A Guide Checklists For Mining Students

Diunggah oleh

Ginalyn MateoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

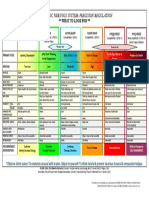

A Guide Checklists For Mining Students

Diunggah oleh

Ginalyn MateoHak Cipta:

Format Tersedia

Saint Louis University

SCHOOL OF ENGINEERING AND ARCHITECTURE

Department of Mining Engineering

3. Organization

A guide/ checklists for On the Job 4. Management by Objectives

Training SLU mining students; 5. Performance Appraisal System

from Engr. Robenson O. Odcheo 6. Education, Training and Development

7. Management Information system.

EM/GE(Asst.Professor- dept. of mining eng’g) 8. Mine productivity

8. Underground Incentive Bonus System.

9. Maintenance Management.

10. Material Management.

Inquiries to do in your on the job training 11. Industrial Relations and Corporate Social Responsibility.

(BSEM Class 2016) 12. Introduction to Quantitative Management Techniques

I-MINE SAFETY IV-MINE DESIGN

1. Engineering Design Process

1. Primary causes of mining accidents 2. Facilities planning, process, manufacturing engineering, and

2. Hazard recognition relative to explosives, mine gases, electrical Re-engineering

and mechanical devices 3. Design Problems (Mineral resource and ore reserve estimation;

3. “Best Practices” to help reduce serious accidents in work sites Surface mine fleet design; Mine dewatering; Underground fleet

4. Establishment of Health and Safety Organizations in design; Ventilation: Underground track haulage; Conveyors and

Mines,Qualification, Duties & Responsibilities of Safety Men, Rights Hoist design)

and Duties of Employees, record Keeping

5. Mine mapping as regards to escape ways, first-aid stations, fire

extinguishers, emergency evacuation plan, barricading V-ORE RESOURCE ESTIMATE

6. Procedures of safely entering and leaving the mine; A) Exploration

transportation; communications -Drilling results for surface and underground

7. Procedures regarding ground control systems -sampling method and results

8. Safe procedures dealing with the usage, transport and storage of B) Ore resource Estimate

explosives -Methods used

9. Safe procedures of using welding and cutting equipment -Declaration of Ore Resource

10. Methods of fighting mine fires *Measured

11. Proper procedure of donning self-rescue device and care of *Indicated

such devices *Inferred

12. Elements of basic first aid

13. Mine Safety rules and regulations VI-ORE RESERVE ESTIMATE

14. Introduction to the principles of quantitative risk assessment in These are based on geological data and the mining

a mining context. methods applied.

-Dilution factor applied

II-MINE VENTILATION (Underground) -The payability

1. Introduction. Definition. Control Process -The Mining recovery

2. Properties and behavior of air. -Declaration of Ore Reserve

3. Quality control (Contaminants, gas and dust control) *Proven

4. Quality control in ventilation. *Probable

5. Types of ventilation and economics of airflow

6. Temperature and humidity control. VII- MINE PLANNING DATA ON THE FOLLOWING;

7. Ventilation surveys -Long Range _5 to 20 years

-Medium Range_3 to 5 years

III-MINE MANAGEMENT -Short Range_1 to 2 years

*Includes weekly

1. Introduction to mine management. *Includes monthly

2. Corporate Planning

Page 1 of 3

Saint Louis University

SCHOOL OF ENGINEERING AND ARCHITECTURE

Department of Mining Engineering

*Includes quarterly Types and parameters on the following;

*Includes semi-annual projections -U/G loaders (standard bucket and width vehicle)

-U/G trucks (Maximum payload capacity and width

VIII-MINE PLANNING and DESIGN vehicle)

These Designs were based the data of geotechnical and geological; -Jumbo drill

-Development Parameters -Scissor lift

*By Mechanized -personnel carrier

*By Conventional or

*Combination of Mechanized and conventional B. Surface Mobile Equipment

method. Loaders/shovels

-The mining method

-Mining Interval

Haulers

-Mining Sequence Drillers

-Manpower and Equipment Miscellaneous equipment(water

-Ventilation System truck,Graders,compactors,etc.)

