Robots Step Outside: September 2005

Diunggah oleh

Ấm LeeJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Robots Step Outside: September 2005

Diunggah oleh

Ấm LeeHak Cipta:

Format Tersedia

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/280776075

Robots Step Outside

Conference Paper · September 2005

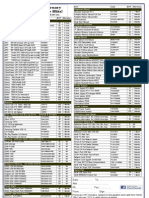

CITATIONS READS

11 1,746

3 authors, including:

Martin Buehler

Walt Disney Imagineering

99 PUBLICATIONS 4,841 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Monopod View project

All content following this page was uploaded by Martin Buehler on 08 August 2015.

The user has requested enhancement of the downloaded file.

Int. Symp. Adaptive Motion of Animals and Machines (AMAM), Ilmenau, Germany, Sept 2005.

Robots Step Outside

M. Buehler, R. Playter, and M. Raibert

Boston Dynamics, Cambridge, MA 02139 USA, buehler@BostonDynamics.com

significant payloads, operating outdoors, with static and

Abstract—We describe BigDog, an ongoing project at Boston dynamic mobility, and fully integrated sensing for mobility.

Dynamics to develop the world’s most advanced power

autonomous quadruped robot for outdoor applications. We will start with a description of the robot’s systems in

section II. Section III gives an overview of a locomotion

Index Terms—Legged Robot, quadruped, legged locomotion,

field robotics. controller we developed in simulation, and section IV

summarizes some of our experiments.

I. INTRODUCTION

J UMPING lemurs, load hauling mules, galloping cheetahs,

camouflaged chameleons, climbing mountain goats and

acrobatic squirrels all conjure up highly desirable tasks for

II. ROBOT

BigDog (Fig. 1) was designed to be relevant to human size

machines in civilian, intelligence, and military applications. in terms of mobility, speed, and load carrying ability. It aims

While some animals can be trained to help out better than to jump over a 1 m ditch, climb 45 degree (100 %) slopes, run

others, machines with similar capabilities would be preferred. at 5 m/s, and carry over 50 kg payload. The current version is

New capabilities, not seen in nature would be possible, like a about 1 m tall, 1 m long and 0.3 m wide, and weights about 90

mule which doubles as a power generator or a water supply. kg. Each of the four legs has four degrees of freedom: one

Since much of animals’ amazing terrestrial mobility is passive linear pneumatic compliance in the lower leg, one

achieved with legs, this proof of existence motivates the powered knee joint, and two powered hip joints.

development of legged robots.

After almost half a century of legged robot research a

tremendous number of walking machines with ever increasing

capabilities have been developed [1, 2]. While most of these

robots are still confined to the laboratory, an increasing

number are able to operate outdoors, carry payloads, and there

is now some evidence (e.g. RHex [3]) of legged machines

with better outdoor mobility than that of a tracked or

articulated tracked machine of similar size and weight. We

have to keep in mind, though, that even when power

autonomy, rugged outdoor operation, and basic mechanical

and dynamic mobility capability were achieved, the full

benefit of legged robots for practical applications will only be

seen once the requisite terrain and environmental sensing,

planning and intelligence are tightly coupled to these

capabilities.

BigDog takes as inspiration and as a point of departure the Figure 1: BigDog

insights and results of the LegLab quadruped [4], and aims to

significantly advance the state of the art towards the creation The heart of BigDog’s power (“DogChow”) is a 17 hp 2

of a mechanical mule - a category with few competitors to cylinder combustion engine (Fig. 2) which drives a hydraulic

date: power autonomous quadrupeds capable of carrying variable displacement pump, providing 3000 PSI system

pressure. This high pressure oil is distributed (Fig. 3) via a

This work was supported by U.S. Defense Advanced Research Projects central manifold to the twelve custom hydraulic actuators

Agency (DARPA) contract N66001-03-C08044 and by Army Contract (Fig. 4). All joints use the same actuator which is tightly

W56HZV-04-C-0089. Approved by DARPA for Public Release, DISTAR

Case 5026, Distribution Unlimited. integrated with its servo valve, piston position potentiometer,

and a load cell. The overall hydraulic system also incorporates

an oil reserve tank, an accumulator, filters, a heat exchanger,

check valve, dump valve, and sensors for oil pressure, flow

and temperature.

