Warehouse 2

Diunggah oleh

aliHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Warehouse 2

Diunggah oleh

aliHak Cipta:

Format Tersedia

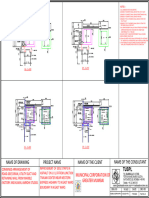

C:\Users\BAREZ\Downloads\Building HeaderSS.

png

Mobile Buildingoffice198@Gmail.com

Email: Number:+ 964 750 8620123

DESIGN NOTES

0

DESIGN BASIS

- The design is performed according to ACI 318-14 code requirement complying for designing all concrete members ( foundation, Tie beams and floors).

- Net allowable bearing capacity is assumed to be 150 kN/m2

MATERIALS

CONCRETE STRUCTURE:

- Portland cement ASTM C150 used in the work shall correspond to basis of concrete for designing concrete mixture proportions. Cement must be identified

in its actual service in order to produce concrete with adequate strength and durability.

- Normal weight aggregate ASTM C33 shall conform to the requirements of test to identify actual service and produce concrete with adequate strength and

durability. 1) ALL DIMENSIONS IN MILLIMETERS

EXCEPT MENTIONED.

- Minimum CUBIC compressive strength (Fc') of ALL CONCRETE MEMBERS must be more than 30 MPa for cube tests. 2) CHARACTERISTIC YIELD STRENGTH

OF REINFORCEMENT SHALL BE Fyk =400

MPa.

3) CHARACTERISTIC COMPRESSIVE

- Carbon steel ASTM A615 must be used to requirement specification, minimum tensile strength must be more than 420 MPa for all sizes of steel STRENGTH OF CONCRETE SHALL BE Fc

CUBE=35MPa, Fc cylinderical = 30 MPa

4) CONCRETE COVER FOUNDATION

reinforcement. Cnom=70mm (Top, Nottom, and side)

TIE BEAM

Cnom= 70mm (Top, Nottom, and side)

STRUCTURE

- Foundations should be accommodated safely against all the imposed forces. Attention is requred to the connection between all the member of superstructure

and to the substructure to the anchoring of any holding-down bolts.

- The connection between column- foundation are pinned connection (shear resistance).

DEAD LOAD

The load of the structure and super dead load with 100mm slab thickness have been considered in the design. Moreover, the cladding load has established

on the beam perimeter. On the other hand, the seismic loads is applied according to ASCE7-10 on the structure. Although, the wind load maybe neglected in the design based on

code, it has been applied in order to gain more safety to the building.

LIVE LOAD PROJECT NAME:

-live load for warehouse building is assumed to be 5 kN/m2 for the entire building. For the Roof 2kN/m2 live load is applied.

DURABILITY Warehouse

-The clear cover between lean concrete and bottom reinforcement in the pad foundation should be restricted to 75 mm

-The clear cover between internal form face and closest steel reinforcement in tie beams should be restricted to 75 mm

-The clear cover between internal form face and closest steel reinforcement in walls and slabs should be restricted to 25 mm LAND NO

- Exposure categories such as freezing and thawing, sulfate and chloride attack,requirement for low permeability and reinforcement

LAND AREA

corrosion protection need to be considered precisely due to different weather throughout construction process according to clause 4.1 in ACI318-14

- Any embedment materials such as conduits, pipes and sleeves must not be harmful to endanger concrete components and rebar. BUILT AREA

PRACTICES TO MINIMIZE PLASTIC CRACKS

DRAWING NAME

+ dampen the sub-grade and form works before placing concrete to avoid excessive water loss

+ Place concrete in deep sections first (beams) and let it settle prior to placing and compacting the top layers (slab) to eliminate occurrence GENERAL NOTE

of plastic settlement due to restraining edges of the form works.

+ Precaution needs to be exercised for avoiding damage of bond between rebar and concrete.

JOB NO 1 JOB TYPE STRU.

+ Prevent excessive moisture surface evaporation by providing for sprays or wind breaks.

+ Cover concrete with wet burlaps or polyethylene sheets between finishing operation DESIGNED BY:

+ Use cooler concrete in hot weather and avoid extremely high concrete temperature in cold weather

+ After the excavation of foundation pit shall timely make the foundation construction, no water and exposure. The underground part after the

construction should be timely backfill of pit. Backfill soil shall be compacted, compaction coefficient should be not less than 0.94.

