Boost-Buck LED Driver Topology Delivers Low Input and Output Ripple for Automotive Applications

Diunggah oleh

sridharmakkapatiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Boost-Buck LED Driver Topology Delivers Low Input and Output Ripple for Automotive Applications

Diunggah oleh

sridharmakkapatiHak Cipta:

Format Tersedia

Boost-Buck LED Driver Topology for Automotive LEDs

Operates with Low Input and Output Ripple

Keith Szolusha

Automotive LED drivers often require step-up/step-down DC/DC converters that

can produce constant current at a voltage stepped up and stepped down from

a varying input voltage (battery). Another important requirement for automotive

applications is low EMI, namely, low input and output ripple. EMI requirements

can be difficult to satisfy, as few of the most commonly used step-up/step-down

DC/DC converter topologies can operate with both low input and low output

ripple, while also meeting other requirements. These demands, however, are easily

met by the unique, patent-pending, boost-buck topology described here.

This new topology is not the only step- The overall size of the combined boost- in buck-boost mode. The input ripple

up/step-down topology available. There buck inductors (or coupled induc- is similar to a SEPIC, but the output

are a number of other topologies that tor) is similar to the single inductor ripple is much lower. The inductor size

can convert a wide-ranging input volt-

age to a VLED within that range. The most

ES1B

LED– LED+

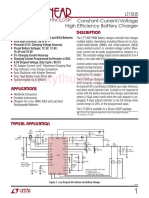

commonly used nonisolated step-up/ Figure 1. The LT3952 8V–36V input to 6V–18V LED 1A boost-

step-down LED driver topologies include: buck LED driver has low input and output ripple with 300:1

6V TO 18V LED

M1 TG

PWM dimming capability at 120Hz and 90% efficiency. 1A ISN

• 4-switch buck-boost for very

10µF

250mΩ

high power and efficiency 25V

ISP

• coupled or uncoupled SEPIC •

L2

L1 22µH

• single inductor buck-boost mode 22µH DFLS260

VIN

•

8V TO 36V 10µF 1µF

• positive-to-negative (buck-based) 50V 50V 4.7µF

100V 365k

single inductor buck-boost. 499k

VIN IVINP IVINN SW GND 100k

Q1 LED–

There are advantages to each of these EN/UVLO FB

topologies, but none can produce both 93.1k OVLO 22.6k

truly low input and output ripple. Linear VIN

VREF

Technology’s patent-pending “boost- 1M

ISP ISP

ISN ISN

buck” (boost-then-buck-mode) floating ANALOG DIM CTRL

LT3952

ISMON

output LED driver topology features 143k DIM PWM PWM

IVINCOMP

low input and output ripple, due to the TG TG

OPENLED OPENLED

input-and output-facing inductors (or VC

SHORTLED SHORTLED

3.3k

coupled windings). In various ways, it

4.7nF SS RT SYNC/SPRD INTVCC 100k 100k

resembles a single inductor buck-boost

0.1µF 287k

mode, a single-switch-node SEPIC and a 2.2µF

350kHz

positive version of a Cuk (which also has

low input and output ripple, but requires

L1: SUMIDA CDRH8D43-220NC (UNCOUPLED)

a negative-referenced feedback circuit). L2: SUMIDA CDRH6D38-220NC

L1A, L1B: COILCRAFT MSD1278-223ML (COUPLED)

M1: VISHAY Si7309DN

Q1: ZETEX FMMT591A

8 | April 2015 : LT Journal of Analog Innovation

design features

There are several step-up/step-down topologies, but none can produce both truly

low input and output ripple. Linear Technology’s patent-pending “boost-buck” (boost-

then-buck-mode) floating output LED driver topology features low input and output

ripple, due to the input- and output-facing inductors (or coupled windings).

