Pip 686a

Diunggah oleh

saminasritnJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pip 686a

Diunggah oleh

saminasritnHak Cipta:

Format Tersedia

March 2012

Process Industry Practices

Machinery

--`,,```,,,,````-`-`,,`,,`,`,,`---

PIP REIE686A

Recommended Practice for

Machinery Installation and Installation Design

(Supplement to PIP REIE686/API RP686)

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

PURPOSE AND USE OF PROCESS INDUSTRY PRACTICES

In an effort to minimize the cost of process industry facilities, this Practice has

been prepared from the technical requirements in the existing standards of major

industrial users, contractors, or standards organizations. By harmonizing these technical

requirements into a single set of Practices, administrative, application, and engineering

costs to both the purchaser and the manufacturer should be reduced. While this Practice

is expected to incorporate the majority of requirements of most users, individual

applications may involve requirements that will be appended to and take precedence

over this Practice. Determinations concerning fitness for purpose and particular matters

or application of the Practice to particular project or engineering situations should not

be made solely on information contained in these materials. The use of trade names

from time to time should not be viewed as an expression of preference but rather

recognized as normal usage in the trade. Other brands having the same specifications

are equally correct and may be substituted for those named. All Practices or guidelines

are intended to be consistent with applicable laws and regulations including OSHA

requirements. To the extent these Practices or guidelines should conflict with OSHA or

other applicable laws or regulations, such laws or regulations must be followed.

Consult an appropriate professional before applying or acting on any material

contained in or suggested by the Practice.

This Practice is subject to revision at any time.

© Process Industry Practices (PIP), Construction Industry Institute, The University of

Texas at Austin, 3925 West Braker Lane (R4500), Austin, Texas 78759. PIP Member

Companies and Subscribers may copy this Practice for their internal use. Changes or

modifications of any kind are not permitted within any PIP Practice without the express

written authorization of PIP. Authorized Users may attach addenda or overlays to clearly

indicate modifications or exceptions to specific sections of PIP Practices. Authorized

Users may provide their clients, suppliers and contractors with copies of the Practice

solely for Authorized Users’ purposes. These purposes include but are not limited to the

procurement process (e.g., as attachments to requests for quotation/ purchase orders or

requests for proposals/contracts) and preparation and issue of design engineering

deliverables for use on a specific project by Authorized User’s client. PIP’s copyright

notices must be clearly indicated and unequivocally incorporated in documents where an

Authorized User desires to provide any third party with copies of the Practice.

PUBLISHING HISTORY

March 2012 Issued

Not printed with State funds

--`,,```,,,,````-`-`,,`,,`,`,,`---

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

March 2012

Process Industry Practices

Machinery

PIP REIE686A

Recommended Practice for

Machinery Installation and Installation Design

(Supplement to PIP REIE686/API RP686)

Table of Contents

Introduction .......................................... 2 Chapter 6 - Piping ................................ 9

Purpose ......................................................... 2 2 Machinery Piping Installation

Scope ........................................................... 2 Design ................................................ 9

2.2 Addition. Accessibility for

References ........................................... 2 Operation and Maintenance .............. 9

Requirements ....................................... 2 2.4 Supports .......................................... 10

2.5 Provision for Field Welds ................. 11

Chapter 4 - Foundations ...................... 3 2.10 Modification. Vents, Drains, and

3 Definitions .......................................... 3 Gauge Connections ......................... 11

4 General Design Requirements .......... 3 2.13 Piping Systems in Pulsating

6 Rectangular Block Foundation Service ............................................. 11

Design ................................................ 3 3 Machinery Specific Piping

11 Anchor Bolt and Reinforcing Steel Installation Design ........................... 11

Design ................................................ 3 3.1 Pumps.............................................. 11

Annex B - Typical Foundation and Anchor 3.1.1 General Requirements .................... 11

Bolt Details ......................................... 4 3.1.2 Pump Suction Piping ....................... 17

3.1.3 Modification. Pump Minimum Flow

Chapter 5 - Mounting Plate Grouting . 7 Bypass/Recycle ............................... 17

2 Machinery Grouting Installation 3.1.6 Addition. Self-Priming Pumps .......... 18

Design Requirements ........................ 7 3.2 Compressors and Blowers .............. 29

