JSA Cable Tray Erection On Pipe Rack

Diunggah oleh

nishanthJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

JSA Cable Tray Erection On Pipe Rack

Diunggah oleh

nishanthHak Cipta:

Format Tersedia

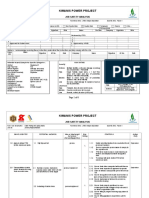

JOB SAFETY ANALYSIS REPORT

Job Title: Cable tray /panel erection Date of Job Analysis:

Projects: BSH Reference No: JSA / EVEREST / 21

Analyst/ Reviewer:

Description of Job: Cable Tray erection at Pipe rack

Sequence of job steps Risks identified Precautions advised

Daily machine checking to ensure

Requirements machine the healthiness of

Al employees should be equipped with

required PPE

Permits and guidelines should be

followed

Tool box meeting should conduct daily

RA briefing to team members must be

done.

A valid certificate should be available for

the vehicle

A only authorized operator should be

operate the vehicle

Collision Root survey should be done before

Arrived boom lift /Hydra to Vehicle/Equipment mobilizations of vehicle

working spot

To ensure should route free from

obstruction

Strict enforcement of speed limit 12km

Securely bounded load while hoisting or

moving

Segregation of pedestrian and vehicles

Trained signal man should be guide

vehicle to move

A operator should be followed the signal

man instructions

Always check overhead electrical

clearance

Ensure operator trained and experience

Vehicle sited on firm and stable ground

Sufficient clearance form obstructions

and overheads when operating

Barriers around MEWP to prevent it

being struck by vehicles or mobile plant

Barriers also act to keep people out from

underneath the cradle

Guard-rails incorporated into the cradle.

Safety harness worn as

additional backup who are working in

cradle height above 2M

All controls of the MEWP must be

operational condition

Not driven with the cradle raised

position

Must not be overloaded and display SWL

signs on cradle

Before carry people must be inspected

as an items of all lifting equipments and

Vehicle

Use restricted to trained , authorized

staff only

No body stand or worked on mid rails

All valid test certificate should be

available with the boom lift and equip

with emergency switch

Refer the operating manual to take

safety precaution if the operational

working condition changes

Unsafe using of Hydra/boom Lift Hydra/Boom lift cannot Only use certified Hydra/ Boom

/ while lifting of working hold weight /Topple lift/Scissor lift and load must be

platform/cable tray Load fall -Injuries, death & fastening rigidly

damage

Hydra/Boom lift operator must inspect

the equipment on a daily basis

Incompetent operator Only certified operator allowed to

Drop weight, injuries, operate the Hydra/

death, damage

Lifting equipment cannot Site Supervisor/Safety to establish the

lift equipment safely weight to be lifted and make sure that all

weight – fall – injuries equipment has the capacity to lift the

death & damage weight safely

Hook load with lifting equipment Incorrect connection Hydra Site Supervisor/Safety must plan the

cannot hold weight – fall – weight, equipment to be used and the

injuries & damage method of connecting equipment

Lift weight Hydra in a wrong location Site supervisor must perform a lifting

Hydra cannot hold weight – plan

fall – injuries & damage

Ground condition Site supervisor/Safety must evaluate the

Hydra not stable – fall – ground conditions before lifting

death - damage commence

Use floating pads under the outriggers

Safety of rigging staff Wear hard hat, boots, safety spectacles

Injuries, death and gloves

Do not stand under the object that is

lifted

Safety of other workers Barricade area to ensure no

Injuries, death unauthorized entrance

Working at height by using boom Sharp edges of Cable tray Use Mandatory PPE’

lift for cable tray erection Cable tray fall on feet Use safety harness and shock absorbers

/Work at heights and attach to cradle or as reasonable

practicable provision of overhead life

cable or permanents structure

Cut on fingers

Foot injuries- Trained persons only in the use of safety

fractures harnesses may perform the work

Inspect the safety harness before

commencing of every shift

Only certified riggers to do slinging work

Use hydra / boom lift to lift Cable tray

and keep in place

Use boom lift with certified operator, for

installation of first tray after that a

person sitting on the tray where the

erected first Cable Tray and to perform

the Cable Tray erection frequently, while

who has hooked with cradle anchor

point while crawling above the cable tray

which is act as a platform while they are

hooked with cradle anchor point.