-Compressed Air Requirement

-Drainage system XII-DRILLING PATTERNS

-Power and Electrical System Showing Cross section and longitudinal section.

IX-DEVELOPMENT PARAMETERS XIII-BLASTING-COLUMN CHARGE

A.Underground Showing Longitudinal section.

The height, width & gradient of the following; -Dry hole on Lifter/kneeholes

-Ramps *using dynamite, primer & detonator

-Crosscuts - Dry hole on Lifter/knee, cut, production & perimeter

-Ore drives holes

-Ventilation raises/Manways *using ANFO, primer & detonator

-Ore passes -Wet hole on all holes

-Muckbays/stockpiles =using straight dynamite & primer

-Sumps

-Footwall drive XIV-BLASTING LAYOUT WITH DETONATING CHORD

-Drainage/haulage drive Showing Cross section layout.

B.Surface

The height, width & gradient of the following; XV-GEOTECHNICAL PARAMETERS

-Ramps Inquire on their data results on items 1 to 6.

-Working face Geomechanics classification / Rockmass rating (RMR)

-Road curvatures - a system of estimating the strength of rock masses using

-Road superelevations the parameters below:

-Parameters of their working pit 1. Uniaxial Compressive Strength of rock material

-stockpile areas 2. Rock Quality Designation (RQD)

-Sumps 3. Spacing of discontinuities

-Drainage system 4. Condition of discontinuities

5. Groundwater conditions

X-ROCK DENSITY 6. Orientation of discontinuities

-In Situ Rock Density (Ore) Inquire on the Classifications on RQD with Rock Mass Quality;

-In Situ Rock Density (Waste) Inquire on the Corrected Rock Mass rating with classification;

-Loose Rock density

-% Swell XVI-GEOTECHNICAL PARAMETERS

Inquire on the ground support requirement applied on the

XI-U/G MINING MOBILE EQUIPMENT classification of ground.

A. Underground Mobile Equipment -Ground support on timbering

Page 2 of 3

Saint Louis University

SCHOOL OF ENGINEERING AND ARCHITECTURE

Department of Mining Engineering

-Ground Support on split set Rockbolts 5.Tailings disposal

-Ground Support on Shotcrete 6. Environmental and legal considerations.

*are they using Dry-mix type of shotcrete or; 7. Other metallurgical concrens

*are they using wet-mix type of shotcrete

XVVII-PORT STOCKPILE AND SMELTERS CHARGES

What are the applications for split sets, using dry-mix and using

wet-mix,pls inquire. COMPUTATIONS

1. Allowable moisture of concentrate/ore content for

XVII-APPLIED MINING METHOD loading.

Inquire on the ground support requirement applied on the

2. Volume per shipment.

classification of ground and the mining methods used.

XVIII-FINANCIAL RUN 3. Cost/ton of concentrate

Inquire on following; 4. Smelters calculations with charges

-Operating cost

*Cost/ton($/t) XVVIII-OTHERS

*Cost/meter($/m.)

-Break-Even Grade XVIX-MINE AND PLANT PRACTICE (Summary)

-Cut-Off Grade 1. Mineral Exploration: geologic principles, mineralogy, mineral

-Financial Analysis (sensitivity analysis) resource/ore reserve estimation and evaluation, and mineral

-Revenue / Profit economics.

XVIV-MINE DECOMISSIONING & CLOSURE PLAN 2. Mining Operation: Mine Engineering, mine development, mine

MINE CLOSURE PLANNING planning and management, and mine design, draw control,

UNDERGROUND FACILITIES mine ventilation and safety, environmental engineering and

SURFACE FACILITIES management.