2.4 Selection of Grout .............................. 7 4 Machinery Piping Installation ........... 29

2.6 Mounting Plate Design ...................... 7 4.2 Field Installation of Auxiliaries ......... 29

3 Machinery Grouting Installation 4.11 Miscellaneous Requirements .......... 29

Requirements .................................... 7

3.10 Direct Grouted Reciprocating Chapter 7 - Shaft Alignment ............. 29

Compressors ..................................... 7

Annex H - Typical Mounting Plate Leveling

Pads ................................................... 8

Process Industry Practices --`,,```,,,,````-`-`,,`,,`,`,,`---

Page 1 of 29

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

PIP REIE686A

Recommended Practice for Machinery Installation and Installation Design March 2012

(Supplement to PIP REIE686/API RP686)

Introduction

Purpose

This Practice supplements PIP REIE686/API RP686, Recommended Practice for Machinery

Installation and Installation Design. Together, this Practice and PIP REIE686/API RP686

provide requirements for installation recommended procedures, practices, and checklists for

the installation and precommissioning of new, existing, and reapplied machinery and to assist

with the installation design of such machinery.

Scope

This Practice describes additions, changes, and deletions that have been made to

PIP REIE686/API RP686. In addition, decisions that have been made regarding options

offered by PIP REIE686/API RP686 are also described.

References

Applicable parts of the following Practice and industry codes and standards shall be

considered an integral part of this Practice. The edition and addendum in effect on the date of

contract award shall be used, except as otherwise noted. Short titles are used herein where

appropriate.

Process Industry Practices (PIP)

– PIP RESP002 - Design of ASME B73.1 and General Purpose Pump Baseplates

– PIP REIE686/API RP686 - Recommended Practice for

Machinery Installation and Installation Design, Second Edition

Industry Codes and Standards

--`,,```,,,,````-`-`,,`,,`,`,,`---

Gas Machinery Research Council (GMRC)

– TR 97-2 - Foundation Guidelines

– TR 97-6 - Compressor Anchor Bolt Design

Requirements

The numbering of the headings and paragraphs in the Requirements section corresponds to

the numbering of PIP REIE686/API RP686, which this Practice revises. The type of revision

made to a specified heading or paragraph is described after the heading or paragraph

identification. Provisions of PIP REIE686/API RP686 that are not revised remain in force.

Process Industry Practices Page 2 of 29

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

PIP REIE686A

Recommended Practice for Machinery Installation and Installation Design March 2012

(Supplement to PIP REIE686/API RP686)

Chapter 4 - Foundations

3 Definitions

3.9 Addition. New definition:

dynamic analysis

Calculation of the natural frequencies of the foundation and a determination of the

response of the foundation to the forces induced by the vibration of the machinery

(e.g., amplitudes of vibration, velocities, or acceleration)

4 General Design Requirements

--`,,```,,,,````-`-`,,`,,`,`,,`---

4.2 NOTE Canned motor pumps do not require a foundation block. These pumps do not

have a coupling that requires alignment. Horizontal canned motor pumps should be

mounted on a stilt mounted baseplate in accordance with PIP RESP002, Figure 4.

Vertical canned motor pumps should be installed on a level surface. Pipe fit up

requirements are the same as pumps with couplings.

6 Rectangular Block Foundation Design

6.6 Modification. To read as follows:

The top of the finished foundation shall be elevated above the finished elevation of

the floor slab or grade to a height that can prevent damage to machinery from a

50-year flood or 20 cm (8 inches), whichever is greater. Other local environmental

factors may dictate other top of concrete criteria such as water spouts. Insurance data

may be beneficial for determining these criteria.

11 Anchor Bolt and Reinforcing Steel Design

11.6 Addition. Supplement as follows:

For reciprocating compressors, anchor bolt embedment lengths should be a minimum

of 1.2 meters (48 inches) and of varying lengths to form a sine wave for stress

distribution. See Figure B-5.

11.6 Addition. New note:

NOTE Industry experience shows an anchor bolt embedment depth of 20 diameters

to a fully engaged nut improves resistance to cracking the foundation block. See

GMRC Technical Reports TR 97-6 and TR 97-2.

