Annex 7-2 Deviation List

Diunggah oleh

abdullah amanullahDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Annex 7-2 Deviation List

Diunggah oleh

abdullah amanullahHak Cipta:

Format Tersedia

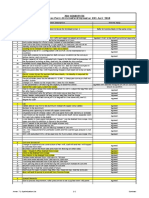

Technical Deviation List

No Ref. Tender Doc Description Conclusion-Agreed by both Parties

5.13 SAMPLING FACILITIES All

automatic sampling stations should be combined

SECTION – 5(SCHEDULE

with a sample Sampling collecting is automatic, but sample

1 OF REQUIREMENT

receiving pot and electrical control to obtain delivery is manual.

(MECHANICAL))

random or composite

samples at variable time intervals.

ANNEXURE –

5A(GENERAL slide gates below hoppers / silo shall be Most of the slide gates below hoppers / silo is

2

SPECIFICATIONS FOR motorized and provided manual.

AUXILIARY EQUIPMENT) with hand wheel with chain.

ANNEXURE –

All the belts can satisfy Max. 1.2m/sec except the

5A(GENERAL 2.0 BELT CONVEYOR

3 capacity 2000tph belt connectting with belts from

SPECIFICATIONS FOR No.2 Belt speed Max. 1.2m / sec.

mines. Its speed is 1.6m/sec.

AUXILIARY EQUIPMENT)

Screw conveyor will not match hanger bearings. But

ANNEXURE – 8.0 SCREW CONVEYOR Max.

the max. length will be decided by equipment

5A(GENERAL length should be 6m. Screw conveyor with

4 supplier. Because in some layout the length of

SPECIFICATIONS FOR hanger bearings

screw conveyor may exceed 6m without hanger

AUXILIARY EQUIPMENT) are not acceptable.

bearings.

ANNEXURE –

5A(GENERAL 16.0 CRANES / HOIST The

5 Follow the crane list provided by JSW.

SPECIFICATIONS FOR capacity should not be less than 5 MT.

AUXILIARY EQUIPMENT)

SECTION –

7(TECHNICAL 7.6 ESTIMATED CAPACITY OF MAIN

Limestone pre-blending stockpiles (Covered) 2x

6 SPECIFICATION FOR MACHINERY AND STORAGES Limestone pre-

36,000 MT

MECHANICAL blending stockpiles (Covered) 2 x 38,000 MT

EQUIPMENTS)

Clinker bulk loading set beneath the clinker silo is

SECTION –

7.7.11 Clinker Extraction and Bulk Loading not suitable. First the clinker silo will be very high.

7(TECHNICAL

Clinker shall be extracted from beneath the Secondly de-dusting beneath the clinker silo cannot

7 SPECIFICATION FOR

Clinker Silo and loaded in the Trucks of 80 MT be achieved. So we consider clinker extraction from

MECHANICAL

carrying Capacity. bottom through set of DPC to fill two Bins of 300 MT

EQUIPMENTS)

each.Bulk loading spouts with weigh bridges -9 Nos.

1.1 Mechanical Necessary

Control Damper for controlling the flow of waste

ANNEXURE –

hot gases to WHR Shut off Dampers (having 100% sealing) for Pre-

10A(SCOPE OF SUPPLY

8 Boilers. Shut heater and Cooler waste hot gas tapping points are

OF PLANT &

off Dampers (having 100% sealing) for Pre- all WHR's scope.

EQUIPMENT)

heater and Cooler waste hot

gas tapping points.

1.1 Engineering Tapping

Locations for taking waste heat from Pre-heater

and Cooler Mid Tap for generation of power

ANNEXURE – through WHR System. The tapping locations Only Control Damper in pre-heater downcomer duct

9 10B(SCOPE OF must be designed to provide the highest , cooler and tap duct to be considered. Shutt-off

SERVICESS) available waste heat to the WHR. Necessary dampers to be excluded from Sinoma scope.

Control and Shut off Dampers (with

100% sealing) shall be also provided by the

Bidder.

32) Cranes / Monorail / Electric Hoist shall be

List of Common Points provided for maintenance of all equipments.

