Ijmet 08 11 083

Diunggah oleh

FitriaRica-ricaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ijmet 08 11 083

Diunggah oleh

FitriaRica-ricaHak Cipta:

Format Tersedia

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 8, Issue 11, November 2017, pp. 812–838, Article ID: IJMET_08_11_083

Available online at http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=8&IType=11

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

REVIEW ON RISK, RISK ASSESSMENT

TECHNIQUES, GUIDELINES AND

FRAMEWORK IN PORT SAFETY

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan

and Astuty Amrin

Department of Engineering, Razak School of Engineering and Advanced Technology,

Universiti Teknologi Malaysia, Jalan Sultan Yahya Petra, Kuala Lumpur, 54100, Malaysia

ABSTRACT

Risk management and risk assessment guidelines and framework have been widely

developed for ages. Even in safety, risk assessment guidelines and framework are

crucial and considered important in the safety management system of an organization.

The variety and complexity of port operations lead to varied risks. These risks, if not

managed well, can affect the overall business operation of the ports, which then leads

to accidents. A study found that port professionals face difficulties in conducting risk

assessments due to the lack of appropriate methodology and evaluation techniques to

support their risk management cycles. The aim of this paper is to identify, review, and

carry out comparisons to risk assessment elements in frameworks related to port

terminal safety activities. The selected frameworks were summarized based on its

requirements, followed by being defined by its advantages and limitations, and finally,

the comparison of frameworks was carried out. The outcomes of the study will be a

supplement to current knowledge on the assessment guidelines and framework of such

systems, advanced risk management models, and general guidelines on the

improvement of current frameworks and procedures. Concurrently, this study shall

benefit the participating ports in analyzing their particular risk management systems.

Keywords: Port, Risk Assessment, Risk Management Framework, Transport and

Logistics.

Cite this Article: Zuritah A. Kadir, Roslina Mohammad, Norazli Othman,

Shreeshivadasan Chelliapan and Astuty Amrin, Review on Risk, Risk Assessment

Techniques, Guidelines and Framework in Port Safety, International Journal of

Mechanical Engineering and Technology 8(11), 2017, pp. 812–838.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=8&IType=11

1. INTRODUCTION

In Malaysia, accident records are updated by the Department of Occupational Safety and

Health (DOSH) Malaysia by industry in order to monitor accidents in Malaysian industries.

According to the statistics of accidents by sector recorded by DOSH Malaysia from the year

http://www.iaeme.com/IJMET/index.asp 812 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

2013 to August 2016, by industry, the highest number of accidents occurred in the

manufacturing industry (6847 cases). It is followed by the agriculture, foresting, logging and

fishing industry (1812 cases), the construction industry (717 cases), and the transport, storage

and communication industry (432 cases). Since the manufacturing industry contributes the

highest number of accidents in Malaysia, massive studies have been conducted by researchers

such as [1, 2, 3, 4, 5, 6, 7, 8] to investigate and propose a solution to improve accident

prevention in the manufacturing industry of Malaysia. However, less attention was directed to

the transportation, storage, and communication industry. This statement was supported by

Auyong et al. [6]. The previous studies conducted in the transport, storage and

communication industry in Malaysia are not as significant as other industries.

In the year 2016, there have been three fatality cases recorded in ports. This number

increased compared to last year, which only recorded 1 case. Even the amount of cases is

small compared to other industries such as the construction industry (55 cases), the

agriculture, forest, logging, and fishing industry (14 cases) and the manufacturing industry

(32 cases), but the fact that the workplace may not be safe as accidents and fatalities have

happened should not be ignored. If fatalities happen, it shows that there is a possibility that

near-miss accidents or any other accidents may happen. This is based on Heinrich’s accident

model theory, where if one serious or fatality case has happened, then there will be at least

twenty-nine minor injury cases, three hundred near-miss accidents, and three thousand unsafe

acts and conditions predicted to happen. This was approved by Gnoni and Salleh [9]. This

shows that necessary countermeasures should be performed to prevent the same accidents

from happening again in the future.

The massive development of the port industry does not align with the development of port

safety management systems [10]. Major accidents such as the warehouse explosion in 2015 at

the Tianjin port are still happening. Ng et al. [11] found that many accidents have happened

while handling cargoes at port, especially if the activity involves manual handling, as the

employees are directly exposed to hazards and risks. The variety of complex activities

performed in port terminals include passenger transport, cargo and container handling, oil and

chemicals storage, vehicle storage and transport, ship, lorry and train circulation, all of which

create risks and hazards. These risks and hazards are exposed to persons such as the crew,

passengers, port users and port workers, the environment (nature) and property such as ships,

port facilities, and port labour, and others [12]. If it is not managed and controlled, it would

create unwanted events like unsafe acts and conditions [9], which will eventually cause major

accidents such as fatalities. These activities have their own risks and need to be assessed and

evaluated to place appropriate control measures to prevent accidents.

Risk assessment in the port industry is necessary. This is because the port is considered as

a high-risk industry [18]. Previously, much port safety research focused on maritime risk

issues which mainly suggested the need for developing a rigid and efficient qualitative and

quantitative risk assessment approaches that prioritizes hazards at ports. However, there are

relatively few studies on port safety and risks that focused on port terminal activities [15,19]

as many other authors only focused on maritime risks which covers ship operations and ship

collisions at any area of the sea or anchorage.

Risk assessment is one of the main components of an effective safety management system

and accident prevention. An effective risk assessment in terms of implementation and

framework is necessary to support the idea of an effective safety management system.

Previous literature has highlighted many gaps in terms of frameworks, scopes, and

methodology in managing accidents in a high-risk industry, especially in organizations with a

complex operational system, such as in the port industry. This gap needs to be closed to

ensure that the dynamic implementation of the theory is established and fully developed.

http://www.iaeme.com/IJMET/index.asp 813 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

2. TERMS, DEFINITIONS, AND CONCEPTS

A fundamental concept in this study is to understand the terms related to risks. Different terms

and definitions exist due to a few factors, such as different perspectives, the adjustment of the

terms itself to fit the industry, and philosophical needs and requirements. Even if it has

different definitions, the objectives and purpose are to be accomplished in the same way.

Generally, risks can be defined as the probability that harm happens [20]. The risk is

symbolized by the function of severity (the degree of harm or its consequences) and the

likelihood of the occurrence of the threatening event, as simplified in Equation 1.

In any case, it provides the risk assessment that leads to the misconception that risk is just

a number in terms of risk (R), its probability (P), and the consequences (C).

= (1)

In the perspective of safety, risk is defined differently depending on the application’s

domain. According to the OSHAS 18001 standard, risk is defined as a combination of the

likelihood of the occurrence of a hazardous event within a specified period or in specified

circumstances and the severity of injury or damage to the health of the people, property, the

environment or any combination of these that are caused by the event. In this standard, the

definition of consequence is more detailed as the consequences are referred to by the harm

that is created if the risk exposure is high is addressed.

Meanwhile, the definition of risk management can be varied as well. But as a general

definition by all researchers, risk management is the structured process of identifying and

assessing risk and then designing strategies and procedures to mitigate and control the

identified risk factors. Risk management is defined in ISO 31000 [37] as the effect of

uncertainty on objectives. Numerous studies have attempted to explain the techniques for

managing and controlling risk.