11.11 Addition. New section:

For reciprocating compressors, anchor bolt termination plates should have an outside

diameter of 3 to 4 bolt diameters, and should be 1.5 bolt diameters thick. Grout

thickness of the final pour should not be greater than 11.5 cm (4.5 inches). Leveling

pours may be thicker.

Process Industry Practices Page 3 of 29

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

PIP REIE686A

Recommended Practice for Machinery Installation and Installation Design March 2012

(Supplement to PIP REIE686/API RP686)

Annex B - Typical Foundation and Anchor Bolt Details

Figure B.1 Modification. Modified to include dimension ED and change D Depth

above grade with H Height above grade. Replace with the following figure:

--`,,```,,,,````-`-`,,`,,`,`,,`---

Figure B.1 — Typical Rectangular Block Foundation Detail

Process Industry Practices Page 4 of 29

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

PIP REIE686A

Recommended Practice for Machinery Installation and Installation Design March 2012

(Supplement to PIP REIE686/API RP686)

Figure B.2 Modification. Modified to include a case drain, and show the grout half

way up the baseplate. Replace with the following figure:

--`,,```,,,,````-`-`,,`,,`,`,,`---

Figure B.2 — Typical Vertically Suspended Can Pump Foundation

Process Industry Practices Page 5 of 29

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

PIP REIE686A

Recommended Practice for Machinery Installation and Installation Design March 2012

(Supplement to PIP REIE686/API RP686)

Figure B.3 Modification. Modified to include dimension BD, and wrap/coat of anchor

bolt with bond breaker. Replace with the following figure:

--`,,```,,,,````-`-`,,`,,`,`,,`---

Figure B.3 — Typical Anchor Bolt Detail — Option 1, Grout Pour Not to Edge of Foundation

Process Industry Practices Page 6 of 29

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

Anda mungkin juga menyukai

- Pip Vefta100 10 PDFDokumen32 halamanPip Vefta100 10 PDFhasan noahBelum ada peringkat

- Pip STS03001Dokumen6 halamanPip STS03001Omisawant100% (1)

- PIP STS03001 (Plain & Reinforced Concrete Specification)Dokumen15 halamanPIP STS03001 (Plain & Reinforced Concrete Specification)mobin1978Belum ada peringkat

- PIP STC01015 Structural Design CriteriaDokumen32 halamanPIP STC01015 Structural Design CriteriaRamesh Ram Hingoranee100% (8)

- CVC 01015Dokumen15 halamanCVC 01015VishalBelum ada peringkat

- Pip Ste03350 2008 PDFDokumen33 halamanPip Ste03350 2008 PDFNagoya Taycho0% (1)

- Cvi 02350Dokumen31 halamanCvi 02350abguyBelum ada peringkat

- Process Industry Practices Civil: PIP CVC01015 Civil Design CriteriaDokumen17 halamanProcess Industry Practices Civil: PIP CVC01015 Civil Design Criteriajakeer7Belum ada peringkat

- PIP CVS02100Site Preparation, Excavation, and Backfill SpecificationDokumen20 halamanPIP CVS02100Site Preparation, Excavation, and Backfill Specificationivanov55590% (1)

- Ste 03350Dokumen34 halamanSte 03350WBelum ada peringkat

- 000.215.1216 20aug2009Dokumen63 halaman000.215.1216 20aug2009Anonymous ya6gBBwHJFBelum ada peringkat

- Pip STF05501 Fixed Ladder and CageDokumen17 halamanPip STF05501 Fixed Ladder and CageTrầnĐạt100% (1)

- Process Industry Practices Coatings: PIP CTSE1000 Application of External CoatingsDokumen87 halamanProcess Industry Practices Coatings: PIP CTSE1000 Application of External CoatingsSivaratnam Navatharan67% (3)

- PIP STE05121 Anchor Bolt Design GuideDokumen56 halamanPIP STE05121 Anchor Bolt Design Guidepklin8866100% (4)

- Cvs 02350Dokumen14 halamanCvs 02350WBelum ada peringkat

- PIP STE03360 Heat Exchanger and Horizontal Vessel FoundationDokumen42 halamanPIP STE03360 Heat Exchanger and Horizontal Vessel FoundationUnwanus Sa'adahBelum ada peringkat

- PIP STC01018 - 2014 - Blast Resistant Building Design CriteriaDokumen51 halamanPIP STC01018 - 2014 - Blast Resistant Building Design Criteriamirko huarancca100% (1)

