Bloom's baffle burner concept reduces NOx

Diunggah oleh

ManojkumarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bloom's baffle burner concept reduces NOx

Diunggah oleh

ManojkumarHak Cipta:

Format Tersedia

7/05

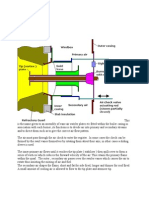

BAFFLE BURNER CONCEPT

Bloom’s baffle burner recirculates furnace luminosity. Geometry also influences the

gas into the flame. Its appearance is amount of furnace gases recirculation into

deceptively simple consisting of a body, gas the port, a major factor in reducing NOx

nozzle, baffle and port. Air enters the burner levels.

body directly and the gas passes through the

body separated from the air with the fuel The baffle passages are essentially nozzles

tube. The refractory baffle separates the which create a jet effect on the exit side. A

body from the burner block (port), which is jet exiting a nozzle creates a recirculation

within the wall of the furnace. zone and a low pressure area at the exit.

The jet phenomenon anchors the flame in

Air passes into the port through a series of the port, ensures thorough mixing of the air

holes around the circumference of the baffle. and fuel, and provides the energy to

Gas enters the port through a hole in the recirculate POC into the port.

center of the baffle. Only after the air and

gas enter the port areas do they mix together Subtle geometric changes to the baffle and

and allow ignition to occur. port affect the jet characteristics. The

standard Bloom burner baffle is effective in

The ceramic baffle provides support to the recirculation furnace gases and is inherently

gas tube and is a radiation shield between a low NOx design. Bloom’s Low and Ultra

the flame and the internal burner parts. Low NOxTM baffles represent an optimization

Baffle hole and port geometries determine of the geometry to maximize furnace gas

the flame characteristics, such as shape and recirculation into the flame.

CAUTION: The improper use of combustion equipment can result in a condition hazardous to people and property. Users are

urged to comply with National Safety Standards and/or Insurance Underwriters recommendations

-1- 7/29/2005

Anda mungkin juga menyukai

- John Deere Workshop Manual PDFDokumen678 halamanJohn Deere Workshop Manual PDFbagus75% (4)

- 140e-5 Series Sen00074-00Dokumen202 halaman140e-5 Series Sen00074-00eshopmanual TigaBelum ada peringkat

- Fluid Bearing Fluid Film Lubrication Technical TopicDokumen2 halamanFluid Bearing Fluid Film Lubrication Technical TopicAlex PerezBelum ada peringkat

- Circulating Fluidized Bed TechnologyDokumen20 halamanCirculating Fluidized Bed Technologytsraja100% (2)

- Introduction To DrillingDokumen25 halamanIntroduction To Drillingrobin2806100% (1)

- The Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Dari EverandThe Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Penilaian: 5 dari 5 bintang5/5 (1)

- North American Series 4682 Flame Retention Gas Burner Nozzles 4682 - BulDokumen2 halamanNorth American Series 4682 Flame Retention Gas Burner Nozzles 4682 - BulcelectricBelum ada peringkat

- Algae As Bio ReactorDokumen25 halamanAlgae As Bio Reactormohanmajhi100% (1)

- Steam Turbine Startup ProceduresDokumen30 halamanSteam Turbine Startup ProceduresVILLANUEVA_DANIEL2064100% (1)

- ISO-14726 (Color Marking On Pipes)Dokumen1 halamanISO-14726 (Color Marking On Pipes)Johan Supriyanto90% (31)

- Registers for Boiler BurnersDokumen2 halamanRegisters for Boiler BurnersrajishrajanBelum ada peringkat

- ONGC Uran plant: Oil and gas processing operationsDokumen46 halamanONGC Uran plant: Oil and gas processing operationsMahipal Singh Ratnu67% (3)

- Duoflex PDFDokumen8 halamanDuoflex PDFTinTunNaingBelum ada peringkat

- Ces Questions Sorted by WordsDokumen619 halamanCes Questions Sorted by WordsAdnana Cadar100% (2)

- Burner FurnaceDokumen5 halamanBurner FurnaceShaikh Muhammad UsamaBelum ada peringkat

- API Safety and Fire Protection PublicationDokumen6 halamanAPI Safety and Fire Protection PublicationDan PascoBelum ada peringkat