10 Follow the crane list provided by JSW.

21.02.2018 (R2).docx Envisaged list of Electric Hoist / Cranes /

Monorail is attached herewith as Annexure-A.

4) 111BS10: Accuracy of Belt Weigher should be

List of Points Discussed +/-0.5% instead of +/-1%. After check and confirm with supplier, the accuracy

11

with Sinoma.DOC of belt weigher only can reach +/-2%.

7) The belt Conveyor 613BC31 should be Belt Conveyor 613BC31 cannot be reversible. It is a

List of Points Discussed

12 reversible. long and declining belt. The calibration can use the

with Sinoma.DOC

divert vavle 613MW35 completely.

The landscape

Only landscapping work is out of scope of

13 engineering design and

contractor.

construction.

Annex 7-2 Deviation List 1/3 Contract

No Ref. Tender Doc Description Conclusion-Agreed by both Parties

Vehicles, wheel loader and

14 other transport vehicles Out of the scope of the contractor

and equipment.

Roads and other

Out of the scope of the contractor,except the work

15 engineerings outside of

of belt conveyor from mines to plant.

the plant boundary.

The flood-proofing outside

16 Out of scope except the through rain gutter.

the site.

JSW Cement FZE Tender part- 6.0 FIXED CARBON DIOXIDE Portable CO2 Fire extinguishers will be considered

2 of 3 An automatic installation of fire detection and for Main sub-stations and electrical rooms. Fire

17 ANNEXURE-5E GENERAL protection by fixed carbon dioxide shall be detection and alarm system is separately covered in

SPECIFICATION FOR FIRE foreseen in the Main sub-stations and electrical Electrical and Instrumentation Section. But it must

FIGHTING rooms. comply with local government safety regulation.

JSW Cement FZE Tender part- 7.7.12 Utilities and Balance of Plant

2 of 3

Fire Fighting System:

18 SECTION-7 TECHNICAL Fire engine(fire truck) will be out of scope

SPECIFICATION FOR

Fire Station with one Fire Tender shall be also

MECHANICAL EQUIPMENTS considered.

Annexure-8.1A(Design 2. GENERAL SITE CONDITIONS All

19 Slip-ring HV motors will be of Protection Class IP54

Criteria & Scope of Work) Motors : IP 55

3. BASIS OF DESIGN e

Lighting, plugs sockets : 220V, 1 Ph + E + N , 50

Lighting, plugs sockets : 230V, 1 Ph + E + N , 50

Hz

20 Hz Maintenance lighting

Maintenance lighting supply : 24 V from portable 2

supply : 24 V from portable 2 KVA transformers

KVA transformers 220/24V

230/24V

3. BASIS OF DESIGN Allowed

voltage drop: The voltage drop of the main

feeder lines from central MV switchboard to the

following maximum voltage drop limits:

departmental load centers shall not exceed 2%.

21 The total allowable voltage drop from the load

center substation to any load shall not exceed

3% for power and lighting circuits.

During the starting of the motors, the allowable

voltage drop shall not exceed 10%.

22 3.2.10 Tapping : ±7.5 % in steps of 2.5 % ±5 % in steps of 2.5 %

4.3 Bus Ducting

The copper cable will be used for interconnection

23 The bus ducting will be used for interconnection

between transformer and incomer

between transformer and incomer

For powers<400 kW, the voltage will be 380V, 6

pulse type.

8.1 Technical requirements of motors For

For 400kW ≤powers ≤ 800 kW, the voltage will be

variable speed motors Up to 300 KW -380V, 6

24 690V, 12pulse type.

pulse drive >300 KW to 800 KW – 690V, 12

For 800kW <powers, the voltage will be

pulse drive >800 KW –11KV, 36-pulse drive

11kV,,36pulse type .

