ANALYSIS OF 10 MM

Sieve 10 mm. aggregate (Sample taken as ….. gm)

Size Wt. Ret % Wet. Ret. Cum. % of Wet. % of passing Limit as per

Ret. IS: 383(%)

10 mm. 85-100

4.75 0-20

mm.

2.36 0-5

mm.

Pan

Signature of Zonal Railway Official Signature of Firm’s Official

3. FINE AGGREGATE

1 SOURCE OF AGGREGATE

2 WHETHER NATURAL OR PROCESSED

3 GRADING ZONE

3 TEST REPORT OF FINE AGGREGATE ANNEXURE………

ATTACHED AT

SIEVE ANALYSIS OF FINE SAND

Sieve Sand

Size (Sample taken as …….. gm) Limit as per

IS: 383(%)

Wt. Ret % Wet. Ret. Cum. % of Wet. % of passing Zone-….

Ret.

4.75 mm

2.36 mm

1.18 mm

600 µ

300 µ

150 µ

Pan

4. ABSTRACT OF TEST RESULTS

S.N. DESCRIPTION 20 MM 10 MM SAND

1 Specific Gravity

2 Flakiness Index %

3 Elongation Index

4 Abrasion Value %

5 Bulk density

6 Crushing Value %

7 Impact Value

8 Organic Impurities

9 Water absorption

Signature of Zonal Railway Official Signature of Firm’s Official

10 Silica Dissolved by 1N

NaOH

11 Soundness Test

12 Reduction in Alkalinity

5. WATER

1 SOURCE OF WATER

2 TEST REPORT ATTACHED AT ANNEXURE………

6. ADMIXTURE

1 ADMIXTURE MAKE

2 TEST REPORT ATTACHED AT ANNEXURE………

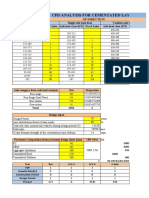

C. MIX DESIGN CALCULATION

Attach mix design calculation as per IS 10262-2009 including

calculation of all mix proportions

D. MIX PROPORTIONS PER CUM OF CONCRETE

S.N. PROPORTIONS QTY PER CUM OF

CONCRETE

1 CEMENT

2 COARSE AGGREGATE 20 mm

3 COARSE AGGREGATE 10mm

4 SAND

5 WATER

6 ADMIXTURE

7 W/C RATIO

8 AGGREGATE/CEMENT RATIO

E) COMBINED AGGREGATE GRADING

S.N. Sieve Size Lower Limits Upper Limits % Passing

1 2omm

2 10mm

3 4.75mm

4 2.36mm

5 1.18mm

Signature of Zonal Railway Official Signature of Firm’s Official

6 0.60mm

7 0.30mm

8 0.15mm

COMBINED GRANULOMETRIC CURVE IS ATTACHED AT ANNEXURE….

F) RESULT OF STEAM CURING CUBE

Steam curing cycle

S.N. ACTIVITY TIME DURATION

1 Presteaming

2 Rise in temperature

3 Constant Temperature

4 Cooling Time

TOTAL TIME

STEAM CYCLE CHART IS ATTACHED AT ANNEXURE…………..

It is certified that all provisions of IS-10262 2009 , IRS T-39/IRS T-45 and

IRS T-40 has been read carefully and has been incorporated in the mix

design.

Signature……………………………….

Name………………………………….

Designation in Firm………………………..

Seal……………………………………………………..

Signature of Zonal Railway Official Signature of Firm’s Official

Steam Cube Test Results

S.N. Batch Cube Date of Date of Age Weight Load Comp.

No. No. Casting Testing in of Strength

Hour Cube (MPa)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

STATISTICAL ANALYSIS IS ATTACHED AS ANNEXURE ……..

Signature of Zonal Railway Official Signature of Firm’s Official

G) RESULT OF WATER CURED CUBE

S.N. Batch Cube Date of Date of Age Weight Load Comp.

