4597-AAB-SC-09 R0v1 33

Diunggah oleh

danieldumapitHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

4597-AAB-SC-09 R0v1 33

Diunggah oleh

danieldumapitHak Cipta:

Format Tersedia

One Za'abeel | 4597-AAB-SC-09

4-3 Typical End Mullion Bracket.xmct

Section Page 10 of 17

Design and Engineering Dept.

______________________________________________________________________________________________________________________________

⌂ This subsec on verifies the tensile failure of bolt material in axial loading.

≡

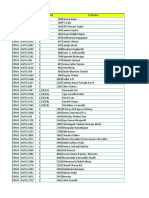

Design Parameters / Analysis

nf = 2.00

edf := 50.00⋅ mm

Direct Tensile Force per Fastener

Fxtf_d := F1 ÷ nf = 5.74⋅ kN

Tensile Force Due to Moment

T

af = ( 0.00 0.00 ) ⋅ mm

T

bf = ( 75.00 − 75.00 ) ⋅ mm

af

2 2

I fy := = 0.00⋅ mm

bf

2 2

I fz := = 11250.00⋅ mm

i := 1 ← Number of the Most Stressed Fastener

r fa := af = 0.00 r fb := bf = 75.00 mm ← Coordinates of the Most Stressed Fastener

i i

( )

Fxtf_m2 := M2 ÷ 2 ÷ 3⋅ edf ÷ nf = 24.51⋅ kN

Fxtf_m3 := M3 ⋅ r fb ÷ I fz = 0.20⋅ kN

F tf := Fxtf_d + Fxtf_m2 + Fxtf_m3 = 30.46⋅ kN ← Design Tensile Force on the Most Stressed Fastener

Code Based Checking BS 5950 Sec on 6.3.4

( )

ρ t := min 0.7Ub , Yb = 450.00⋅ MPa ← Limi ng Stress of Fastener

Ρnomf := 0.80ρ t⋅ As = 56.40⋅ kN ← Design Tensile Resistance of Fastener Material

Design Criteria : F tf ≤ Ρnomf Code Check : Safe! ; Utilization Ratio = 54.00%

▄▄▄

⌂ This subsec on verifies the combined shear and tensile failure of bolt material.

≡

Code Based Checking BS 5950 Sec on 6.3.4

Combined Stress Ra o

Design Criteria : F sf F tf Code Check : Safe! ; Utilization Ratio = 39.22%

+ ≤ 1.4

▄▄▄ Ρsf Ρnomf

33 of 72

TempVer20.0_012018 | Engineer: D. Dumapit | Checked: S.M. Lomboy Jr.

Anda mungkin juga menyukai

- 4597-AAB-SC-09 R0v1 28Dokumen1 halaman4597-AAB-SC-09 R0v1 28danieldumapitBelum ada peringkat

- 4597-AAB-SC-09 R0v1 31Dokumen1 halaman4597-AAB-SC-09 R0v1 31danieldumapitBelum ada peringkat

- 4597-AAB-SC-09 R0v1 29Dokumen1 halaman4597-AAB-SC-09 R0v1 29danieldumapitBelum ada peringkat

- 4597-AAB-SC-09 R0v1 34Dokumen1 halaman4597-AAB-SC-09 R0v1 34danieldumapitBelum ada peringkat

- 4597-AAB-SC-09 R0v1 27Dokumen1 halaman4597-AAB-SC-09 R0v1 27danieldumapitBelum ada peringkat

- 4597-AAB-SC-09 R0v1 32Dokumen1 halaman4597-AAB-SC-09 R0v1 32danieldumapitBelum ada peringkat

- Ii. Analysis and Design Verifica On: A) Connec On On Typical MullionDokumen1 halamanIi. Analysis and Design Verifica On: A) Connec On On Typical MulliondanieldumapitBelum ada peringkat

- 4597-AAB-SC-09 R0v1 39Dokumen1 halaman4597-AAB-SC-09 R0v1 39danieldumapitBelum ada peringkat

- 4597-AAB-SC-09 R0v1 40Dokumen1 halaman4597-AAB-SC-09 R0v1 40danieldumapitBelum ada peringkat

- Sample Only: SECTION 3.05Dokumen3 halamanSample Only: SECTION 3.05azur0301Belum ada peringkat

- Columns DesignDokumen60 halamanColumns DesignifsrebraBelum ada peringkat

- Base Plate TopDokumen7 halamanBase Plate TopUpendra WalinjkarBelum ada peringkat