LED– LED+

ES1B A low EMI positive boost-buck

Figure 2. The LT3952 single inductor buck-boost can easily be built with a boost

mode LED driver used for comparison to Figure 1 M1 TG

6V TO 18V LED LED driver, such as the LT3952.

boost-buck topology 1A ISN

10µF

25V

250mΩ BOOST-BUCK TOPOLOGY AND

ISP FLOATING LED OUTPUT

Figure 1 shows a single switch 60V

L1

DFLS260

VIN

10µH monolithic LT3952 LED driver with 4A

8V TO 36V 10µF 1µF peak switch current, which can be used

50V 50V 4.7µF

499k

100V 365k as an automotive boost-buck LED driver.

VIN IVINP IVINN SW GND 100k This 350kHz , 1A LED driver can power

Q1 LED–

EN/UVLO FB 6V to 18V of LEDs from an 8V to 36V

93.1k OVLO 22.6k input with up to 90% efficiency at maxi-

VIN

VREF mum load. High conversion efficiency

ISP ISP

1M is a result of the powerful internal MOS

LT3952 ISN ISN

ANALOG DIM CTRL ISMON switch. Efficiencies with various LED

143k DIM

IVINCOMP

PWM PWM string voltages are shown in Figure 3.

TG TG

OPENLED OPENLED

VC Like other LED drivers, the LT3952’s

SHORTLED SHORTLED

2.7k

versatile single, low side power switch

2.2nF SS RT SYNC/SPRD INTVCC 100k 100k

architecture can be used to power floating

0.1µF 287k

2.2µF

output step-up and step-down converters

350kHz such as boost-buck and single inductor

buck-boost mode. The LED string’s volt-

L1: SUMIDA CDRH104R-100

M1: VISHAY Si7309DN age reference to ground is not important

Q1: ZETEX FMMT591A

since LED output is visible light only.

Because of this, the unique floating LED

is the same as a SEPIC, but with a single driver topologies such as boost-buck

100

1A ILED switch node instead of two (a smaller and buck-boost mode are possible.

95 hot-loop) and without the complica-

The LT3952’s ability to PWM dim the

tion of a coupling capacitor between

17.5V LED

90 floating LED string with the floating top

the two windings. The input and output

EFFICIENCY (%)

14.5V LED gate (TG) pin PWM MOSFET driver easily

ripple resemble that of a low input and

85

supports floating LED loads. The boost-

output ripple (inverting) Cuk converter,

buck in Figure 1 can PWM dim at ratios

80 but again, with a single switch node

7.3V LED of 300:1 and higher (at a “no-flicker”

9.7V LED instead of two, and most importantly,

75 120Hz). The high side TG driver effort-

without the need for a negative-refer-

lessly provides PWM dimming to boost,

70 enced circuit feedback architecture.

5 10 15 20 25 30 35 40 SEPIC, buck-boost mode, buck mode and

VIN (V)

boost-buck LED drivers. It even doubles

Figure 3. Boost-buck efficiency of Figure 1 is as high

as 90% with 12V input and 17.5V 1A LED string.

as a short-circuit protection disconnect

April 2015 : LT Journal of Analog Innovation | 9

to protect against dreaded LED+-to-GND 100 100

PEAK VIN = 12V, VLED = 18V, 1A AVERAGE VIN = 12V, VLED = 18V, 1A

conditions. The LT3952 protects against 90 90

FIGURE 2 FIGURE 2

and reports short-circuit and open LED 80 80

AVERAGE AMPLITUDE (dBµV)

BUCK-BOOST MODE BUCK-BOOST MODE

PEAK AMPLITUDE (dBµV)

70 70

conditions in boost-buck topology. FIGURE 1 FIGURE 1

60 BOOST-BUCK 60 BOOST-BUCK

The boost-buck LED driver topology can 50 50

both step-up and step-down the input- 40 40

to-output voltage as it regulates the LED 30 30

current. Boost-buck duty cycle, efficiency, 20 20

switch current and VOUT node voltage are 10 10

the same as both single inductor buck- 0 0

150k 10M 150k 10M

boost mode and SEPIC. Here are some FREQUENCY (Hz) FREQUENCY (Hz)

properties of the boost-buck LED driver: Figure 4. (a) Figure 1 boost-buck conducted EMI is much lower than (b) Figure 2 buck-boost mode conducted

EMI for 12V input, 18V, 1A LED string.