Figure 4: Custom Hydraulic Actuator with Servo Valve,

Load Cell, and Potentiometer

Figure 2: DogChow combustion engine, cooling fan, and

hydraulic pump

Figure 5: BigDog Sensors

We are integrating a stereo vision system (Fig. 6) developed

by our JPL partner team. It consists of a pair of firewire

cameras mounted on a calibrated stereo bar, a Pentium M

computer assembly, and software. The software performs

stereo vision computations and delivers a depth map as its

output. Algorithms for ground plane estimation and visual

Figure 3: Hydraulic System odometry were developed and are being tested on BigDog

during outdoor trials. Currently, 320x240 stereo range images

are computed at 29 frames/s (fps), additional visual odometry

and ground plane estimation at 14 fps. Our short term plans

are to use this system to predict upcoming slopes, identify

BigDog has about fifty sensors to sense body state (gyros,

large obstacles to be avoided, and to track the robot’s position

accelerometers, oil temperature), its environment (vision, via the visual odometry.

ambient temperature, etc), and the interactions between robot

and environment (load cells, foot contact switches, vision,

etc), illustrated in Figure 5.

III. CONTROL

Postural control algorithms coordinate the kinematics and

ground reaction forces of the robot while responding to basic

postural commands. The control distributes load amongst the

legs to optimize their load carrying ability. The vertical

loading across the limbs is kept as equal as possible while

individual legs are encouraged to generate ground reactions

directed toward the hip/shoulder, thus lowering required joint

torques and actuator efforts. The simulated robot stands and

coordinates the motion of its legs and body through any

number of desired paths, such as side-to-side, circular,

pitching, rolling, yawing, etc.

Basic walking control uses the control system diagramed

below. A gait coordination algorithm, responsible for inter-leg

communication initiates leg state transitions to produce

different stable quadruped gaits, two of which are shown

below. A virtual leg model coordinates the legs.

Figure 6: Stereo Vision System

A ‘nervous system’ wiring grid connects all the sensors and

actuators to the central electronics box (Fig. 7). It contains a

PC104 Pentium processor running a multi-rate real time

operating system (low level control rates 0.5 – 1 kHz) under

QNX as well as I/O cards and I/O interfaces.

Figure 8: Control Diagram

We developed quadrupedal walking algorithms for inclined

and rough terrain and tested it in dynamic simulation. The

simulated robot walks on inclines and declines ranging from

30 to 60 degrees, it makes transitions from walking on the

level to an incline or decline, and it accommodates unexpected

changes in terrain height caused by irregularities in the terrain,

such as would be caused by rocks (Fig. 9).

The control system adapts to terrain changes through terrain

sensing and posture control. The control system uses

proprioceptive sensory information from load cells and

kinematic sensors in the legs to determine when feet are in

contact with the ground and to determine the load on each leg

and actuator. A posture algorithm controls body position, by

coordinating the kinematics of the legs with the reaction

forces of legs in contact with the ground. The posture

Figure 7: Electronics Box

algorithm implements computed leg compliance on uneven

terrain. This approach allows control of body roll, pitch, and

Operators control BigDog via high level commands like

height relative to the ground, thus supplying adaptation to

desired speed, direction, or gait, via an Operator Control Unit local terrain without higher level sensing.

which communicates with the BigDog onboard computer via

standard wireless Ethernet. The OCU displays in real time This adaptation takes two forms: it adjusts body height and

selected critical variables, and can log over 1000 variables at attitude to conform to the local terrain, and it adjusts footfall

100 Hz. placement to compensate for orientation of the robot body and

ground plane relative to gravity. The control system leans the

quadruped forward while climbing slopes, leans the body

backwards while descending slopes, and leans it sideways

while crossing walking along the contour line. The control

system accommodates shallow to moderate inclines by making

slight adjustments to body posture, while it accommodates

inclines steeper than 45 degrees by also adjusting the walking

gait pattern and using smaller steps. We tested these

locomotion controls in dynamic simulation tests in which the

robot climbs various inclines from 15° through 61°.

Figure 11: Trotting Gait

Figure 9: BigDog Simulation

IV. EXPERIMENTS

Based, in part, on gait control concepts described above, we

have implemented walking and trotting gaits, as well as

standing up and sitting down. Since its creation in the fall of

2004, BigDog has already logged tens of hours of walking,

climbing and running time. It has walked up and down 35

degree inclines (a 25 deg incline shown in Fig. 10), trotted

(Fig. 11) at speeds up to 0.8 m/s and carried over 50 kg of

payload (Fig. 12).

