Bridas Espesores

Diunggah oleh

Julio Enrique Oliver CuelloHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bridas Espesores

Diunggah oleh

Julio Enrique Oliver CuelloHak Cipta:

Format Tersedia

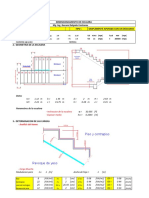

RING FLANGE DESIGN Symbol Unit Value Value Remark

FLANGE DIMENSIONS

Flange outside diameter A in 46.00 46.00

Flange inside diameter B in 36.25 36.25

Circle diameter C in 42.75 42.75

Face outside diameter F in 40.25 40.25

BOLT INFORMATION

Cantidad ea 32.00 32.00

Nominal diameter a in 0.75 0.75

Series sin Coarse Coarse

Threads per in 1/in 10.00 10.00

Area esfuerzo de tensión At in2 0.334 0.334

Area al diametro menor Ar in2 0.302 0.302

Material A193 Gr B7 A193 Gr B7

1 DESIGN CONDITIONS

Desing internal pressure P psi 60.00 60.00

Design temperature T F 212.00 212.00

Flange Material sin ASTM A36 ASTM A36

Bolting Material sin A193 Gr B7 A193 Gr B7

Corrosion Allowance in - -

Allowable Stresses

At flange design Temp Sfo psi 15,700 15,700

At flange atmospheric Temp Sfa psi 15,700 15,700

At bolting design Temp Sb psi 25,000 25,000

At bolting atmospheric Temp Sa psi 25,000 25,000

2 GASKET

Material sin Asbestos+Binder Elastomer <75A Shore

Outside diameter in 40.25 40.25

Inside diameter in 35.50 35.50

Thickness in 0.0625 0.0625

2.1 FACE

Type sin Raised/plain face Raised/plain face

Outside diameter F in 40.25 40.25

Thickness in 0.0625 0.0625

3 FROM FIG UA-49

N N in 2.00 2.00

Facing sketch sin No (4) No (4)

Column for Basic gasket seating width sin II II

Basic gasket width bo in 0.88 0.88

Effective gasket width b in 0.47 0.47

Gasket diameter=(F-2b) G in 39.31 39.31

Desing seating stress y psi 3,700 -

Gasket factor m sin 2.75 0.50

4 LOAD AND BOLT CALCULATIONS

Mín required bolt load for gasket seating=b*pi*G*y Wm2 lb 213,737 -

Total joint-contact-surface compression load=2*b*pi*G*m*P Hp lb 19,063 3,466

Total hydrostatic end force=G^2*pi*P/4 H lb 72,836 72,836

Required bolt load, operating conditions=Hp+H Wm1 lb 91,899 76,302

Total required bolt cross-section area for seating=Wm2/Sa Am' in2 8.55 -

Total required bolt cross-section area for operating=Wm1/Sb Am'' in2 3.68 3.05

Total required bolt cross-section area (Mayor de Am', Am'') Am in2 8.55 3.05

Actual total cross-sectional area of bolts at root of thread or section

of least diameter under stress Ab in2 9.66 9.66

Cumple diseño de tornillos? Si sin Si cumple Si cumple

Flange design bolt load for operating or seating condicions, as may

apply=0.5*(Am+Ab)*Sa W lb 227,668 158,951

5 MOMENTS

Operating loads

Hydrostatic end force on area inside of flange=PI()*B^2*P/4 HD lb 61,924 61,924

Gasket load, operating=Wm1-H HG lb 19,063 3,466

Difference between H and Hd =H-Hd HT lb 10,913 10,913

Operating lever arms

Radial distance from C to the circle on which HD acts=0.5*(C-B) hd in 3.25 3.25

Radial distance from G to C =0.5*(C-G) hg in 1.72 1.72

Radial distance from C to the circle on which Ht acts=0.5(hd+hg) ht in 2.48 2.48

Operating moments

Component of moment due to HD, operating =HD*hd MD lb-in 201,252 201,252

Component of moment due to HG, operating =HG*hg MG lb-in 32,745 5,954

Component of moment due to HT, operating =HT*ht MT lb-in 27,105 27,105

Total moment acting upon the flange, operating = MD+MG+MT Mo lb-in 261,102 234,311

