Sae J1397-1992 PDF

Diunggah oleh

Adam GordonJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Sae J1397-1992 PDF

Diunggah oleh

Adam GordonHak Cipta:

Format Tersedia

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SURFACE J1397

REV.

MAY92

VEHICLE

400 Commonwealth Drive, Warrendale, PA 15096-0001

INFORMATION Issued 1982-07

REPORT Revised 1992-05

Superseding J1397 DEC88

An American National Standard

(R) ESTIMATED MECHANICAL PROPERTIES AND MACHINABILITY OF STEEL BARS

Foreword—This Document has also changed to comply with the new SAE Technical Standards Board format.

1. Scope—This SAE Information Report is intended to provide a guide to mechanical and machinability

characteristics of some SAE steel grades. The ratings and properties shown are provided as general

information and not as requirements for specifications unless each instance is approved by the source of

.pw

supply. The data are based on resources which may no longer be totally accurate. However, this report is

retained as a service in lieu of current data.

2. References

2.1

on

Applicable Publication—The following publication forms a part of this specification to the extent specified

a ti

herein.

U. S. Air Force Machinability Report, Volume 2, 1951, published by Curtiss-Wright Corporation

ific

--`-`-`,,`,,`,`,,`---

2.2 Related Publications—The following publications are provided for information purposes only and are not a

required part of this document.

pec

Metals Handbook, 8th ed., Volume 3, Machining, American Society for Metals, Metals Park, OH 44073.

Machining Data Handbook, Volumes 1 and 2.

w.s

Machinability Data Center, Metcut Research Associates, 3980 Rosslyn Drive, Cincinnati, OH 45209.

3. Carbon Steel—Mechanical properties and machinability ratings for carbon steel grades 10xx, 11xx, 12xx, and

ww

15xx are listed in Tables 1, 2, and 3. These properties can generally be expected from bars ranging in size

from 20 to 30 mm (3/4 to 1-1/4 in) based on the standard round tensile test specimen with 50 mm (2 in) gage

length.

Sizes under 20 mm (3/4 in) will show a strength which is slightly higher than those shown in the Tables. The

mass effect of larger sections has a direct influence on mechanical properties and results in slightly lower

values as the section size increases.

SAE Technical Standards Board Rules provide that: “This report is published by SAE to advance the state of technical and engineering sciences. The use of this report is entirely

voluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user.”

SAE reviews each technical report at least every five years at which time it may be reaffirmed, revised, or cancelled. SAE invites your written comments and suggestions.

QUESTIONS REGARDING THIS DOCUMENT: (724) 772-8512 FAX: (724) 776-0243

TO PLACE A DOCUMENT ORDER; (724) 776-4970 FAX: (724) 776-0790

SAE WEB ADDRESS http://www.sae.org

Copyright 1992 Society of Automotive Engineers, Inc.

All rights reserved.

Copyright SAE International

Printed in U.S.A.

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SAE J1397 Revised MAY92

Properties of turned and polished or turned and ground types of cold finished material will correspond to the

hot rolled values.

The cold drawn properties are based on conventional production from hot rolled bars.

Cold drawn carbon steel bars in grades 1042 and higher are frequently thermally treated prior to cold drawing

to enhance machinability.

4. Alloy Steel—Hardness and machinability ratings for cold drawn alloy steel bars are listed in Table 4 with the

appropriate microstructure. The microstructure listed for alloy steels in Table 4 is identified as follows:

a. Type A—Predominantly lamellar pearlite and ferrite.

b. Type B—Predominantly spheroidized.

c. Type C—This is a hot rolled structure which depends upon grade, size, and rolling conditions of the

producing mill. The structure may be coarse or fine pearlite or bainite. The pearlite at low

magnification may be blocky or acicular. For descriptive information, see U. S. Air Force Machinability

Report, Volume 2, 1951, published by Curtiss-Wright Corporation.