Putting cable tray on Working at heights Use certified man lift basket only –

structures/pipe rack and inspected every day

fastening bolts and nuts

Trained and certified operators only to

operate man lift basket

Workers must not have a fear of heights

Workers must use safety harness and

lanyard attached to man lift

Man lift in a wrong location Lifting supervisor /Site safety

supervisor /Site safety supervisor must

perform a lifting plan

Ground condition Lifting supervisor /Site safety supervisor

must evaluate the ground conditions

before lifting commence

Falling tools Kept tools in a bag on man lift

Or Tie tools with rope to wrist

Fasten nuts on bolts Tools slipping from nuts Ensure that it is the correct tool for the

job

Inspect the tools daily

Wear gloves

Dust - metal pieces from Wear safety spectacles

structure

Bolt fixing of Cable tray Electrical tools Barricade area of work

Electrocution Keep all unauthorized persons out of

barricaded area

Use tools with correct colour code

Only 110V equipment is allowed

Inspect electrical cables before use

No connections in cables around

Do not use in water or wet conditions

Ensure generator is earthed

Ensure all electrical cable are properly

routed able 2m above

Ensure all electrical tripping devices are

functioning properly like

ELCB/RCCB/MCCB

Ensure all electrical cable joints are

through industrial plugs top only

Ensure ELCB/RCCB using in PDB

Ensure power cable free from cut/joints

Set-up work piece on fixture 1) Strain/sprain from heavy 1) Use mechanical hoist or get assistance

and or awkward work from co-worker to set-up or adjust work

piece. piece. -- (2) Wear recommended

2) Foot injury from footwear. Ensure work piece is securely

dropping work piece. clamped to fixture. -- (3) Clean/clear

3) Trip or fall in area where work area/surfaces of unused

arc welding. tools/materials. Remove dust/debris. --

4) Damage to work piece (4) Work piece should be clean and

from incorrect set-up. secure to fixture. -- (5) Wear

5) Hand/finger laceration recommended gloves when handling

from edge of work piece. work pieces with sharp edges. -- (6) Use

6) Hand/finger contusion correct tool and wear recommended

from tool slippage while gloves. Pay attention to job at hand,

tightening fixture. focus on task.

Install electrode rod into torch. Electric shock/burn from Ensure arc welding machine power to

electrode rod arc is electrically de-energize when

changing electrical rod.

Energize and set Arc Welding 1) Electrical shock/burn 1) Ensure welding machine is properly

Machine amperage/current from contact with grounded. Welder should be insulated

electrode rod holder. -- (2) from live electrical parts and dry.

Damage to work piece Inspect and replace cables, plugs and

from incorrect leads that show any signs of defects.

amperage/current. Wear recommended gloves and clothing.

-- (2) Refer to instructor instructions for

correct amperage/current.

Earth plate welding on Pipe Rack. 1) Eye injury from welding 1) Wear welding helmet with proper

flash and or spatter. -- (2) grade of filter plate. Ensure flash

Burns from welding spatter, curtains/barriers are used to protect

UV/infrared radiation and bystanders/observers. -- (2) Wear

or electrical contact. -- (3) recommended protective clothing.

Inhalation of welding Ensure any exposed skin is covered

fumes or asphyxiation from during the welding process. Do not wear

displaced oxygen. -- (4) metal jewelry and clothing with cuffs

Bodily injury from and/or pockets. Stay a safe distance

condition or type of work away from arc. -- (3) Use local exhaust

piece being welded. -- (5) ventilation and a fan to maintain good

Electrical shock hazard. -- air circulation. -- (4) Do not weld work

(6) Hearing loss from piece unless it is properly cleaned. -- (5)

chronic exposure to noisy Ensure welding machine is properly

machinery. -- (7) Fire due grounded. Welder should be insulated

to combustible material in from live electrical parts and dry. Do not

welding area. -- (8) weld when wet. Inspect and replace

Hand/finger contact burn cables, plugs and leads that show any

from hot electrode rod. sign of defect. -- (6) Hearing protection

should be worn. -- (7) Remove any

combustible material from the

immediate welding site. Keep a fire

extinguisher and a fire blanket readily

available. -- (8) When electrode rod gets

too short, stop welding and restart with

a new electrode rod. Wear

recommended gloves.