• VOUT = VIN + VLED

• DC = VLED /(VIN + VLED)

separation of input and output wind- long, as in a car. Mitigating radiated EMI

• ISW(PEAK) = IIN + ILED + IL(P–P) /2 ings prevents the output ripple current with additional LC filtering on the output

• IL(P–P) = IL1(P–P) + IL2(P–P) from coupling to the input capacitor of of an LED driver is not recommended,

the boost-buck, thus reducing EMI. The since it can inhibit optimal PWM dimming

LOW INPUT AND OUTPUT RIPPLE EMI in Figure 4 shows low AM band EMI performance by slowing PWM transi-

TOPOLOGY = LOW EMI

from 530kHz to 1.8Mhz, reducing the tions and causing unwanted ringing. The

Figure 2 shows an “equivalent” single requirement for a large EMI input filter. low ripple, output-facing inductor of the

inductor buck-boost driver—compa- boost-buck yields the best combination of

Figure 5 compares the input and output

rable to the boost-buck driver shown in PWM dimming performance and low out-

ripple paths of the boost-buck topology

Figure 1. Although there are similarities put EMI, similar to a buck-only converter.

with those of a SEPIC converter, which

between the two, they differ greatly in

does not have the same low output ripple. Note that the positive-to-negative single

input and output ripple. Figure 4 demon-

High ripple on either the input or out- inductor buck-boost converter also has

strates the reduced conducted EMI of the

put lines can radiate and increase EMI, low output ripple and high bandwidth,

boost-buck driver (Figure 1) versus the

especially if those lines are several meters but its input and output ripple are coupled

buck-boost mode version (Figure 2). The

into the large system input capacitance,

creating greater conducted EMI.

Figure 5. Boost-buck LED INVERTING CUK

driver is similar to SEPIC Both the input and output capacitors

SW1 SW2

LED driver topology VIN –VOUT in the boost-buck topology easily filter

•

L1 L2

CIN S1 HOT COUT low triangular ripple current equal to

LOOP

IL1(P–P) /√12. A bit more capacitance or

inductance can further reduce EMI in this

topology. Neither the input nor output

SEPIC

capacitor is crucial in the converter’s high

SW1 SW2

VIN VOUT dI/dt hot-loop. In this topology, the critical

•

L1 •

CIN S1 L2 HOT COUT

hot-loop is constrained to the catch diode,

LOOP

OUT-to-GND capacitor, and the internal

low side switch, as indicated in Figure 5,

simplifying the layout. If the two induc-

FLOATING OUTPUT POSITIVE BOOST-BUCK LED DRIVER tors or windings of the boost-buck are tied

VIN

SW1

LED–

together and the LED− node is connected

•

L1 L2

HOT to the input, the boost-buck is converted

CIN S1 LOOP COUT

to buck-boost mode. In this scenario,

LED+ the hot-loop currents and the input and

VOUT

10 | April 2015 : LT Journal of Analog Innovation

design features

9V TO 16V

1µF M1

25V

200k

1% 220nF

VIN TG L2

EN EN/UVLO BOOST

4.7µH

38.3k D1

INTVCC 12V TO

16V

CTRLT 10µF 10µF

2V 3A LED

VREF LT3744 25V

×2 VEE L1 10µF

2.2nF 100k 50V

10k SGND 4.7µH

1% ×4

FAULT

5mΩ

CTRL1 1M

ISN

30.1k CTRL2,3

ISP D2

SW

10µF

2V BG M2 25V

PWM1

0V ×4

PWM2,3 VEE

SYNC VFNEG VEE

FB

SS 71.5k

10nF VC1 PWM_OUT2,3

VC2,3

VEE 10k VEE

PWM_OUT1 M2

4.7nF 10Ω

LED_ISP

VEE

RT 20mΩ

102k 10Ω

400kHz LED_ISN

VEE

VEE

M1, M2: INFINEON BSC067N06LS3

M3: INFINEON BSC010N04LS

L1: WÜRTH 7443551470 4.7µH

L2: WÜRTH 744325420 4.2µH

D1: PMEG4002EB Figure 6. The LT3744 9V–16V input, 16V, 3A LED string positive-to-negative boost-buck LED driver has low