WATER MANAGEMENT

SITE REHABILITATION

3. Mineral processing: Size reduction and concentration

SOCIO-ECONOMIC processes, dewatering stages, auxiliary operations, tailings

CLOSE-OUT disposal, and environmental and legal considerations.

4. Mill flowsheet.

XVV- WATER AND POWER RESOURCES

A.WATER RESOURCES A wise proverb;

1.main There are four sorts of men.

2.supplementary He who knows not, and knows not he knows not;

-Flowsheet of water distribution on the ff; He is a fool-shun him.

a. mining operation He who knows not, and knows he knows not;

b. milling operations He is simple-teach him.

c. Domestic usages He who knows and knows not he knows;

A.POWER RESOURCES He is sleeping-wake him.

1.main He who knows and knows he knows;

2.supplementary He is wise-follow him.

-Flowsheet of power distribution on the ff;

Enjoy, learn, explore then take notes. The future is yours.

a. mining operation

b. milling operations

c. Domestic usages

XVVI- Mineral processing:

1. Size reduction

2. Concentration processes

3. Dewatering stages

4. Auxiliary operations

Page 3 of 3

Anda mungkin juga menyukai

- Method Statement For Lifting WorksDokumen12 halamanMethod Statement For Lifting WorksBeomHee Lee100% (1)

- Rig Move Procedures DevelopmentDokumen23 halamanRig Move Procedures DevelopmentAli Ahmed Pathan100% (2)

- Sistema NervosoDokumen1 halamanSistema NervosoPerisson Dantas100% (2)

- Method Statement For Rock Armoured SeawallDokumen25 halamanMethod Statement For Rock Armoured Seawalljucar fernandez100% (4)

- Part 1 Fundamentals of Reservior Engineering-Abbas 2020Dokumen184 halamanPart 1 Fundamentals of Reservior Engineering-Abbas 2020PX PR100% (2)

- Template Hazid WorksheetDokumen43 halamanTemplate Hazid WorksheetJagan Bose100% (3)

- M265 Lec 13 - Epidemiology and Public HealthDokumen10 halamanM265 Lec 13 - Epidemiology and Public HealthSawsan Z. JwaiedBelum ada peringkat

- Fundamental Res EngDokumen199 halamanFundamental Res EngTeddy GeovanieBelum ada peringkat

- Micro Tunneling On SiteDokumen3 halamanMicro Tunneling On SitemhetrajkarBelum ada peringkat

- Endocrine SystemDokumen32 halamanEndocrine Systemlee bon hukBelum ada peringkat

- 12mine LayoutDokumen54 halaman12mine Layouttridev kant tripathi100% (1)

- Mine Planning and DesignDokumen394 halamanMine Planning and DesignUdhaya Kumar100% (5)

- Mine Planning and Scheduling42Dokumen228 halamanMine Planning and Scheduling42Martin JanuaryBelum ada peringkat

- Neuro Lymphatic MassageDokumen2 halamanNeuro Lymphatic Massagewolfgangl70Belum ada peringkat

- Sensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesDari EverandSensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesBelum ada peringkat

- Mining For Non Miners 2Dokumen20 halamanMining For Non Miners 2Mohammad Fahry Aladjai100% (1)

- Amie Syllabus Sec B MiningDokumen19 halamanAmie Syllabus Sec B MiningSangeet SharmaBelum ada peringkat

- Guide To Clinical Audit Antibiotic Use in Urinary Tract InfectionDokumen10 halamanGuide To Clinical Audit Antibiotic Use in Urinary Tract Infectionihtisham1Belum ada peringkat

- Reservoir Surveillance and Diagnostic - Production ProblemDokumen63 halamanReservoir Surveillance and Diagnostic - Production ProblemminahlehBelum ada peringkat

- Safety Plan For Chemical PlantDokumen7 halamanSafety Plan For Chemical PlantM Amir Haris100% (1)

- 1) Preventive & Predictive MaintenanceDokumen70 halaman1) Preventive & Predictive MaintenanceRicky David SimanjuntakBelum ada peringkat