10.0 LT Power Cables 01

25

Voltage : 1.1 kV

9.0 11 KV HT Power Cables 01

26 Rated voltage: 12kV (IEC60502)

Voltage : 11 kV + 10%

11.0 Control & Instrumentation Cables 01

27 Rated voltage: 450V/750V (IEC60245-4)

Voltage Grade : 1100 V

1.) Plant C&I System CI

System 3.1.3

Annexure-8.2B(Control &

28 Functional Aspects Digital Input / 24 VDC is appropriate

Automation System)

Output Modules a) Digital input shall

accept 220 VAC potential free signals

Change the MV cabinet for WHR to spare, the main

29 Null Null receiving MV cabinet will be for CPP+WHR with one

cable feeding loop.

Annex 7-2 Deviation List 2/3 Contract

No Ref. Tender Doc Description Conclusion-Agreed by both Parties

For power cables, SINOMA can use 2.5mm2 and

30 Null Null

4mm2 copper and aluminum above 6mm2.

For power/control/instrument cables, SINOMA will

31 Null Null supply armoured type, For communication cables,

SINOMA will supply unarmoured type.

32 Null Null Level detector for silos shall be Radar type only

Motor fed and controlled MCC rating equal or

33 Null Null greater 55KW will be provided with Profibus DP to

DCS.

Load break switches near the motors without local

sub control cabinet shall be considered to meet

34 Null Null

local regulations. Local PB station may be

combined with load break switch

The transformer capacity will be from 800 to

2500kVA and max 3 types except transformers for

35 Null Null OLBC and VFD.

The capacity will be detemined during detail design

following less than 70% load after compensation.

All PCCs are connected to the secondary side of

power distribution transformer. MCCs for each

process section including frequency converters(<

90kW) are fed by PCCs and soft starters and

36 Null Null frequency converters(≥90kW) are connected to

PCCs busbar directly.

MCC will be of with drawable design up to 75kW

and above 75kW will be fixed type and connected to

PCCs busbar directly,

Motor current should be displayed on the MCC front

37 Null Null

panel for motor equal to and above 55kW.

Cyclone 5 (Precalciner) outlet and Kiln inlet for O2,

CO NOx and SOx analysis;

38 Null Null

Preheater outlet for O2, CO analysis;

Fine coal bins for CO analysis;

Annex 7-2 Deviation List 3/3 Contract

Anda mungkin juga menyukai

- Bridge Technology ReportDari EverandBridge Technology ReportBelum ada peringkat

- Tabel Berat Besi IIDokumen4 halamanTabel Berat Besi IIHermawan Septian Adittya100% (1)

- Procedure Erection Rev.1 PDFDokumen25 halamanProcedure Erection Rev.1 PDFFadhil J AhmadBelum ada peringkat

- MizuDokumen1 halamanMizuPrima Fitra SaputraBelum ada peringkat

- Work Method of Sandwich Panel Halim StationDokumen84 halamanWork Method of Sandwich Panel Halim Stationirvan udin utomoBelum ada peringkat

- Comfort A I Re Brochure 10610Dokumen14 halamanComfort A I Re Brochure 10610averentzBelum ada peringkat

- Brosur Pt. Srirejeki Perdana Steel-1Dokumen16 halamanBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahBelum ada peringkat

- Lokfix E75 TDS 8072020Dokumen5 halamanLokfix E75 TDS 8072020KumarRamBelum ada peringkat

- Zinc Rich Cold Galvanizing (UZZIEL 215) : Product DescriptionDokumen1 halamanZinc Rich Cold Galvanizing (UZZIEL 215) : Product DescriptionImam SitumeangBelum ada peringkat

- Fabricate and Install Fencing: Standard Operating ProcedureDokumen5 halamanFabricate and Install Fencing: Standard Operating ProceduremahandhieBelum ada peringkat

- Work Method of Mezzanine-1 Extension Rev.01Dokumen14 halamanWork Method of Mezzanine-1 Extension Rev.01NiamDe'Belum ada peringkat

- Geomembrane HDPE Smooth Black PDFDokumen1 halamanGeomembrane HDPE Smooth Black PDFandriarisetiawan0% (1)

- CMP0000599 - PC - Katalog Bevananda PDFDokumen8 halamanCMP0000599 - PC - Katalog Bevananda PDFRieskeIswardhanyBelum ada peringkat

- Form Inspeksi PondasiDokumen15 halamanForm Inspeksi Pondasieka mantiBelum ada peringkat