D2: PMEG4010

input and output ripple and high 93% efficiency at 48W LED.

output ripple currents can find their frequency boost response and higher when driving a high power LED string,

way onto the input and output capaci- frequency buck response of this boost- such as the 3A, 48W LED load in Figure 6.

tors, respectively, resulting in increased buck can be seen in both the loop Bode Synchronous step-up and down boost-

input and output ripple measurements. plots and in the transient response. buck LED drivers are possible with both

synchronous boost and buck LED drivers.

LOOP ANALYSIS FOR STABILITY POSITIVE-TO-NEGATIVE BOOST-

(SEPIC-LIKE CONTROL LOOP) MODE-THEN-BUCK TOPOLOGY CONCLUSION

WITH SIMILAR PERFORMANCE

The control loop of the boost-buck New, patent-pending boost-buck LED

ADVANTAGES

converter has the personality of a SEPIC. driver topologies from Linear Technology

The loop response can be measured Another patent-pending boost-buck LED

provide step-up and step-down input to

with a network analyzer by injecting a driver topology with low ripple input and

VLED ratios with low input and output rip-

noise perturbation into the ISN line and output is shown in Figure 6. The LT3744

ple. New LED drivers such as the LT3952

measuring the gain and phase of the positive-to-negative boost-buck (boost-

and LT3744 can be used for both simple

loop response at the sense resistor. The mode-then-buck) is also a low input and

and high power LED strings in automotive

uncoupled boost-buck in Figure 1 pro- output ripple LED driver, but instead uses

and industrial applications, where high

duces a 7kHz crossover frequency and well using a synchronous step-down converter

power and low noise are crucial, without

over 60° of phase margin and 10° of gain with negative regulation capability.

sacrificing PWM dimming performance. n

margin at 12V input to 18V VLED at 1A. This unique floating negative output topol-

If no network analyzer is available, the ogy takes advantage of the strengths of the

loop dynamics can be determined by the synchronous step-down LT3744 LED driver

shape of LED current transient response with PWM and output flag level-shift

waveforms when the CTRL input is capabilities. One of those strengths is the

toggled from 50% to 100% LED cur- high efficiency that is only possible with

rent or vice versa. The merged lower a synchronous switching IC, especially

April 2015 : LT Journal of Analog Innovation | 11

Anda mungkin juga menyukai

- Acpl 337J 500eDokumen18 halamanAcpl 337J 500eAandk NovaBelum ada peringkat

- 24V, High Current Synchronous Buck Converter With +/-1.5A LDO and Buffed ReferenceDokumen21 halaman24V, High Current Synchronous Buck Converter With +/-1.5A LDO and Buffed Reference8ctanoBelum ada peringkat

- LT3865 FBDokumen38 halamanLT3865 FBarmin rahmatiBelum ada peringkat

- LM5030 Application: DC - DC Converter Utilizing The Push-Pull TopologyDokumen10 halamanLM5030 Application: DC - DC Converter Utilizing The Push-Pull TopologyEdoardoBelum ada peringkat

- Lm3280 Adjustable Step-Down DC-DC Converter and 3 Ldos For RF Power ManagementDokumen27 halamanLm3280 Adjustable Step-Down DC-DC Converter and 3 Ldos For RF Power ManagementEliecer MenesesBelum ada peringkat

- Lm3280 Adjustable Step-Down DC-DC Converter and 3 Ldos For RF Power ManagementDokumen26 halamanLm3280 Adjustable Step-Down DC-DC Converter and 3 Ldos For RF Power ManagementAdi PopaBelum ada peringkat