- Method of Statement Scafollding WorksDokumen6 halamanMethod of Statement Scafollding WorksAhmed saberBelum ada peringkat

- Response in OppositionDokumen36 halamanResponse in OppositionForeclosure FraudBelum ada peringkat

- Advanced Mine Ventilation: Respirable Coal Dust, Combustible Gas and Mine Fire ControlDari EverandAdvanced Mine Ventilation: Respirable Coal Dust, Combustible Gas and Mine Fire ControlPenilaian: 3 dari 5 bintang3/5 (2)

- Education Mine Planning and Automation Docs48Dokumen54 halamanEducation Mine Planning and Automation Docs48elangelang99Belum ada peringkat

- Method of Statement For Road Crossing WorkDokumen7 halamanMethod of Statement For Road Crossing WorkAnonymous voA5Tb0Belum ada peringkat

- How Human Microbiome Talks To Health and DiseaseDokumen7 halamanHow Human Microbiome Talks To Health and DiseaseRafa SotoBelum ada peringkat

- Day2 2 PINKS PDFDokumen30 halamanDay2 2 PINKS PDFPeng TerBelum ada peringkat

- Mine Design GuidelinesDokumen7 halamanMine Design GuidelinesShaiter NaseffBelum ada peringkat

- Asset Integrity ManagementDokumen30 halamanAsset Integrity Managementanouar82Belum ada peringkat

- Extraction of PillarsDokumen240 halamanExtraction of PillarsDaniel SantanaBelum ada peringkat

- L 65 - Prevention of Fire and Explosion, and Emergency Response On Offshore Installations - Approved Code of Practice and Guidance - HSE - 2010Dokumen56 halamanL 65 - Prevention of Fire and Explosion, and Emergency Response On Offshore Installations - Approved Code of Practice and Guidance - HSE - 2010Barkat UllahBelum ada peringkat

- CourseOutline MINE3430 S1 2016Dokumen10 halamanCourseOutline MINE3430 S1 2016FarhanIslamBelum ada peringkat

- Bulk Material Handling: Practical Guidance for Mechanical EngineersDari EverandBulk Material Handling: Practical Guidance for Mechanical EngineersPenilaian: 5 dari 5 bintang5/5 (1)

- Third Year SyllabusDokumen50 halamanThird Year SyllabusMukesh Kumar MahtoBelum ada peringkat

- SpecializationDokumen7 halamanSpecializationNicole De VeraBelum ada peringkat

- Syllabus: (Mining Sirdar T&S GR-C)Dokumen5 halamanSyllabus: (Mining Sirdar T&S GR-C)VIVEK BHANDARIBelum ada peringkat

- Perencanaan Dan Pelaksanaan Konstruksi OffshoreDokumen38 halamanPerencanaan Dan Pelaksanaan Konstruksi OffshoreRosfin OpinBelum ada peringkat

- 31 MI136 Rock Mechanics IIDokumen2 halaman31 MI136 Rock Mechanics IISealdeSaBelum ada peringkat

- Excavation and Trenching PlanDokumen26 halamanExcavation and Trenching Plananto.subhakarBelum ada peringkat

- Executive-Summary-for-the-Public-ESP-English Coto MineDokumen11 halamanExecutive-Summary-for-the-Public-ESP-English Coto MineChatz BalagtasBelum ada peringkat

- PD HMDCDokumen25 halamanPD HMDCSam De WaeleBelum ada peringkat

- S.No Test Name Test Launch Date Test DurartionDokumen3 halamanS.No Test Name Test Launch Date Test DurartionAAADSFDVSDVBelum ada peringkat

- MinedRockOverburdenPile Investigation+DesignManual 2Dokumen177 halamanMinedRockOverburdenPile Investigation+DesignManual 2tesfaye wolde100% (1)

- Method of Statement Shutdown Water LineDokumen10 halamanMethod of Statement Shutdown Water LineFrancis Mier SereñoBelum ada peringkat

