Canusawrap™: Product Description Applications

Diunggah oleh

olalekanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Canusawrap™: Product Description Applications

Diunggah oleh

olalekanHak Cipta:

Format Tersedia

Product Data Sheet

CanusaWrap™

Two-piece protective bulk roll with separate closure

Canusa-CPS is a leading manufacturer of

specialty pipeline coatings which, for over

-CPS

30 years, have been used for sealing and CANUSA

corrosion protection of pipeline joints and

other substrates. Canusa high

performance products are manufactured

S

to the highest quality standards and are SA-CP

CANU

available in a number of configurations to

acking

accommodate your specific project Black B

applications.

Product Description Backi

ng

Yel l ow

CanusaWrap™ is a wraparound sleeve

with a separate closure designed for

corrosion protection of buried and Flexibility on the Job Site Applications

exposed steel pipelines. CanusaWrap™ is

Since CanusaWrap™ is supplied in bulk

supplied in bulk rolls consisting of a

crosslinked polyolefin backing, coated

rolls, just-in-time customized lengths can Oil & Gas

be quickly cut in the field to protect any

with a protective heat activated adhesive.

pipe size. This flexibility results in reduced

Once installed, the system effectively Water Pipelines

inventories and cost savings on the job

bonds and protects steel substrates and

site. CanusaWrap™ is also available in a

common main line pipe coatings including

high shrink ratio for high profile joint

polyethylene and fusion bonded epoxy. Polypropylene

protection. Consult the High Shrink data

sheet or your Canusa representative for

Features & Benefits additional information.

Pre-Insulated Pipes

Long-Term Corrosion Protection

CanusaWrap™ provides excellent resis- Easy Field Installation

tance to cathodic disbondment resulting in CanusaWrap™ can be installed quickly Girth-Weld Joints

effective long term corrosion protection. and easily in most environments. Since no

The high performance crosslinked special taping, priming or operator Configurations

backing, in combination with a broad equipment is required, product installation

range of adhesives, can be engineered for is quick and labour costs are kept to a CanusaWrap™

regular or high stress environments. Once minimum. CanusaWrap™ and the closure

installed, CanusaWrap™ provides the seals are available in yellow with a

structural integrity of a seamless tube, and thermochromic indicator and a patented 2-Layer

provides the substrate with durable Windoweld feature which visually con-

protection against abrasion and chemical firms optimum installation.

attack. Standard Shrink

Pipe Sizes

55 - 1520 (2” - 60”)

Temperature Range

up to 80°C (176°F)

CANUSA-CPS is registered to ISO 9001:2000.

CanusaWrap™

The product selection chart shown here is intended as a guide for standard products.

Consult your Canusa representative for specific projects or unique applications.

The following are typical values based on Black, Heavy Duty (L) Sleeves.

Product Selection Guide Choose your sleeve based on Operating Temperature and Characteristics listed below.

Mastic Adhesives Hot Melt Adhesives

Celsius Fahrenheit

WLG WLC WLS WLO WLON WLNN WLA WLAS

110° 230° WTG WTC WTS WTO WTON WTNN

Pipeline

Operating 90° 194°

Temperature

Sleeve Operating Characteristics

70° 158°

50° 122°

30° 86°

-40°C -40°F -40°C -40°F

Minimum Installation Temperature °C (°F) 50 (122) 60 (140) 65 (150) 75 (167) 75 (167) 90 (195) 60 (140) 90 (195)

Resistance to Circumferential Forces fair fair good good good good v. good excl

Resistance to Soil Stress fair fair good good good good v. good excl

Resistance to Axial Pipe Movement fair fair good good good good v. good excl

Main Line Coating Compatibility PE, PP, FBE, PU, Coal tar, Bitumen, PE, PP, FBE PE, FBE PE, FBE

Typical Product Properties * For higher temperature requirements refer to Canusa GTS product line.