No. No. Casting Testing in of Strength

Days Cube (MPa)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

STATISTICAL ANALYSIS IS ATTACHED AS ANNEXURE ……..

Signature of Zonal Railway Official Signature of Firm’s Official

Signature of Zonal Railway Official Signature of Firm’s Official

Anda mungkin juga menyukai

- Nutrition Science by B Srilakshmi PDFDokumen6 halamanNutrition Science by B Srilakshmi PDFRohan Rewatkar46% (35)

- Structural Analysis With The Finite Element Method Linear Statics Volume 1, Basis and Solids - E.OñateDokumen495 halamanStructural Analysis With The Finite Element Method Linear Statics Volume 1, Basis and Solids - E.OñateSerruchin 84100% (26)

- Tutorials Pad Footing Nta 5 (2012&2013)Dokumen3 halamanTutorials Pad Footing Nta 5 (2012&2013)Host FredyBelum ada peringkat

- Timber Bridge 12m Span DesignDokumen12 halamanTimber Bridge 12m Span DesignEngineeri TadiyosBelum ada peringkat

- LESSON PLAN IN wRITING A REPORTDokumen2 halamanLESSON PLAN IN wRITING A REPORTMarkaton Dihagnos100% (4)

- Public Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inDokumen10 halamanPublic Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inSanthosh BabuBelum ada peringkat

- UPVC Pipe SizeDokumen2 halamanUPVC Pipe SizefebousBelum ada peringkat

- Plinth Area RatesDokumen10 halamanPlinth Area Ratessunilrathi86Belum ada peringkat

- Hot Finished Square Hollow Sections in Accordance With EN 10210Dokumen5 halamanHot Finished Square Hollow Sections in Accordance With EN 10210bggariyoBelum ada peringkat

- Design and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankDokumen5 halamanDesign and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankGRD JournalsBelum ada peringkat

- Precast ConcreteDokumen10 halamanPrecast ConcreteNIDHI SINGHBelum ada peringkat

- Hydraulic Calculation of Box Culvert: Bekri Primary Canal ##+### BBK1a 3-Barrel BoxDokumen1 halamanHydraulic Calculation of Box Culvert: Bekri Primary Canal ##+### BBK1a 3-Barrel BoxelfitaBelum ada peringkat

- D.I. Catalogue) 9th Edition) PDFDokumen70 halamanD.I. Catalogue) 9th Edition) PDFArunprasad MurugesanBelum ada peringkat

- IS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFDokumen22 halamanIS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFRajan VABelum ada peringkat

- Site: Date: Job No. Designer: Sheet No.: Calculation/ SketchDokumen5 halamanSite: Date: Job No. Designer: Sheet No.: Calculation/ SketchAlma M. LaraBelum ada peringkat

- Economical Steel Plate Girder BridgesDokumen5 halamanEconomical Steel Plate Girder BridgesMagdy BakryBelum ada peringkat

- Book - Advanced Steel Structures, Fire and Fatigue Design - by W LuDokumen118 halamanBook - Advanced Steel Structures, Fire and Fatigue Design - by W LuAbbes ChakchoukBelum ada peringkat

- Is 9523 (2000) - Ductile Iron Fittings For Pressure Pipes For Water, Gas and SewageDokumen38 halamanIs 9523 (2000) - Ductile Iron Fittings For Pressure Pipes For Water, Gas and SewageSainaveen Thota100% (2)

- S.Muthu Vel Murugan: Behaivour of Earth Quake Resisting Masonry Building As Per Is 4326:1993Dokumen55 halamanS.Muthu Vel Murugan: Behaivour of Earth Quake Resisting Masonry Building As Per Is 4326:1993Praveenkumar ShanmugamBelum ada peringkat

- Signature BridgeDokumen49 halamanSignature BridgesheetalBelum ada peringkat

- BE (Hons) - Civil EngineeringDokumen139 halamanBE (Hons) - Civil EngineeringalexBelum ada peringkat