- PIP STF05501 Fixed Ladders and CagesDokumen11 halamanPIP STF05501 Fixed Ladders and CagesHowo4Die86% (7)

- Pip Arc01016Dokumen12 halamanPip Arc01016Ulises CastroBelum ada peringkat

- Process Industry PracticeDokumen12 halamanProcess Industry PracticeRonald George100% (1)

- PIP STF05511 Fixed Industrial StairDokumen13 halamanPIP STF05511 Fixed Industrial StairErik Perez100% (2)

- Pip PNSM0120Dokumen6 halamanPip PNSM0120romerobernaBelum ada peringkat

- PIP CVS02830 Chain Link Fence and Gates Installation SpecificationDokumen11 halamanPIP CVS02830 Chain Link Fence and Gates Installation Specificationplmo100% (1)

- STF 05530Dokumen13 halamanSTF 05530aby_abraham5005Belum ada peringkat

- INEG1000Dokumen29 halamanINEG1000Dana Guerrero100% (1)

- PIP CVC01016 (Plant Site & Project Data Sheets-Introduction & References)Dokumen5 halamanPIP CVC01016 (Plant Site & Project Data Sheets-Introduction & References)Javad MonfaredBelum ada peringkat

- Guidelines For Tank Foundation Designs (Process Industry Practices Pip)Dokumen83 halamanGuidelines For Tank Foundation Designs (Process Industry Practices Pip)Suresh Rao100% (2)

- PIP CVE02350 Roadway Design Guide PDFDokumen53 halamanPIP CVE02350 Roadway Design Guide PDFAnonymous 7eVc6RBelum ada peringkat

- Pip PDFDokumen21 halamanPip PDFRajanji Srivastava50% (4)

- PIP STS03600 (Nonshrink Cementitous Grout Specification)Dokumen8 halamanPIP STS03600 (Nonshrink Cementitous Grout Specification)Javad Monfared100% (1)

- Pip Stf05521Dokumen16 halamanPip Stf05521joelgir32100% (5)

- Vefv1100 Vessel/S&T Heat Exchanger Standard DetailsDokumen55 halamanVefv1100 Vessel/S&T Heat Exchanger Standard Detailskmilo1978Belum ada peringkat

- Process Industry Practices Structural: PIP STE05530 Grating Design GuideDokumen10 halamanProcess Industry Practices Structural: PIP STE05530 Grating Design GuideLumy NastaseBelum ada peringkat

- Process Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideDokumen55 halamanProcess Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuidemithileshBelum ada peringkat

- PIP STE05121 (Anchor Bolt Design Guide)Dokumen55 halamanPIP STE05121 (Anchor Bolt Design Guide)bowitchhazelBelum ada peringkat

- PIP CVS02350 Roadway and Area Paving Construction SpecificationDokumen4 halamanPIP CVS02350 Roadway and Area Paving Construction SpecificationkleidervinBelum ada peringkat

- PIP VESV1002 Design and Fabrication Specification For Vessels ASME Code Section VIII, Divisions 1 and 2Dokumen44 halamanPIP VESV1002 Design and Fabrication Specification For Vessels ASME Code Section VIII, Divisions 1 and 2d-fbuser-93320248Belum ada peringkat

- STF05121 Fabrication and Installation of Anchor BoltsDokumen8 halamanSTF05121 Fabrication and Installation of Anchor Boltsbobmarley20161934100% (1)

- The Grouting Handbook: A Step-by-Step Guide for Foundation Design and Machinery InstallationDari EverandThe Grouting Handbook: A Step-by-Step Guide for Foundation Design and Machinery InstallationPenilaian: 5 dari 5 bintang5/5 (2)

- Process Industry Practices Structural: PIP STC01015 Structural Design CriteriaDokumen32 halamanProcess Industry Practices Structural: PIP STC01015 Structural Design CriteriaquaisarBelum ada peringkat

- 1.wind Guide 1Dokumen32 halaman1.wind Guide 1quaisarBelum ada peringkat

- PIP ELSAP01 2013 Design and Fabrication of Battery ChargersDokumen13 halamanPIP ELSAP01 2013 Design and Fabrication of Battery ChargersManuel Jumbo Ramírez100% (1)