- Mining Attachee Programme - UZDokumen6 halamanMining Attachee Programme - UZMatthew Tinashe NezandonyiBelum ada peringkat

- Challenges and Proposed Action Plan For DGMS: Ministry of Labour & Employment Directorate General of Mines SafetyDokumen4 halamanChallenges and Proposed Action Plan For DGMS: Ministry of Labour & Employment Directorate General of Mines Safetysrinibas mohapatraBelum ada peringkat

- Underground Mining of Coal Course Code: 3362203Dokumen6 halamanUnderground Mining of Coal Course Code: 3362203Santosh KumarBelum ada peringkat

- Unit IV Solid Waste Management: Curriculum & Syllabi: M.E. Industrial Safety and Engineering - Electives - Regulation 2014Dokumen31 halamanUnit IV Solid Waste Management: Curriculum & Syllabi: M.E. Industrial Safety and Engineering - Electives - Regulation 2014omer1299Belum ada peringkat

- Safety RegulationsDokumen32 halamanSafety Regulationsomer1299Belum ada peringkat

- Test Name: S.No Test Launch Date Test DurartionDokumen4 halamanTest Name: S.No Test Launch Date Test DurartionAAADSFDVSDVBelum ada peringkat

- SurfaceDokumen2 halamanSurfaceRiswan RiswanBelum ada peringkat

- GCMPRA-UGGeotechnicalFinal V1Dokumen15 halamanGCMPRA-UGGeotechnicalFinal V1Chandan ChamanBelum ada peringkat

- Road Preparation WorkDokumen19 halamanRoad Preparation WorkDhaneswar SwainBelum ada peringkat

- Company Profile: 4. Mine Infrastructure 1. GeologyDokumen2 halamanCompany Profile: 4. Mine Infrastructure 1. Geologysyahrir83Belum ada peringkat

- Drones 04 00034 (2) TerjemahanDokumen24 halamanDrones 04 00034 (2) TerjemahanDonelBelum ada peringkat

- Drones: A Comprehensive Review of Applications of Drone Technology in The Mining IndustryDokumen25 halamanDrones: A Comprehensive Review of Applications of Drone Technology in The Mining IndustryDonelBelum ada peringkat

- Mine Closure Planning at Umrer OCP: Present Shape of The Project Work and Some FindingsDokumen40 halamanMine Closure Planning at Umrer OCP: Present Shape of The Project Work and Some FindingskhaninBelum ada peringkat

- Mining Engineering SyllabusDokumen8 halamanMining Engineering SyllabusRaju P SundaramBelum ada peringkat

- Final SMP Aik Docm PDFDokumen153 halamanFinal SMP Aik Docm PDFAmit sawantBelum ada peringkat

- Amie Syllabus Sec B Mining PDFDokumen19 halamanAmie Syllabus Sec B Mining PDFMunavir kBelum ada peringkat

- IwmsyllabiDokumen2 halamanIwmsyllabinarayanan77Belum ada peringkat

- Ace-Test Series Broucher Test Syllabus and Test ScheduleDokumen12 halamanAce-Test Series Broucher Test Syllabus and Test SchedulebharatBelum ada peringkat

- Syllabus Btech MiningDokumen19 halamanSyllabus Btech MiningSimanta SinhaBelum ada peringkat

- Silabus Mata Kuliah/Bidang Ilmu: Program Diploma Pelayaran-UHT-SurabayaDokumen2 halamanSilabus Mata Kuliah/Bidang Ilmu: Program Diploma Pelayaran-UHT-Surabayaari sriantiniBelum ada peringkat

- Feasibility Analysis: Muhammad Ade IrfanDokumen34 halamanFeasibility Analysis: Muhammad Ade Irfanmuhammad ade irfanBelum ada peringkat

- AMP MIcro Project Final ReportDokumen13 halamanAMP MIcro Project Final Reportvedantbakal043Belum ada peringkat