- Metode Kerja FireproofingDokumen7 halamanMetode Kerja Fireproofingarrojak maksumBelum ada peringkat

- Lampiran 3. WPS of Pile JointDokumen3 halamanLampiran 3. WPS of Pile JointDoni TriatmojoBelum ada peringkat

- 1 Gala Bronze Y-Strainer Fig 7654 SMDokumen1 halaman1 Gala Bronze Y-Strainer Fig 7654 SMNon Etabas Gadnatam100% (1)

- Uraian Analisa Harga SatuanDokumen6 halamanUraian Analisa Harga Satuandwi istBelum ada peringkat

- EmbankmentDokumen5 halamanEmbankmentAmila Priyadarshana Dissanayake100% (1)

- Patchroc RSPDokumen46 halamanPatchroc RSPvietpineBelum ada peringkat

- Door Bostinco PDFDokumen3 halamanDoor Bostinco PDFBobby Underscore Tangger0% (1)

- Additional Works BoQ - Aspex Kumbong 300421Dokumen16 halamanAdditional Works BoQ - Aspex Kumbong 300421My pouBelum ada peringkat

- NDT For Steel Pipe PilingDokumen2 halamanNDT For Steel Pipe PilingSaid Alauddeen FaiszBelum ada peringkat

- Katalog TSP PT PDFDokumen24 halamanKatalog TSP PT PDFdeniBelum ada peringkat

- FCA Foam ChamberDokumen5 halamanFCA Foam ChamberN AfiyahBelum ada peringkat

- Company Profile Intra 091020Dokumen7 halamanCompany Profile Intra 091020Catur Pribadi100% (1)

- Harga Sand Blasting PDFDokumen9 halamanHarga Sand Blasting PDFYU D HI100% (1)

- Gondola Load CalculationsDokumen6 halamanGondola Load Calculationssaskia0% (1)

- Brosur PerancahDokumen64 halamanBrosur PerancahandreasBelum ada peringkat

- TWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodDokumen11 halamanTWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodBangkit SamosirBelum ada peringkat

- Methods of Repairing CracksDokumen21 halamanMethods of Repairing CracksAlfar Amal100% (2)

- Afco - CV01 Series - Swing Check ValveDokumen4 halamanAfco - CV01 Series - Swing Check Valveafie pio pioBelum ada peringkat

- Site Inspection and Test Plan (ITP) For Instrument Ite I N S P Ec Tion A N D T e S T P Lan (I T P) F O R P A N e LsDokumen33 halamanSite Inspection and Test Plan (ITP) For Instrument Ite I N S P Ec Tion A N D T e S T P Lan (I T P) F O R P A N e LsGhazi LuthfiBelum ada peringkat

- Tensile Pull Out Test by HILTIDokumen1 halamanTensile Pull Out Test by HILTIDwiagus Saputra100% (1)

- KDK Exhaust FanDokumen6 halamanKDK Exhaust FanATMANEGARA TV100% (1)

- Grouting Format Report (Electrical Panel)Dokumen1 halamanGrouting Format Report (Electrical Panel)Anas PratamaBelum ada peringkat

- CP PT TTI (Jan 2018) New PDFDokumen38 halamanCP PT TTI (Jan 2018) New PDFHaryadiBelum ada peringkat

- SWC Methode Angkur Revisi Dari KEDokumen14 halamanSWC Methode Angkur Revisi Dari KERandy SetiawanBelum ada peringkat

- Request For Inspection Rebar On SiteDokumen4 halamanRequest For Inspection Rebar On Siteiwan100% (1)

- Method Statement Sound Insulation RevDokumen9 halamanMethod Statement Sound Insulation RevArland AsraBelum ada peringkat

- Besi Kotak Pipa Hollow Square Tubes Rectangular Beyond Steel 2Dokumen4 halamanBesi Kotak Pipa Hollow Square Tubes Rectangular Beyond Steel 2didiBelum ada peringkat