Seating

Gasket load, seating HG=W HG lb 227,668 158,951

Radial distance from G to C =0.5*(C-G) hg in 1.72 1.72

Total moment acting on the flange, seating =HG*hg MG lb-in 391,068 273,032

6 SHAPE CONSTANTS

K=A/B K sin 1.269 1.269

Y= Y sin 8.29 8.29

If bolt spacing exceeds 2a+t, multiply Mo and MG in t equations by

(Bolt spacing/(2*a+t))^0.5

7 FLANGE THICKNESS

Operating t = ((Mo*Y)/(Sfo*B))^0.5 in 1.95 1.85

Seating t = ((MG*Y)/(Sfa*B))^0.5 in 2.39 1.99

t selected in 2.39 1.99

Bolt spacing = (pi*C)/n in 4.20 4.20

2*a+t in 3.89 3.49

Is Bolt spacing > 2*a+t ? (Yes, No) sin corregir espesor corregir espesor

Factor corrección espesor sin 1.02 1.05

Espesor corregido final t in 2.43 2.09

Anda mungkin juga menyukai

- Platinum Series Absolute-Rated Bag-Sized Cartridges: Maximum Dirt-Holding CapacityDokumen4 halamanPlatinum Series Absolute-Rated Bag-Sized Cartridges: Maximum Dirt-Holding CapacityJulio Enrique Oliver CuelloBelum ada peringkat

- Rosedale Cartridge Stainless Steel 2014 PDFDokumen2 halamanRosedale Cartridge Stainless Steel 2014 PDFJulio Enrique Oliver CuelloBelum ada peringkat

- Cartridge Filters: Rugged, Low-Cost Cartridge Design For Flow Rates To 100 GPMDokumen2 halamanCartridge Filters: Rugged, Low-Cost Cartridge Design For Flow Rates To 100 GPMJulio Enrique Oliver CuelloBelum ada peringkat

- Previous Index Next: High-Capacity Cartridge Filter HousingDokumen9 halamanPrevious Index Next: High-Capacity Cartridge Filter HousingJulio Enrique Oliver CuelloBelum ada peringkat

- Weld WeightDokumen10 halamanWeld WeightDivyesh PatelBelum ada peringkat

- Tabla Americana de Avances de Accesorios... RAUL SUAREZDokumen9 halamanTabla Americana de Avances de Accesorios... RAUL SUAREZJulio Enrique Oliver CuelloBelum ada peringkat

- Weld WeightDokumen10 halamanWeld WeightDivyesh PatelBelum ada peringkat

- Rosedale Cartridge Stainless Steel 2014 PDFDokumen2 halamanRosedale Cartridge Stainless Steel 2014 PDFJulio Enrique Oliver CuelloBelum ada peringkat

- Plano Carcasa en F4752-1Dokumen1 halamanPlano Carcasa en F4752-1Julio Enrique Oliver CuelloBelum ada peringkat

- Detalle de AnclajeDokumen1 halamanDetalle de AnclajeJulio Enrique Oliver CuelloBelum ada peringkat

- Aes DesignDokumen97 halamanAes DesigndineshsirasatBelum ada peringkat

- Aes DesignDokumen97 halamanAes DesigndineshsirasatBelum ada peringkat

- Design partition plate for refinery distillation columnDokumen5 halamanDesign partition plate for refinery distillation columnpippo2378793Belum ada peringkat

- New - Reinforcement of NozzleDokumen31 halamanNew - Reinforcement of NozzleChagar HarshpalBelum ada peringkat

- New - Reinforcement of NozzleDokumen31 halamanNew - Reinforcement of NozzleChagar HarshpalBelum ada peringkat

- Manual de Calculos Del Ingeniero MecanicoDokumen16 halamanManual de Calculos Del Ingeniero Mecanicomadenicola10Belum ada peringkat

- Diseño de Viga Doblemente ReforzadaDokumen4 halamanDiseño de Viga Doblemente ReforzadaJulio Enrique Oliver CuelloBelum ada peringkat

- Diseños Escalera - Ing. Genaro DelgadoDokumen7 halamanDiseños Escalera - Ing. Genaro DelgadofredoBelum ada peringkat

- Diseño de Viga Doblemente ReforzadaDokumen4 halamanDiseño de Viga Doblemente ReforzadaJulio Enrique Oliver CuelloBelum ada peringkat

- Programadores Goyen TS 200 Series Pulse Catalogo CompletoDokumen21 halamanProgramadores Goyen TS 200 Series Pulse Catalogo CompletoJulio Enrique Oliver CuelloBelum ada peringkat

- Tabla Americana de Avances de Accesorios... RAUL SUAREZDokumen9 halamanTabla Americana de Avances de Accesorios... RAUL SUAREZrobertoBelum ada peringkat

- Honey Well Hvac Controls ManualDokumen472 halamanHoney Well Hvac Controls Manualgohvicc100% (4)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- STC PDFDokumen34 halamanSTC PDFМиша ШаулаBelum ada peringkat

- Energy Monitoring With Ultrasonic Flow MetersDokumen35 halamanEnergy Monitoring With Ultrasonic Flow MetersViswa NathanBelum ada peringkat

- Comparing characteristics and properties of various crude oilsDokumen2 halamanComparing characteristics and properties of various crude oilsnishant bhushanBelum ada peringkat