Risk assessment study is not new but in fact, it has been analyzed and practiced for ages.

Many companies practices and manages risks to standardize and organize the organization’s

operations [20, 21, 22]. Thekdi and Aven [23] proposed a good risk management system that

is able to reduce risks (risk reduction shown by risk assessments or understood as perceived

risk reduction), improve occupational safety and health levels (to reduced risk), meet the

requirements set by current practices (for example, by using quantitative risk analysis, risk

acceptance criteria, or tolerability limits), meet the International risk management standards,

and meet the ideas of other “broader” risk frameworks. One of the major components in port

risk management standards is risk assessment [24, 25]. During the last three decades, risk

assessment has emerged as an essential and systematic tool that plays a relevant role in the

overall management of many aspects of our life [26]. Analysis techniques are applied in many

different areas for different purposes [27]. Risk assessment is generally defined as the process

of identifying and evaluating risks or hazards [28]. Pak et al. [29] agreed and defined risk

assessment or risk analysis as the process of identifying and evaluating risks in an

organization. Risk assessment can be defined as the process of identifying and evaluating risk

in the organization. The definition of risk management can be varied. But as a general

definition by all researchers, risk management is the structured process of identifying and

assessing risks and then designing strategies and procedures to mitigate and control the

identified risk factors. Table 1 below provides terms, definition and concepts of risk, risk

assessment, and risk management based on selected standards and guidelines. In many risk

management frameworks, risk assessments are one of the major components which serve as a

crucial step in managing risks. Risk assessments can have varied definitions. In general, a risk

assessment is the process of identifying, evaluating and assessing risk. Table 1 summarized a

few definitions of risk assessment based on a few sources.

http://www.iaeme.com/IJMET/index.asp 814 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

Table 1 Risk Assessment definitions

Occupational Safety

and Health Act International

ISO 31000: 1994 (Act 514)- OSHAS 18001: Maritime

2009 ‘Risk Hazard Occupational Health Organization

Terms Management- Identification, Risk and Safety (IMO) 2001-

Principles and Assessment and Management System Formal Safety

Guidelines[37] Risk Control [39] Assessment

(HIRARC), (FSA)[40]

2008[38]

A combination of the

likelihood of an

occurrence of a

hazardous event

(within a specified

period or in specified

The effect of

circumstances) and

Risk uncertainty on N/A N/A

the severity of injury

objectives

or damage (to the

health of people,

property, or the

environment) or any

combination of these

caused by the event.

The process of

evaluating the risks

arising from the

The process of

The overall hazards (a

evaluating any risks The combination

process of risk combination of the

potentially of the frequency

Risk identification, likelihood of a

endangering safety and the severity

Assessment risk analysis, hazardous event or the

and health arising of the

and risk exposure to it and the

from hazards at consequence.

evaluation. severity of injury or ill

work.

health that can be

caused by the event

after exposure).

A series of The total procedure

coordinated associated with

activities to identifying a hazard,

Risk direct and assessing the risks,

N/A N/A

Management control an putting in place

organization control measures,

with regards to and reviewing the

risk outcomes.

3. OVERVIEW OF PORT OPERATIONS

The main activities conducted in Malaysian ports are importation, exportation, and

transshipment. There are many types of operations and cargo handling at ports. A

multipurpose port offers dedicated facilities and services to handle a wide variety of cargoes

ranging from containers to cars, break bulk cargoes, as well as the capacity to handle liquid

and dry bulk cargoes of all types and shipment sizes. There are also Malaysian ports which

focus on containerized types of cargoes only while there are also ports focused on liquid bulk

http://www.iaeme.com/IJMET/index.asp 815 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

or break bulk cargoes only. It all depends on the availability of port facilities and the business

orientation of the port. Despite the main activities of a port which is the handling of cargoes, a

port is also exposed to major risks in handling dangerous goods in cargoes or containers.

Several ports in Malaysia function solely as a liquid bulk terminal which handles not only

non-dangerous goods cargoes such as palm-oil, but it also handles dangerous goods cargoes

such as liquid nitrogen gas (LNG), petroleum, etc. There are also dangerous goods cargoes

packed in containers, tankers, and loose cargoes, which also bring about a high safety risk

which may result in scenarios such as explosions, corrosions, fires, and environmental risks.

The port industry is considered as a complex industry which involves several logistics

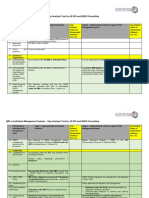

activities. The industry is unique as it involves a combination of sea and land activities

(Figure 1). A great variety of activities are performed at ports: marine operations such as

towage and pilotage, transportation of passengers; transportation of cargoes; storage of oil and

chemicals; storage and transportation of cars; circulation of ships, cranes, lorries, and trains

etc.

Figure 1 Port Operations (container terminal)

4. METHODOLOGY

In this paper, a total of 210 papers with keywords of “Risk”, “Risk assessment at ports”, and

“Safety at ports” were identified. A total of 186 papers were reviewed and discussed in this

paper. An extensive review was conducted on available risk assessment guidelines to identify

the current risk assessment and risk management frameworks and guidelines. The findings

from the preliminary study were used as the basis for developing the risk assessment

frameworks and guidelines. Since the involvement of international connections with ports,

ports need to comply with local rules and regulations, which will lead to safety in maritime

transports, which is an essential condition for the proper functioning of economies.

5. HAZARDS AND RISK IN THE PORT INDUSTRY

In the port industry, there are many hazards produced from complex activities. For example,

Lu and Kuo [30] found that container terminal operations are hazardous since stevedores are

often involved in various risky workplace activities that include cranes operations, lashing,

electrical repairs, tally operations and truck driving. The complexity of the variety of activities

of the port led to the port to be considered as “a place of risk”, where hazards can be directed

to persons, the environment, and/or property [13]. Regarding port hazards, Chlomoudis et al.

[12], collected feedback from port experts and grouped the hazards into five groups of risk

categories based on accident causes, which included human, machinery, environment,

security and natural causes. This study suggested the Port Risk Assessment (PRA) method,

which was workable in the ports in Greece.

http://www.iaeme.com/IJMET/index.asp 816 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

A case study was conducted by Bouzaher et al. [13] on the Algerian port. This study aims

to contribute to the management of risks associated with port operations by designing a matrix

for the specific assessment of this type of risk based on analysis of several incidents and

accidents regarding maneuvering ships in Algerian ports. The design of the evaluation matrix

of risks associated with port operations in Algeria is done in the context of the Formal Safety

Assessment methodology for improved performance of this method in terms of precision and

accuracy of results.

Chlomoudis et al. [12] also suggested a risk assessment method based on man-related risk

factors, by which cover nine risk factors. Ding and Tseng [14] conducted a risk assessment on

safety operations for exclusive container terminals at the Kaohsiung port in Taiwan. The case

studies involved sixteen (16) risk factors which were categorized into four groups: man,

machine, media, and management. From this study, it was found that three (3) risk factors

which were all categorized in the man category was identified as high leading risks. Based on

the analysis of the typical accidents in China in the last decade, new challenges in safety risk

management include the control of unsafe human behavior, technological innovation in safety

risk management, and design of safety risk management regulations. This is the main factor in

managing risk and safety not only in the port industry but in all industries. Fabiano et al. [15]

studied the interaction between the human factor and accidents at ports. They found that the

human factor was not the most vital factor, but is the technical or technology factor instead.