.pw

d. Type D—This is a structure resulting from a subcritical anneal or temper anneal. It is usually a

granular or spheroidized carbide condition confined to the hot rolled grain pattern, which may be blocky

or acicular.

5.

on

Machinability—While it is recognized that the views regarding alloy steel machinability vary considerably, it is

believed that the ratings contained in this report reflect current industry experience. The data on which the

a ti

ratings were based were obtained by a detailed survey of both producers and users. The data summarize the

combined experience of both groups. Various factors influence machinability and, therefore, results shown in

Table 1 are average and may be affected to some degree by the amount of cold reduction, mechanical

ific

--`-`-`,,`,,`,`,,`---

properties, grain size, microstructure, type of tooling, and machining operation(s) performed.

The machinability ratings listed are based on a value of 100% for SAE 1212 cold drawn steel. This value

pec

involves turning at a cutting speed of 55 m (180 surface feet) per minute for feeds up to 0.18 mm (0.007 in) per

revolution and depths of cut up to 6.4 mm (0.250 in), using appropriate cutting fluids with high speed steel

tools, SAE Grade T-1 (18-4-1) hardened to 63-65 HRC (SAE J437, J438).

w.s

Most low carbon alloy steels are machined in the as-rolled or as-rolled and cold drawn or cold finished

condition. Higher carbon alloy steels and high hardenability low carbon steels, such as SAE 9310, may be

ww

conditioned for machining by a variety of heat treatments. Thermal treatments used to condition these steels

for machining include subcritical annealing, annealing for softening to no specified structure, annealing to a

specified structure such as lamellar pearlite or a percentage of lamellar pearlite and spheroidization, or to a

fully spheroidized condition.

The structures imparted to the bars are evaluated in the machining operation by the tooling setup and the type

of tool used. It is possible to use widely diverging hardnesses and structures with different tooling setups and

obtain satisfactory results both as to finish and parts per hour.

Copyright SAE International

-2-

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SAE J1397 Revised MAY92

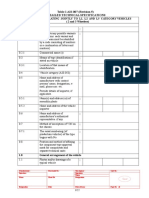

TABLE 1—ESTIMATED MECHANICAL PROPERTIES AND MACHINABILITY RATINGS

OF NONRESULFURIZED CARBON STEEL BARS, MANGANESE 1.00% MAXIMUM

Estimated Estimated Estimated

Minimum Minimum Minimum Average

Values Values Values Machinability

SAE Tensile Tensile Yield Yield Elongation Reduction Rating

UNS and/or Type of Strength Strength Strength Strength in in Brinell (Cold Drawn)