- BS Iso 14654-1999Dokumen39 halamanBS Iso 14654-1999hz135874Belum ada peringkat

- BS8666 2000 (Spec For Cutting Reinforcement)Dokumen25 halamanBS8666 2000 (Spec For Cutting Reinforcement)Lam-ang MagitingBelum ada peringkat

- Design of Septic Tank - Types, Design CalculationDokumen6 halamanDesign of Septic Tank - Types, Design CalculationFarman Ali KhaskheliBelum ada peringkat

- Tekla SoakwayDokumen2 halamanTekla SoakwayBalaji Naik100% (1)

- RC08 Shear1Dokumen13 halamanRC08 Shear1Ce WinBelum ada peringkat

- Percolation - Tank DesignDokumen25 halamanPercolation - Tank DesignSanthosh Kumar Baswa100% (1)

- Plate Girders With Corrugated WebsDokumen6 halamanPlate Girders With Corrugated WebsLệnh BùiBelum ada peringkat

- Generator Set RoomsDokumen7 halamanGenerator Set RoomsAnonymous TvOpvXBelum ada peringkat

- Design OfSteel Structures-IDokumen50 halamanDesign OfSteel Structures-IBhagyshri SiddheBelum ada peringkat

- Analysis (Autosaved) FightingDokumen15 halamanAnalysis (Autosaved) FightingBUGTOK TVBelum ada peringkat

- Table 60001 Concrete DurabilityDokumen1 halamanTable 60001 Concrete DurabilityZaid JamilBelum ada peringkat

- 01 02 10 Reference StandardsDokumen49 halaman01 02 10 Reference StandardsKiran D AnvekarBelum ada peringkat

- EST MCQ 1 ST UNITDokumen23 halamanEST MCQ 1 ST UNITDhanesh Uday PujareBelum ada peringkat

- Traffic Loads On Bridges - En.1991.2.2003Dokumen167 halamanTraffic Loads On Bridges - En.1991.2.2003mika1nzjBelum ada peringkat

- ENGGBOQEstimation ReportDokumen266 halamanENGGBOQEstimation ReportUTTAL RAYBelum ada peringkat

- Presentation MSCDokumen10 halamanPresentation MSCMd. Mominul IslamBelum ada peringkat

- Wade ChannelDokumen24 halamanWade ChannelAbdul NabiBelum ada peringkat

- JICA MRTS Proposals May 2018 PDFDokumen305 halamanJICA MRTS Proposals May 2018 PDFDaniel KariukiBelum ada peringkat

- DPP Installation of 02 Nos Deep Tube Well P&DDokumen27 halamanDPP Installation of 02 Nos Deep Tube Well P&DMahfuzur RahmanBelum ada peringkat

- Irwm CS Upto 10Dokumen263 halamanIrwm CS Upto 10Ponnudurai DuraiBelum ada peringkat

- A23.3-04 Precast Corbel Design Spreadsheet Jan 2008Dokumen6 halamanA23.3-04 Precast Corbel Design Spreadsheet Jan 2008mukhleshBelum ada peringkat

- Cyclone-Brochure PubDokumen2 halamanCyclone-Brochure Pubsk lukoBelum ada peringkat

- Hume Pipe Culvert Within Sump No - 2Dokumen21 halamanHume Pipe Culvert Within Sump No - 2MD Maruf HussainBelum ada peringkat

- BS 206-1-2001-Concrete-Specification, Performance, Production and ConformityDokumen1 halamanBS 206-1-2001-Concrete-Specification, Performance, Production and Conformitymys85100% (1)

- Return Period & Others GuidelinesDokumen1 halamanReturn Period & Others GuidelinesHarish Kumar Mahavar100% (1)

- MoRTH - Standard Data BookDokumen342 halamanMoRTH - Standard Data BookNo OneBelum ada peringkat

- Major Axis Bending Minor Axis BendingDokumen26 halamanMajor Axis Bending Minor Axis Bendingarunkumar.mgsBelum ada peringkat