- Bolt AnalysisDokumen1 halamanBolt AnalysisNajibullah AziziBelum ada peringkat

- 4597-AAB-SC-09 R0v1 37Dokumen1 halaman4597-AAB-SC-09 R0v1 37danieldumapitBelum ada peringkat

- 4597-AAB-SC-09 R0v1 36Dokumen1 halaman4597-AAB-SC-09 R0v1 36danieldumapitBelum ada peringkat

- Design of Coping Beam (Portal) : A. Basic DataDokumen7 halamanDesign of Coping Beam (Portal) : A. Basic DataUzziel Abib GabiolaBelum ada peringkat

- Shear lug design calculationDokumen3 halamanShear lug design calculationRama Subramanyam ManepalliBelum ada peringkat

- Design of Singly Reinforced Concrete Beam PDFDokumen3 halamanDesign of Singly Reinforced Concrete Beam PDFAnton_Young_1962Belum ada peringkat

- Design of Steel I-Section (BS5950)Dokumen3 halamanDesign of Steel I-Section (BS5950)gertjaniBelum ada peringkat

- Helical Stair - CalculationDokumen5 halamanHelical Stair - CalculationLalima Chatterjee67% (6)

- Design beam roof levels and floorsDokumen14 halamanDesign beam roof levels and floorsheheloveBelum ada peringkat

- Analysis: Tedds Calculation Version 1.0.23Dokumen10 halamanAnalysis: Tedds Calculation Version 1.0.23Sachin AgarwalBelum ada peringkat

- Design of two-way reinforced concrete slabDokumen15 halamanDesign of two-way reinforced concrete slabMohammed Saleem Syed KhaderBelum ada peringkat

- AISC ASD-89 Example 001 - Software Verification Matches Independent ResultsDokumen5 halamanAISC ASD-89 Example 001 - Software Verification Matches Independent Resultsgusla7Belum ada peringkat

- 05 - Flex BDokumen23 halaman05 - Flex BNathan MolongwanaBelum ada peringkat

- Design of Singly Reinforced Concrete BeamDokumen4 halamanDesign of Singly Reinforced Concrete BeamAnton_Young_1962Belum ada peringkat

- Design of One-way SlabDokumen4 halamanDesign of One-way SlabAnton_Young_1962Belum ada peringkat

- PT Hollow Box (BR 18m X 20m) Girder Design-Rev FINALDokumen25 halamanPT Hollow Box (BR 18m X 20m) Girder Design-Rev FINALlyty WUBelum ada peringkat

- Glass Check 550mm X 1550mmDokumen7 halamanGlass Check 550mm X 1550mmAniket InarkarBelum ada peringkat

- Design of BeamDokumen14 halamanDesign of BeamUdhasu NayakBelum ada peringkat

- Mathcad - Column Base Plate CheckDokumen12 halamanMathcad - Column Base Plate CheckValentinBelum ada peringkat

- JEROME M. GUETA QUIZ 3 - Advance Steel DesignDokumen105 halamanJEROME M. GUETA QUIZ 3 - Advance Steel DesignJerome M. GuetaBelum ada peringkat

- NIC Components NRSY SeriesDokumen6 halamanNIC Components NRSY SeriesNICCompBelum ada peringkat

- ASD-Design of Steel BeamDokumen5 halamanASD-Design of Steel BeamsivakumarBelum ada peringkat

- 5.3 SHEAR AND DIAGONAL TENSION (Vertical Stirrup Design)Dokumen4 halaman5.3 SHEAR AND DIAGONAL TENSION (Vertical Stirrup Design)Nadet KhomBelum ada peringkat

- JLG X 430 - Arrivals SlabCalcs - GOODDokumen29 halamanJLG X 430 - Arrivals SlabCalcs - GOODKailin JuBelum ada peringkat

- Steel Beam Design CalculationsDokumen11 halamanSteel Beam Design CalculationsAllan Añavisa Ostique Jr.Belum ada peringkat

- Design of Precast Wall Panel SMDC Lights Residences 11-15-2010 MMTHKDokumen7 halamanDesign of Precast Wall Panel SMDC Lights Residences 11-15-2010 MMTHKmarr_ulepBelum ada peringkat

- Practical Lesson 4Dokumen11 halamanPractical Lesson 4marjory.dezBelum ada peringkat