Adhesive

Test Standard Unit

Softening Point ASTM E28 °C (°F) 100 (212) 90 (194) 77 (171) 102 (216) 102 (216) 124 (255) 72 (162) 90 (194)

Lap Shear DIN 30 672 M N/cm2 (psi) 8 (12) 30 (44) 40 (58) 40 (58) 40 (58) 52 (75) 60 (87) 117 (170)

Specific Gravity ASTM D792 .93 .93 .93 .93 .95 .95 .93 .93

Tensile Strength ASTM D638 MPa (psi) 20 (2900) 20 (2900) 20 (2900) 24 (3480) 24 (3480) 24 (3480) 20 (2900) 24 (3480)

Elongation ASTM D638 % 600 600 600 700 700 700 600 700

Hardness ASTM D2240 Shore D 46 46 46 48 52 52 46 48

Backing

Abrasion Resistance ASTM D1044 mg 45 45 45 35 30 30 45 35

Volume Resistivity ASTM D257 ohm-cm 1017 1017 1017 1017 1018 1018 1017 1017

Dielectric Voltage Brkdwn. ASTM D149 kV/mm 27 20 20 27 20 20 20 27

Impact * DIN 30 672 class C -- pass pass pass pass pass pass pass

Indentation * DIN 30 672 class C -- pass pass pass pass pass pass pass

Peel ASTM D1000 N/cm (pli) 15 (9) 55 (31) 79 (45) 80 (46) 80 (46) 115 (66) 50 (29) 120 (70)

Peel DIN 30 672 N/cm (pli) 8 (5) 50 (29) 70 (40) 65 (37) 65 (37) 90 (51) 35 (20) 86 (50)**

Cathodic Disbondment ASTM G8 mm rad 6 6 8 8 8 10 13 11

Water Absorption ASTM D570 % 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05

Low Temp. Flexibility ASTM D2671C °C (°F) -40 (-40) 5 (23) -20 (-4) -14 (7) -14 (7) -15 (5) -32 (-26) -28 (-18)

Sleeve

DIN Approval * DIN 30 672 class -- -- -- C30 C30 -- C50 C50

Fully Recovered T Sleeve Thickness mm (mils) 2.5 (99) 2.3 (90) -- --

Fully Recovered L Sleeve Thickness mm (mils) 3.3 (131) 2.8 (111) 3.3 (131)

* Denotes L sleeve thickness** backing elongation during peeling due to superior bond strength

How To Order:

Dimensions & Ordering Info

WLO-B 450-30 BK Bulk Roll Ordering Options

CLW-B 100-15 ZZ

Closure Seal Options

CLH-B XXX-15 BK CLS-B 100-15 ZZ

Heavy Duty Thickness (L) Regular Thickness (T)

Weldable Closure Hot Melt Closure Butyl Adhesive Closure

²Colour BK-Black, YE-Yellow ZZ-BK, WW, YE BK ZZ-BK, YE

Bulk Roll Length 15, 30 m (50, 100 ft) Bulk:15,30 m (50,100 ft) Precut: 300,450,600,900mm, (12,18,24,36”)

Sleeve / Closure Width 300, 450, 600, 900mm, (12, 18, 24, 36”) 100mm (4”) 115, 150mm (4,6”) 100mm (4”)

Bulk Roll Designation B - Bulk Roll designation B - Bulk Roll

Adhesive (thickness as supplied) 1.7 mm (65 mils)¹ 1.25 mm (50 mils)¹ W- n/a H-0.35mm (14mils) S-0.75 mm (30mils)

Backing (thickness as supplied) L - 0.9 mm (36 mils) T - 0.6 mm (25 mils) 0.65mm (27 mils) 0.6mm (32 mils) 0.8mm (32 mils)

Configuration W - Bulk Roll C - Closure Seal

1

NN has an adhesive thickness of 1.1mm (45 mils) Bulk Roll Lengths: up to 600 mm width: 30 m (100ft), above 600 mm width: 15 m (50ft)

The above represents standard ordering options Consult your Canusa representative for any unique project requirements, including pre-cut sleeves or closures.