APPROVED

DATE Feb. 2019

SHEET NO SCALE

A 02 N.T.C

Anda mungkin juga menyukai

- 1.CWRPH-00 - Gad-R0-1550 KL Gad-1Dokumen1 halaman1.CWRPH-00 - Gad-R0-1550 KL Gad-1sBelum ada peringkat

- 1.CWRPH-00 - Gad-R0-1400 KL Gad-1Dokumen1 halaman1.CWRPH-00 - Gad-R0-1400 KL Gad-1sBelum ada peringkat

- 2100 KL Correction - 220211 - 015003Dokumen3 halaman2100 KL Correction - 220211 - 015003sBelum ada peringkat

- 2100 KL GAD Correction - 220211 - 015654Dokumen1 halaman2100 KL GAD Correction - 220211 - 015654sBelum ada peringkat

- 1.CWRPH-00 - Gad-R0-2100 KL Gad-1Dokumen1 halaman1.CWRPH-00 - Gad-R0-2100 KL Gad-1sBelum ada peringkat

- 25M Tower FDN - 2Dokumen1 halaman25M Tower FDN - 2Hikmat B. Ayer - हिक्मत ब. ऐरBelum ada peringkat

- Olla STR DesignDokumen23 halamanOlla STR DesigntahaelnourBelum ada peringkat

- Summary of Submittals by Macro Wall IndustrialDokumen4 halamanSummary of Submittals by Macro Wall IndustrialKrysna JorizaBelum ada peringkat

- Cable Route MarkerDokumen2 halamanCable Route Markersundareee96Belum ada peringkat

- Design of CorbalDokumen47 halamanDesign of CorbalHussam JumahBelum ada peringkat

- DETAILING DIMENSIONSDokumen5 halamanDETAILING DIMENSIONSCamille Ariel100% (1)

- Safdeck Specification Sheet - KenyaDokumen3 halamanSafdeck Specification Sheet - KenyagraceBelum ada peringkat

- Potato Stroage Design AAPMP2-ModelDokumen1 halamanPotato Stroage Design AAPMP2-ModelshuaibBelum ada peringkat

- General construction notes and requirementsDokumen4 halamanGeneral construction notes and requirementsGrachelle Tan100% (1)

- MosquejDokumen12 halamanMosquejdr.afroza1875Belum ada peringkat

- MR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFDokumen1 halamanMR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFMr. SinghBelum ada peringkat

- 1.JVLR Retaining Wall R-1-13Dokumen1 halaman1.JVLR Retaining Wall R-1-13samir bendreBelum ada peringkat

- Design Criteria: Reinforcing SteelDokumen12 halamanDesign Criteria: Reinforcing SteelALL-ROUNDER CIVIL ENGINEERS ENGLISHBelum ada peringkat

- عمار الانشائي - compressedDokumen36 halamanعمار الانشائي - compressedzakariaBelum ada peringkat

- LN2 SYNC REVIEW OF FLEXURAL ANALYSIS OF BEAMS - PART 1 MarkedDokumen10 halamanLN2 SYNC REVIEW OF FLEXURAL ANALYSIS OF BEAMS - PART 1 MarkedRalph Denver RomanoBelum ada peringkat

- PD 0158 SM 01Dokumen1 halamanPD 0158 SM 01FAIZAN AHMEDBelum ada peringkat

- Foundations Lighting Columns PDFDokumen2 halamanFoundations Lighting Columns PDFtexas_peteBelum ada peringkat

- 60020-00sit-Al-Eng-Arc-Spd-0009 - Excavation PlanDokumen1 halaman60020-00sit-Al-Eng-Arc-Spd-0009 - Excavation PlanniyasBelum ada peringkat

- NotesDokumen1 halamanNotesMohammad AlkahteebBelum ada peringkat

- Structural Notes and DetailsDokumen1 halamanStructural Notes and DetailsMohammad AlkahteebBelum ada peringkat

- Waterproofing membranes for concrete substructuresDokumen4 halamanWaterproofing membranes for concrete substructuresEngr KamalBelum ada peringkat

- INTRODUCTION-THEORY AND BEHAVIOURDokumen4 halamanINTRODUCTION-THEORY AND BEHAVIOURarunBelum ada peringkat

- Inhinyero Review CenterDokumen2 halamanInhinyero Review CenterVincent NavaBelum ada peringkat

- 1.JVLR Retaining Wall R-1-08Dokumen1 halaman1.JVLR Retaining Wall R-1-08samir bendreBelum ada peringkat

- Boundary Wall May Be Proposed For BagnanDokumen3 halamanBoundary Wall May Be Proposed For BagnanSuman BhaiBelum ada peringkat