- 4597-AAB-SC-09 R0v1 35Dokumen1 halaman4597-AAB-SC-09 R0v1 35danieldumapitBelum ada peringkat

- Punching Shear Check ACI 318RM-02Dokumen1 halamanPunching Shear Check ACI 318RM-02OktayBelum ada peringkat

- Lecture Reading 13: Structural Analysis of Structural Steel BeamsDokumen13 halamanLecture Reading 13: Structural Analysis of Structural Steel BeamsKim CalaguiBelum ada peringkat

- VMH AnchorDokumen4 halamanVMH Anchormohamed rafiBelum ada peringkat

- Mono Rail Beams DesignDokumen4 halamanMono Rail Beams DesignpandianBelum ada peringkat

- Design of a General Column in PROKONDokumen10 halamanDesign of a General Column in PROKONShamitha KanchanaBelum ada peringkat

- Top of FTG: DB12 (Ok.) @200 (Ratio 0.12)Dokumen9 halamanTop of FTG: DB12 (Ok.) @200 (Ratio 0.12)vijay kumar yadavBelum ada peringkat

- Web Design For Shear and Transverse Bending Segment R2: Check If Shear PredominatesDokumen2 halamanWeb Design For Shear and Transverse Bending Segment R2: Check If Shear PredominatesSharyn PolleyBelum ada peringkat

- Steel Cal CulDokumen1 halamanSteel Cal CulheinsteinzBelum ada peringkat

- ANODE SLED Padeye CalculationDokumen5 halamanANODE SLED Padeye Calculationejim2Belum ada peringkat

- Ridge Connection Design RSP-1.Dokumen121 halamanRidge Connection Design RSP-1.Asaru DeenBelum ada peringkat

- Calculation Sheet-F3 Node-3 10: Design of Combined Footing:-ZDokumen25 halamanCalculation Sheet-F3 Node-3 10: Design of Combined Footing:-Zask.kulkarni Kulkarni100% (1)

- Calculating crack width and capacity of a reinforced concrete slabDokumen3 halamanCalculating crack width and capacity of a reinforced concrete slabOmar MokhtarBelum ada peringkat

- Beam Design RusselDokumen155 halamanBeam Design RusselRonald CostalesBelum ada peringkat

- AISC 360-16 Check of Single Plate Shear ConnectionDokumen9 halamanAISC 360-16 Check of Single Plate Shear ConnectionVietanh PhungBelum ada peringkat

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDari EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionBelum ada peringkat

- Aerothermodynamics of Turbomachinery: Analysis and DesignDari EverandAerothermodynamics of Turbomachinery: Analysis and DesignBelum ada peringkat

- Solution Manual for an Introduction to Equilibrium ThermodynamicsDari EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsBelum ada peringkat

- Par Al Plan View of Structure: Ii. Structural SystemDokumen1 halamanPar Al Plan View of Structure: Ii. Structural SystemdanieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 18Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 18danieldumapitBelum ada peringkat

- C.4 Torsional Strength, Chapter H: Nominal Axial Strength, Sec On E7 Nominal Axial StrengthDokumen1 halamanC.4 Torsional Strength, Chapter H: Nominal Axial Strength, Sec On E7 Nominal Axial StrengthdanieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 44Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 44danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 31Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 31danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 39Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 39danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 43Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 43danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 40Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 40danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 41Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 41danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 35Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 35danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 34Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 34danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 32Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 32danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 42Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 42danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 36Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 36danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 17Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 17danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 38Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 38danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 61Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 61danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 37Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 37danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 66Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 66danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 30Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 30danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 65Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 65danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 55Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 55danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 64Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 64danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 60Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 60danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 56Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 56danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 80Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 80danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 63Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 63danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 62Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 62danieldumapitBelum ada peringkat

- 8 Installation Data: Profis Anchor 2.8.8Dokumen1 halaman8 Installation Data: Profis Anchor 2.8.8danieldumapitBelum ada peringkat

- 4597 AAB SC 07 Addendum 2 R0v0 57Dokumen1 halaman4597 AAB SC 07 Addendum 2 R0v0 57danieldumapitBelum ada peringkat

- International Humanitarian Law - Atty. Mercado (July 2016)Dokumen77 halamanInternational Humanitarian Law - Atty. Mercado (July 2016)MiroBelum ada peringkat

- Corporate Taxation IntroductionDokumen48 halamanCorporate Taxation IntroductionSatyajeet MohantyBelum ada peringkat