No. AISI No. Processing MPa psi MPa psi 2 in, % Area % Hardness 1212=100%

G10060 1006 Hot Rolled 300 43 000 170 24 000 30 55 86

Cold Drawn 330 48 000 280 41 000 20 45 95 50

G10080 1008 Hot Rolled 303 44 000 170 24 500 30 55 86

Cold Drawn 340 49 000 290 41 500 20 45 95 55

G10100 1010 Hot Rolled 320 47 000 180 26 000 28 50 95

.pw

Cold Drawn 370 53 000 300 44 000 20 40 105 55

G10120 1012 Hot Rolled 330 48 000 180 26 500 28 50 95

Cold Drawn 370 54 000 310 45 000 19 40 105 55

G10150 1015 Hot Rolled 340 50 000 190

on 27 500 28 50 101

Cold Drawn

a ti 390 56 000 320 47 000 18 40 111 60

G10160 1016 Hot Rolled 380 55 000 210 30 000 25 50 111

ific

Cold Drawn 420 61 000 350 51 000 18 40 121 70

G10170 1017 Hot Rolled 370 53 000 200 29 000 26 50 105

pec

Cold Drawn 410 59 000 340 49 000 18 40 116 65

G10180 1018 Hot Rolled 400 58 000 220 32 000 25 50 116

w.s

Cold Drawn 440 64 000 370 54 000 15 40 126 70

G10190 1019 Hot Rolled 410 59 000 220 32 500 25 50 116

ww

Cold Drawn 460 66 000 380 55 000 15 40 131 70

G10200 1020 Hot Rolled 380 55 000 210 30 000 25 50 111

Cold Drawn 420 61 000 350 51 000 15 40 121 65

G10210 1021 Hot Rolled 420 61 000 230 33 000 24 48 116

Cold Drawn 470 68 000 390 57 000 15 40 131 70

G10220 1022 Hot Rolled 430 62 000 230 34 000 23 47 121

Cold Drawn 480 69 000 400 58 000 15 40 137 70

G10230 1023 Hot Rolled 370 56 000 210 31 000 25 50 111

Cold Drawn 430 62 000 360 52 500 15 40 121 65

G10250 1025 Hot Rolled 400 58 000 220 32 000 25 50 116

Cold Drawn 440 64 000 370 54 000 15 40 126 65

G10260 1026 Hot Rolled 440 64 000 240 35 000 24 49 126

Cold Drawn 490 71 000 410 60 000 15 40 143 75

Copyright SAE International

-3- --`-`-`,,`,,`,`,,`---

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SAE J1397 Revised MAY92

TABLE 1—ESTIMATED MECHANICAL PROPERTIES AND MACHINABILITY RATINGS

OF NONRESULFURIZED CARBON STEEL BARS, MANGANESE 1.00% MAXIMUM (CONTINUED)

Estimated Estimated Estimated

Minimum Minimum Minimum Average

Values Values Values Machinability

SAE Tensile Tensile Yield Yield Elongation Reduction Rating

UNS and/or Type of Strength Strength Strength Strength in in Brinell (Cold Drawn)

No. AISI No. Processing MPa psi MPa psi 2 in, % Area % Hardness 1212=100%

G10300 1030 Hot Rolled 470 68 000 260 37 500 20 42 137

Cold Drawn 520 76 000 440 64 000 12 35 149 70

G10350 1035 Hot Rolled 500 72 000 270 39 500 18 40 143

Cold Drawn 550 80 000 460 67 000 12 35 163 65

G10370 1037 Hot Rolled 510 74 000 280 40 500 18 40 143

Cold Drawn 570 82 000 480 69 000 12 35 167 65

.pw

G10380 1038 Hot Rolled 520 75 000 280 41 000 18 40 149

Cold Drawn 570 83 000 480 70 000 12 35 163 65

G10390 1039 Hot Rolled

Cold Drawn

540

610

79 000

88 000

300

510

on 43 500

74 000

16

12

40

35

156

179 60

a ti

G10400 1040 Hot Rolled 520 76 000 290 42 000 18 40 149

Cold Drawn 590 85 000 490 71 000 12 35 170 60

ific

G10420 1042 Hot Rolled 550 80 000 300 44 000 16 40 163

Cold Drawn 610 89 000 520 75 000 12 35 179 60

pec

NCD(1) 590 85 000 500 73 000 12 45 179 70

G10430 1043 Hot Rolled 570 82 000 310 45 000 16 40 163

w.s

Cold Drawn 630 91 000 530 77 000 12 35 179 60

NCD(1) 600 87 000 520 75 000 12 45 179 70

ww

G10440 1044 Hot Rolled 550 80 000 300 44 000 16 40 163

G10450 1045 Hot Rolled 570 82 000 310 45 000 16 40 163

Cold Drawn 630 91 000 530 77 000 12 35 179 55

ACD (2) 590 85 000 500 73 000 12 45 170 65

G10460 1046 Hot Rolled 590 85 000 320 47 000 15 40 170

Cold Drawn 650 94 000 540 79 000 12 35 187 55

ACD(2) 620 90 000 520 75 000 12 45 179 65

G10490 1049 Hot Rolled 600 87 000 330 48 000 15 35 179

Cold Drawn 670 97 000 560 81 500 10 30 197 45

ACD(2) 630 92 000 530 77 000 10 40 187 55

G10500 1050 Hot Rolled 620 90 000 340 49 500 15 35 179

Cold Drawn 690 100 000 580 84 000 10 30 197 45

ACD(2) 660 95 000 550 80 000 10 40 189 55

Copyright SAE International

--`-`-`,,`,,`,`,,`---

-4-

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SAE J1397 Revised MAY92

TABLE 1—ESTIMATED MECHANICAL PROPERTIES AND MACHINABILITY RATINGS

OF NONRESULFURIZED CARBON STEEL BARS, MANGANESE 1.00% MAXIMUM (CONTINUED)