- Design and Analysis of Interleaved Boost Converter for Increased Renewable Energy OutputDokumen18 halamanDesign and Analysis of Interleaved Boost Converter for Increased Renewable Energy OutputHarshitBelum ada peringkat

- Oral Hygiene: Presented By: Anis Anis Andreas KyriakidisDokumen60 halamanOral Hygiene: Presented By: Anis Anis Andreas Kyriakidislenami_91Belum ada peringkat

- Understanding the Four Aspects of EmotionsDokumen13 halamanUnderstanding the Four Aspects of EmotionsRaymond FaeldoñaBelum ada peringkat

- Hanoi 2023 Peoples Picks AwardsDokumen113 halamanHanoi 2023 Peoples Picks AwardsNguyen Anh VuBelum ada peringkat

- Wiper & Washer Circuit PDFDokumen1 halamanWiper & Washer Circuit PDFluis eduardo corzo enriquezBelum ada peringkat

- Max 223C Pipeline Welding InverterDokumen2 halamanMax 223C Pipeline Welding InvertermtonellyBelum ada peringkat

- Case Presentation On Actue Gangrenous Calculos CholecystitisDokumen16 halamanCase Presentation On Actue Gangrenous Calculos CholecystitisNayak DrNareshBelum ada peringkat

- #4 Types of Food, Ingredients and Procedures.Dokumen7 halaman#4 Types of Food, Ingredients and Procedures.Peter GonzálezBelum ada peringkat

- B. WoolworthsDokumen5 halamanB. WoolworthsNjabulo Shakes NtuliBelum ada peringkat

- Exercise - 8.1 NewDokumen24 halamanExercise - 8.1 NewAkriti Sharma 757Belum ada peringkat

- Answer Example Source Questio N Type Topic: Glish/Doanddoeshasandhave/Bjgd /post - HTMDokumen92 halamanAnswer Example Source Questio N Type Topic: Glish/Doanddoeshasandhave/Bjgd /post - HTMFarhan HakimiBelum ada peringkat

- Mathematics: Full Marks Zero Marks: 0 in All Other CasesDokumen31 halamanMathematics: Full Marks Zero Marks: 0 in All Other CasesAbhishek KumarBelum ada peringkat

- Anotações - Seminários em Língua Inglesa - Discurso LiterárioDokumen17 halamanAnotações - Seminários em Língua Inglesa - Discurso LiterárioAline MoraisBelum ada peringkat

- DVRP Newsletter Resilience Vol. 2, Issue 2Dokumen6 halamanDVRP Newsletter Resilience Vol. 2, Issue 2Lucius Doxerie Sr.Belum ada peringkat

- Week 2 - Risk AssessmentDokumen35 halamanWeek 2 - Risk AssessmentTahir BashirBelum ada peringkat

- Zip Grade 100 Question V2Dokumen1 halamanZip Grade 100 Question V2Jesus Daniel Anaya AlvaradoBelum ada peringkat

- GMSARN Conf: Design Criteria on Substation ProtectionDokumen6 halamanGMSARN Conf: Design Criteria on Substation Protectionbdaminda6701Belum ada peringkat

- Aqua Mon 4000 PH Red Ox AnalyserDokumen4 halamanAqua Mon 4000 PH Red Ox Analyserarvindgupta_2005Belum ada peringkat

- Yara Crop Nutrition For HorticultureDokumen8 halamanYara Crop Nutrition For HorticultureadjieBelum ada peringkat

- M.E. (Mechanical - Heat Power Engineering) SyllabusDokumen37 halamanM.E. (Mechanical - Heat Power Engineering) SyllabusKapil KotangaleBelum ada peringkat

- Compression Molding of Gypsum Blocks Using Ecological Brick MachinesDokumen11 halamanCompression Molding of Gypsum Blocks Using Ecological Brick Machinessami fanuaelBelum ada peringkat

- Geneaid DNA Reagent Plant GR200Dokumen4 halamanGeneaid DNA Reagent Plant GR200Gandi SogandiBelum ada peringkat

- Lectures On Quadratic FormsDokumen170 halamanLectures On Quadratic FormsyusamengBelum ada peringkat

- Interaction of Radiation With Matter: Dhruba GuptaDokumen36 halamanInteraction of Radiation With Matter: Dhruba GuptaHala SweetBelum ada peringkat

- Balance of Payment (BoP) Definition, Importance and ComponentsDokumen21 halamanBalance of Payment (BoP) Definition, Importance and ComponentsAnkita Sharma PandeyBelum ada peringkat

- Renal Cortical CystDokumen2 halamanRenal Cortical Cystra222j239Belum ada peringkat

- Comp7 - Answer Key - Dec. Exam - 1st SetDokumen2 halamanComp7 - Answer Key - Dec. Exam - 1st SetHazel Joy LusellaBelum ada peringkat