Figure 12: Payload 120 lbs

ACKNOWLEDGEMENTS

BigDog is the result of the ingenuity, hard work and talent

of many individuals at Boston Dynamics, and our partners at

Foster-Miller (DogChow), JPL (vision system), and Harvard

University (biology).

REFERENCES

[1] Walking Machine Catalogue, http://www.walking-machines.org/

[2] D. C. Kar: Design of Statically Stable Walking Robot: A Review, J.

Figure 10: Incline Robotic Systems, 20(11):671-686, 2003.

[3] U. Saranli, M. Buehler, and D. E. Koditschek, “RHex: A Simple and

Highly Mobile Hexapod Robot,” Int. J. Robotics Research, Vol. 20, No.

7, pp. 616-631, 2001.

[4] M. H. Raibert, Legged Robots That Balance, MIT Press, Cambridge,

MA, 1986.

View publication stats

Anda mungkin juga menyukai

- 2005 AMAM BigDogDokumen5 halaman2005 AMAM BigDogDiriba AbdiBelum ada peringkat

- Design of An Autonomous Humanoid Robot: ArticleDokumen7 halamanDesign of An Autonomous Humanoid Robot: ArticleAnil Kumar AchariBelum ada peringkat

- Design of A Bipedal Walking RobotDokumen14 halamanDesign of A Bipedal Walking RobotRaja ManeBelum ada peringkat

- Preprints202007 0217 v2Dokumen21 halamanPreprints202007 0217 v2Thoan MạnhBelum ada peringkat

- BigDog IFAC Apr-8-2008Dokumen5 halamanBigDog IFAC Apr-8-2008varaújo_14Belum ada peringkat

- Voice Controlled Biped Walking Robot For Industrial ApplicationsDokumen15 halamanVoice Controlled Biped Walking Robot For Industrial ApplicationsNarendar Singh DBelum ada peringkat

- Amphibious Robot II PDFDokumen6 halamanAmphibious Robot II PDFAman TripathiBelum ada peringkat

- Stability Controller Atlas Robot ExampleDokumen6 halamanStability Controller Atlas Robot ExampleIvan PasterBelum ada peringkat

- Development of A Compliant Legged Quadruped RobotDokumen18 halamanDevelopment of A Compliant Legged Quadruped Robotmuhammad fauzanBelum ada peringkat

- Evolution of Central Pattern Generators For BipedaDokumen11 halamanEvolution of Central Pattern Generators For Bipedaanhquan maleBelum ada peringkat

- MIT Cheetah 3: Design and Control of A Robust, Dynamic Quadruped RobotDokumen9 halamanMIT Cheetah 3: Design and Control of A Robust, Dynamic Quadruped RobotJoseph ProstBelum ada peringkat

- A Survey of Bio-Inspired Compliant Legged Robot Designs: Home Search Collections Journals About Contact Us My IopscienceDokumen21 halamanA Survey of Bio-Inspired Compliant Legged Robot Designs: Home Search Collections Journals About Contact Us My IopscienceRovi Andra PradivaBelum ada peringkat

- Biological Biped HumanoidDokumen33 halamanBiological Biped HumanoidalfonsoBelum ada peringkat

- Walking and Crawling With ALoF-A Robot For AutonomDokumen9 halamanWalking and Crawling With ALoF-A Robot For AutonomjosepezalazaroBelum ada peringkat

- UNIT5 RoboticsDokumen60 halamanUNIT5 RoboticsthamizmaniBelum ada peringkat

- Research Article: Design of Information Acquisition and Control System For The Exoskeleton RobotDokumen8 halamanResearch Article: Design of Information Acquisition and Control System For The Exoskeleton RobotHarshesh GokaniBelum ada peringkat

- Baby Humanoid RobotDokumen15 halamanBaby Humanoid RobotalfonsoBelum ada peringkat

- RHEXDokumen7 halamanRHEXJose Torres NuñezBelum ada peringkat

- Design and Experimental Evaluation of The Hydraulically Actuated Prototype Leg of The Hyq RobotDokumen6 halamanDesign and Experimental Evaluation of The Hydraulically Actuated Prototype Leg of The Hyq RobotМатвей КузнецовBelum ada peringkat

- Wahde Pettersson ReviewDokumen9 halamanWahde Pettersson ReviewtsigeBelum ada peringkat