- Project Apartemen The Padmayana: Solution For Control, Mecanical, Electrical, Plumbing & HvacDokumen22 halamanProject Apartemen The Padmayana: Solution For Control, Mecanical, Electrical, Plumbing & HvacLiku Lituhayu100% (1)

- ITP Mini Pile PDFDokumen2 halamanITP Mini Pile PDFscriptd_ozd3nBelum ada peringkat

- Model Potongan Counterfort Retaining WallDokumen1 halamanModel Potongan Counterfort Retaining WallStefano ManurungBelum ada peringkat

- Nitoproof 280 Method StatementDokumen3 halamanNitoproof 280 Method StatementBramandito DamarBelum ada peringkat

- ETERSET 2960 Data SheetDokumen2 halamanETERSET 2960 Data Sheetahmed mahmoudBelum ada peringkat

- ZR102D STC 38 Steel Single Fire Door Theater PDFDokumen1 halamanZR102D STC 38 Steel Single Fire Door Theater PDFOkta RizalBelum ada peringkat

- Project Reference Catalogue TOTODokumen36 halamanProject Reference Catalogue TOTOnovalferdyanBelum ada peringkat

- Astm A325-04 STD Specs For Structural Bolts, Steel, Heat TreDokumen8 halamanAstm A325-04 STD Specs For Structural Bolts, Steel, Heat TreCharwin Picao100% (1)

- Kabel MetalDokumen2 halamanKabel Metalsri haryadiBelum ada peringkat

- Wiremesh InstallationDokumen3 halamanWiremesh InstallationFitriansyah Adi Putra IrwanBelum ada peringkat

- AB Wool Glasswool PDFDokumen2 halamanAB Wool Glasswool PDFAmin Danar NoviyantoBelum ada peringkat

- Karmand K - 404 CGDokumen5 halamanKarmand K - 404 CGNokus itsmeBelum ada peringkat

- Welding Material Control ProcedureDokumen12 halamanWelding Material Control ProcedureWalter RuedaBelum ada peringkat

- Quality Products: Here Are The Products FeaturedDokumen3 halamanQuality Products: Here Are The Products FeaturedMoh YadhiBelum ada peringkat

- Underground Installation of Thermoplastic Pipe For Sewers and Other Gravity-Flow ApplicationsDokumen10 halamanUnderground Installation of Thermoplastic Pipe For Sewers and Other Gravity-Flow ApplicationsDavid SolisBelum ada peringkat

- GeoDokumen5 halamanGeoRizal AdyBelum ada peringkat

- POWERGRID Tech Spec For 765kV Reactor Rev 06Dokumen70 halamanPOWERGRID Tech Spec For 765kV Reactor Rev 06sitam_nitj4202Belum ada peringkat

- 06b AppendixB2 (1000HPRig) 1582535891879Dokumen103 halaman06b AppendixB2 (1000HPRig) 1582535891879Harsh TiwariBelum ada peringkat

- Power Point ConveyorDokumen16 halamanPower Point ConveyorJaytitusprabhu PrabhuBelum ada peringkat

- Nonmetal Ducts - Guide Specification - Updated 6-2019Dokumen17 halamanNonmetal Ducts - Guide Specification - Updated 6-2019abdullah amanullahBelum ada peringkat

- Aurora Fire PumpDokumen8 halamanAurora Fire Pumpabdullah amanullahBelum ada peringkat

- Mohamed Anas.S: Job ObjectiveDokumen3 halamanMohamed Anas.S: Job Objectiveabdullah amanullahBelum ada peringkat

- Sabb-Gray Water WsfuDokumen22 halamanSabb-Gray Water Wsfuabdullah amanullahBelum ada peringkat

- CR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016Dokumen5 halamanCR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016abdullah amanullahBelum ada peringkat

- New Indian Model School, Sharjah: Islamic Holidays' Assignment Primary SectionDokumen1 halamanNew Indian Model School, Sharjah: Islamic Holidays' Assignment Primary Sectionabdullah amanullahBelum ada peringkat

- Science Summer Break - Holiday Assignment 2019 - 20Dokumen2 halamanScience Summer Break - Holiday Assignment 2019 - 20abdullah amanullahBelum ada peringkat