- 3827 FFDokumen36 halaman3827 FFDMITRIY DOMOCHKINBelum ada peringkat

- LTC 3777Dokumen40 halamanLTC 3777unwantedadvertisementBelum ada peringkat

- Features Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersDokumen28 halamanFeatures Description: LT3755/LT3755-1/LT3755-2 40V, 75V LED ControllersMick Thomson RcBelum ada peringkat

- 6244 FBDokumen26 halaman6244 FBjuracyleandroBelum ada peringkat

- Gate Driver Design - From Basics To Details: Wei ZhangDokumen33 halamanGate Driver Design - From Basics To Details: Wei ZhangRajiv ChaudhariBelum ada peringkat

- 3798 FaDokumen20 halaman3798 FaFavio IousBelum ada peringkat

- Features: Lt1375/Lt1376 1.5A, 500Khz Step-Down Switching RegulatorsDokumen29 halamanFeatures: Lt1375/Lt1376 1.5A, 500Khz Step-Down Switching RegulatorsSergio MuriloBelum ada peringkat

- 50W 0/1-10V LED Driver (Constant Voltage) : Important: Read All Instructions Prior To InstallationDokumen1 halaman50W 0/1-10V LED Driver (Constant Voltage) : Important: Read All Instructions Prior To InstallationThai NguyenBelum ada peringkat

- Di-143 Design Idea Topswitch-Hx: High Effi Ciency Inkjet Power Supply Provides Up To 80 Watts of Peak PowerDokumen2 halamanDi-143 Design Idea Topswitch-Hx: High Effi Ciency Inkjet Power Supply Provides Up To 80 Watts of Peak PowerJose BenavidesBelum ada peringkat

- lc5222d Ds enDokumen11 halamanlc5222d Ds enRick HunterBelum ada peringkat

- Power Factor Corrector: Minidip SO8 Ordering Numbers: L6561 (Minidip) L6561D (SO8)Dokumen11 halamanPower Factor Corrector: Minidip SO8 Ordering Numbers: L6561 (Minidip) L6561D (SO8)Karim CocasBelum ada peringkat

- 60V Step-Down DC/DC Converter Maintains High Effi Ciency: Design Note 269 Mark W. MarosekDokumen2 halaman60V Step-Down DC/DC Converter Maintains High Effi Ciency: Design Note 269 Mark W. MarosekMes BenBelum ada peringkat

- SC4541 Rev.2.1Dokumen19 halamanSC4541 Rev.2.1Akhil GargBelum ada peringkat

- MEHRAN UNIVERSITY OF ENGINEERING & TECHNOLOGY SZAB CAMPUS GROUP (C) Online Mid Term Examination on Summing AmplifierDokumen9 halamanMEHRAN UNIVERSITY OF ENGINEERING & TECHNOLOGY SZAB CAMPUS GROUP (C) Online Mid Term Examination on Summing AmplifierNoor SabaBelum ada peringkat

- Features Description: Ltc3565 1.25A, 4Mhz, Synchronous Step-Down DC/DC ConverterDokumen22 halamanFeatures Description: Ltc3565 1.25A, 4Mhz, Synchronous Step-Down DC/DC Converterferney_09Belum ada peringkat

- Mp2565dn LF ZDokumen20 halamanMp2565dn LF ZnvkjhejfjBelum ada peringkat

- Acpl 332JDokumen23 halamanAcpl 332JAdir FigueiredoBelum ada peringkat

- Features: LT1176/LT1176-5 Step-Down Switching RegulatorDokumen8 halamanFeatures: LT1176/LT1176-5 Step-Down Switching RegulatorDreavus HashirobiBelum ada peringkat

- MP6001 r1.0Dokumen13 halamanMP6001 r1.0nan keBelum ada peringkat

- LTC 1267 FDokumen1 halamanLTC 1267 FEdson HenriqueBelum ada peringkat

- Features Description: LT8631 100V, 1A Synchronous Micropower Step-Down RegulatorDokumen26 halamanFeatures Description: LT8631 100V, 1A Synchronous Micropower Step-Down RegulatorAle NqnBelum ada peringkat