- 18IS31 OHSAS 18000, ISO 14000 AND ISO 9000: Unit I 9 Hours Ohsas StandardDokumen4 halaman18IS31 OHSAS 18000, ISO 14000 AND ISO 9000: Unit I 9 Hours Ohsas StandardBharath KumarBelum ada peringkat

- Principles of Mining: Valuation, Organization and AdministrationDari EverandPrinciples of Mining: Valuation, Organization and AdministrationBelum ada peringkat

- Mine Design Lec RPRTNGDokumen27 halamanMine Design Lec RPRTNGGinalyn MateoBelum ada peringkat

- EM - Reviewer IIDokumen18 halamanEM - Reviewer IIGinalyn MateoBelum ada peringkat

- Answer 6Dokumen16 halamanAnswer 6Ginalyn MateoBelum ada peringkat

- PD 1586Dokumen3 halamanPD 15861hewlettBelum ada peringkat

- Triamcinolone AcetonideDokumen12 halamanTriamcinolone Acetonideawais khanBelum ada peringkat

- PDFDokumen278 halamanPDFmahesh babu100% (1)

- 3 Ways To Prune RhododendronDokumen4 halaman3 Ways To Prune RhododendronAndreBelum ada peringkat

- Centaur CortisolDokumen12 halamanCentaur CortisolMohamed AliBelum ada peringkat

- Prevalence of Water Borne Diseases Within Households in The Bamendankwemunicipalitynorth West Cameroon 2332 0893 1000122Dokumen7 halamanPrevalence of Water Borne Diseases Within Households in The Bamendankwemunicipalitynorth West Cameroon 2332 0893 1000122Welly SuryaBelum ada peringkat

- Waste ManagementDokumen34 halamanWaste ManagementSivaRamanBelum ada peringkat

- Safety Data Sheet For NEBNext End Prep Reaction BufferDokumen9 halamanSafety Data Sheet For NEBNext End Prep Reaction BufferNabilahBelum ada peringkat

- United States Patent (19) 11 Patent Number: 5,676,977: Antelman 45 Date of Patent: Oct. 14, 1997Dokumen4 halamanUnited States Patent (19) 11 Patent Number: 5,676,977: Antelman 45 Date of Patent: Oct. 14, 1997Sunita MarturBelum ada peringkat

- Physiology Practical 2: Toad HeartDokumen10 halamanPhysiology Practical 2: Toad HeartAdams OdanjiBelum ada peringkat

- Erbacher Vita 2010Dokumen5 halamanErbacher Vita 2010HuntMBelum ada peringkat

- Ept, PoDokumen2 halamanEpt, PoStacieBelum ada peringkat

- Connections Issue 11Dokumen21 halamanConnections Issue 11Victoria University, Melbourne, AustraliaBelum ada peringkat

- Personal Business Model Canvas v1.1.8 A2Dokumen1 halamanPersonal Business Model Canvas v1.1.8 A2Laura Natalia SalcedoBelum ada peringkat

- Jurnal GadarDokumen6 halamanJurnal GadarLycia Dwi LindiyaniBelum ada peringkat

- Philippine Health Care Delivery SystemDokumen24 halamanPhilippine Health Care Delivery SystemoisloeBelum ada peringkat

- Cannistra 2007Dokumen4 halamanCannistra 2007amdreyBelum ada peringkat

- Monkeypox: VirusDokumen18 halamanMonkeypox: Virusdiela dwi lestariBelum ada peringkat

- Osha Note Topic 1Dokumen49 halamanOsha Note Topic 1Hasnol HaiqalBelum ada peringkat

- Brochure Kombitroll2000 2064411Dokumen16 halamanBrochure Kombitroll2000 2064411Jmi AzimBelum ada peringkat

- Schedule of Charges-Holy Family - Sep 08Dokumen64 halamanSchedule of Charges-Holy Family - Sep 08Quirinevv100% (1)

- Form g11Dokumen23 halamanForm g11Armely NiedoBelum ada peringkat