² WTON, WLON, WTNN, WLNN are available in black only.

www.canusacps.com

Canada U.S.A./Latin America Europe/Middle East Asia/Pacific

CANUSA-CPS CANUSA-CPS CANUSA-CPS CANUSA-CPS

a division of SHAWCOR LTD. a division of SHAWCOR INC. a division of Canusa Systems Ltd. BrederoShaw (S) Pte Ltd

25 Bethridge Road 2408 Timberloch Place Unit 3, Sterling Park 101 Thomson Road

Rexdale, Ontario Building C-8 Gatwick Road #17-01/02, United Square

M9W 1M7, The Woodlands, Texas Crawley, West Sussex Singapore

Canada 77380, U.S.A. England RH10 9QT 307591

Tel: +1 (416) 743-7111 Tel: +1 (281) 367-8866 Tel: +44 (1293) 541254 Tel +65-6732-2355

Fax: +1 (416) 743-5927 Fax: +1 (281) 367-4304 Fax: +44 (1293) 541777 Fax +65-6732-9073

Canusa warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the installation guide when used in compliance with Canusa’s written instructions. Since

many installation factors are beyond our control, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities in connection therewith. Canusa’s liability is stated in

the standard terms and conditions of sale. Canusa makes no other warranty either expressed or implied. All information contained in this installation guide is to be used as a guide and is subject to change without

notice. This installation guide supersedes all previous installation guides on this product. E&OE Printed on recycled paper. Recyclable. PDS-CW-rev012

Anda mungkin juga menyukai

- Hss Installation CanusaDokumen2 halamanHss Installation Canusaresp-ectBelum ada peringkat

- 516 Vs 515Dokumen2 halaman516 Vs 515Madan YadavBelum ada peringkat

- Technology Guide 15: SSPC: The Society For Protective CoatingsDokumen16 halamanTechnology Guide 15: SSPC: The Society For Protective CoatingsIris Carmen100% (1)

- Otc 20506Dokumen12 halamanOtc 20506Rasheed YusufBelum ada peringkat

- Christmas Tree (Oil Wells)Dokumen4 halamanChristmas Tree (Oil Wells)Rachelly1Belum ada peringkat

- ET Subsea Ball ValvesDokumen9 halamanET Subsea Ball ValvesAndrew BaileyBelum ada peringkat

- GOMO Complete Document December 2022Dokumen309 halamanGOMO Complete Document December 2022Luana Marchiori100% (1)

- BR N-1594 D - Non Destructive Testing - UltrasonicDokumen20 halamanBR N-1594 D - Non Destructive Testing - UltrasonicJose Alejandro Mansutti GBelum ada peringkat

- Norsok Systems No 7Dokumen2 halamanNorsok Systems No 7ahmerkhateebBelum ada peringkat

- 02 Samss 006Dokumen17 halaman02 Samss 006inatt101Belum ada peringkat

- ASTM A-802 - Falhas de FundiçãoDokumen3 halamanASTM A-802 - Falhas de FundiçãoCristian RodeghelBelum ada peringkat

- API 651 Reading ChecklistDokumen1 halamanAPI 651 Reading ChecklistbacabacabacaBelum ada peringkat

- Astm A105Dokumen1 halamanAstm A105Isaac SamuelBelum ada peringkat

- Nawcpf Msbi NCPF 000 Me LST 31139 c01 Tie in ListDokumen5 halamanNawcpf Msbi NCPF 000 Me LST 31139 c01 Tie in ListnizardsouissiBelum ada peringkat

- Material Comparison F316L Vs F321Dokumen1 halamanMaterial Comparison F316L Vs F321Vivi OktaviantiBelum ada peringkat

- Bubble Cap FucntionDokumen4 halamanBubble Cap FucntionPujo PurwantoBelum ada peringkat

- Design Requirements of Precoat Filters For Water FiltrationDokumen445 halamanDesign Requirements of Precoat Filters For Water FiltrationYesi CeballosBelum ada peringkat

- Leak Detection InspectorDokumen41 halamanLeak Detection InspectortonBelum ada peringkat

- Catalogo Inyectores de QuimicoDokumen6 halamanCatalogo Inyectores de QuimicoOscar Mauricio Santos MBelum ada peringkat

- Public-: Rev. D E English 03 / 2014Dokumen33 halamanPublic-: Rev. D E English 03 / 2014xaviereduardoBelum ada peringkat

- Water Technology Understanding, Interpreting and UTILIZING WATER ANALYSIS DATADokumen12 halamanWater Technology Understanding, Interpreting and UTILIZING WATER ANALYSIS DATAMohamed HaboBelum ada peringkat

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDokumen2 halaman1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFrabmusukeBelum ada peringkat