--`-`-`,,`,,`,`,,`---

Estimated Estimated Estimated

Minimum Minimum Minimum Average

Values Values Values Machinability

SAE Tensile Tensile Yield Yield Elongation Reduction Rating

UNS and/or Type of Strength Strength Strength Strength in in Brinell (Cold Drawn)

No. AISI No. Processing MPa psi MPa psi 2 in, % Area % Hardness 1212=100%

G10550 1055 Hot Rolled 650 94 000 360 51 500 12 30 192

ACD (2) 660 96 000 560 81 000 10 40 197 55

G10600 1060 Hot Rolled 680 98 000 370 54 000 12 30 201

SACD(3) 620 90 000 480 70 000 10 45 183 60

G10640 1064 Hot Rolled 670 97 000 370 53 500 12 30 201

SACD (3) 610 89 000 480 69 000 10 45 183 60

.pw

G10650 1065 Hot Rolled 690 100 000 380 55 000 12 30 207

SACD(3) 630 92 000 490 71 000 10 45 187 60

on

G10700 1070 Hot Rolled 700 102 000 390 56 000 12 30 212

SACD(3) 640 93 000 500 72 000 10 45 192 55

a ti

G10740 1074 Hot Rolled 720 105 000 400 58 000 12 30 217

SACD(3) 650 94 500 500 73 000 10 40 192 55

ific

G10780 1078 Hot Rolled 690 100 000 380 55 000 12 30 207

SACD (3) 650 94 000 500 72 500 10 40 192 55

pec

G10800 1080 Hot Rolled 770 112 000 420 61 500 10 25 229

SACD(3) 680 98 000 520 75 000 10 40 192 45

w.s

G10840 1084 Hot Rolled 820 119 000 450 65 500 10 25 241

SACD(3) 690 100 000 530 77 000 10 40 192 45

ww

G10850 1085 Hot Rolled 830 121 000 460 66 500 10 25 248

SACD(3) 690 100 500 540 78 000 10 40 192 45

G10860 1086 Hot Rolled 770 112 000 420 61 500 10 25 229

SACD (3) 670 97 000 510 74 000 10 40 192 45

G10900 1090 Hot Rolled 840 122 000 460 67 000 10 25 248

SACD(3) 700 101 000 540 78 000 10 40 197 45

G10950 1095 Hot Rolled 830 120 000 460 66 000 10 25 248

SACD (3) 680 99 000 520 76 000 10 40 197 45

1. NCD represents normalized cold drawn.

2. ACD represents annealed cold drawn.

3. SACD represents spheroidized annealed cold drawn.

Copyright SAE International

-5-

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SAE J1397 Revised MAY92

TABLE 2—ESTIMATED MECHANICAL PROPERTIES AND MACHINABILITY RATINGS

OF RESULFURIZED CARBON STEEL BARS(1)

Estimated Estimated Estimated

Minimum Minimum Minimum Average

Values Values Values Machinability

SAE Tensile Tensile Yield Yield Elongation Reduction Rating

UNS and/or Type of Strength Strength Strength Strength in in Brinell (Cold Drawn)