- L-4 Environment NotesDokumen2 halamanL-4 Environment Notesabdullah amanullahBelum ada peringkat

- English Summer Break - Holiday Assignment 2019 - 20Dokumen2 halamanEnglish Summer Break - Holiday Assignment 2019 - 20abdullah amanullahBelum ada peringkat

- Tamil (Second Language) Summer Break - Holiday Assignment 2019 - 20Dokumen2 halamanTamil (Second Language) Summer Break - Holiday Assignment 2019 - 20abdullah amanullahBelum ada peringkat

- New Indian Model School, Sharjah: Holiday Homework Hindi - Grade 3Dokumen3 halamanNew Indian Model School, Sharjah: Holiday Homework Hindi - Grade 3abdullah amanullahBelum ada peringkat

- 15730-DX Cooling Units Rev 01Dokumen10 halaman15730-DX Cooling Units Rev 01abdullah amanullahBelum ada peringkat

- Uae Social Studies Summer Break - Holiday Assignment 2019 - 20Dokumen2 halamanUae Social Studies Summer Break - Holiday Assignment 2019 - 20abdullah amanullahBelum ada peringkat

- Revision SSTDokumen2 halamanRevision SSTabdullah amanullahBelum ada peringkat

- PT2 Revision Worksheet EnglishDokumen3 halamanPT2 Revision Worksheet Englishabdullah amanullahBelum ada peringkat

- Worksheet - WaterDokumen2 halamanWorksheet - Waterabdullah amanullah100% (2)

- Sub Enrichment - Gr-3 - Our BodyDokumen2 halamanSub Enrichment - Gr-3 - Our Bodyabdullah amanullahBelum ada peringkat

- Automatedmeterreadingtechnology PDFDokumen5 halamanAutomatedmeterreadingtechnology PDFabdullah amanullahBelum ada peringkat

- AD R 004 Acoustic ReportDokumen43 halamanAD R 004 Acoustic Reportabdullah amanullahBelum ada peringkat

- 0.list of Drawing - Lower LevelDokumen1 halaman0.list of Drawing - Lower Levelabdullah amanullahBelum ada peringkat

- Technical Review Report: Applicant InformationDokumen3 halamanTechnical Review Report: Applicant Informationabdullah amanullahBelum ada peringkat

- Annex 13 Exclusion ListDokumen1 halamanAnnex 13 Exclusion Listabdullah amanullahBelum ada peringkat

- A) Condition Unable To Understand Something: IV Match The MeaningsDokumen2 halamanA) Condition Unable To Understand Something: IV Match The Meaningsabdullah amanullahBelum ada peringkat

- New Indian Model School, SharjahDokumen2 halamanNew Indian Model School, Sharjahabdullah amanullahBelum ada peringkat

- Infrastructure Charges Notice CalculatorDokumen1 halamanInfrastructure Charges Notice Calculatorabdullah amanullahBelum ada peringkat

- Annex 11 List of Spare Parts For 2 Year OperationDokumen16 halamanAnnex 11 List of Spare Parts For 2 Year Operationabdullah amanullahBelum ada peringkat

- 1 Extra External Piping Going To Each Lab MTR 250 100 25000.00 2 Extra Point For Kitchen MTR 50 20 1000Dokumen5 halaman1 Extra External Piping Going To Each Lab MTR 250 100 25000.00 2 Extra Point For Kitchen MTR 50 20 1000abdullah amanullahBelum ada peringkat

- 10.final Master Plan ParadipDokumen128 halaman10.final Master Plan Paradipabdullah amanullahBelum ada peringkat

- Deliverable SDokumen2 halamanDeliverable Sabdullah amanullahBelum ada peringkat

- Annex 7.1 Optimization ListDokumen5 halamanAnnex 7.1 Optimization Listabdullah amanullahBelum ada peringkat

- Grade 8 Science - Second GradingDokumen5 halamanGrade 8 Science - Second GradingMykelCañete0% (1)

- PDFDokumen3 halamanPDFAhmedraza123 NagdaBelum ada peringkat

- PD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsDokumen20 halamanPD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsHazel Jael HernandezBelum ada peringkat