- Alloy: C95800: Typical UsesDokumen2 halamanAlloy: C95800: Typical UsesJarbas MoraesBelum ada peringkat

- PLR 205Dokumen121 halamanPLR 205Meysha Almira ZainabBelum ada peringkat

- Iso 10423 - Api 6aDokumen1 halamanIso 10423 - Api 6agregkilaton0% (1)

- Norma - UL 125-2007 Standard For Valves For Anhydrous Ammonia and LP-Gas (Other Than Safety Relief)Dokumen28 halamanNorma - UL 125-2007 Standard For Valves For Anhydrous Ammonia and LP-Gas (Other Than Safety Relief)André AmaralBelum ada peringkat

- Deaerators BrochureDokumen4 halamanDeaerators BrochurefahimshkBelum ada peringkat

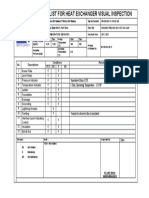

- Checklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSDokumen1 halamanChecklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSRizqiBelum ada peringkat

- Boil Out ProceduresDokumen11 halamanBoil Out ProceduresJorge DiazBelum ada peringkat

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDokumen1 halamanWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedBelum ada peringkat

- Groundbed Design With HSCI AnodesDokumen8 halamanGroundbed Design With HSCI AnodesAlexander David CarrasqueroBelum ada peringkat

- Sanicro 38 PDFDokumen4 halamanSanicro 38 PDFJose Luis Gomez Ortiz100% (1)

- Petrobras N-2409-A2Dokumen88 halamanPetrobras N-2409-A2traveller_16812847100% (4)

- Raychem e CatalogDokumen99 halamanRaychem e Catalogarifayee-1Belum ada peringkat

- Astm A 335Dokumen8 halamanAstm A 335Ruben Dario Espinoza Vasquez100% (1)

- Ni 2543Dokumen11 halamanNi 2543marguepaBelum ada peringkat

- Meg-Cgc-Pro-Lis-004-R0. Tie inDokumen2 halamanMeg-Cgc-Pro-Lis-004-R0. Tie inBrainer SanchezBelum ada peringkat

- Norma Astm e 165Dokumen20 halamanNorma Astm e 165joseBelum ada peringkat

- B467Dokumen8 halamanB467odqm_25Belum ada peringkat

- DIN en 1561 - Ferro Fundido CinzentoDokumen21 halamanDIN en 1561 - Ferro Fundido Cinzentofbotini32Belum ada peringkat

- ASTM F1545 Plastic Lined Pipe 0803Dokumen6 halamanASTM F1545 Plastic Lined Pipe 0803JabranYounasBelum ada peringkat

- Ref SA 515Dokumen5 halamanRef SA 515nachoircBelum ada peringkat

- (API 610-10th) Centrifugal Pump - SI Units PDFDokumen2 halaman(API 610-10th) Centrifugal Pump - SI Units PDFParaschiv AlexandruBelum ada peringkat

- Toyo Stainless Steel Valves PDFDokumen16 halamanToyo Stainless Steel Valves PDFvirgilius lopezBelum ada peringkat

- Of The Nuclear Safety Standards Commission (KTA)Dokumen123 halamanOf The Nuclear Safety Standards Commission (KTA)smallik3Belum ada peringkat

- Molykote® P-37 Datasheet Eng PDFDokumen2 halamanMolykote® P-37 Datasheet Eng PDFBib GmzBelum ada peringkat

- P8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Dokumen4 halamanP8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Shruti SrinivasBelum ada peringkat

- Publication - Painting, Coating & Corrosion Protection - Alfsen Og Gunderson - Dehumidifiers For The Oil and Gas ApplicationsDokumen4 halamanPublication - Painting, Coating & Corrosion Protection - Alfsen Og Gunderson - Dehumidifiers For The Oil and Gas Applicationszinha_alBelum ada peringkat

- Iso 18752 2022Dokumen11 halamanIso 18752 2022Eric ChuBelum ada peringkat

- NI 0133 (English)Dokumen112 halamanNI 0133 (English)Cebrac ItatibaBelum ada peringkat

- Wireline Cable Test ResultDokumen10 halamanWireline Cable Test Resultasponce2003Belum ada peringkat