No. AISI No. Processing MPa psi MPa psi 2 in, % Area % Hardness 1212=100%

G11080 1108 Hot Rolled 340 50 000 190 27 500 30 50 101

Cold Drawn 390 56 000 320 47 000 20 40 121 80

G11170 1117 Hot Rolled 430 62 000 230 34 000 23 47 121

Cold Drawn 480 69 000 400 58 000 15 40 137 90

G11320 1132 Hot Rolled 570 83 000 310 45 500 16 40 167

Cold Drawn 630 92 000 530 77 000 12 35 183 75

.pw

G11370 1137 Hot Rolled 610 88 000 330 48 000 15 35 179

Cold Drawn 680 98 000 570 82 000 10 30 197 70

G11400 1140 Hot Rolled

Cold Drawn

540

610

79 000

88 000

300

510

on 43 500

74 000

16

12

40

35

156

170 70

a ti

G11410 1141 Hot Rolled 650 94 000 360 51 500 15 35 187

Cold Drawn 720 105 100 610 88 000 10 30 212 70

ific

G11440 1144 Hot Rolled 670 97 000 370 53 000 15 35 197

Cold Drawn 740 108 000 620 90 000 10 30 217 80

pec

G11460 1146 Hot Rolled 590 85 000 320 47 000 15 40 170

Cold Drawn 650 94 000 550 80 000 12 35 187 70

w.s

G11510 1151 Hot Rolled 630 92 000 340 50 500 15 35 187

Cold Drawn 700 102 000 590 86 000 10 30 207 65

ww

G12110 1211 Hot Rolled 380 55 000 230 33 000 25 45 121

Cold Drawn 520 75 000 400 58 000 10 35 163 95

G12120 1212 Hot Rolled 390 56 000 230 33 500 25 45 121

Cold Drawn 540 78 000 410 60 000 10 35 167 100

G12130 1213 Hot Rolled 390 56 000 230 33 500 25 45 121

Cold Drawn 540 78 000 410 60 000 10 35 167 135

G12144 12L14 Hot Rolled 390 57 000 230 34 000 22 45 121

Cold Drawn 540 78 000 410 60 000 10 35 163 160

1. All 1100 and 1200 series steels are rated on the basis of 0.10% maximum silicon or coarse grain melting practice.

--`-`-`,,`,,`,`,,`---

Copyright SAE International

-6-

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

--`-`-`,,`,,`,`,,`---

SAE J1397 Revised MAY92

TABLE 3—ESTIMATED MECHANICAL PROPERTIES AND MACHINABILITY RATINGS

OF NONRESULFURIZED CARBON STEEL BARS, MANGANESE MAXIMUM OVER 1.00%

Estimated Estimated Estimated

Minimum Minimum Minimum Average

Values Values Values Machinability

SAE Tensile Tensile Yield Yield Elongation Reduction Rating

UNS and/or Type of Strength Strength Strength Strength in in Brinell (Cold Drawn)

No. AISI No. Processing MPa psi MPa psi 2 in, % Area % Hardness 1212=100%

G15240 1524 Hot Rolled 510 74 000 280 41 000 20 42 149

Cold Drawn 570 82 000 480 69 000 12 35 163 60

G15270 1527 Hot Rolled 520 75 000 280 41 000 18 40 149

Cold Drawn 570 83 000 480 70 000 12 35 163 65

G15360 1536 Hot Rolled 570 83 000 310 45 500 16 40 163

.pw

Cold Drawn 630 92 000 530 77 500 12 35 187 55

G15410 1541 Hot Rolled 630 92 000 350 51 000 15 40 187

Cold Drawn 710 102 500 600 87 000 10 30 207 45

ACD (1)

on

a ti 650 94 000 550 80 000 10 45 184 60

G15480 1548 Hot Rolled 660 96 000 370 53 000 14 33 197

Cold Drawn 730 106 500 620 89 500 10 28 217 45

ACD(1) 640 93 500 540 78 500 10 35 192 50

ific

G15520 1552 Hot Rolled 740 108 000 410 59 500 12 30 217

ACD(1) 680 98 000 570 83 000 10 40 193 50

pec

1. ACD represents annealed cold drawn.

w.s

ww

Copyright SAE International

-7-

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SAE J1397 Revised MAY92

TABLE 4—MACHINABILITY OF ALLOY STEEL

Range of

Typical

UNS AISI and/or Machinability Hardness Microstructure

No. SAE No. Rating Condition HB Type(1)