Port activities are wide-ranging and include berthing/unberthing, vessel

loading/unloading, assets maintenance, dangerous goods management, warehousing, storage

of bulk goods, inter-modal transport movements, waste disposal, stevedoring, bunkering,

pilotage, towage and boat repairs, and maritime services. The complexity of port activities

implies certain risks. Risk management is effective in its ability to reduce accidents [16, 23].

The existence of a hazard at the workplace such as physical hazards [31], ergonomics hazards

[32, 33], safety hazards, chemical and dust hazards [34], and health hazards need to be

managed and controlled. These hazards contribute to the possibility of people getting harmed.

If not identified, these hazards can cause accidents if the exposure to the hazards is high.

Thus, it is essential for risk to be managed and controlled to reduce the accident rate. By

doing that, an organization can avoid damage and loss of profit and reputation.

The main activities conducted in Malaysia ports are importation, exportation and

transshipment. There are many types of operations and cargo handling activities at a port. For

a multipurpose port, it usually offers dedicated facilities and services to handle the wide

variety of cargoes ranging from containers to cars, break bulk cargoes, as well as having the

capacity to handle liquid and dry bulk cargoes of all types and shipment sizes. There are also

Malaysia ports which focus on containerized cargoes only and there are also ports focused on

liquid bulk or break bulk cargoes only. Despite the main activity of the port, which is

handling cargoes, the port is also exposed to major risks in handling Dangerous Goods

cargoes or containers. Several ports in Malaysia act solely as liquid bulk terminals, which

handle not only non-dangerous goods cargoes such as palm oil, but also handles dangerous

goods cargoes such as liquid nitrogen gas (LNG), petroleum, etc. There may also be

dangerous goods cargoes packed in containers, tankers, and loose cargoes, which bring about

a high safety risk that may cause incidents such as explosions, corrosions, fires, and

environmental risks [35]. The development of the port industry is still blooming [1]. Many of

the ports in Malaysia are still expanding and developing. The pressure for good port

management in handling the safety and health of their employees in their organizations is

highly important [36]. Thus, specialized and specific port safety management systems and

risk management systems can help these ports in managing their occupational safety and

health management processes. To facilitate the port safety management system, suitable risk

http://www.iaeme.com/IJMET/index.asp 817 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

assessments and decision support tools are required. The port industry requires access to

several methods and tools to be able to analyze the wide variety of risk-related problems

(which could raise qualitatively or quantitatively) or more advanced techniques (that consider

the complexity and variety of the system and uncertainties) are needed, but for different

purposes and situations.

6. LEGAL REQUIREMENTS IN IMPLEMENTING RISK

MANAGEMENT SYSTEMS AT PORTS

Port activities cover both maritime and terminal areas. Thus, the complexity of port activities

can be varied. It involves both sea and inland activities. Since there is the involvement of

international connections at ports, ports need to comply with local rules and regulations which

will lead to safety in maritime transport, which is an essential condition for the proper

functioning of economies. As of now, in Malaysia, there are no specific safety guidelines for

ports. In many countries, whether on a national or international scope, risk management is

legally required by the authorities to promote a safety management system. The legal

requirements in implementing a risk management system is an effort by safety and health

authorities in controlling and preventing accidents in the industry [41, 42, 43]. Even though it

is a legal requirement, the implementation of risk management in the industry is still

challenging.

A study conducted by Lenhard and Beck [44] revealed that only one out of four

companies carry out risk assessments in Germany. This does not only happen in Germany, but

in other countries such as Sweden and other country as well. It shows that the implementation

of risk assessments is still very challenging. Lenhard and Beck [44] found that the availability

of safety specialist assistance, occupational health specialist assistance, a relationship with the

production sector, the presence of an employee representative body, and the economic

situation of the company can all affect the implementation of a risk assessment system. This

shows that the implementation of a risk assessment system can be very challenging for

companies or institutions, even though it is legally required.

From Malaysian legislation perspectives, it is stressed that it is the employer’s

responsibility in managing occupational safety and health in the workplace. It also believes

that the responsibility of the general safety of the workplace lies in the hands of the employer,

as the hazards and risk exposure is created by them. Thus, most of the world’s organizations

have implemented a risk management system not only for safety reasons but also for the

business overview of the company to manage the risks within their company [45]. Malaysia’s

Department of Occupational Safety and Health (DOSH) established the Hazard Identification,

Risk Assessment and Risk Control (HIRARC) guidelines in 2005 with the purpose of

promoting and providing help to industries to perform hazard identification and risk

assessments. The guideline provides a systematic and objective approach to assessing hazards

and their associated risks that will provide an objective measure for managing an identified

hazard as well as provide a method to control the risk. The existing frameworks in the

guideline should be simple enough to be used by small and medium industries and versatile

enough to be used by those involved in various economic sectors, either in the manufacturing

sector, construction sector, or any other economic sectors. However, the implementation of a

risk management system in preventing accidents in Malaysia is still lacking [46]. The

implementation of a risk assessment system seems to be hard for industries to cope with.

Since it is not specific, the organization might find it harder and less motivating to

implementing a risk assessment system in the organization.

http://www.iaeme.com/IJMET/index.asp 818 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

7. RISK MANAGEMENT STANDARDS, GUIDELINES, AND

FRAMEWORKS

There are many risk management standards that have been developed in other industries, such

as the Project Management Institute, the National Institute of Standards and Technology,

actuarial societies, Australia and New Zealand’s standard, the British standard, the American

standard, and International Standard Organization (ISO) standards as listed in Table 2. Each

of these standards provides different frameworks that suit the needs of different institutions or

organizations. Most of the risk management standards using the same process, but with

enhanced criteria to best suit each component and application of risk management. One of the

major components in risk management standards is risk assessment.

Table 2 Selected standards/ frameworks/ guidelines

Standards/

Framework/ Main Components Description

Guidelines

Policy (elements: policy and worker

participation);

Organizing (elements:

responsibility and accountability,

competence and training,

documentation, and

communication);

Planning and implementation The guidelines emphasize the need for

ILO Guidelines on (elements: initial review, system continual improvement of performance

Occupational Safety planning, development and through the constant development of

and Health implementation, objectives and policies, systems, and techniques to

Management hazard prevention); prevent and control work-related

Systems [46] Evaluation (elements: performance injuries, ill health, diseases, and

monitoring and measurement, accidents.

investigation of work-related

injuries, ill-health, diseases and

incidents, audit and management

review).

Action for improvement (elements:

preventive and corrective action and

continual improvement).

Planning for hazard assessment,

risk assessment, and risk control

OHSAS management programme OHSAS 18001 specifies requirements

Structure and responsibility for the OH&S management system,

Occupational Training, awareness and which is to enable organizations to

Health and Safety competence control their risks and improve their

Management

Consultation and communication performance. The specification is

System (OHSAS

Operational control intended to address occupational health

18001)[39]

Emergency preparation and and safety rather than product or service

response safety.