- Pipe Wall ThicknessDokumen1 halamanPipe Wall ThicknessFurkan Burak MuhammedBelum ada peringkat

- Spec ListDokumen27 halamanSpec ListArun CPBelum ada peringkat

- ASME I Part PMB Requirements For Miniature BoilersDokumen2 halamanASME I Part PMB Requirements For Miniature BoilersAmanda Ariesta ApriliaBelum ada peringkat

- Brzina Proticanja API RP 14EDokumen4 halamanBrzina Proticanja API RP 14EMile ZoricBelum ada peringkat

- Analyse de La Performance Financière de La SAR PDFDokumen80 halamanAnalyse de La Performance Financière de La SAR PDFattiori fabriceBelum ada peringkat

- Tweco Welding Catalogue 2001Dokumen84 halamanTweco Welding Catalogue 2001Andrew Schroeder0% (1)

- High Shrink Sleeves: Product DescriptionDokumen2 halamanHigh Shrink Sleeves: Product DescriptionCristobal Leal ArandaBelum ada peringkat

- K60-Product Data Sheet PDFDokumen2 halamanK60-Product Data Sheet PDFdakidofdaboomBelum ada peringkat

- HSS Canusa PDFDokumen2 halamanHSS Canusa PDFresp-ectBelum ada peringkat

- PPL-SU-5023 Materials and Fabrication of Liquid Transportation PipelinesDokumen74 halamanPPL-SU-5023 Materials and Fabrication of Liquid Transportation PipelinesolalekanBelum ada peringkat

- Sid Su 5106 CDokumen13 halamanSid Su 5106 ColalekanBelum ada peringkat

- Wem Pu 6089 A PDFDokumen74 halamanWem Pu 6089 A PDFolalekanBelum ada peringkat

- Edu 780 Agricultural Science MethodsDokumen120 halamanEdu 780 Agricultural Science MethodsolalekanBelum ada peringkat

- Com Su 4042 IDokumen38 halamanCom Su 4042 Iolalekan100% (1)

- PPL Su 1050 O.1Dokumen56 halamanPPL Su 1050 O.1olalekanBelum ada peringkat

- HSE Trainnig SlideDokumen82 halamanHSE Trainnig SlideolalekanBelum ada peringkat

- Edu 726 Measurement and EvaluationDokumen21 halamanEdu 726 Measurement and EvaluationolalekanBelum ada peringkat

- Edu 726 Measurement and Evaluation PDFDokumen213 halamanEdu 726 Measurement and Evaluation PDFolalekan100% (1)

- Tutorial - Import Coordinates From Excel To AutoPIPE PDFDokumen23 halamanTutorial - Import Coordinates From Excel To AutoPIPE PDFolalekanBelum ada peringkat

- Tutorial - Import Coordinates From Excel To AutoPIPEDokumen1 halamanTutorial - Import Coordinates From Excel To AutoPIPEolalekanBelum ada peringkat

- Os H203 PDFDokumen33 halamanOs H203 PDFolalekanBelum ada peringkat

- SAES-H-204 - Procedure For Heat-Shrink Sleeves To Coated PipeDokumen32 halamanSAES-H-204 - Procedure For Heat-Shrink Sleeves To Coated Pipeolalekan100% (1)

- Fundamentals of S Lay and Engineering Analysis Using OFFPIPE GEP PDFDokumen98 halamanFundamentals of S Lay and Engineering Analysis Using OFFPIPE GEP PDFolalekan100% (1)

- Grid Line 100m Interval: Pipelines and Surface Facilities Between Meren 102 and Meren WipDokumen1 halamanGrid Line 100m Interval: Pipelines and Surface Facilities Between Meren 102 and Meren WipolalekanBelum ada peringkat

- Course Code EDU 712 Professionalism in TeachingDokumen73 halamanCourse Code EDU 712 Professionalism in TeachingolalekanBelum ada peringkat

- Analog Geophysical Survey of Meren Jacket 102-WIP RouteDokumen26 halamanAnalog Geophysical Survey of Meren Jacket 102-WIP RouteolalekanBelum ada peringkat

- Assignment Strategic Inventroy MGTDokumen39 halamanAssignment Strategic Inventroy MGTMuriithi MichaelsBelum ada peringkat