G13300 1330 55 Annealed and Cold Drawn 179/235 A

G13350 1335 55 Annealed and Cold Drawn 179/235 A

G13400 1340 50 Annealed and Cold Drawn 183/241 A

G13450 1345 45 Annealed and Cold Drawn 183/241 A

G40230 4023 70 Cold Drawn 156/207 C

G40240 4024 75 Cold Drawn 156/207 C

G40270 4027 70 Annealed and Cold Drawn 167/212 A

G40280 4028 75 Annealed and Cold Drawn 167/212 A

G40320 4032 70 Annealed and Cold Drawn 174/217 A

.pw

G40370 4037 70 Annealed and Cold Drawn 174/217 A

--`-`-`,,`,,`,`,,`---

G40420 4042 65 Annealed and Cold Drawn 179/229 A

G40470 4047 65 Annealed and Cold Drawn 179/229 A

G41180 4118 60 Cold Drawn 170/207 C

G41300

G41350

4130

4135

70

70

on

Annealed and Cold Drawn

Annealed and Cold Drawn

187/229

187/229

A

A

a ti

G41370 4137 70 Annealed and Cold Drawn 187/229 A

G41400 4140 65 Annealed and Cold Drawn 187/229 A

G41420 4142 65 Annealed and Cold Drawn 187/229 A

ific

G41450 4145 60 Annealed and Cold Drawn 187/229 A

G41470 4147 60 Annealed and Cold Drawn 187/235 A

G41500 4150 55 Annealed and Cold Drawn 187/241 A, B

pec

G41610 4161 50 Spheroidized and Cold Drawn 187/241 B, A

G43200 4320 60 Annealed and Cold Drawn 187/229 D, B, A

G43400 4340 50 Annealed and Cold Drawn 187/241 B, A

w.s

G43406 E4340 50 Annealed and Cold Drawn 187/241 B, A

G44220 4422 65 Cold Drawn 170/212 C

G44270 4427 65 Annealed and Cold Drawn 170/212 A

ww

G46150 4615 65 Cold Drawn 174/223 C

G46170 4617 65 Cold Drawn 174/223 C

G46200 4620 65 Cold Drawn 183/229 C

G46260 4626 70 Cold Drawn 170/212 C

G47180 4718 60 Cold Drawn 187/229 C

G47200 4720 65 Cold Drawn 187/229 C

G48150 4815 50 Annealed and Cold Drawn 187/229 D, B

G48170 4817 50 Annealed and Cold Drawn 187/229 D, B

G48200 4820 50 Annealed and Cold Drawn 187/229 D, B

G50401 50B40 65 Annealed and Cold Drawn 174/223 A

G50441 50B44 65 Annealed and Cold Drawn 174/223 A

G50460 5046 60 Annealed and Cold Drawn 174/223 A

G50461 50B46 60 Annealed and Cold Drawn 174/223 A

G50501 50B50 55 Annealed and Cold Drawn 183/235 A

G50600 5060 55 Spheroidized Annealed and Cold 170/212 B

Drawn

G50601 50B60 55 Spheroidized Annealed and Cold 170/212 B

Drawn

G51150 5115 65 Cold Drawn 163/201 C

Copyright SAE International

-8-

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SAE J1397 Revised MAY92

TABLE 4—MACHINABILITY OF ALLOY STEEL (CONTINUED)

Range of

Typical

UNS AISI and/or Machinability Hardness Microstructure

No. SAE No. Rating Condition HB Type(1)