- PIP STF05511 Fixed Industrial StairsDokumen13 halamanPIP STF05511 Fixed Industrial StairsCodrut StanciuBelum ada peringkat

- PIP INIH1000 - Hot InsulationDokumen26 halamanPIP INIH1000 - Hot InsulationRauf AliyevBelum ada peringkat

- Blast Resistant Building Design CriteriaDokumen51 halamanBlast Resistant Building Design Criteriahrol31060100% (2)

- Pip Ste05121 Anchor BoltDokumen65 halamanPip Ste05121 Anchor BoltHui LiuBelum ada peringkat

- Tank FoundationsDokumen83 halamanTank Foundationsdroates100% (17)

- PIP - Specification For Small Pressure Vessels and Heat ExchangersDokumen12 halamanPIP - Specification For Small Pressure Vessels and Heat ExchangersPRESIDENCIA SEVIGEABelum ada peringkat

- PIP VEDTA003 Atmospheric Storage Tank Data SheetDokumen7 halamanPIP VEDTA003 Atmospheric Storage Tank Data SheetPRESIDENCIA SEVIGEABelum ada peringkat

- Process Industry Practices Electrical: Pip Eleha01 Engineering Guide For Determining Electrical Area ClassificationDokumen21 halamanProcess Industry Practices Electrical: Pip Eleha01 Engineering Guide For Determining Electrical Area Classificationhrol31060Belum ada peringkat

- PIP PNSMV034 Bronze and Iron Globe Valve Descriptions (2004)Dokumen6 halamanPIP PNSMV034 Bronze and Iron Globe Valve Descriptions (2004)Maksim.em001Belum ada peringkat

- Pip STF05121 Anchor BoltDokumen12 halamanPip STF05121 Anchor BoltHui LiuBelum ada peringkat

- PIP PNE00003 Process Unit and Offsites Layout GuideDokumen23 halamanPIP PNE00003 Process Unit and Offsites Layout GuideJhonny RinconesBelum ada peringkat

- Pip Elsmc13 Electronic Entry Data Sheet For Low-Voltage Motor Control CentersDokumen2 halamanPip Elsmc13 Electronic Entry Data Sheet For Low-Voltage Motor Control Centersist93993Belum ada peringkat

- PIP CTSE1000-2018 DatasheetsDokumen2 halamanPIP CTSE1000-2018 DatasheetsJohn Buntales0% (1)

- STD PIP VEDV1003 2012 Electronic Entry Documentation Requirements For Vessels Div 1 & 2Dokumen2 halamanSTD PIP VEDV1003 2012 Electronic Entry Documentation Requirements For Vessels Div 1 & 2Nikunj KBelum ada peringkat

- PIP INIC1000 (2012) - Cold Insulation Installation DetailsDokumen25 halamanPIP INIC1000 (2012) - Cold Insulation Installation DetailsAbimelech Salas100% (3)

- PIP Ste05121 Anchor Bolt Design GuideDokumen55 halamanPIP Ste05121 Anchor Bolt Design Guideel.salumbidesBelum ada peringkat

- Process Industry Practices Civil: PIP CVE02350 Roadway Design GuideDokumen53 halamanProcess Industry Practices Civil: PIP CVE02350 Roadway Design GuideVrbank KrabBelum ada peringkat

- Drawer 75 MM Wall For 2940B Cabinet - 2940B-75: DescriptionDokumen1 halamanDrawer 75 MM Wall For 2940B Cabinet - 2940B-75: DescriptionsaminasritnBelum ada peringkat

- d01c25e978d2f79c771828530390SHIPPING CI PDokumen1 halamand01c25e978d2f79c771828530390SHIPPING CI PsaminasritnBelum ada peringkat

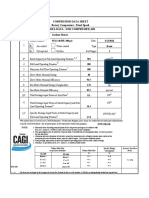

- STG2-40 100psi AirCooled 04 11 2016Dokumen1 halamanSTG2-40 100psi AirCooled 04 11 2016saminasritnBelum ada peringkat

- ERFIFRANCE English Catalog PDFDokumen111 halamanERFIFRANCE English Catalog PDFsaminasritnBelum ada peringkat