- DR - 1.majid Albana Structural 13 Floor BUILDING 23Dokumen1 halamanDR - 1.majid Albana Structural 13 Floor BUILDING 23Mohamad RammelBelum ada peringkat

- 150mm Beam & Block Data SheetDokumen2 halaman150mm Beam & Block Data SheetErnie ErnieBelum ada peringkat

- Problem Set No.2 - Ultimate Stress Design (USD)Dokumen1 halamanProblem Set No.2 - Ultimate Stress Design (USD)Catherine Shaina O. PasionBelum ada peringkat

- Summary Layout For DrawingDokumen1 halamanSummary Layout For DrawingSuhail AhamedBelum ada peringkat

- Fatigue Analysis GuideDokumen1 halamanFatigue Analysis Guidebalamech91Belum ada peringkat

- Simply Supported Beam AlinDokumen8 halamanSimply Supported Beam Alinnkamalinmastura0000Belum ada peringkat

- 1.JVLR Retaining Wall R-1-10Dokumen1 halaman1.JVLR Retaining Wall R-1-10samir bendreBelum ada peringkat

- F.A.L. CONDUCIVE ENGINEERING REVIEWDokumen3 halamanF.A.L. CONDUCIVE ENGINEERING REVIEWJerome AdduruBelum ada peringkat

- Kabasis-15 - BBS Concrete Sleeper DetailsDokumen1 halamanKabasis-15 - BBS Concrete Sleeper DetailsMarvin ItolondoBelum ada peringkat

- Inhinyero Review Center: Provided MaxDokumen2 halamanInhinyero Review Center: Provided MaxVincent NavaBelum ada peringkat

- A Steel MAX Extra Information ItemsDokumen15 halamanA Steel MAX Extra Information ItemsAnh Linh LeBelum ada peringkat

- 1.Jvlr Retaining Wall R-1-09Dokumen1 halaman1.Jvlr Retaining Wall R-1-09samir bendreBelum ada peringkat

- CULVERT DRAWING BINDERDokumen5 halamanCULVERT DRAWING BINDERAhmed Nader KhurshidBelum ada peringkat

- SmartBeam Composite Castellated Beam DesignDokumen2 halamanSmartBeam Composite Castellated Beam Designmulyati fnuBelum ada peringkat

- Esr 3699Dokumen15 halamanEsr 3699K Sambasiva RaoBelum ada peringkat

- 1.JVLR Retaining Wall R-1-11Dokumen1 halaman1.JVLR Retaining Wall R-1-11samir bendreBelum ada peringkat

- General notes for RCC designDokumen1 halamanGeneral notes for RCC designVemajala GaneshBelum ada peringkat

- Cemex Solid K4 - Raw Meal SiloDokumen3 halamanCemex Solid K4 - Raw Meal Silojoselito navarroBelum ada peringkat

- Construction notes for reinforced concrete detailingDokumen1 halamanConstruction notes for reinforced concrete detailingShariah MelonBelum ada peringkat

- STRUCTURAL RESIDENCEDokumen4 halamanSTRUCTURAL RESIDENCE2226558Belum ada peringkat

- CONCRETE CUNNAGE, 17''x17''x10'-Layout1Dokumen1 halamanCONCRETE CUNNAGE, 17''x17''x10'-Layout1Mc Dowell CampangBelum ada peringkat

- SD-208 - Rev 2Dokumen1 halamanSD-208 - Rev 2sathishBelum ada peringkat

- CMC Steel Products Composite Castellated Beam Design ProgramDokumen2 halamanCMC Steel Products Composite Castellated Beam Design Programspen_prihatantoBelum ada peringkat

- Bat-Dwg-Dd-Me-00-Eg-6101 - R0 - Grounding, Earthing and Lightning Protection System Shematic DiagramDokumen1 halamanBat-Dwg-Dd-Me-00-Eg-6101 - R0 - Grounding, Earthing and Lightning Protection System Shematic DiagramCosphiiiBelum ada peringkat

- DWG 5 DecDokumen1 halamanDWG 5 DecMickey DalbeheraBelum ada peringkat

- Annex J Design DrawingsDokumen5 halamanAnnex J Design DrawingsCarmen RiveraBelum ada peringkat

- Ol P: As - M20, M25, CalledDokumen8 halamanOl P: As - M20, M25, CalledKartik JainBelum ada peringkat

- General: Structural SteelDokumen1 halamanGeneral: Structural SteelDerf Jayson AdanteBelum ada peringkat

- Leica Flexline Ts03/Ts07/Ts10 Manual Total StationsDokumen2 halamanLeica Flexline Ts03/Ts07/Ts10 Manual Total StationsaliBelum ada peringkat