- Microstructure Evolution in Metal Forming Processes (2012)Dokumen2 halamanMicrostructure Evolution in Metal Forming Processes (2012)MedSparkBelum ada peringkat

- Caesar II App GuideDokumen5 halamanCaesar II App GuideVenkat RanganBelum ada peringkat

- Introduction of PavementDokumen28 halamanIntroduction of PavementFahad AreebBelum ada peringkat

- All About TextileDokumen8 halamanAll About Textilesathieswaran100% (2)

- Post-Tensioning SystemsDokumen16 halamanPost-Tensioning Systemshasib100% (1)

- ECJ 0612 OxazolidinesDokumen4 halamanECJ 0612 OxazolidinesmajidBelum ada peringkat

- 4 Retrofitting of BridgesDokumen19 halaman4 Retrofitting of BridgeskhelanparmarBelum ada peringkat

- IRB6650S 220818 DatasheetDokumen2 halamanIRB6650S 220818 DatasheetJuanjoBelum ada peringkat

- Sci PPT q3 Wk4 Day 1-5Dokumen66 halamanSci PPT q3 Wk4 Day 1-5Sarah Visperas Rogas100% (12)

- Sample MCQ - Facility Location and LayoutDokumen3 halamanSample MCQ - Facility Location and Layoutpartha sarathiBelum ada peringkat

- Epoxy Resin Admixture For Concrete PDFDokumen51 halamanEpoxy Resin Admixture For Concrete PDFStrike HardBelum ada peringkat

- Certificado ISO 17025 - San Luis PotosiDokumen3 halamanCertificado ISO 17025 - San Luis PotosiGerardo Raamiireez FüğėėnBelum ada peringkat

- Scientific Study On Tension Reel Poly Urethane Sleeve2Dokumen10 halamanScientific Study On Tension Reel Poly Urethane Sleeve2Anonymous pC7MGOBelum ada peringkat

- Lanco PP 1362 DDokumen2 halamanLanco PP 1362 DAkhtar aliBelum ada peringkat

- PC-005R3 Polymers and Additives For Paints, Coatings, and AdhesivesDokumen20 halamanPC-005R3 Polymers and Additives For Paints, Coatings, and AdhesivesDM AfteniBelum ada peringkat

- Concrete Column Design Flow ChartsDokumen10 halamanConcrete Column Design Flow Chartsayoub bahmani k100% (4)

- 1.4301 Austenite Stainless SteelDokumen3 halaman1.4301 Austenite Stainless SteelSM Waqas ImamBelum ada peringkat

- CIVE 302 - Lab 1 - Tensile Testing of Steel PDFDokumen9 halamanCIVE 302 - Lab 1 - Tensile Testing of Steel PDFAhmadAliAKbarPhambraBelum ada peringkat

- Towards A Deeper Understanding of Plastic Deformation in Mono-Crystalline SiliconDokumen12 halamanTowards A Deeper Understanding of Plastic Deformation in Mono-Crystalline Siliconmanhcuongctk39lBelum ada peringkat

- RestrepoDokumen5 halamanRestrepomasteriragaBelum ada peringkat

- Material Handling Equipment Selection: New Classifications of Equipments and AttributesDokumen9 halamanMaterial Handling Equipment Selection: New Classifications of Equipments and Attributesabdul ghoniBelum ada peringkat

- Sikawrap Method StatementDokumen17 halamanSikawrap Method StatementJet Toledo100% (1)

- Carbon TrainingDokumen42 halamanCarbon TrainingantonioBelum ada peringkat

- Griffith TheoryDokumen24 halamanGriffith TheorysarvannnBelum ada peringkat

- AluminiumDokumen112 halamanAluminiumKomal Singhal100% (1)

- Engineering ReviewDokumen52 halamanEngineering ReviewChristine Verena Sarte100% (2)

- Conventional PM Materials PDFDokumen2 halamanConventional PM Materials PDFTowkir AhmmadBelum ada peringkat

- Bizongo Packaging HandbookDokumen154 halamanBizongo Packaging Handbookmukulazad1988Belum ada peringkat

- Chapter 13 Alibanto SherwinDokumen17 halamanChapter 13 Alibanto SherwinMhekylha's AñepoBelum ada peringkat