Performance measurement,

monitoring, and improvement

AS/NZ ISO 31000: Establishing the context Standards that stress the purpose &

2009 ‘Risk Risk assessment – risk benefits, risk assessment, the risk

http://www.iaeme.com/IJMET/index.asp 819 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

Standards/

Framework/ Main Components Description

Guidelines

management- identification, risk analysis, risk management frameworks, and the risk

Principles and evaluation management process.

guidelines[37] Risk treatment

Communication and consultation

Monitoring and review

The Formal Safety Assessment (FSA)

standard offers a structured and

systematic methodology for assessing

the risks related to maritime safety and

Hazard identification marine environmental protection and for

International

Risk analysis evaluating the costs and reducing risks.

Maritime

The FSA recognizes that there are

Organization (IMO) Risk control options

several different interests involved in

2001- Formal Cost-benefits assessment shipping, such as ship owners, cargo

Safety Assessment Recommendations for decision- owners, third parties, passengers, crews,

(FSA)[40] making flag states, port states, insurers, class

societies, associations, and much more.

Their attitudes and actions are

significant influential factors in safety

and marine environmental protection.

The HIRARC guideline provides a

systematic and objective approach to

Occupational Safety

Classify work activities assessing hazards and their associated

and Health Act

Hazard identification risks that will provide an objective

1994 (Act 514)-

Analyze and estimate risks measure to eliminate an identified

Hazard

hazard as well as provide a method to

Identification, Risk Risk assessment

control the risk. It is one of the general

Assessment and Selecting control duties as prescribed by the Occupational

Risk Control Implement Safety and Health Act 1994 (Act 514)

(HIRARC),

Review and monitoring for the employer to provide a safe

2008[38]

workplace for their employees and other

related persons.

These techniques are applied to British

waters and ports to assess risks of the

maritime transportation of dangerous

Definition of ports and hazardous goods in British waters and ports. The

DNV (2011)- trades framework helps control the risks of

Quantitative Risk Hazard identification major accidents from bulk shipment of

Assessment (QRA) Frequency estimation dangerous cargoes including crude oil,

technique. [47] Consequence estimation flammable and toxic liquefied gases,

Risk presentation flammable liquid petroleum products,

flammable liquid chemicals, and

ammonium nitrate (i.e. dry bulk cargoes)

from affecting people ashore.

The guidelines developed and used for

Marine Accident maritime risk calculation. It was

Risk Calculation Analyze historical accident data to developed in a project named SAFECO

System (MARCS), predict risks. (Safety of Shipping in Coastal Waters)

2000 [48] that was carried out by a consortium

contracted by the Commission of

http://www.iaeme.com/IJMET/index.asp 820 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

Standards/

Framework/ Main Components Description

Guidelines

European Community (CEC) through

the 4th Framework Programme,

Waterborne Transport.

Guidelines that provide a massive

number of tools. It was developed by

Risk-Based

Variation of risk assessment tools various organisations and individuals.

Decision-Making

collected by various expert Some of the guidelines were exclusively

(RBDM) Guidelines

organizations and experts developed for the USCG, such as the

U.S. Coast Guard

individuals. Port and Waterway Risk Assessment

(USCG 2001)[49]

Guides (PWRA) and the Waterway

Evaluation Tool (WET).

Identification of the causes of

possible events;

Assessment of the probability of

possible accidents and boundary

conditions; A model focused on the transportation of

hazardous substances which risk

QRA and Risk- Calculation of the physical effects

assessment approach has been developed

Effect Model of an accident;

in the Netherlands for applications on

(REM)[50] Assessment of the probability of the roads, trains, pipelines, and inland

consequences for people and the waterway transportation.

environment;

Assessment of individual risks,

societal risks, environmental risks,

and economic risks.

As mentioned in terms, definitions, and concepts, risk management systems include risk

assessment, risk analysis, and risk evaluation. Risk assessment is generally defined as the

process of identifying and evaluating risks or hazards. Risk management guidelines and

frameworks have been widely developed for ages [51]. Even in safety, risk assessment

guidelines and frameworks are crucial in the safety management system of an organization.

The variety and complexity of port operations bring about various risks. These risks, if not

managed well, can affect the overall business operation of ports, which then lead to accidents.

A study found that a problem that port professionals (e.g. port risk managers and port

auditors) are facing is the lack of appropriate methodology and evaluation techniques to

support their risk management cycles [52]. Port activities cover both maritime and terminal

areas. Thus, the complexity of port activities can be varied. It involves both sea and inland

activities. Since there is involvement of international connections with ports, ports need to

comply with local rules and regulations on the safety of maritime transportation for the proper

functioning of economies.

Preben and Kringen [53] argued on the important role of risk governance in risk

management implementation. They highlighted the function of roles and responsibilities,

knowledge, and regulatory complexity by comparing two cases at a Norwegian port that was

affected by the implementation of effective risk management in its port area. These risk

governance processes are indeed shaped by individual actions and organizational strategies,

but more generally by interactions and communication that have conditioned the social

process of risk perception and the characterization of the risks. The complexity of technical,

economic, organizational, and political conditions underline that the risk assessment

framework cannot independently characterize risks of a specific established institution, such

as the port itself and practical arrangements in local context. The real challenge appears to be

http://www.iaeme.com/IJMET/index.asp 821 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

related to the implementation of both the conceptual, analytical, and not least, the practical

concerns that arise in dealing with the multifaceted and complex risk governance processes in

modern society, in which sufficient governmental capacity is needed to integrate all the

concerns and issues in such processes, which appears to be the most critical factor.

The structured and specific guidelines and frameworks are necessary to ensure the

effectiveness of risk management, especially at ports [54]. This was agreed by Le Duy et al.

[55], as they found that the implementation and standards of risk management are not aligned

between organizations due to some unfulfilled criteria. In their study, they suggested that

some criteria be modified so that the same standard can be practiced across different

organizations. Knudsen and Hassle [56] argued on the effectiveness of risk management since

it is not possible to eliminate risks completely, but partly and more relevantly because

existing global regulations are not being implemented effectively.

A study conducted by Montewka et al. [57] showed that within certain, predefined

boundaries, the modular nature of the risk framework allows for its continuous improvement

and adaptation to various conditions. Despite the simplifications and the assumptions made in

the framework, the results obtained are promising and show good agreement with the

available statistical or modelled data on RoPax accidents operating around Europe. However,

this study does not state any specific risk factors for risks in the Gulf of Finland, as the aim of

the analysis presented is to demonstrate the abilities of the framework for knowledge-based

risk assessment and proper reflection of uncertainties, which are inherent to any risk analysis.

The International Standard Organisation AS/NZ ISO 31000: 2009 ‘Risk Management -

Principles and Guidelines’ [37] provides principles and common procedures on risk

management. The general principles of risk management can be applied to any public, private,

or community-based enterprise, association, group, or individual. Thus, the use of this

international standard is not industry or sector specific. In this sense, these principles can be

recommended for most organization’s risk management process for any projects. The

recognition of these principles is the first step towards the construction of a risk management

framework. The main steps in this framework are to start with establishing the context, then

conduct a risk assessment through risk identification, risk analysis, and risk evaluation. Next,

risk treatment is introduced, accompanied by risk communication and consultation and

finally, performance monitoring and reviews. In advanced countries such as Australia,

Ireland, New Zealand and the United Kingdom, safety authorities have taken advanced

initiatives in established guidelines and codes of practice specific for port management

systems, as they consider the complexity and variety of port operations different from other

industries [58]. Recently, Ireland’s health and safety authorities published the “Code of

Practice for Health and Safety in Dock Work, 2016” in accordance with Section 60 of the

Safety, Health and Welfare at Work Act 2005. This code of practice provides practical

guidance on observing the control of hazards in the docks and ports industry.