- Our Commitment. Your Success.: Leica Geosystems Active Customer CareDokumen8 halamanOur Commitment. Your Success.: Leica Geosystems Active Customer CarealiBelum ada peringkat

- Scope of Works PDFDokumen143 halamanScope of Works PDFaliBelum ada peringkat

- DOT's Federal Pipeline Safety Program: Background and Key Issues For CongressDokumen32 halamanDOT's Federal Pipeline Safety Program: Background and Key Issues For CongressaliBelum ada peringkat

- Ansi z87 1 2003Dokumen73 halamanAnsi z87 1 2003Carlos Monsalve VejarBelum ada peringkat

- DOT's Federal Pipeline Safety Program: Background and Key Issues For CongressDokumen32 halamanDOT's Federal Pipeline Safety Program: Background and Key Issues For CongressaliBelum ada peringkat

- API 682 Shaft Seal System For Centrifugal Rotary PumpDokumen53 halamanAPI 682 Shaft Seal System For Centrifugal Rotary PumpnguyentrungBelum ada peringkat

- Laser Scanner Total Station: TsshieldDokumen4 halamanLaser Scanner Total Station: TsshieldaliBelum ada peringkat

- Annex H - Technical Evaluation CriteriaDokumen2 halamanAnnex H - Technical Evaluation CriteriaaliBelum ada peringkat

- Iraq Earthquake Paper PDFDokumen16 halamanIraq Earthquake Paper PDFnajdjanBelum ada peringkat

- Scope of Work PDFDokumen113 halamanScope of Work PDFaliBelum ada peringkat

- DOT's Federal Pipeline Safety Program: Background and Key Issues For CongressDokumen32 halamanDOT's Federal Pipeline Safety Program: Background and Key Issues For CongressaliBelum ada peringkat

- Drawing BasicsDokumen2 halamanDrawing BasicsaliBelum ada peringkat

- Standards and Specifications For Roads and Bridges Revised To Date 14-02-2007 (Iraqi Standard Code) PDFDokumen369 halamanStandards and Specifications For Roads and Bridges Revised To Date 14-02-2007 (Iraqi Standard Code) PDFnadher albaghdadi80% (10)

- Warehouse 1Dokumen1 halamanWarehouse 1aliBelum ada peringkat

- Single Lever Basin Mixer Tap Spec SheetDokumen2 halamanSingle Lever Basin Mixer Tap Spec SheetaliBelum ada peringkat

- Pipeline Investigation ReportDokumen34 halamanPipeline Investigation ReportaliBelum ada peringkat

- 04 Metric Single Lever Basin Mixer Tap PDFDokumen2 halaman04 Metric Single Lever Basin Mixer Tap PDFaliBelum ada peringkat

- Atmos International Provides Pipeline Software SolutionsDokumen1 halamanAtmos International Provides Pipeline Software SolutionsaliBelum ada peringkat

- ACI 207.4R-05 Cooling and Insulating Systems For Mass Concrete (Reapproved 2012)Dokumen19 halamanACI 207.4R-05 Cooling and Insulating Systems For Mass Concrete (Reapproved 2012)farhadamBelum ada peringkat

- ACI 216.1-07 Code Requirements For Determining Fire Resistance of Concrete and Masonry Construction Assemblies - MyCivil - IrDokumen32 halamanACI 216.1-07 Code Requirements For Determining Fire Resistance of Concrete and Masonry Construction Assemblies - MyCivil - IraliBelum ada peringkat

- Guide To Sealing Joints in Concrete StructuresDokumen44 halamanGuide To Sealing Joints in Concrete StructuresCivilEngClub100% (3)

- ACI 216.1-07 Code Requirements For Determining Fire Resistance of Concrete and Masonry Construction Assemblies - MyCivil - IrDokumen32 halamanACI 216.1-07 Code Requirements For Determining Fire Resistance of Concrete and Masonry Construction Assemblies - MyCivil - IraliBelum ada peringkat

- Guide To Sealing Joints in Concrete StructuresDokumen44 halamanGuide To Sealing Joints in Concrete StructuresCivilEngClub100% (3)

- ACI 305.1-06 Specification For Hot Weather Concreting PDFDokumen12 halamanACI 305.1-06 Specification For Hot Weather Concreting PDFNafnaf TroopBelum ada peringkat

- Problems Set 1Dokumen10 halamanProblems Set 1Vincent Lasconia Jr.Belum ada peringkat