- System Design and Control of Anthropomorphic Walking Robot LOLADokumen9 halamanSystem Design and Control of Anthropomorphic Walking Robot LOLAManuela MartínezBelum ada peringkat

- Objective & Outcome of RoboticsDokumen3 halamanObjective & Outcome of RoboticsMechanicalBelum ada peringkat

- Growing Momentum in The Various Field of Robotics-A Review: A. Narrow Wall Climbing of Six-Legged RobotDokumen9 halamanGrowing Momentum in The Various Field of Robotics-A Review: A. Narrow Wall Climbing of Six-Legged RobotYogeshPalanisamyBelum ada peringkat

- Research Paper - Biped RobotDokumen6 halamanResearch Paper - Biped RobotHarkishen SinghBelum ada peringkat

- (2006) Modeling and Simulation of Biped Kinematics Using Bond-GraphsDokumen6 halaman(2006) Modeling and Simulation of Biped Kinematics Using Bond-GraphsPaul AlvarezBelum ada peringkat

- Advanced Distributed Architecture For A Small Biped Robot ControlDokumen7 halamanAdvanced Distributed Architecture For A Small Biped Robot ControlFernando Angel Rodríguez CortésBelum ada peringkat

- 0620Dokumen7 halaman0620Shahrzad GhasemiBelum ada peringkat

- Modeling and Experimental Evaluation of An Improved Amphibious Robot With Compact StructureDokumen16 halamanModeling and Experimental Evaluation of An Improved Amphibious Robot With Compact StructureRicardo Sebastian Ricardo RanillaBelum ada peringkat

- Design of Six Legged Spider Robot and Evolving Walking AlgorithmsDokumen6 halamanDesign of Six Legged Spider Robot and Evolving Walking AlgorithmsNgọc Minh LêBelum ada peringkat

- MIT+猎豹+Dynamic Locomotion in the MIT Cheetah 3 Through Convex Model-Predictive ControlDokumen8 halamanMIT+猎豹+Dynamic Locomotion in the MIT Cheetah 3 Through Convex Model-Predictive ControlZhipeng HOUBelum ada peringkat

- Dynamic Torque Control of A Hydraulic Quadruped RobotDokumen6 halamanDynamic Torque Control of A Hydraulic Quadruped RobotPrathamesh SarafBelum ada peringkat

- Ism06 43FDokumen5 halamanIsm06 43Fnur atirahBelum ada peringkat

- AR2398 Expochamacos 9aDokumen30 halamanAR2398 Expochamacos 9aJose AguilarBelum ada peringkat

- Quadruped Walking Running SimulationDokumen49 halamanQuadruped Walking Running SimulationbilynbkBelum ada peringkat

- Design of Quadruped Robot MDokumen5 halamanDesign of Quadruped Robot MJai Rajesh100% (1)

- Development of A Microcontroller Based Robotic ArmDokumen10 halamanDevelopment of A Microcontroller Based Robotic ArmHus Forth CorrentyBelum ada peringkat

- The Designand Constructionofa Robotic Arm Usingan 8051 MicrocontrollerDokumen10 halamanThe Designand Constructionofa Robotic Arm Usingan 8051 MicrocontrollerJhonnathan FerreiraBelum ada peringkat

- Design Analysis of A Remote Controlled P PDFDokumen12 halamanDesign Analysis of A Remote Controlled P PDFVũ Mạnh CườngBelum ada peringkat

- World's Largest Science, Technology & Medicine Open Access Book PublisherDokumen36 halamanWorld's Largest Science, Technology & Medicine Open Access Book PublisherAbdulGhaffarBelum ada peringkat

- MIT Cheetah 3: Design and Control of A Robust, Dynamic Quadruped RobotDokumen9 halamanMIT Cheetah 3: Design and Control of A Robust, Dynamic Quadruped RobotFernando Angel Rodríguez CortésBelum ada peringkat

- Ahmad Najib 135833 - Assigment (Part DR Wan) - Eem345 ManufactDokumen9 halamanAhmad Najib 135833 - Assigment (Part DR Wan) - Eem345 ManufactNajib HairiBelum ada peringkat

- Dynamic Walking RobotDokumen27 halamanDynamic Walking Robotflv_91Belum ada peringkat

- Mechanical Design and Optimal Control of HumanoidDokumen12 halamanMechanical Design and Optimal Control of HumanoidDavi AssunçãoBelum ada peringkat