- D 3613Dokumen4 halamanD 3613osminmaganaBelum ada peringkat

- Sabp A 014 PDFDokumen22 halamanSabp A 014 PDFShubhodeep SarkarBelum ada peringkat

- CFBC BoilersDokumen11 halamanCFBC BoilersManoj DesaiBelum ada peringkat

- Crude and Refinery CalculationsDokumen4 halamanCrude and Refinery Calculationsbakhtyar21100% (1)

- Nox ControlDokumen9 halamanNox Controlsureshbabu7374Belum ada peringkat

- Aircraft Engine Rools-RoyceDokumen40 halamanAircraft Engine Rools-RoyceShanmuga100% (9)

- Specify Better Low NOx Burners For FurnacesDokumen4 halamanSpecify Better Low NOx Burners For Furnacesyogitadoda100% (1)

- EPRI2009HeatRateConference FINALDokumen14 halamanEPRI2009HeatRateConference FINALcynaiduBelum ada peringkat

- Specialized coal and pet-coke combustion designDokumen6 halamanSpecialized coal and pet-coke combustion designary.engenharia1244Belum ada peringkat

- M25 ToolsDokumen40 halamanM25 Toolsabuzer1981Belum ada peringkat

- CFBC Boiler DescriptionDokumen9 halamanCFBC Boiler Descriptioncmani_bweBelum ada peringkat

- Getting Strated With Aspen PIMS (1st Ed)Dokumen180 halamanGetting Strated With Aspen PIMS (1st Ed)Ahsan Jalal89% (36)

- Next Generation Dry Low NOx For Gas TurbinesDokumen12 halamanNext Generation Dry Low NOx For Gas TurbinesMijail David Felix Narvaez100% (1)

- VGO HydrocrackingDokumen14 halamanVGO HydrocrackingAndy DolmanBelum ada peringkat

- Understand Boiler Performance HydrocarbonDokumen5 halamanUnderstand Boiler Performance HydrocarbonSteve WanBelum ada peringkat

- Air Staged Double Swirl Low NO LPG BurnerDokumen18 halamanAir Staged Double Swirl Low NO LPG Burnerben garciaBelum ada peringkat

- PDFDokumen5 halamanPDFnodyyyBelum ada peringkat

- Low Nox Rotary Kiln Burner Technology Design Principles Case StudyDokumen6 halamanLow Nox Rotary Kiln Burner Technology Design Principles Case Studyanthony okojipgs100% (1)

- Journal - CFD Use of Numerical Modeling For Designing A Biomass-Fired BFB Boiler Air System For Low NOx EmissionsDokumen8 halamanJournal - CFD Use of Numerical Modeling For Designing A Biomass-Fired BFB Boiler Air System For Low NOx EmissionsHamdani MesinBelum ada peringkat

- Chap 15Dokumen14 halamanChap 15nelson escuderoBelum ada peringkat

- Low NOx Rotary Kiln Burner TechnologyDokumen6 halamanLow NOx Rotary Kiln Burner TechnologyKristínaBelum ada peringkat

- Duo FlexDokumen8 halamanDuo Flexdwindra ramadhan100% (1)

- Chap 20 PDFDokumen18 halamanChap 20 PDFnelson escuderoBelum ada peringkat

- Experimental Flow Field Characteristics of OFA For Large-Angle Counter Flow of Fuel-Rich Jet Combustion TechnologyDokumen9 halamanExperimental Flow Field Characteristics of OFA For Large-Angle Counter Flow of Fuel-Rich Jet Combustion TechnologyclaralisieBelum ada peringkat

- 1 s2.0 S1359431122012704 MainDokumen12 halaman1 s2.0 S1359431122012704 Maindigitalginga2Belum ada peringkat

- 1 s2.0 S1743967117307869 MainDokumen13 halaman1 s2.0 S1743967117307869 Maindigitalginga2Belum ada peringkat

- Importance of Air Distribution Between BurnersDokumen2 halamanImportance of Air Distribution Between BurnersKamal ArabBelum ada peringkat

- Com Bust orDokumen9 halamanCom Bust orDanishAmanBelum ada peringkat

- Energies 13 05077 v2Dokumen17 halamanEnergies 13 05077 v2truongtxBelum ada peringkat