- Carpentry 1Dokumen159 halamanCarpentry 1Shena Mae SamarroBelum ada peringkat

- KTV 3/Ktv 4: Automatic Revolving DoorsDokumen32 halamanKTV 3/Ktv 4: Automatic Revolving Doorszahee007Belum ada peringkat

- Al Hamra Tower: Kuwait City, KuwaitDokumen20 halamanAl Hamra Tower: Kuwait City, Kuwaitayush dattaBelum ada peringkat

- Q4 TVL Eim 12 Week2Dokumen4 halamanQ4 TVL Eim 12 Week2Harold Vernon MartinezBelum ada peringkat

- Steel ConnectionDokumen23 halamanSteel Connectionមជ្ឈមណ្ឌលបណ្តុះបណ្តាល វិស្វកម្មសំណង់ស៊ីវិលBelum ada peringkat

- Department of Construction Sessional Examination (Spring Semester)Dokumen9 halamanDepartment of Construction Sessional Examination (Spring Semester)Harry LaiBelum ada peringkat

- Modelling Masterclass: Part One. The Wargames TableDokumen32 halamanModelling Masterclass: Part One. The Wargames TableAlberto Spartaco OttonelliBelum ada peringkat

- MSTP Quiz2 ReviewerDokumen6 halamanMSTP Quiz2 ReviewerChester Dave Bal-otBelum ada peringkat

- Non-Loadbearing Steel Stud Partitions: National GypsumDokumen10 halamanNon-Loadbearing Steel Stud Partitions: National GypsumGerald De OcampoBelum ada peringkat

- Cost Estimating 21 Dr. Emad ElbeltagiDokumen7 halamanCost Estimating 21 Dr. Emad Elbeltagiari civilian100% (2)

- Carpentry 10 - 1st Quarter Summative TestDokumen3 halamanCarpentry 10 - 1st Quarter Summative Testjohn paulBelum ada peringkat

- Method StatementDokumen39 halamanMethod Statementmodest_dhu100% (1)

- Types of Special and Lightweight ConcreteDokumen64 halamanTypes of Special and Lightweight ConcreteAbhishek GoundBelum ada peringkat

- HVAC Project Report - Ziad ShairDokumen33 halamanHVAC Project Report - Ziad ShairAhmad ZubaidiBelum ada peringkat

- Interior Wall FinishingDokumen20 halamanInterior Wall FinishingEdgar Javier100% (1)

- FREYSSISOL - MSE Wall Construction ManualDokumen105 halamanFREYSSISOL - MSE Wall Construction ManualUzmaNaumanBelum ada peringkat

- Knauf Fire & Moisture Resistant Gypsum Boards (FM)Dokumen2 halamanKnauf Fire & Moisture Resistant Gypsum Boards (FM)Joe PsBelum ada peringkat

- KIOT Building Construction LectureDokumen26 halamanKIOT Building Construction Lecturebini1221Belum ada peringkat

- List of Manufacturers & Materials: CivilDokumen4 halamanList of Manufacturers & Materials: CivilNnabuife OzorBelum ada peringkat

- 1-21 Fire Resistance of Building AssembliesDokumen37 halaman1-21 Fire Resistance of Building Assembliesthongtn2007Belum ada peringkat

- Side Elevation Front Elevation: Schedule of Doors and WindowsDokumen2 halamanSide Elevation Front Elevation: Schedule of Doors and WindowsKancelari RoganoBelum ada peringkat

- S0-04 - General NotesDokumen1 halamanS0-04 - General NotesJason toraldeBelum ada peringkat

- Lexsha's BoqDokumen81 halamanLexsha's BoqJan Lawrence AlbertoBelum ada peringkat

- 8 - Precast Concrete Structures-Students PDFDokumen17 halaman8 - Precast Concrete Structures-Students PDFsitehabBelum ada peringkat

- Structural Steel ErectionDokumen7 halamanStructural Steel ErectionVeronica De Jesus50% (4)

- Cable Tray Fill AreaDokumen20 halamanCable Tray Fill AreaNibin P SBelum ada peringkat

- .Precast Concrete ConnectionsDokumen3 halaman.Precast Concrete Connectionsparamarthasom1974Belum ada peringkat

- Types of Construction DrawingsDokumen7 halamanTypes of Construction DrawingsMd Mukarram RezaBelum ada peringkat

- Concrete Pavements and Linings Installed in Corrugated Steel Structures in The FieldDokumen4 halamanConcrete Pavements and Linings Installed in Corrugated Steel Structures in The Fieldvuqar0979Belum ada peringkat