- Kinematic Analysis and Control Algorithm For The BallbotDokumen8 halamanKinematic Analysis and Control Algorithm For The BallbotThanh TrungfdrBelum ada peringkat

- Design of Space Robotic Arm-Hand System and Operation ResearchDokumen6 halamanDesign of Space Robotic Arm-Hand System and Operation ResearchSiraj AhmedBelum ada peringkat

- A Novel Design of A Quadruped Robot For Research PurposesDokumen13 halamanA Novel Design of A Quadruped Robot For Research Purposessushreet2754Belum ada peringkat

- Applied Sciences: Special Feature On Bio-Inspired RoboticsDokumen7 halamanApplied Sciences: Special Feature On Bio-Inspired RoboticsJHON LEWIS LORA CHINCHIABelum ada peringkat

- Seminar Group 14Dokumen22 halamanSeminar Group 14Mohith M NaIrBelum ada peringkat

- EE16704 UNIT5 RoboticsDokumen60 halamanEE16704 UNIT5 RoboticsthamizmaniBelum ada peringkat

- 2020 Ral BjelonicDokumen8 halaman2020 Ral BjelonicdimtecBelum ada peringkat

- Balancing RobotDokumen5 halamanBalancing RobotMilton MuñozBelum ada peringkat

- Hyundai Wearable Robotics For Walking Assistance Offer A Full Spectrum of MobilityDokumen11 halamanHyundai Wearable Robotics For Walking Assistance Offer A Full Spectrum of MobilityNelson TacyBelum ada peringkat

- Dynamic Obstacle Avoidance For 4 Wheeled Omni Wheelchair Using A New Type of Mecanum WheelDokumen7 halamanDynamic Obstacle Avoidance For 4 Wheeled Omni Wheelchair Using A New Type of Mecanum WheelAnonymous izrFWiQBelum ada peringkat

- Ism06 43F PDFDokumen5 halamanIsm06 43F PDFmaldiniBelum ada peringkat

- Design of A Biped RobotDokumen6 halamanDesign of A Biped RobotSharan LuckBelum ada peringkat

- Dynamic Modelling & Simulation of A Four Legged Jumping Robot With Compliant LegsDokumen8 halamanDynamic Modelling & Simulation of A Four Legged Jumping Robot With Compliant LegsRodrigo VenturaBelum ada peringkat

- Materials Today: Proceedings: T. Deepa, S. Angalaeswari, D. Subbulekshmi, S. Krithiga, S. Sujeeth, Raja KathiravanDokumen5 halamanMaterials Today: Proceedings: T. Deepa, S. Angalaeswari, D. Subbulekshmi, S. Krithiga, S. Sujeeth, Raja KathiravanReshab SahooBelum ada peringkat

- Spider-Bots: A Low Cost Cooperative Robotics Platform: Damien Laird Jack Price Ioannis A. RaptisDokumen6 halamanSpider-Bots: A Low Cost Cooperative Robotics Platform: Damien Laird Jack Price Ioannis A. RaptisLuis RuizBelum ada peringkat

- Micromachines 13 01404 v2Dokumen20 halamanMicromachines 13 01404 v2technologie collegeBelum ada peringkat

- Eecs563 Fall23Dokumen6 halamanEecs563 Fall23Ấm LeeBelum ada peringkat

- Law and Crimes CombinedDokumen10 halamanLaw and Crimes CombinedẤm LeeBelum ada peringkat

- Sample of Email To ProfessorDokumen3 halamanSample of Email To ProfessorẤm Lee0% (1)

- BBC Focus - Christmas 2017 UKDokumen100 halamanBBC Focus - Christmas 2017 UKAntonio Lima FilhoBelum ada peringkat

- IELTS WRITING 2017 Review PDFDokumen154 halamanIELTS WRITING 2017 Review PDFẤm LeeBelum ada peringkat

- Sample SQA QA Software Quality Assurance ResumeDokumen3 halamanSample SQA QA Software Quality Assurance ResumeArif Masood100% (1)

- Assignment DLDDokumen2 halamanAssignment DLDTauqir Hassan100% (1)

- Java AssignmentDokumen55 halamanJava AssignmentAnanya BhagatBelum ada peringkat

- Pubg CCDokumen9 halamanPubg CCRukmini AdithyaBelum ada peringkat

- RUBRICSDokumen1 halamanRUBRICSKeren Joy OrillosaBelum ada peringkat

- Quiz App Javascript Report Css Mini Project-1Dokumen32 halamanQuiz App Javascript Report Css Mini Project-1Kamini SalunkheBelum ada peringkat