- Transition-Mode PFC Controller: BCD TechnologyDokumen15 halamanTransition-Mode PFC Controller: BCD TechnologyWilson vargas de la cruzBelum ada peringkat

- LLC Half-Bridge Controller For Multi-String LED Lighting: Features ApplicationsDokumen34 halamanLLC Half-Bridge Controller For Multi-String LED Lighting: Features ApplicationsDiego DiegoteBelum ada peringkat

- Jlpea 11 00047 v2Dokumen13 halamanJlpea 11 00047 v2卓七越Belum ada peringkat

- Features Description: Lt3791 60V 4-Switch Synchronous Buck-Boost Led Driver ControllerDokumen28 halamanFeatures Description: Lt3791 60V 4-Switch Synchronous Buck-Boost Led Driver ControllerThallys BatistaBelum ada peringkat

- Nb679a MpsDokumen19 halamanNb679a MpswarkeravipBelum ada peringkat

- Features: LT1010 Fast 150ma Power BufferDokumen16 halamanFeatures: LT1010 Fast 150ma Power BufferArie DinataBelum ada peringkat

- Features: LT1010 Fast 150ma Power BufferDokumen16 halamanFeatures: LT1010 Fast 150ma Power BufferArie DinataBelum ada peringkat

- Features: LT1010 Fast 150ma Power BufferDokumen16 halamanFeatures: LT1010 Fast 150ma Power BufferArie DinataBelum ada peringkat

- Switching From The L6561 To The L6562: AN1757 Application NoteDokumen9 halamanSwitching From The L6561 To The L6562: AN1757 Application Notedeilyn rivasBelum ada peringkat

- Features Descriptio: LTC1624 High Efficiency SO-8 N-Channel Switching Regulator ControllerDokumen28 halamanFeatures Descriptio: LTC1624 High Efficiency SO-8 N-Channel Switching Regulator ControllervetchboyBelum ada peringkat

- DC Converter With Low PassDokumen38 halamanDC Converter With Low PassMuhammad Fikri Hidayat FikriBelum ada peringkat

- VACON NXC Low Harmonic Single Drive AFEDokumen20 halamanVACON NXC Low Harmonic Single Drive AFEDave DuasoBelum ada peringkat

- RMS-to-DC Conversion Just Got EasyDokumen2 halamanRMS-to-DC Conversion Just Got Easyzeropoint_romeoBelum ada peringkat

- 3727 FCDokumen32 halaman3727 FCtommy99Belum ada peringkat

- Hvled New High Power Factor PSR LED Drivers: Hvled807Pf Hvled815PfDokumen22 halamanHvled New High Power Factor PSR LED Drivers: Hvled807Pf Hvled815PfMARCoOBelum ada peringkat

- Arquitectura y Aplicacion de Sistemas de Ups Familia TleDokumen69 halamanArquitectura y Aplicacion de Sistemas de Ups Familia TleCarlos BallesterosBelum ada peringkat

- Features Description: LTC3780 High Efficiency, Synchronous, 4-Switch Buck-Boost ControllerDokumen30 halamanFeatures Description: LTC3780 High Efficiency, Synchronous, 4-Switch Buck-Boost ControllerjeffBelum ada peringkat

- 100% Duty Cycle Synchronous: 4A, 21V, 500Khz Step-Down ConverterDokumen19 halaman100% Duty Cycle Synchronous: 4A, 21V, 500Khz Step-Down ConverterRivaldo Barbosa GomesBelum ada peringkat

- DP950XB REV2.0 2019-08-16 CN - ZH-CN - enDokumen10 halamanDP950XB REV2.0 2019-08-16 CN - ZH-CN - enSunu Pradana0% (1)

- LTC1250Dokumen8 halamanLTC1250fcojrpBelum ada peringkat

- Descriptio Features: LT1505 Constant-Current/Voltage High Efficiency Battery ChargerDokumen16 halamanDescriptio Features: LT1505 Constant-Current/Voltage High Efficiency Battery ChargerCarlos Henrique RibasBelum ada peringkat