Complete welding Electrical shock/burn or Ensure arc welding machine power to

electrical contact with arc is electrically de-energized. When

conducting objects, not in use electrode rod should be

flammable liquids, and/or removed from holder and holder should

compressed gas cylinders be placed so it cannot make electrical

due to energized electrode contact with conducting objects,

rod holder. flammable liquids and/or compressed

gas cylinders.

Remove work piece from fixture 1) Strain/sprain from heavy 1) Use mechanical hoist or get assistance

and transport to inspection. and or awkward work from co-workers to transport work piece.

piece. -- (2) Foot injury -- (2) Wear recommended footwear.

from dropping work piece. Ensure work piece is securely clamped to

-- (3) Trip/fall in area fixture. -- (3) Clean/clear work

around arc welding area/surfaces of unused tools/materials.

workstation. -- (4) Remove dust/debris regularly. -- (4)

Hand/finger laceration Wear recommended gloves when

from edge of work piece. -- handling work pieces with sharp edges.

(5) Hand/finger contusion -- (5) Use correct tool and wear

from tool slippage. recommended gloves.

Oil Daily check oil / any chemical spillage

Environmental aspects of boom spillages/chemical Designated battery charging area with

lift Hydrogen gas good ventilation

Sulphuric acid Fire equipment no smoking and signage

and Protective cloths

Separate disposal of chemical and cotton

wastes

Kept in Secondary containment to

control of oil spillages for unexpected

failure

During Night shift work Working during bad light & Provide sufficient illumination for task

poor visibility

Working during bad light & Ensure emergency vehicle and

poor visibility preparedness and task supervisor/safety

supervisor

Ensure MEWP equipped with warning

alarm and swing alarm

Supervisor must be ensure sufficient

manpower to do the night works

Signal man must carry lights for signaling

for signaling for night works

Work will be stopped during bad

weather conditions.

Suggested safe system of work

Check the condition of tools prior to use

Ensure electrical and fire safety

Ascend / descend the no one underneath

Use properly hooked safety belt work at more than 2M of height

Use the appropriate PPEs

Suggested Review date: (if required)

As and when required

Suggested further job safety instructions: (if required)

Take utmost care for interference from other activities in the vicinity

Suggested training programmes: (Tool Box Talks)

Working at height, hand and power tools safety, operator, Signalman

& hot work

Prepared By: Approved By :

Anda mungkin juga menyukai

- Fabrication Work Risk AssessmentDokumen11 halamanFabrication Work Risk Assessmentstansilous100% (1)

- Jsa-Ht & LT Panel InstallationDokumen1 halamanJsa-Ht & LT Panel Installationpushpanath reddy100% (1)

- Jsa Cable LayingDokumen2 halamanJsa Cable LayingAbcd efgh100% (1)

- Method Statement For Cable & TerminationDokumen6 halamanMethod Statement For Cable & TerminationRajuBelum ada peringkat

- 004 Annexure D Job Safety SAnalysis JSADokumen3 halaman004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- Electrical InstallationDokumen3 halamanElectrical InstallationWalid KhelfaBelum ada peringkat

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDokumen23 halamanCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Jsa For Cable Tray ErectionDokumen2 halamanJsa For Cable Tray Erectionanko heroBelum ada peringkat

- EEEPL - JSA Light Fitting ErectionDokumen6 halamanEEEPL - JSA Light Fitting ErectionnishanthBelum ada peringkat

- AST JSA Excavations.Dokumen3 halamanAST JSA Excavations.md_rehan_2Belum ada peringkat

- Temporary Electrical Supply HSE Procedure For Construction Site - Method Statement HQ PDFDokumen9 halamanTemporary Electrical Supply HSE Procedure For Construction Site - Method Statement HQ PDFjaimonjoyBelum ada peringkat