- Karjat Project Affordable HousingDokumen19 halamanKarjat Project Affordable Housingfaheem_roshanBelum ada peringkat

- Surface Dressing Pavement DesignDokumen5 halamanSurface Dressing Pavement DesignSang RawalBelum ada peringkat

- NCRTC DM0GC PBG ZZZZ TRK RP RT 00001 PDFDokumen7 halamanNCRTC DM0GC PBG ZZZZ TRK RP RT 00001 PDFAkshay WahalBelum ada peringkat

- Beam Design To Bs8110Dokumen3 halamanBeam Design To Bs8110Niyitegeka Simon100% (1)

- Hydrology Assignment 1Dokumen7 halamanHydrology Assignment 1sunsleyndhlakama100% (1)

- Equation For Estimation of Fundamental Time Period For Elevated Water TankDokumen10 halamanEquation For Estimation of Fundamental Time Period For Elevated Water TankIAEME PublicationBelum ada peringkat

- Durability Design of Concrete Structures - Part 1 Analysis FundamentalsDokumen18 halamanDurability Design of Concrete Structures - Part 1 Analysis FundamentalsCivilEngClubBelum ada peringkat

- Loc-1 - Up Traffic On DownDokumen14 halamanLoc-1 - Up Traffic On DownPriyanka YadavBelum ada peringkat

- Study The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadDokumen4 halamanStudy The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadEditor IJTSRDBelum ada peringkat

- Rigorous Continuous BeamsDokumen1 halamanRigorous Continuous Beamsmdelacua2Belum ada peringkat

- Concrete Technical SpecificationDokumen44 halamanConcrete Technical SpecificationNgoc BangBelum ada peringkat

- Report 3523 M40 08 12 2019Dokumen20 halamanReport 3523 M40 08 12 2019Imran KhanBelum ada peringkat

- DBM Gupta ConstructionDokumen24 halamanDBM Gupta Constructionimran khanBelum ada peringkat

- M35 Bhole ConstructionDokumen6 halamanM35 Bhole ConstructionBIPL REPORT100% (1)

- S.E.C M35 PIle Birla Gold Cement 1042 UDokumen5 halamanS.E.C M35 PIle Birla Gold Cement 1042 UBIPL REPORTBelum ada peringkat

- Comparison of ANSYS Elements SHELL181 and SOLSH190: September 2014Dokumen54 halamanComparison of ANSYS Elements SHELL181 and SOLSH190: September 2014Sunil ReddyBelum ada peringkat

- Technical Report TR 5 Conc Mix DesignDokumen18 halamanTechnical Report TR 5 Conc Mix DesignSunil ReddyBelum ada peringkat

- Worked Examples Ec2 Def080723Dokumen120 halamanWorked Examples Ec2 Def080723dan_ospir67% (3)

- Met Sec Purlin DetailsDokumen86 halamanMet Sec Purlin DetailsSunil ReddyBelum ada peringkat

- Lec 3 Fatigue Failure 031004 - For - StudentsDokumen32 halamanLec 3 Fatigue Failure 031004 - For - Studentsargentino_ar01Belum ada peringkat

- Module 24 - Static Failure TheoriesDokumen33 halamanModule 24 - Static Failure TheoriesSunil ReddyBelum ada peringkat

- Offshore Structures PDFDokumen20 halamanOffshore Structures PDFamadhubalanBelum ada peringkat

- Wave CalculationsDokumen9 halamanWave CalculationsSunil ReddyBelum ada peringkat

- Proximity Principle of DesignDokumen6 halamanProximity Principle of DesignSukhdeepBelum ada peringkat

- SerpılDokumen82 halamanSerpılNurhayat KaripBelum ada peringkat

- A Note On RhotrixDokumen10 halamanA Note On RhotrixJade Bong NatuilBelum ada peringkat

- Sample CVDokumen3 halamanSample CVsam_mad00Belum ada peringkat

- HG G2 Q1 W57 Module 3 RTPDokumen11 halamanHG G2 Q1 W57 Module 3 RTPJennilyn Amable Democrito100% (1)