- Steam Power Plant Layout & WorkingDokumen17 halamanSteam Power Plant Layout & WorkingJoseph SajanBelum ada peringkat

- Experimental Study of Combustion of Hydrogen-Syngas/ Methane Fuel Mixtures in A Porous BurnerDokumen9 halamanExperimental Study of Combustion of Hydrogen-Syngas/ Methane Fuel Mixtures in A Porous BurnerTinhBelum ada peringkat

- Burners For Glass Melting Furnaces FinalDokumen9 halamanBurners For Glass Melting Furnaces FinalDavid WattsBelum ada peringkat

- Design Optimization of Can Type Combustor: T J Prasanna Kumar, S Koteswara Rao, S Durga Prasad, MD Faisal, P AnilDokumen8 halamanDesign Optimization of Can Type Combustor: T J Prasanna Kumar, S Koteswara Rao, S Durga Prasad, MD Faisal, P AnilSakuBelum ada peringkat

- Mechanism Analysis On The Pulverized Coal Combustion Ame Stability and Nox Emission in A Swirl Burner With Deep Air StagingDokumen14 halamanMechanism Analysis On The Pulverized Coal Combustion Ame Stability and Nox Emission in A Swirl Burner With Deep Air StagingPSS PrasadBelum ada peringkat

- International Journal of Thermal Sciences: Sen Li, Tongmo Xu, Qulan Zhou, Houzhang Tan, Shien HuiDokumen9 halamanInternational Journal of Thermal Sciences: Sen Li, Tongmo Xu, Qulan Zhou, Houzhang Tan, Shien HuiMatias MancillaBelum ada peringkat

- 17 Sep PDFDokumen22 halaman17 Sep PDFShivshankar MudaliarBelum ada peringkat

- Bps-06 NOx ControlDokumen4 halamanBps-06 NOx ControlLTE002Belum ada peringkat

- Design of LPG Burner for Hot Air Puffing MachineDokumen8 halamanDesign of LPG Burner for Hot Air Puffing MachineMauricio Jesus Enciso UretaBelum ada peringkat

- 1 Description of ICE-finalDokumen12 halaman1 Description of ICE-finalaliBelum ada peringkat

- 1-s2.0-S0360544211007134-mainDokumen11 halaman1-s2.0-S0360544211007134-mainHugo CostaBelum ada peringkat

- Investigation of Tangential Trapped VortDokumen7 halamanInvestigation of Tangential Trapped Vortbigsteve9088Belum ada peringkat

- Developments in Falling Film Type (Downflow) Reboilers in The Air Separation IndustryDokumen9 halamanDevelopments in Falling Film Type (Downflow) Reboilers in The Air Separation IndustryrezaBelum ada peringkat

- Normal OperationDokumen15 halamanNormal OperationRaiAsifnawazBelum ada peringkat

- Registers: Air RegisterDokumen2 halamanRegisters: Air RegisterTin Aung KyiBelum ada peringkat

- Air Breathing Propulsion Unit-2Dokumen54 halamanAir Breathing Propulsion Unit-2api-271354682Belum ada peringkat

- Research Article: Parametric Study of High-Efficiency and Low-Emission Gas BurnersDokumen8 halamanResearch Article: Parametric Study of High-Efficiency and Low-Emission Gas BurnersRolando PradaBelum ada peringkat

- 04 Combustion ChamberDokumen6 halaman04 Combustion ChamberprasannabalajiBelum ada peringkat

- Ultralow NOx BurnersDokumen3 halamanUltralow NOx Burnersdatalogger123456100% (2)

- 05 - G. Hesslemann (Doosan Babcock)Dokumen20 halaman05 - G. Hesslemann (Doosan Babcock)engr kazamBelum ada peringkat

- MW 12Dokumen8 halamanMW 12dio prabowoBelum ada peringkat

- New Microsoft Office Word DocumentDokumen6 halamanNew Microsoft Office Word DocumentHosam ElgoharyBelum ada peringkat

- CHE Facts - Industrial Gas Burners - July 2016Dokumen1 halamanCHE Facts - Industrial Gas Burners - July 2016John UrdanetaBelum ada peringkat