In the United States of America, the Port Marine Safety Code (PMSC) [59] was first

published in March 2000 by the Department of Transport and revised in 2009. It establishes

an agreed national standard for port marine safety and a measure where the harbour

authorities can be held accountable for legal powers and duties, so they must run their

harbours safely. New Zealand recently revised their 2004 Code and set up a collaborative

programme for outstanding performance on Safety Management System (SMS) assessments

by establishing the 2015 edition of the New Zealand Port and Harbour Marine Safety Code

(the Code) [26]. The Code intends to assist port operators and councils in managing the safety

of marine activities in their ports and harbours by providing a voluntary national standard to

support international and local legislation. In Australia, the Australian Port Marine Safety

Management Guidelines (2015) [61] were introduced. The aim of the Port Marine Safety

http://www.iaeme.com/IJMET/index.asp 822 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

Management Guidelines for Australian Ports (the Guidelines) is to promote good practice in

the conduct of safe marine operations. They provide a framework which ports in Australia

may choose to use as a guide.

Internationally, formal safety assessment guidelines are available for the port, maritime,

and shipping industries [20, 63]. Literary reviews show studies on numerous maritime-related

risks using formal safety assessment methods [13, 57, 64]. Wang and Foinikis [65] explored

the formal safety assessment (FSA) of containerships by using fault tree analysis (FTA) for

hazard identification and risk evaluation. Formal safety assessment guidelines are a stepwise

approach comprising of the five following interrelated steps [66]: hazard identification, risk

analysis, risk control options, cost-benefit assessment, and recommendations for decision

making [67]. Many elements of this formal safety assessment were established in other

industries and sectors. However, they are adapted for application in the shipping industry,

covering the risks to people, the marine environment, and property resulting from ship

operations and other related activities.

In Malaysia, there is no specific risk assessment guideline and framework in the port

industry as of now. The only applicable risk assessment guideline available is the hazard

identification, risk assessment, and risk control (HIRARC), guideline, 2008 which provides

general guidelines for any industry in implementing risk assessment systems. Even though the

guideline is considered sufficient, as a proactive measure, it is essential for specific risk

assessment frameworks and guidelines of port authorities to be established in Malaysia as a

leading step towards preventing accidents and managing safety in the port industry.

The specific guidelines and codes of practice which provide risk assessment frameworks

are believed to be motivating and helpful to the ports in handling and managing the risks of

the industry. The operational level of port terminals is characterized by huge infrastructure,

critical resources, and limited and rapidly changing traffic. This complex situation has led to

many points of failure at several levels such as administrative activities, operations

management, incident management, facilities management, and infrastructure management.

Such problems require a particular methodology to identify and assess operational risks to

establish preventive measures at port terminals [68]. The standard risk management is able to

provide guidance in handling and managing the risks by identifying unacceptable risks and its

impact [69]. Thus, the ports require a proper and structured risk management system to handle

risks.

The selected frameworks and guidelines are produced to suit the needs of the industry,

institution, or organization. Most risk management standards share similar components and

the same process, but with enhanced criteria to best suit each risk management component

and application. Most of the ports in the world do not stick to only one standard or guideline,

but rather, they choose the guideline or standard that best suits their organization’s objective.

However, not all standards or guidelines are applicable to all industries. Table 3 provides a

comparison of a framework’s application, objectives, and the type of document. Based on the

comparison made as Table 4, it was found that risk identification, risk analysis, risk

evaluation, and risk control are the main components of a risk management system because

most of the standards, frameworks and guidelines have these as their main components. Table

5 describes the advantages and limitations of the frameworks accordingly.

http://www.iaeme.com/IJMET/index.asp 823 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

Table 3 Comparison of selected framework’s application, main objectives, and type of documents

Standards /Framework/ Main

Applicable to Type of Document

Guidelines Objectives

ILO Guidelines on Occupational

Compliance

Safety and Health Management All industries Guidance Document

and control

Systems [46]

Occupational Health and Safety

Management System (OHSAS All industries Organization Primary standard

18001)[39]

ISO 31000: 2009 ‘Risk

management- Principles and All industries Organization Primary standard

guidelines[37]

International Maritime Organization Maritime and

(IMO) 2001- Formal Safety shipping industry, sea Regulation Legal Document

Assessment (FSA) [40] transport industry

Occupational Safety and Health Act

1994 (Act 514)- Hazard Compliance

All industries Guidance Document

Identification, Risk Assessment and and Control

Risk Control (HIRARC), 2008[38]

Maritime and

DNV (2011)-Quantitative Risk Compliance

shipping industry, sea Guidance Document

Assessment (QRA) technique [47] and Control

transport industry

Maritime and

Marine Accident Risk Calculation Compliance

shipping industry, sea Guidance Document

System (MARCS), 2000 and Control

transport industry

Risk-Based Decision-Making Maritime and

Compliance

(RBDM) Guidelines U.S. Coast shipping industry, sea Guidance Document

and Control

Guard (USCG 2001) transport industry

Maritime and

QRA and Risk-Effect Model Compliance

shipping industry, sea Guidance Document

(REM)[50] and Control

transport industry

Table 4 Main Components of Risk Management

Risk Training

Establish the Risk Risk Risk Risk Risk Cost Benefit

Monitoring and and

context Identification Analysis Evaluation Control Communication Analysis

Review Awareness

AS/NZ ISO 31000 : 2009 ‘Risk

management-Principles and

guidelines

International Maritime Organization

(IMO) 2001- Formal Safety

Assessment (FSA)

Occupational Safety and Health Act

1994 (Act 514)- Hazard

Identification, Risk Assessment and

Risk Control (HIRARC), 2008

DNV, Quantitative Risk

Assessment (QRA) technique, 2011

QRA and Risk-Effect Model

(REM), 2011

Ireland Code of Practice for Health

and Safety in Dock Work, 2016

New Zealand Port and Harbour

Marine Safety Code, 2015

Port Marine Safety Management

Guidelines for Australian Ports (the

Guidelines), 2016

http://www.iaeme.com/IJMET/index.asp 824 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

Table 5 Advantages and limitation of frameworks

Standards

/Framework/ Advantages Limitation

Guidelines

ILO Guidelines on

Not legally binding and does

Occupational Safety Compatible with other management

not replace national laws,

and Health systems, standards and guidelines (ILO

regulations, and accepted

Management Systems 2001).

standards.

[46]

Promotes organized occupational safety and

Occupational Health health management in stressing the risk The system is too general in

and Safety assessment element as part of the main its application on ports.

Management System components of the standard. However, it is still one of the

(OHSAS 18001)[39] best practices to be followed.

Promotes continuous improvement.