G51200 5120 70 Cold Drawn 163/201 C

G51300 5130 70 Annealed and Cold Drawn 174/212 A

G51320 5132 70 Annealed and Cold Drawn 174/212 A

G51350 5135 70 Annealed and Cold Drawn 179/217 A

G51400 5140 65 Annealed and Cold Drawn 179/217 A

G51470 5147 65 Annealed and Cold Drawn 179/229 A

G51500 5150 60 Annealed and Cold Drawn 183/235 A, B

G51550 5155 55 Annealed and Cold Drawn 183/235 A, B

G51600 5160 55 Spheroidized Annealed and Cold 179/217 B

Drawn

G51601 51B60 55 Spheroidized Annealed and Cold 179/217 B

Drawn

.pw

G50986 50100 40 Spheroidized Annealed and Cold 183/241 B

Drawn

G51986 51100 40 Spheroidized Annealed and Cold 183/241 B

Drawn

on

G52986 52100 40 Spheroidized Annealed and Cold 183/241 B

Drawn

G61180 6118 60 Cold Drawn 179/217 C

a ti

G61500 6150 55 Annealed and Cold Drawn 183/241 B, A

G81150 8115 65 Cold Drawn 163/202 C

ific

G81451 81B45 65 Annealed and Cold Drawn 179/223 A

G86150 8615 70 Cold Drawn 179/235 C

G86170 8617 70 Cold Drawn 179/235 C

pec

G86200 8620 65 Cold Drawn 179/235 C

G86220 8622 65 Cold Drawn 179/235 C

G86250 8625 60 Annealed and Cold Drawn 179/223 A

G86270 8627 60 Annealed and Cold Drawn 179/223 A

w.s

G86300 8630 70 Annealed and Cold Drawn 179/229 A

G86370 8637 65 Annealed and Cold Drawn 179/229 A

G86400 8640 65 Annealed and Cold Drawn 184/229 A

ww

G86420 8642 65 Annealed and Cold Drawn 184/229 A

G86450 8645 65 Annealed and Cold Drawn 184/235 A

G86451 86B45 65 Annealed and Cold Drawn 184/235 A

G86500 8650 60 Annealed and Cold Drawn 187/248 A, B

G86550 8655 55 Annealed and Cold Drawn 187/248 A, B

G86600 8660 55 Spheroidized Annealed and Cold 179/217 B

Drawn

G87200 8720 65 Cold Drawn 179/235 C

G87400 8740 65 Annealed and Cold Drawn 184/235 A

G88220 8822 55 Cold Drawn 179/223 B

G92540 9254 45 Spheroidized Annealed and Cold 187/241 B

Drawn

G92600 9260 40 Spheroidized Annealed and Cold 184/235 B

Drawn

G93106 9310 50 Annealed and Cold Drawn 184/229 D

G94151 94B15 70 Cold Drawn 163/202 C

G94171 94B17 70 Cold Drawn 163/202 C

G94301 94B30 70 Annealed and Cold Drawn 170/223 A

1. (See section 3) for description of type.

--`-`-`,,`,,`,`,,`---

Copyright SAE International

-9-

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SAE J1397 Revised MAY92

6. Notes

6.1 Marginal Indicia—The change bar (l) located in the left margin is for the convenience of the user in locating

areas where technical revisions have been made to the previous issue of the report. An (R) symbol to the left

of the document title indicates a complete revision of the report.

PREPARED BY THE SAE IRON AND STEEL DIVISION 1—CARBON AND ALLOY STEELS

.pw

on

a ti

ific

pec

w.s

ww

--`-`-`,,`,,`,`,,`---

Copyright SAE International

-10-

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

SAE J1397 MAY1992–Estimated Mechanical Properties and Machinability of Steel Bars

Downloaded from www.specification.pw

SAE J1397 Revised MAY92

Rationale—Not applicable.

Relationship of SAE Standard to ISO Standard—Not applicable.

Application—This SAE Information Report is intended to provide a guide to mechanical properties and

machinability characteristics of some SAE steel grades. The ratings and properties shown are provided

as general information and not as requirements for specifications unless each instance is approved by

the source of supply.

Reference Section

Metals Handbook, 8th ed., Volume 3, Machining, American Society for Metals, Metals Park, OH 44073.