- JSA FOR Shakthi ElectricalDokumen8 halamanJSA FOR Shakthi Electricalwahyu nugroho100% (1)

- Pre Commissioning Electrical EquipmentDokumen4 halamanPre Commissioning Electrical Equipmentmohammed a hseBelum ada peringkat

- Jsa For Brick WorkDokumen4 halamanJsa For Brick WorkSushil Kumar YadavBelum ada peringkat

- JSA For Flue Gas Duct Height WorkDokumen4 halamanJSA For Flue Gas Duct Height Worksubhadipmanna8Belum ada peringkat

- Jsa. Cable Laying and TerminationDokumen10 halamanJsa. Cable Laying and TerminationMon Trang NguyễnBelum ada peringkat

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDokumen5 halamanJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (3)

- Jha Energize Distribution DBDokumen1 halamanJha Energize Distribution DBAhmad Zahir100% (2)

- JSP For Electrical and HV TestingDokumen4 halamanJSP For Electrical and HV TestingmohammedBelum ada peringkat

- Jsa - Earthing SystemDokumen4 halamanJsa - Earthing SystemAkash Shukla75% (4)

- Jha RebarsDokumen7 halamanJha RebarsJaycee QuinBelum ada peringkat

- JSA E&I 4.earthing Bonding InstallationDokumen3 halamanJSA E&I 4.earthing Bonding InstallationAmyBelum ada peringkat

- Jsa Working at Height (Maintenance & Cleaning)Dokumen2 halamanJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Dokumen4 halamanThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaBelum ada peringkat

- Jsa Installing BracketDokumen3 halamanJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- JSA FOR Fixing of Light FittingsDokumen1 halamanJSA FOR Fixing of Light Fittingswahyu nugroho100% (1)

- JSA For Electrical ActivitiesDokumen14 halamanJSA For Electrical Activitiesdrparihary100% (2)

- Job Safety Analysis (JSA) Stringing WorkDokumen4 halamanJob Safety Analysis (JSA) Stringing WorkSivaram Dasari100% (1)

- JSA Transformer InstallationDokumen10 halamanJSA Transformer InstallationWeru Morris100% (1)

- JOB HAZARD ANALYSIS - Cable TrayDokumen10 halamanJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (1)

- JSA Template 2017-05-31 Cable Tray InstallationDokumen19 halamanJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezBelum ada peringkat

- L & T Construction - PT & D Ic: Safe Operating ProcedureDokumen20 halamanL & T Construction - PT & D Ic: Safe Operating Procedurearvindsarkar100% (1)

- JSA Hydrant Pipe LineDokumen7 halamanJSA Hydrant Pipe Lineakshay pradeepBelum ada peringkat

- HV Cable Termination: Standard Work Method StatementDokumen6 halamanHV Cable Termination: Standard Work Method StatementOsama SharafBelum ada peringkat

- JSA Transformer InstallationDokumen1 halamanJSA Transformer Installationpushpanath reddyBelum ada peringkat

- EHS Risk Assessment - 5. DTR ErectionDokumen2 halamanEHS Risk Assessment - 5. DTR Erectionshamshu123Belum ada peringkat

- Job Safety Analysis Report: DG Lifting & InstallationDokumen2 halamanJob Safety Analysis Report: DG Lifting & Installationvijay kumar singh100% (1)

- ISC-JSA Installation of Portable CabinDokumen4 halamanISC-JSA Installation of Portable CabinSameer Almahboub25% (4)

- JSA For Chimney Works 17.09.2021Dokumen2 halamanJSA For Chimney Works 17.09.2021Brenden PalanithangamBelum ada peringkat

- 0019 JSA Crane LiftingDokumen4 halaman0019 JSA Crane LiftingViron BaxhiaBelum ada peringkat

- Scrap Material Handling & Loading Jha - 1Dokumen2 halamanScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- Job Safety Analysis Worksheet: Tie - in For Power Cable 33 KVDokumen3 halamanJob Safety Analysis Worksheet: Tie - in For Power Cable 33 KVmohammed a hseBelum ada peringkat