AS/NZ ISO 31000: Details stress on risk assessment process

and techniques. The guideline is too general

2009 ‘Risk

in its application on ports.

management- Promotes involvement from the top to the

However, it is still one of the

Principles and bottom of the organization.

best practices to be followed.

guidelines [37] Promotes continuous improvement

Highly generic framework

that is not intended for

application in all

circumstances (IMO 2002).

Recognizes that there are several different Not readily applicable to risk

interests involved in shipping, such as ship analysis in the maritime

owners, cargo owners, third parties, transportation of dangerous

International Maritime passengers, crews, flag states, port states, goods, including packaged

Organization (IMO) insurers, class societies, associations, etc. dangerous goods.

2001- Formal Safety Includes the identification of shipping Lacks the essential concepts

Assessment (FSA) interests and consideration on the impact of or variables for representing

[40] regulatory options for the relevant shipping and measuring the maritime

interests. transportation system of

Numerous techniques are provided to dangerous goods and risks

facilitate the process. associated with it.

Does not contain a single

term describing essential

concepts related to risks of

dangerous goods.

Occupational Safety

and Health Act 1994

The application is too

(Act 514)- Hazard

general, especially for large

Identification, Risk Easy and simple guideline to be followed.

organizations that require

Assessment and Risk

deeper assessments.

Control (HIRARC),

2008[38]

Confined to the risks of major accidents Limited to risks of the

affecting people ashore in bulk shipment of maritime transport of large

DNV (2011)-

dangerous cargoes, including crude oil, amounts of different types of

Quantitative Risk

flammable and toxic liquefied gases, dangerous goods carried in

Assessment (QRA)

flammable liquid petroleum products, packaged form, injuries and

technique [47]

flammable liquid chemicals, and other health risks, and the

ammonium nitrate (i.e. dry bulk cargoes). marine environment risks.

http://www.iaeme.com/IJMET/index.asp 825 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

Standards

/Framework/ Advantages Limitation

Guidelines

Limited to analyzing

Marine Accident Risk The model enables the assessment of each historical and accidents data

Calculation System set of the risk control options within a single only. Thus, there are

(MARCS), 2000 framework. possibilities of data

insufficiency.

Risk-Based Decision- Reliable and suitable risk assessment tools Not legally binding and does

Making (RBDM) are provided in the guidelines. not replace national laws,

Guidelines U.S. Coast regulations, and accepted

Guard (USCG 2001) Focused on port and waterway areas. standards.

Able to provide specific risk criteria and

calculation of individual and societal risks

while considering aspects such as volume of Not legally binding and does

QRA and Risk-Effect transport, substances transported, and not replace national laws,

Model (REM)[50] population data along transport routes, and regulations, and accepted

weather effects. standards.

Focused on Netherland’s transportation

such as port, train and etc.

8. RISK MANAGEMENT STANDARDS, GUIDELINES, AND

FRAMEWORKS

One of the major components in port risk management standards is risk assessment. During

the last three decades, risk assessment has emerged as an essential and systematic tool that

plays a relevant role in the overall management of many aspects of our life [26]. Analysis

techniques are applied in many different areas for different purposes [27]. Risk assessment is

generally defined as the process of identification and evaluation of risks or hazards [28]. A

basic risk assessment comprises of five (5) basic steps [68], as illustrated in Figure 2 below:

1. Identification of risks. In this step, risk factors, the triggering events, their causes and

each risk’s potential consequences will be identified.

2. Risk analysis. In this step, the nature and level of risk will be qualitatively or

quantitatively analyzed. Then, risk analysis will provide a picture of the causes and

consequences and aims to describe the risk.

3. Action Plan. In this step, preventive and corrective action will be planned and

scheduled based on the risk level and priority.

4. Monitoring and implementation of action plans.

5. Effective monitoring of measures taken via mechanisms of prevention and protection.

1. Identify 2. Analyze 3. Planning 4.Follow up 5. Control

Figure 2 Risk Assessment Process

http://www.iaeme.com/IJMET/index.asp 826 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

The risk assessment process starts with the identification of the activity, its risks, and its

hazards. After the hazards and risks have been identified, it is necessary for the risks and

hazards to be analyzed [70]. There are two mains technique categories in risk analysis. It can

either be analyzed qualitatively or quantitatively. In the past few decades, qualitative

techniques have been widely used in many applications. As modernization occurs, more

advanced mathematical techniques have been derived. Both techniques have its own

advantages and disadvantages. However, the main objective is to provide the best solution for

risk analysis. Recently, many studies focused on the integration of both methodologies to gain

a solid and acceptable solution in analyzing risks [20]. This effort simultaneously

supplements to current knowledge on risk management of such systems, advanced risk

management models, and general guidelines on the improvement of current frameworks and

procedures. Motivated by this tremendous effort, this study was undertaken to take a leading

step in designing interrelated frameworks related to these three main components and evaluate

their effectiveness and implementation, which would be beneficial to system theories and

indirectly, to the industry. As mentioned earlier, risks have many categories. Some examples

are financial risks, business risks, compliance risks, and operational risks. The most popular

forms of risks are financial risk, investment risk, project or multi-project risk, operational

risks such as in operations involving petrochemical & natural gases, information technology

risk, market price and cost risk, quality risk such as in pharmaceutical drugs, human resources

risk, institutional risk, environmental risk, security risk, and occupational health & safety risk.

In a qualitative approach, the risk factor is identified and its impact and likelihood are

assessed. Common qualitative techniques are risk matrix techniques, such as those being

enforced by the Malaysian Department of Occupational Safety and Health (DOSH) in their

guidelines, and the Guidelines for Hazard Identification, Risk Assessment, and Risk Control

(HIRARC), 2005. This method classifies and categorizes the risk based on its risk level

(usually high, medium, or low). The risk control or control measures shall take place based on

the urgency of the risk level. Other examples of qualitative risk assessment include failure

mode effect analysis, which is a technique focused on the impact of the failure, which is

found by multiplying the severity, detection, and occurrence to gain a risk priority number.

This is one of the famous qualitative risk analysis techniques that were used back then,

especially in high-risk analysis.

The advantages of qualitative techniques are it is applicable, it is able to identify the

priority and urgency of the risk, and its simple approach is easily understood. These

techniques usually required experience or an expert team in making decisions based on the

risk severity and likelihood, which can lead to disadvantages such as human bias or

misjudgment. Many studies conducted have overcome the bias problem by suggesting a team

approach in conducting risk assessments, but this approach does not reduce the amount of

subjectivity present in the process. Besides, the technique also contributes to subjectivity, as

every task or activity varies in location, industry, organization, and many more aspects.

Meanwhile, the quantitative approach requires a systematic framework or model that can

quantify the likelihood of the risk. These techniques are using mathematics to calculate the

probability of risk. Techniques such as the Probabilistic Risk Assessment (PRA) have become

increasingly popular. With these techniques, complex systems and operational situations, the

increase of data and information, the increase in safety and environment concerns, and

advanced technology have become some of the factors that have created the need for a

systematic, rigid, transparent, and quantitative risk assessment. The major advantages of

quantifying the risks are that they provide an adequate understanding of failure, consequences

and events, which are difficult to explain from a qualitative approach. In addition, it is easy to

understand the overall process, reach the appropriate decisions, and allocate resources based

http://www.iaeme.com/IJMET/index.asp 827 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

on quantitative data rather than qualitative opinions. The quantitative techniques are

compliments to qualitative techniques. As time has passed, many frameworks were

established by researchers in combining the two methods in managing risks. The objectives of

this combination are to close the gap of disadvantages of both methods. Many improvements

in managing risks have been made by researchers. However, there are also a few researchers

still using only one of the methods to prove the effectiveness of their theory. Most of them are

still acceptable; however, there will be some limitations. The key objectives of managing risk

are to prevent accidents from happening.