- Reverse Logistics Implementation in The Construction Industry: Paper Waste FocusDokumen9 halamanReverse Logistics Implementation in The Construction Industry: Paper Waste FocusSamuel YuliusBelum ada peringkat

- Short and Sweet Experiences With Homoeopathy!Dokumen3 halamanShort and Sweet Experiences With Homoeopathy!Homoeopathic Pulse100% (1)

- Vygotsky's Theory of Creative ImaginationDokumen15 halamanVygotsky's Theory of Creative ImaginationAslı Kaya100% (1)

- M.SC Maths (Previous)Dokumen11 halamanM.SC Maths (Previous)hari sharmaBelum ada peringkat

- Q4 English 9 Module 4 React To Lay Value Judgement FINAL PDFDokumen20 halamanQ4 English 9 Module 4 React To Lay Value Judgement FINAL PDFLeona Jane SimbajonBelum ada peringkat

- Madurai Corporation Contempt CaseDokumen6 halamanMadurai Corporation Contempt Caseforpublic 2011100% (1)

- Tutorial Law083 Acceptance 26Dokumen4 halamanTutorial Law083 Acceptance 26NOOR FAIZURA FAAUZEI ABDULLAHBelum ada peringkat

- Early Aristocratic Seals: An Anglo-Norman Success Story : Jean-François NieusDokumen25 halamanEarly Aristocratic Seals: An Anglo-Norman Success Story : Jean-François NieusIZ PrincipaBelum ada peringkat

- Soal BHS Dan Sastra Inggris - Xii 2020Dokumen9 halamanSoal BHS Dan Sastra Inggris - Xii 2020laroibafiBelum ada peringkat

- Oracle VM Server For Sparc: Key Features and BenefitsDokumen4 halamanOracle VM Server For Sparc: Key Features and BenefitsRochdi BouzaienBelum ada peringkat

- Understanding Paragraph StructureDokumen11 halamanUnderstanding Paragraph Structuresiti kholijah rayBelum ada peringkat

- Ingredient Trends in The: Personal Care and Cosmetics Industry 2020Dokumen33 halamanIngredient Trends in The: Personal Care and Cosmetics Industry 2020Akash SharmaBelum ada peringkat

- PasTest MCQs With AnswersDokumen562 halamanPasTest MCQs With Answersياسر بن خميسBelum ada peringkat

- Pre-BASIC VOCABULARY BRILLIANT ENGLISH COURSEDokumen7 halamanPre-BASIC VOCABULARY BRILLIANT ENGLISH COURSERisMank Sani QuiCken Heart100% (1)

- Inductive Vs Deductive MethodDokumen31 halamanInductive Vs Deductive MethodKaren Delfino MosendeBelum ada peringkat

- Project On Brand Awareness of TulipDokumen46 halamanProject On Brand Awareness of TulipBappaditya Bhowal100% (5)

- Cello BachDokumen3 halamanCello BachPera PericBelum ada peringkat

- From Ramesh - Updated CRO Names 03022021Dokumen90 halamanFrom Ramesh - Updated CRO Names 03022021Vamsi SattiBelum ada peringkat

- Emerald Spire Player's GuideDokumen13 halamanEmerald Spire Player's Guidejosh BrittonBelum ada peringkat

- Nayna PorediDokumen7 halamanNayna PorediMukesh ShettyBelum ada peringkat

- Idirect Install Ti On BasicDokumen1 halamanIdirect Install Ti On BasicEsko KonopiskiBelum ada peringkat

- Adjective Clause: Dependent ClausesDokumen8 halamanAdjective Clause: Dependent ClausesRosevelle AyapBelum ada peringkat

- Hospital Waste Management ArticleDokumen5 halamanHospital Waste Management ArticleFarrukh AzizBelum ada peringkat

- Stella Artois in South AfricaDokumen8 halamanStella Artois in South AfricaJavier Andrés Mora ArtéagaBelum ada peringkat

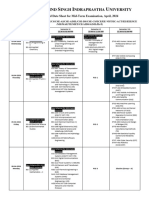

- Mid Term Date Sheet - pq0NsApDokumen2 halamanMid Term Date Sheet - pq0NsApSahil HansBelum ada peringkat

- Economy India (Bain Report)Dokumen103 halamanEconomy India (Bain Report)Yogesh GuttaBelum ada peringkat

- Biological Basis of BehaviourDokumen6 halamanBiological Basis of BehaviourRichard ManuelBelum ada peringkat