- Attachement E-Square Catalogue PDFDokumen225 halamanAttachement E-Square Catalogue PDFsaminasritnBelum ada peringkat

- VCXT ™ Data Sheet: Debtor in PossessionDokumen2 halamanVCXT ™ Data Sheet: Debtor in PossessionsaminasritnBelum ada peringkat

- Problems With B16.5 and B16.47 Flange StandardsDokumen1 halamanProblems With B16.5 and B16.47 Flange StandardsManohar SeetharamBelum ada peringkat

- XIX Paper 59Dokumen15 halamanXIX Paper 59saminasritnBelum ada peringkat

- Offshore LNG Loading Problem SolvedDokumen13 halamanOffshore LNG Loading Problem SolvedpriyoBelum ada peringkat

- 336 AcDokumen172 halaman336 AcsaminasritnBelum ada peringkat

- GPT 1-9CasingSpacerManual OCT2013 LR en-NA 21Dokumen2 halamanGPT 1-9CasingSpacerManual OCT2013 LR en-NA 21saminasritnBelum ada peringkat

- 6604 Issue 2 Testing of Insulating JointsDokumen5 halaman6604 Issue 2 Testing of Insulating Jointssaminasritn100% (1)

- 2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFDokumen19 halaman2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFsaminasritnBelum ada peringkat

- 2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFDokumen19 halaman2.11 FinalReport MFL-DMR-GEO EXAMPLE PDFsaminasritnBelum ada peringkat

- Test Equipment 2 (Accbe) Answer KeyDokumen1 halamanTest Equipment 2 (Accbe) Answer KeysaminasritnBelum ada peringkat

- Energies 05 03892Dokumen16 halamanEnergies 05 03892Daodu Olugbenga OlusegunBelum ada peringkat

- Natural Gas Knowledge Series - Laying Natural Gas PipelineDokumen15 halamanNatural Gas Knowledge Series - Laying Natural Gas PipelineswordprincesBelum ada peringkat

- Commissionning of Atlantic LNG Plant-PassingthebatonDokumen12 halamanCommissionning of Atlantic LNG Plant-Passingthebatonsaminasritn100% (1)

- Paper20508 5121Dokumen5 halamanPaper20508 5121saminasritnBelum ada peringkat

- MEASURING AND TEST EQUIPMENT CALIBRATION AND CONTROL - 01548 - EE37 - PWI - ET - 1907 - 0004 Rev.1Dokumen3 halamanMEASURING AND TEST EQUIPMENT CALIBRATION AND CONTROL - 01548 - EE37 - PWI - ET - 1907 - 0004 Rev.1saminasritnBelum ada peringkat

- Operation LNG TankDokumen4 halamanOperation LNG TankpramodtryBelum ada peringkat

- Integration of Major Liquefaction Units Within Existing Import TerminalsDokumen8 halamanIntegration of Major Liquefaction Units Within Existing Import TerminalshortalemosBelum ada peringkat

- EE37 PPR ET 1919 0032 Rev 1 - Drying - Purge ProcedureDokumen7 halamanEE37 PPR ET 1919 0032 Rev 1 - Drying - Purge ProceduresaminasritnBelum ada peringkat

- Support Pipng TechnipDokumen23 halamanSupport Pipng TechnipsaminasritnBelum ada peringkat

- Corrosion Protection Under Insulation: PanoramaDokumen4 halamanCorrosion Protection Under Insulation: PanoramasaminasritnBelum ada peringkat

- PE Pipe Joining Procedures PDFDokumen31 halamanPE Pipe Joining Procedures PDFymessaoudBelum ada peringkat

- G. Spare Parts ManagementDokumen12 halamanG. Spare Parts ManagementVipul TikekarBelum ada peringkat

- Material Class ChevronDokumen29 halamanMaterial Class ChevronsaminasritnBelum ada peringkat

- Typrical Piping TCCIDokumen18 halamanTyprical Piping TCCIsaminasritnBelum ada peringkat

- Netrunner AllCardsDokumen154 halamanNetrunner AllCardsIvo PantaleaoBelum ada peringkat

- StringTokenizer in JavaDokumen11 halamanStringTokenizer in JavaNeha saxena Neha saxenaBelum ada peringkat

- Excess Fluid VolumeDokumen27 halamanExcess Fluid VolumeAdrian Ardamil100% (1)