Advanced risk assessments that combines qualitative and quantitative methods, such as

Fuzzy failure mode effect analysis, is very popular these days. Improved risk assessment

techniques were established by researchers by combining the two methods of qualitative and

quantitative analysis in managing risk. Thus, the terms “fuzzy failure mode effect analysis”

[71], fuzzy Bayesian model [52], and fuzzy analytical hierarchy process [29] were introduced.

Francesco Castaldo [78] presented a framework based on Bayesian networks for the

surveillance of public transportation sites. The analysis of behaviors and interactions allow a

reduced but exhaustive picture of the state of the observed scenarios. The system could

represent a useful support for human operators in charge of large and crowded areas such as

ports, canals, or airports, where often, a single person must check many monitors and

indicators related to the same area at the same time. Goerlandt and Kujala [73] also used

quantitative risk techniques. They analyzed the reliability of quantitative risk analysis through

a case study of ship–ship collision risk analysis for a given seaport area. It was found that the

probability and indicator-based risk perspectives do not necessarily provide the same risk

picture when the analysis is repeated. It varies with the factor and input respectively.

An example of another technique is the Analytical Hierarchal Process. It is a structured

multi-attribute decision method. This technique was used to facilitate decisions made under

risky or uncertain situations. The main advantage of the Analytical Hierarchal Process is its

capability to check and reduce the inconsistency of expert judgments. While reducing bias in

the decision-making process, this method provides group decision-making through a

consensus using the geometric mean of the individual judgments. The Analytical Hierarchal

Process derives scales of values from pairwise comparisons in conjunction with ratings and is

suitable for multi-objective, multi-criteria, and multi-actor decisions with any number of

alternatives. Mabrouki et al. [68] used this technique to describe the problem of operational

risk management within the RO–RO activity at port terminals, which is a real application of

the multi-criteria approach and a critical analysis method. He implemented three steps, where

the first step is to define and identify the risk factors via the brainstorming approach. In this

stage, we can define a list of major risks. The second step aims to describe the risks

quantitatively to determine the level and the nature of the risks using an analysis. Finally, the

development of criteria and their weighting, where the most probable risks are assessed under

the analytical hierarchal analysis method. This study proposed a strong tool for the decision

makers to prepare preventive action plans for the most critical risks. The objectives of this

combination are to close the gap of disadvantages of both qualitative and quantitative

methods. However, there are a few researchers still using only one of the methods to prove

the effectiveness of their theory. Most of them are still acceptable; however, there will be

some limitations.

Even when comparing the qualitative and quantitative methods, in the complex and rapid

development of the port industry, the semi-quantitative risk analysis still seems to be the more

realistic approach. The semi-quantitative risk assessment approach provides an intermediate

level between the textual evaluation of qualitative risk assessment and the numerical

evaluation of quantitative risk assessment by evaluating risks with a score. The semi-

http://www.iaeme.com/IJMET/index.asp 828 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

quantitative method is more frequently used in estimating risks than the quantitative method

[70]. The advantages of a semi-quantitative risk assessment are that this method is the most

useful for providing a structured way to rank risks (according to their probability and impact)

and for ranking the effectiveness of risk-reduction actions. This is achieved through a

predefined scoring system that allows one to place perceived risks into categories, where there

is a logical and explicit hierarchy between them. Semi-quantitative risk assessment offers the

advantage of being able to evaluate a larger number of risk issues than quantitative risk

assessment because a full mathematical model is unnecessary, especially in the port industry.

The semi-quantitative risk assessment approach provides an intermediate level between

the textual evaluation of qualitative risk assessment and the numerical evaluation of

quantitative risk assessment by evaluating risks with a score. The analysis is more easily

practiced. It has been argued that the semi-quantitative method is more frequently used in

estimating risks than the quantitative method [70]. Semi-quantitative risk assessment is most

useful for providing a structured way to rank risks according to their probability and impact

and for ranking the effectiveness of risk-reduction actions. This is achieved through a

predefined scoring system that allows one to place perceived risks into categories, where there

is a logical and explicit hierarchy between them.

Semi-quantitative risk assessment offers the advantage of being able to evaluate a larger

number of risk issues than quantitative risk assessment because a full mathematical model is

unnecessary. The classic risk matrix approach uses the multiplication of severity and

likelihood to produce a risk rating, where the risk category is then decided based on the risk

rating [12]. Based on the risk assessment, the organization will be able to identify and

evaluate the risk based on whether the risk is in the high or low category. This will be able to

help the organization focus on the most significant risks to be handled and consider the

suitable risk measure to be put in place.

Many researchers have been employed and proved the semi-quantitative risk assessment

techniques in their study to be effective, as in Table 6. Wijeratne et al. [74] used risk matrices

with two dimensions namely, the frequency of occurrence of an accident and the severity of

its consequences. Semi-quantitative analysis is the most preferred technique of stating risks in

the industry [74]. The simplified yet structured technique is easily implemented and adopted.

The risk calculator and the semi-quantitative risk rating matrix can be identified as the most

preferred methods for risk analysis [70]. The techniques are also easy to understand and

communicate. It is an advantage to apply this technique in such complex scenarios. The risk

matrix model is able to assess placement of risk levels in terms of risk analysis and

evaluation. The risk matrix model can help risk managers to develop highly efficient risk

management strategies across multiple risk levels in accordance with various risk factors,

which lessens loss occurrence rates and thereby reduce corporate financial impact [14]. The

simplicity of semi-quantitative techniques enables it to be implemented and conducted in

many industries. The risk matrix model can assess placement of risk levels in terms of risk

analysis and evaluation. The simplicity of semi-quantitative techniques helps it be

implemented and conducted by many industries

From Malaysian legislation perspectives, the employer’s responsibility in managing

occupational safety and health in the workplace is stressed. It believes that the responsibility

of the safety of an organization lies in the employer, as the exposure to hazards and risks were

created by them. Thus, most of the world’s organization has implemented risk management

systems not only in safety but also in their business overview to manage the risks within their

company. Risk matrix techniques have been applied and enforced by the Malaysian

Department of Occupational Safety and Health (DOSH) in their guidelines, which is the

Guidelines for Hazard Identification, Risk Assessment and Risk Control (HIRARC), 2005.

http://www.iaeme.com/IJMET/index.asp 829 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

This method classified and categorized the risks based on risk level, which categories are

usually named high, medium, and low. The risk control or control measure shall take place

based on the priority and urgency of the risk level. Other examples of qualitative risk

assessment are failure mode effect analysis. This technique focuses on failure impact by

multiplying the severity, detection, and occurrence to obtain a risk priority number. This is

one of the famous qualitative risk analysis techniques used back then, especially in high-risk

analysis.