- Finman CH 18 SolmanDokumen32 halamanFinman CH 18 SolmanJoselle Jan Claudio100% (1)

- Auto Loan Application Form - IndividualDokumen2 halamanAuto Loan Application Form - IndividualKlarise EspinosaBelum ada peringkat

- The Anti Cancer Essential Oil ReferenceDokumen9 halamanThe Anti Cancer Essential Oil ReferenceΡαφαέλα ΠηλείδηBelum ada peringkat

- Introduction To Personal FinanceDokumen15 halamanIntroduction To Personal FinanceMa'am Katrina Marie MirandaBelum ada peringkat

- Week 4Dokumen5 halamanWeek 4عبدالرحمن الحربيBelum ada peringkat

- Syllabus Tourism Laws CKSCDokumen6 halamanSyllabus Tourism Laws CKSCDennis Go50% (2)

- Silent Reading With Graph1Dokumen2 halamanSilent Reading With Graph1JonaldSamueldaJoseBelum ada peringkat

- DIN EN 16842-1: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeDokumen23 halamanDIN EN 16842-1: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeanupthattaBelum ada peringkat

- Services Marketing-Unit-Ii-ModifiedDokumen48 halamanServices Marketing-Unit-Ii-Modifiedshiva12mayBelum ada peringkat

- Nava V Artuz AC No. 7253Dokumen7 halamanNava V Artuz AC No. 7253MACASERO JACQUILOUBelum ada peringkat

- RightShip Inspections Ship Questionaire RISQ 3.0Dokumen207 halamanRightShip Inspections Ship Questionaire RISQ 3.0Philic Rohit100% (1)

- JSRG - Mom - DRM - 04 (13.12.2018) PDFDokumen3 halamanJSRG - Mom - DRM - 04 (13.12.2018) PDFNithyanandhan TranzionBelum ada peringkat

- Lampiran 18-Lesson Plan 02Dokumen5 halamanLampiran 18-Lesson Plan 02San Louphlii ThaBelum ada peringkat

- US. Peace Corps Tetun Language CourseDokumen305 halamanUS. Peace Corps Tetun Language CoursePeter W Gossner100% (1)

- Q4 SMEA-Sta.-Rosa-IS-HS-S.Y 2021-2022Dokumen38 halamanQ4 SMEA-Sta.-Rosa-IS-HS-S.Y 2021-2022junapoblacioBelum ada peringkat

- IGCSE-Revision-Booklet-Part-1-2018-2019 - (New-Spec)Dokumen69 halamanIGCSE-Revision-Booklet-Part-1-2018-2019 - (New-Spec)MaryamBelum ada peringkat

- Physicochemical, Phytochemical, Mineral Analysis and Invitro Anti-Oxidant Activity of Shatavari Ghrita (Polyherbal Formulation)Dokumen11 halamanPhysicochemical, Phytochemical, Mineral Analysis and Invitro Anti-Oxidant Activity of Shatavari Ghrita (Polyherbal Formulation)International Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Sow English Year 4 2023 2024Dokumen12 halamanSow English Year 4 2023 2024Shamien ShaBelum ada peringkat

- Written Test 4-Book 3Dokumen2 halamanWritten Test 4-Book 3Vinícius MoreiraBelum ada peringkat

- ISDGTIE 2023 BrochureDokumen9 halamanISDGTIE 2023 BrochureAshish KumarBelum ada peringkat

- Text Al Capone B1Dokumen2 halamanText Al Capone B1Andjela JevremovicBelum ada peringkat

- Playing Djembe PDFDokumen63 halamanPlaying Djembe PDFpbanerjeeBelum ada peringkat

- Napoleon Lacroze Von Sanden - Crony Capitalism in ArgentinaDokumen1 halamanNapoleon Lacroze Von Sanden - Crony Capitalism in ArgentinaBoney LacrozeBelum ada peringkat