- Risk Assessment For UPS & Accessories InstallationDokumen9 halamanRisk Assessment For UPS & Accessories Installationguspriy100% (1)

- Jsa For Pilling WorkDokumen12 halamanJsa For Pilling WorkLakhan kumar100% (1)

- 2020 06 17 JSA For Installation of The AC Unit in The Server RoomDokumen11 halaman2020 06 17 JSA For Installation of The AC Unit in The Server RoomDarren OscarBelum ada peringkat

- Jsa For Manual Backfiling Usin Hand Roller CompactorDokumen5 halamanJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadBelum ada peringkat

- 11 - JSA (Tower Crane) 12-9-06Dokumen11 halaman11 - JSA (Tower Crane) 12-9-06sattiBelum ada peringkat

- Job Hazard Assessment For Cable TestingDokumen4 halamanJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- Jsa For Welding, Grinding, Gas CuttingDokumen2 halamanJsa For Welding, Grinding, Gas Cuttingwahyu nugroho50% (2)

- Jsa For ScaffoldingDokumen3 halamanJsa For Scaffoldingsoubhagya100% (4)

- Plumbing Work JSA HSE ProfessionalsDokumen1 halamanPlumbing Work JSA HSE ProfessionalsStansilous Tatenda NyagomoBelum ada peringkat

- JSA Transformer Installations, Testing, Commissioning.Dokumen6 halamanJSA Transformer Installations, Testing, Commissioning.Kiran Bhatt75% (4)

- JSA Cable Pulling and Laying WorksDokumen6 halamanJSA Cable Pulling and Laying Workskabir100% (1)

- Job Safety Analysis: Required References Jsa ReviewDokumen3 halamanJob Safety Analysis: Required References Jsa ReviewMajdiSahnounBelum ada peringkat

- One Direct Method Statement: Preventative MeasuresDokumen4 halamanOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiBelum ada peringkat

- JSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)Dokumen6 halamanJSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)babjihanumanthuBelum ada peringkat

- Adr Jsa 1711 002Dokumen7 halamanAdr Jsa 1711 002Dada KhalandarBelum ada peringkat

- Fill-Up This Card Before Commencement of Critical WorksDokumen4 halamanFill-Up This Card Before Commencement of Critical WorksSiddhant choudharyBelum ada peringkat

- Job Safety Analysis (Jsa) FormDokumen4 halamanJob Safety Analysis (Jsa) FormNaukhez A. KashifBelum ada peringkat

- Sunmow Jha 001Dokumen3 halamanSunmow Jha 001Douglas DellyBelum ada peringkat

- EEEPL - JSA Light Fitting ErectionDokumen6 halamanEEEPL - JSA Light Fitting ErectionnishanthBelum ada peringkat

- Job Safety & Environment Analysis: Revision NoDokumen3 halamanJob Safety & Environment Analysis: Revision NonishanthBelum ada peringkat

- JSA Cable LayingDokumen2 halamanJSA Cable Layingnishanth100% (2)

- Job Safety & Environment Analysis: Revision NoDokumen3 halamanJob Safety & Environment Analysis: Revision NonishanthBelum ada peringkat

- EEEPL - JSA Unloading MaterialsDokumen3 halamanEEEPL - JSA Unloading MaterialsnishanthBelum ada peringkat

- JSA-Using A Type Ladder 2015Dokumen1 halamanJSA-Using A Type Ladder 2015nishanthBelum ada peringkat

- EEEPL - JSA EARTH FLAT LAYING New 123Dokumen7 halamanEEEPL - JSA EARTH FLAT LAYING New 123nishanthBelum ada peringkat

- PC750-7 Operation PDFDokumen329 halamanPC750-7 Operation PDFQuy Le ThanhBelum ada peringkat

- ToR - Qaisar-Laman PDFDokumen22 halamanToR - Qaisar-Laman PDFGolam MasudBelum ada peringkat

- Catalago XCMG GR180 PDFDokumen156 halamanCatalago XCMG GR180 PDFAnonymous 9fCAFynM91% (11)