The advantages of qualitative techniques are that it is easier to be conducted, it is able to

identify the priority and urgency of risks, and it is easily understood, as it is a simple

approach. These techniques usually require experience or an expert team in making decisions

on the risk severity and likelihood, which lead to disadvantages caused by human bias or

misjudgment. Many studies conducted have overcome the bias problem by suggesting a team

approach in conducting risk assessments, but still, these approaches do not necessarily reduce

the amount of subjectivity present in the process [68]. Besides, the technique also contributes

to subjectivity as every task or activities varies according to location, industry, organization,

and many more aspects. Meanwhile, the quantitative approach requires a systematic

framework or model that can quantify the likelihood of the risk. These techniques use

mathematics to calculate the probability of risks. The major advantage of quantifying the risks

is that it provides an adequate understanding of failure, consequences, and events, which are

difficult to explain by a qualitative approach. In addition, it is easy to understand the overall

process, reach the appropriate decision, and allocate resources based on quantitative data

rather than qualitative opinions. The quantitative techniques compliment qualitative

techniques.

Table 6 List of studies with research assessment techniques

No. Author, year Location Methodology Techniques Data

Pak, J. Y. et al., Fuzzy AHP

1 Korea port Qualitative Questionnaire

2015[29] Questionnaire

Accident data

Zhang et al., Qualitative and

2 Tianjin port analysis Bayesian Accident data

2016[52] Quantitative

Belief Networks

Fuzzy set theory

Mokhtari, K. et al., (FST) Qualitative and

3 Iranian Port Case study

2012 [72] Case Study Quantitative

sensitivity analysis

Mabrouki, C. et al. RO-RO port

4 AHP method Qualitative Statistical data

2014 [68] activity

Vidmar, P.and

Formal Safety

5 Perkovic. M., 2015 Port cruise Qualitative Statistical data

Assessment

[64]

Abdelhakim

Formal Safety

6 Bouzaher et al., Algerian port Qualitative Accident data

assessment

2015[13]

Montewka, J. et Formal Safety

7 Port Qualitative Case study

al., 2014 [57] Assessment

Lu, C.S and Kuo, hierarchical Qualitative and historical

8 Port

S.Y., 2016 [30] regression analysis Quantitative statistical data

Preben H. L. &

9 Kringen, J, Port Case study Qualitative Audit

2015[53]

http://www.iaeme.com/IJMET/index.asp 830 editor@iaeme.com

Review on Risk, Risk Assessment Techniques, Guidelines and Framework in Port Safety

Wang et al., 2016

10 Port Statistical data Qualitative Historical data

[75]

Wen-Kai K. Hsu, Qualitative and

11 Port AHP and Fuzzy Historical data

2012[76] Quantitative

12 Lei, 2015[77] Port Case study Quantitative Case study

Castaldo,F. Topological map; Qualitative and

13 Port Experiment

2016[78] Bayesian model Quantitative

Perkovic, et al., Port-LNG

14 Statistics Qualitative AIS data

2012 [79] operation

DEMATEL Method,

Yang et. al., Qualitative and Questionnaire,

15 Port cause and effect

2014[80] Quantitative interview

diagram

Abderrahmane et

17 Port Statistics Qualitative Historical data

al.,2016 [81]

Antão, P. et Key Performance

18 Port Qualitative Sampling

al.2015 [58] Indicator

Esma Gül Emecen

19 Port Mathematics Quantitative Sampling

Kara, 2016 [82]

Akyuz et al., 2016 Fuzzy Failure Mode Qualitative and

20 Port Historical data

[71] Effect Analysis Quantitative

Adam, E. F. et al.,

21 Port Statistical Qualitative Historical data

2014[19]

Fabiano, B. et al.,

22 Port Statistical Qualitative Historical data

2010 [15]

9. EXPERT JUDGEMENT IN RISK ASSESSMENT

During the past recent years, risk assessment has been investigated by many researchers using

and relying on expert’s judgements. For example, Akyuz et al. [71] used fuzzy Failure mode

effect analysis and supported it with a rule-based expert system, which systematically

reconsiders potential failure modes and effects at the system level. Therefore, the proposed

approach transforms its database into a risk priority number (RPN) of system failures. Failure

Modes and Effects Analysis (FMEA) is a qualitative, systematic, and highly structured

technique that is used to investigate the way a system or system components can result in

performance problems. In 2012, Mokhtari et al. [72] proposed the fuzzy set theory using a

proposed generic risk evaluation model. First, risks levels of the 22 individual risk factors for

three Iranian ports were evaluated by using the Fuzzy Set Theory based on expert’s judgment.

The evolutions for three Iranian ports were synthesized by using evidence and reason to

derive the belief degrees of the same risk factors for the mentioned ports. In the last part, by

feeding the relative weights available from an illustrative example, along with the belief

degrees calculated through the proposed methodology using computer software, the overall

scores of the three nominated ports were calculated. By using an expert’s opinion, eventually,

the proposed methodology and model in the form of decision support can be implemented on

any specific port during the risk management cycle, auditing, port-to-port risk evaluations,

etc. They proposed that the methodology can help the port and terminal managers and

professionals. For example, port risk managers and port auditors can take corrective and

preventive actions at early stages of risks to defeat a variety of problems. Chlomoudis et al.

[12] collected the feedback from port experts and grouped the hazards into five group of risk

categories based on accident factor causes.

http://www.iaeme.com/IJMET/index.asp 831 editor@iaeme.com

Zuritah A. Kadir, Roslina Mohammad, Norazli Othman, Shreeshivadasan Chelliapan and Astuty

Amrin

Both qualitative and quantitative techniques usually require experience or an expert team

in making the decisions. In qualitative techniques, the expert’s judgement is often critical in

determining the risk’s severity and likelihood, which leads to disadvantages where it will

contribute to bias or misjudgment of humans. The complexity of quantitative risk analysis

might be easy for researchers, but Mou et al. [83] argued that implementation in the industry

would have varied outcomes. In order to conduct a quantitative risk assessment, the assessor

must be a statistics expert in calculating the risk using statistical mathematical methods. With

the rapid change in the development of the industry, the industry might not be able to catch

up. Many studies conducted overcame the bias problem by suggesting a team approach in

conducting risk assessments, but these approaches do not necessarily reduce the amount of

subjectivity present in the process.

In 2016, Kontogiannis et al. [42] argued that the risk assessment should require full

involvement from many parties, such as safety practitioners, managers, supervisors, and

technicians. In most cases, a risk assessment is performed on how jobs should be performed,

rather than on how they are performed in practice. Thus, critical alterations or abuse of

procedures are missed in this analysis. This can be avoided by conducting a participative risk

assessment that would involve people on all organizational levels in certain stages of the

analysis. It engages all levels at the organization, which serves as an advantage. Another

advantage of this approach would be that the workforce is encouraged to monitor emerging

hazards and report them, which can update and improve the results of the earlier analysis.

Finally, it would be easier to design safety measures and barriers that are compatible with the

competencies and preferences of workers when they are part of that process, hence enabling a

more efficient human-system interaction. The assessment of these risks is an opportunity to

initiate prevention measures to preserve port facilities, property, marine environments, and the

safety of the people at work.

10. CONTROL MEASURES: AS LOW AS REASONABLY APPLICABLE

(ALARP)

The control measure assessment of risks is essential in managing risk [86]. Risk tolerance