- L6561Dokumen11 halamanL6561Gilson3DBelum ada peringkat

- Simulation of Buck Converter with Synchronous RectifierDokumen7 halamanSimulation of Buck Converter with Synchronous RectifierThinh NguyenBelum ada peringkat

- 24V, High Current Synchronous Buck Converter With LDO: The Future of Analog IC TechnologyDokumen19 halaman24V, High Current Synchronous Buck Converter With LDO: The Future of Analog IC TechnologyIndika BandaraBelum ada peringkat

- 2.75V To 17V, 6A, 1.2Mhz, Synchronous, Ultra-Thin Power Module Description FeaturesDokumen22 halaman2.75V To 17V, 6A, 1.2Mhz, Synchronous, Ultra-Thin Power Module Description FeaturesEugene FlexBelum ada peringkat

- 8-Bit, 100 MSPS+ Txdac D/A Converter: LinearityDokumen17 halaman8-Bit, 100 MSPS+ Txdac D/A Converter: LinearityNicoli LourençoBelum ada peringkat

- Innoswitch-Ep Family Datasheet PDFDokumen34 halamanInnoswitch-Ep Family Datasheet PDFanand shekhawatBelum ada peringkat

- 5V/12V Synchronous-Rectified Buck Controller With Reference InputDokumen19 halaman5V/12V Synchronous-Rectified Buck Controller With Reference InputIgor LabutinBelum ada peringkat

- L6565 DatasheetDokumen17 halamanL6565 DatasheetJose BenavidesBelum ada peringkat

- Features Description: 1997 Burr-Brown Corporation PDS-1412A Printed in U.S.A. May, 1998Dokumen13 halamanFeatures Description: 1997 Burr-Brown Corporation PDS-1412A Printed in U.S.A. May, 1998Umair MansoorBelum ada peringkat

- Descriptio Features: Lt1370 500Khz High Efficiency 6A Switching RegulatorDokumen16 halamanDescriptio Features: Lt1370 500Khz High Efficiency 6A Switching RegulatorvvvBelum ada peringkat

- Study On Convection Heat Transfer of End-Winding For A 10kW External Rotor PMSM With Open End CapDokumen11 halamanStudy On Convection Heat Transfer of End-Winding For A 10kW External Rotor PMSM With Open End CapsridharmakkapatiBelum ada peringkat

- Single-Stage AC/DC Boost-Forward Converter With High Power Factor, Regulated Bus and Output VoltagesDokumen4 halamanSingle-Stage AC/DC Boost-Forward Converter With High Power Factor, Regulated Bus and Output VoltagessridharmakkapatiBelum ada peringkat

- C28x1Day WorkshopDokumen100 halamanC28x1Day WorkshopsridharmakkapatiBelum ada peringkat

- P C KRAUSE Analysis of Electric Machinary and Drive Systems PDFDokumen632 halamanP C KRAUSE Analysis of Electric Machinary and Drive Systems PDFsridharmakkapati75% (4)

- Lecture 1Dokumen9 halamanLecture 1NikhilDamodaranBelum ada peringkat

- FB77WPCC/T04: M-18 Iridium Industrial Spark PlugDokumen11 halamanFB77WPCC/T04: M-18 Iridium Industrial Spark PlugAlexanderBelum ada peringkat

- SR715 SR720 MeterDokumen109 halamanSR715 SR720 MetermustaquBelum ada peringkat

- LincolnDokumen4 halamanLincolnJuan CaceresBelum ada peringkat

- A25DA30D03diagrams PDFDokumen109 halamanA25DA30D03diagrams PDFcruz Tobilla100% (1)

- Maruti 800 LPG - ManualDokumen120 halamanMaruti 800 LPG - Manuala_grassl1920Belum ada peringkat

- PUMP SELECTION GUIDEDokumen13 halamanPUMP SELECTION GUIDEHeymonth ChandraBelum ada peringkat