- GM868 Gas Ultrasonic FlowmeterDokumen4 halamanGM868 Gas Ultrasonic FlowmeterDikranBelum ada peringkat

- Network Security v1.0 - Module 3 ESDokumen51 halamanNetwork Security v1.0 - Module 3 ESbcdavila0% (1)

- Questions - Topics Data Eng - FresherDokumen6 halamanQuestions - Topics Data Eng - Fresherabhinav khokharBelum ada peringkat

- UntitledDokumen50 halamanUntitledWinefred jr EspinoBelum ada peringkat

- Design and Fabrication of Coconut Tree Climbing and Harvesting Robot ReviewDokumen3 halamanDesign and Fabrication of Coconut Tree Climbing and Harvesting Robot ReviewIJIRSTBelum ada peringkat

- Forex Spectrum: Hi ThereDokumen10 halamanForex Spectrum: Hi ThereSonu ThakurBelum ada peringkat

- Buzzword Brief Assignment: Basic InformationDokumen3 halamanBuzzword Brief Assignment: Basic InformationRenu SudipBelum ada peringkat

- Linux CommandsDokumen7 halamanLinux CommandsBharath ThambiBelum ada peringkat

- Sinamics g120c Training Booklet enDokumen76 halamanSinamics g120c Training Booklet enValentina RocaBelum ada peringkat

- OCR Computer Science A Level: 1.1.1 Structure and Function of The ProcessorDokumen471 halamanOCR Computer Science A Level: 1.1.1 Structure and Function of The ProcessorIncognitoBelum ada peringkat

- Emergence of Risk-Based Authentication in Online Financial Services: You Can'T Hide Your Lyin' IpsDokumen11 halamanEmergence of Risk-Based Authentication in Online Financial Services: You Can'T Hide Your Lyin' IpsforoldpcBelum ada peringkat

- Logix 5000 Controlers I/O & Tag DataDokumen76 halamanLogix 5000 Controlers I/O & Tag Datafrancois lecreuxBelum ada peringkat

- AdvanCloud - 170710 - Template DevelopmentDokumen60 halamanAdvanCloud - 170710 - Template DevelopmentBrBelum ada peringkat

- Bondwell Specials Combo SpecDokumen1 halamanBondwell Specials Combo SpecMaxFijiBelum ada peringkat

- Clinical Neurophysiology PracticeDokumen13 halamanClinical Neurophysiology Practicejacinto isaac galvez cortezBelum ada peringkat

- XRD Machine For Clinker Quality AssessmentDokumen4 halamanXRD Machine For Clinker Quality AssessmentApurba SarmaBelum ada peringkat

- Event Guide: Bringing The Latest Technology Solutions To The Legal ProfessionDokumen5 halamanEvent Guide: Bringing The Latest Technology Solutions To The Legal ProfessionOmar Ha-RedeyeBelum ada peringkat

- Get Backlinks For Free - Easy Backlink Builder GuideDokumen4 halamanGet Backlinks For Free - Easy Backlink Builder GuidejurarajanBelum ada peringkat

- <%TRUSTED SSD CHEMICAL SOLUTION FOR CLEANING BLACK NOTES+27780171131 Activation Powder to clean all type of black color currency, defaced bank notes durban North West Northern Cape Western Cape Call +27780171131 to purchaseDokumen184 halaman<%TRUSTED SSD CHEMICAL SOLUTION FOR CLEANING BLACK NOTES+27780171131 Activation Powder to clean all type of black color currency, defaced bank notes durban North West Northern Cape Western Cape Call +27780171131 to purchasejona tumukundeBelum ada peringkat

- Workshop Power Apps - Day 1Dokumen80 halamanWorkshop Power Apps - Day 1alfredtelBelum ada peringkat

- JListDokumen39 halamanJListsidhanshuBelum ada peringkat

- Manual Sizer ComponentoneDokumen191 halamanManual Sizer ComponentoneGilbertoJulioMuñozBelum ada peringkat

- TPL Presentation-CT (20071)Dokumen16 halamanTPL Presentation-CT (20071)syed huzaifaBelum ada peringkat

- Lesson5 Hyperlink and Embedding ObjectDokumen16 halamanLesson5 Hyperlink and Embedding ObjectHanz DeañoBelum ada peringkat