- Middle East ManufacturerDokumen6 halamanMiddle East Manufacturerhsco rdBelum ada peringkat

- Kingspan 30 GSNDokumen1 halamanKingspan 30 GSNNoella AguiarBelum ada peringkat

- Vivo X5Pro Smartphone Specifications: Brand and ModelDokumen4 halamanVivo X5Pro Smartphone Specifications: Brand and ModelEric AndriantoBelum ada peringkat

- Final Cor 011 Reviewer PDFDokumen104 halamanFinal Cor 011 Reviewer PDFMary JuneBelum ada peringkat

- Ultrasonic Inspection of Welds in Tubes & Pipes: Educational NoteDokumen13 halamanUltrasonic Inspection of Welds in Tubes & Pipes: Educational NoteleonciomavarezBelum ada peringkat

- Comparative Superlative With Key PDFDokumen1 halamanComparative Superlative With Key PDFAnonymous 8AHCMsPuBelum ada peringkat

- Essentials of o Ste 00 DaveDokumen112 halamanEssentials of o Ste 00 DaveGeki Iovan100% (1)

- Conference Programme Critical EmancipationsDokumen3 halamanConference Programme Critical Emancipationswr7md5b55fBelum ada peringkat

- VF (Kyhkkjrh VK Qfozkkulalfkku) - F'KDS"K) MRRJK (K.M& 249201Dokumen3 halamanVF (Kyhkkjrh VK Qfozkkulalfkku) - F'KDS"K) MRRJK (K.M& 249201RajaBelum ada peringkat

- Flood RateDokumen367 halamanFlood RatetpktpkBelum ada peringkat

- Manual de Servico Samsung Sgh-I677-Eplis-11Dokumen10 halamanManual de Servico Samsung Sgh-I677-Eplis-11Anselmo Antunes0% (1)

- Approved Reading List Editions 2019ff As of 01 19 2023 2Dokumen9 halamanApproved Reading List Editions 2019ff As of 01 19 2023 2nikolBelum ada peringkat

- An Automated Energy Meter Reading System Using GSM TechnologyDokumen8 halamanAn Automated Energy Meter Reading System Using GSM TechnologyBarBelum ada peringkat

- Buk Uuuuuu UuuuuuuDokumen92 halamanBuk Uuuuuu UuuuuuuJanaliyaBelum ada peringkat

- BNB SB0114Dokumen4 halamanBNB SB0114graziana100% (2)

- Optimizing With eGaN FETsDokumen6 halamanOptimizing With eGaN FETskhsniperBelum ada peringkat

- 9trffi&hpr.! Ni-: Use E EDokumen2 halaman9trffi&hpr.! Ni-: Use E ERafi ZulfiBelum ada peringkat

- American National Standard Safety Signs: ANSI Z535.1-2016Dokumen42 halamanAmerican National Standard Safety Signs: ANSI Z535.1-2016Luis Enrique GonzalesBelum ada peringkat

- COR5500U Series: Digital and CRT Readout OscilloscopeDokumen7 halamanCOR5500U Series: Digital and CRT Readout OscilloscopeFlavio FalcãoBelum ada peringkat

- A Very Old MachineDokumen20 halamanA Very Old MachineSwathi G. SalemBelum ada peringkat

- CHEM333 Syllabus 2020 2021Dokumen4 halamanCHEM333 Syllabus 2020 2021lina kwikBelum ada peringkat

- LEM 91-161 Fla E 0612Dokumen13 halamanLEM 91-161 Fla E 0612Julen IturriozBelum ada peringkat

- Factorisation PDFDokumen3 halamanFactorisation PDFRaj Kumar0% (1)

- EPTT5100 - Pressure - Temperature Sensor - 1308 - GDokumen2 halamanEPTT5100 - Pressure - Temperature Sensor - 1308 - GHendry Putra RahadiBelum ada peringkat

- Draf Model LC 2024 Non TransferableDokumen3 halamanDraf Model LC 2024 Non TransferablepresidenciaBelum ada peringkat

- 10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtDokumen145 halaman10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtVuong DiepBelum ada peringkat

- Brochure Smart Grid Foundation CourseDokumen6 halamanBrochure Smart Grid Foundation CourseKULDEEP MEENABelum ada peringkat