- Chap 14 PDFDokumen22 halamanChap 14 PDFnelson escuderoBelum ada peringkat

- 04 - Control Method For Low Oxygen Concentration in Reheating Furnace PDFDokumen8 halaman04 - Control Method For Low Oxygen Concentration in Reheating Furnace PDFVăn Tuấn NguyễnBelum ada peringkat

- The Visible Shape and Size of A Turbulent Hydrocarbon Jet Diffusion Flame in A Cross-WindDokumen16 halamanThe Visible Shape and Size of A Turbulent Hydrocarbon Jet Diffusion Flame in A Cross-WindRoberto CoelhoBelum ada peringkat

- Performance Analysis of Separating and Throttling Calorimeter To Determine PDFDokumen5 halamanPerformance Analysis of Separating and Throttling Calorimeter To Determine PDFCarolin megitaBelum ada peringkat

- Air Register FunctionsDokumen2 halamanAir Register Functionsanil kumarBelum ada peringkat

- Advantages of Ultra Super - FINALDokumen6 halamanAdvantages of Ultra Super - FINALAmar N. MauryaBelum ada peringkat

- TP PC 11 02Dokumen16 halamanTP PC 11 02Khoirul Walad100% (1)

- DampnerDokumen2 halamanDampnerManojkumarBelum ada peringkat

- Audel Oil Burner Guide CH 11eDokumen3 halamanAudel Oil Burner Guide CH 11eNoman AliBelum ada peringkat

- NPTEL Compressible Flows FundamentalsDokumen57 halamanNPTEL Compressible Flows FundamentalsJasim RasheedBelum ada peringkat

- 17012018SUJCSBXGPFRwithannexures PDFDokumen265 halaman17012018SUJCSBXGPFRwithannexures PDFManojkumarBelum ada peringkat

- ISO 14726 Color Marking On PipesDokumen14 halamanISO 14726 Color Marking On PipesManojkumarBelum ada peringkat

- Manual Centrifuga UniversalDokumen35 halamanManual Centrifuga Universallebiatan89Belum ada peringkat

- Welding Positions. Weld GuruDokumen11 halamanWelding Positions. Weld GuruValli RajuBelum ada peringkat

- B Check TrainingDokumen3 halamanB Check TrainingGIGIBelum ada peringkat

- Model Nc-1 Neutrapal' Condensate Neutralization Kit: 1.6 Gal/hr (6.05l/hr)Dokumen2 halamanModel Nc-1 Neutrapal' Condensate Neutralization Kit: 1.6 Gal/hr (6.05l/hr)Hot Water NowBelum ada peringkat

- Aggreko - Chevron Supplier For CabindaDokumen8 halamanAggreko - Chevron Supplier For CabindaLuiz EduardoBelum ada peringkat

- Engine Powered AWP Brochure PDFDokumen24 halamanEngine Powered AWP Brochure PDFMohanraj VenuBelum ada peringkat

- Raptor 44 ReseminDokumen6 halamanRaptor 44 ReseminlucasmaltaBelum ada peringkat

- GM Lada Niva TBI System GuideDokumen11 halamanGM Lada Niva TBI System Guidemicki3Belum ada peringkat

- Unit 1 Introduction To Automobile Engineering: StructureDokumen6 halamanUnit 1 Introduction To Automobile Engineering: StructureJai Kumar KaushilBelum ada peringkat

- Operating CostingDokumen16 halamanOperating CostingHardik RavalBelum ada peringkat

- 368kW (500mhp) : First Class Power - The Yanmar 6HYDokumen2 halaman368kW (500mhp) : First Class Power - The Yanmar 6HYRudy PriatnaBelum ada peringkat

- Nexus 250 I.E. UPUTSTVO - 1559729845Dokumen96 halamanNexus 250 I.E. UPUTSTVO - 1559729845Aleksandar RakićBelum ada peringkat

- TCS-PTG Savings With Extra PowerDokumen9 halamanTCS-PTG Savings With Extra PowerfatboykrBelum ada peringkat

- Alimpolos, Christian R. BSMT LL - CanuposDokumen3 halamanAlimpolos, Christian R. BSMT LL - Canuposjona100% (1)