- Mansoor Ali Khan: Summary of QualificationsDokumen6 halamanMansoor Ali Khan: Summary of QualificationsMansoor Khanali100% (1)

- RMC Online Washing System Industrial Gas TurbineDokumen3 halamanRMC Online Washing System Industrial Gas TurbinepayamzarBelum ada peringkat

- HPCL RecruitmentDokumen19 halamanHPCL RecruitmentPraneeta KatdareBelum ada peringkat

- The 2022 G7 SummitDokumen2 halamanThe 2022 G7 SummitKgjkg KjkgBelum ada peringkat

- Ici Catalogo2017 enDokumen348 halamanIci Catalogo2017 enIvano50% (2)

- Top 100 Items That Disappear First in DisastersDokumen6 halamanTop 100 Items That Disappear First in DisastersEdward G WalshBelum ada peringkat

- Plumbing Pre-Board Exam-Answer KeyDokumen18 halamanPlumbing Pre-Board Exam-Answer KeyKrizia Charish MejiaBelum ada peringkat

- Zehnder - CSY - ComfoValve Luna - TES - SI - enDokumen2 halamanZehnder - CSY - ComfoValve Luna - TES - SI - enDanielCBelum ada peringkat

- Electronic Devices and CircuitsDokumen2 halamanElectronic Devices and CircuitsKing AshokBelum ada peringkat

- Safety ShoesDokumen13 halamanSafety ShoesyustimdBelum ada peringkat

- Trouble Shooting: Causes RemedyDokumen3 halamanTrouble Shooting: Causes RemedyredouaneBelum ada peringkat

- Run-Up Test: FI-37240 Linnavuori, Nokia FinlandDokumen4 halamanRun-Up Test: FI-37240 Linnavuori, Nokia FinlandGaston SosaBelum ada peringkat

- 4.1 Site Roads Crane Spec 3MW-DFIG-120 130 137-xxHz EMEA EN r08Dokumen44 halaman4.1 Site Roads Crane Spec 3MW-DFIG-120 130 137-xxHz EMEA EN r08Georgescu MirceaBelum ada peringkat

- Tujuan Pembangunan Berkelanjutan (SDGS) Nusantara Berbasis Tinjauan Lokal Sukarela (VLR)Dokumen28 halamanTujuan Pembangunan Berkelanjutan (SDGS) Nusantara Berbasis Tinjauan Lokal Sukarela (VLR)Magister PSDALBelum ada peringkat

- SK Crude Dewaxing ProcessDokumen23 halamanSK Crude Dewaxing ProcessBabji MunagalaBelum ada peringkat

- Workshop II ManualDokumen76 halamanWorkshop II Manualzelalem walie100% (1)

- Decoding NRCC PRF HandoutDokumen75 halamanDecoding NRCC PRF HandoutThomas ChanBelum ada peringkat

- Solar Micro InverterDokumen23 halamanSolar Micro InverterHassan SouleymanBelum ada peringkat

- LC1-D115, LC1-D150, LC2-D115, LC2-D150 3P: DangerDokumen5 halamanLC1-D115, LC1-D150, LC2-D115, LC2-D150 3P: DangerJhon RamboBelum ada peringkat

- Introduction To Green EconomyDokumen11 halamanIntroduction To Green Economyvineet soodBelum ada peringkat

- Tecnotest Analizador Gases Dignostico Stargas Family898 495 enDokumen12 halamanTecnotest Analizador Gases Dignostico Stargas Family898 495 ennewslemBelum ada peringkat

- Ebara DW VoxDokumen2 halamanEbara DW Voxmarckalhi100% (1)

- Review On A Protective Scheme For Wind Power Plant Using Co-Ordination of Overcurrent Relay-NOTA TECNICADokumen5 halamanReview On A Protective Scheme For Wind Power Plant Using Co-Ordination of Overcurrent Relay-NOTA TECNICAEdgardo Kat ReyesBelum ada peringkat

- VAV System Design GuideDokumen35 halamanVAV System Design Guide123john123Belum ada peringkat