- NBC205Dokumen43 halamanNBC205Salin Shrestha100% (1)

- Hydril 513™Dokumen4 halamanHydril 513™renatoBelum ada peringkat

- LISTA Ing, Civil InglesDokumen8 halamanLISTA Ing, Civil InglesErik RomeroBelum ada peringkat

- Bs ConcreteDokumen61 halamanBs ConcreteSarada DalaiBelum ada peringkat

- Api 3171 IomDokumen66 halamanApi 3171 IomAdemola Olakunle AjayiBelum ada peringkat

- Elevation Section: 20 MM Cement Mortar 230 MM THK BK Wall 25 MM THK External PlasterDokumen1 halamanElevation Section: 20 MM Cement Mortar 230 MM THK BK Wall 25 MM THK External PlastersriBelum ada peringkat

- Che 111 Elements of Chemical Engineering: M.A.A. Shoukat Choudhury, PHDDokumen29 halamanChe 111 Elements of Chemical Engineering: M.A.A. Shoukat Choudhury, PHDMahfuzur Rahman SiddikyBelum ada peringkat

- Design & Development of Parkinson Gear Tester For Spur Gear To Check The Flank SurfaceDokumen6 halamanDesign & Development of Parkinson Gear Tester For Spur Gear To Check The Flank SurfaceMaharajan McsBelum ada peringkat

- Form 1 - GEOMATE Journal TemplateDokumen3 halamanForm 1 - GEOMATE Journal TemplateMinangkabau BreederBelum ada peringkat

- BoilerDokumen45 halamanBoilerEr Prem PrincepsBelum ada peringkat

- GCS General Control BrochureDokumen4 halamanGCS General Control BrochureGlobalContSolutionsBelum ada peringkat

- Sclairpipe Marine PDFDokumen16 halamanSclairpipe Marine PDFjeedanBelum ada peringkat

- UO - 048 BD Glue and Adhesive Tapes 1x2700 - 2018-10-26Dokumen8 halamanUO - 048 BD Glue and Adhesive Tapes 1x2700 - 2018-10-26johnBelum ada peringkat

- FAMED LO-23 BROCHURE INGLES - UnlockedDokumen1 halamanFAMED LO-23 BROCHURE INGLES - UnlockedKatyaBelum ada peringkat

- DuraSystems - AHR2011 BrochureDokumen2 halamanDuraSystems - AHR2011 BrochureDuraSystemsBelum ada peringkat

- Your Free Ebook Making Your Mark PDFDokumen21 halamanYour Free Ebook Making Your Mark PDFMaria Iacob0% (1)

- AquaFit4Use - Water Quality Demands in Paper-Chemical-Food-Textile Industry PDFDokumen125 halamanAquaFit4Use - Water Quality Demands in Paper-Chemical-Food-Textile Industry PDFVania Putri SenitaBelum ada peringkat

- TGSLCoil MakingDokumen12 halamanTGSLCoil MakingmmorestesBelum ada peringkat

- Crawford ECS 430PDokumen8 halamanCrawford ECS 430PIvan Grech0% (1)

- All Specifiers CheckedDokumen698 halamanAll Specifiers CheckedroyalbrahmanBelum ada peringkat

- OriginalDokumen2 halamanOriginalYousufRanaBelum ada peringkat

- 2008 ARCTIC CAT 366 Service Repair Manual PDFDokumen40 halaman2008 ARCTIC CAT 366 Service Repair Manual PDFfuksekfmmd100% (1)

- Prince2 1Dokumen88 halamanPrince2 1545137Belum ada peringkat

- Laboratory Test EquipmentDokumen3 halamanLaboratory Test EquipmentRaqibul HasanBelum ada peringkat

- ISO Certification BodyDokumen24 halamanISO Certification BodyUsamah Al-hussainiBelum ada peringkat

- Operating Manual WLR 7 & 8: AanderaaDokumen56 halamanOperating Manual WLR 7 & 8: AanderaaGleison PrateadoBelum ada peringkat

- Installation and Service ManualDokumen78 halamanInstallation and Service ManualNalasoc2Belum ada peringkat