- SP-Chapter 14 PresentationDokumen83 halamanSP-Chapter 14 PresentationLoiDa FloresBelum ada peringkat

- CH-5 Further Percentages AnswersDokumen5 halamanCH-5 Further Percentages AnswersMaram MohanBelum ada peringkat

- Bcom (HNRS) Project Final Year University of Calcutta (2018)Dokumen50 halamanBcom (HNRS) Project Final Year University of Calcutta (2018)Balaji100% (1)

- ADokumen54 halamanActyvteBelum ada peringkat

- Day6 7Dokumen11 halamanDay6 7Abu Al-FarouqBelum ada peringkat

- Financial Market - Bsa 2A Dr. Ben E. Bunyi: Imus Institute of Science and TechnologyDokumen3 halamanFinancial Market - Bsa 2A Dr. Ben E. Bunyi: Imus Institute of Science and TechnologyAsh imoBelum ada peringkat

- Been There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerDokumen8 halamanBeen There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerNanis DimmitrisBelum ada peringkat

- Grade 7 Nap MayDokumen6 halamanGrade 7 Nap Mayesivaks2000Belum ada peringkat

- 2nd Term Project 4º Eso Beauty Canons 2015-16 DefinitivoDokumen2 halaman2nd Term Project 4º Eso Beauty Canons 2015-16 DefinitivopasferacosBelum ada peringkat

- Traditional Perceptions and Treatment of Mental Illness in EthiopiaDokumen7 halamanTraditional Perceptions and Treatment of Mental Illness in EthiopiaifriqiyahBelum ada peringkat

- The Rise of Australian NovelDokumen412 halamanThe Rise of Australian NovelSampath Kumar GummadiBelum ada peringkat

- Sample REVISION QUESTION BANK. ACCA Paper F5 PERFORMANCE MANAGEMENTDokumen43 halamanSample REVISION QUESTION BANK. ACCA Paper F5 PERFORMANCE MANAGEMENTAbayneh Assefa75% (4)

- Vitamins - CyanocobalaminDokumen12 halamanVitamins - CyanocobalaminK PrashasthaBelum ada peringkat

- Dutch Iris Eng 9734 HappyPattyCrochetDokumen68 halamanDutch Iris Eng 9734 HappyPattyCrochetFrancisca Rico100% (6)

- Caterpillar Cat C7 Marine Engine Parts Catalogue ManualDokumen21 halamanCaterpillar Cat C7 Marine Engine Parts Catalogue ManualkfsmmeBelum ada peringkat

- COK - Training PlanDokumen22 halamanCOK - Training PlanralphBelum ada peringkat

- SW OSDokumen11 halamanSW OSErnest OfosuBelum ada peringkat

- Session 1Dokumen18 halamanSession 1Akash GuptaBelum ada peringkat

- Conducting Focus GroupsDokumen4 halamanConducting Focus GroupsOxfam100% (1)

- G2 Rust Grades USA PDFDokumen2 halamanG2 Rust Grades USA PDFSt3fandragos4306Belum ada peringkat

- Data MiningDokumen28 halamanData MiningGURUPADA PATIBelum ada peringkat

- D25KS Sanvick PDFDokumen4 halamanD25KS Sanvick PDFJiménez Manuel100% (1)

- Chapter 1 - Main Hydrological ConceptsDokumen16 halamanChapter 1 - Main Hydrological ConceptsWhy Merah0% (1)

- Quality Control of Rigid Pavements 1Dokumen58 halamanQuality Control of Rigid Pavements 1pranjpatil100% (1)

- Ultra ConductorsDokumen28 halamanUltra ConductorsAnu Kp50% (8)

- Lodge at The Ancient City Information Kit / Great ZimbabweDokumen37 halamanLodge at The Ancient City Information Kit / Great ZimbabwecitysolutionsBelum ada peringkat

- Universitas Tidar: Fakultas Keguruan Dan Ilmu PendidikanDokumen7 halamanUniversitas Tidar: Fakultas Keguruan Dan Ilmu PendidikanTheresia Calcutaa WilBelum ada peringkat