Machining Data Handbook, Volumes 1 and 2.

Machinability Data Center, Metcut Research Associates, 3980 Rosslyn Drive, Cincinnati, OH

.pw

45209.

U.S. Air Force Machinability Report, Vol. 2, 1951, Published by Curtiss-Wright Corp., Wood-Ridge,

NJ 07075.

on

a ti

Developed by the SAE Iron and Steel Division 1—Carbon and Alloy Steels

Sponsored by the SAE Iron and Steel Executive Committee

ific

pec

--`-`-`,,`,,`,`,,`---

w.s

ww

Copyright SAE International

Provided by IHS under license with SAE

No reproduction or networking permitted without license from IHS Not for Resale

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Steam Calculators - Steam Turbine Calculator2Dokumen2 halamanSteam Calculators - Steam Turbine Calculator2Adam GordonBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Sae j429 Vs Astm A354 BD PDFDokumen2 halamanSae j429 Vs Astm A354 BD PDFAdam GordonBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Gems LS1900 PN35676 FLOTANTEDokumen1 halamanGems LS1900 PN35676 FLOTANTEAdam GordonBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Cadenas RR-C-271F PDFDokumen45 halamanCadenas RR-C-271F PDFAdam GordonBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- One Way BearingsDokumen3 halamanOne Way BearingsAdam GordonBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Ansi Icwm 2012Dokumen65 halamanAnsi Icwm 2012Adam GordonBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Ansi C3752Dokumen17 halamanAnsi C3752Adam GordonBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Cadenas RR-C-271F PDFDokumen45 halamanCadenas RR-C-271F PDFAdam GordonBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Dimensiones y Acotaciones PDFDokumen34 halamanDimensiones y Acotaciones PDFAdam GordonBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Tabale de ParafusoDokumen54 halamanTabale de ParafusoSilas MendesBelum ada peringkat

- FORTRON® 1140L4 - PPS - Glass Reinforced: DescriptionDokumen7 halamanFORTRON® 1140L4 - PPS - Glass Reinforced: DescriptionAdam GordonBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Standard For Wood Containers 2012Dokumen51 halamanStandard For Wood Containers 2012Cristina Garcia100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Din 580Dokumen1 halamanDin 580safaozhanBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- 004 Industrieniete enDokumen10 halaman004 Industrieniete en'Verness'NotoBudyoBelum ada peringkat

- Sae j429 Vs Astm A354 BDDokumen2 halamanSae j429 Vs Astm A354 BDAdam GordonBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Parker O-Ring Handbook: Approximate Service Temperature Ranges For Commonly Used Basic Polymer TypesDokumen53 halamanParker O-Ring Handbook: Approximate Service Temperature Ranges For Commonly Used Basic Polymer Typesvadim.isheevBelum ada peringkat

- Steel PipesDokumen16 halamanSteel PipesAdam GordonBelum ada peringkat

- Naca Report 1368Dokumen86 halamanNaca Report 1368Adam GordonBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Polymer LectureDokumen12 halamanPolymer LectureAdam GordonBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- SW11Dokumen6 halamanSW11Adam GordonBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- CSK..P, CSK..PP CSK..P-2RS: Combined Bearing/FreewheelDokumen2 halamanCSK..P, CSK..PP CSK..P-2RS: Combined Bearing/FreewheelAdam GordonBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Chtmultiregionfoam4regiontutorial 140818030511 Phpapp01Dokumen24 halamanChtmultiregionfoam4regiontutorial 140818030511 Phpapp01Adam GordonBelum ada peringkat

- CHT Multi Region Simple Boussinesq Foam 7Dokumen31 halamanCHT Multi Region Simple Boussinesq Foam 7Adam GordonBelum ada peringkat

- Curva 4HF 70LDokumen1 halamanCurva 4HF 70LAdam GordonBelum ada peringkat

- Norris Maximum Torque Values For PCP ApplicationsDokumen2 halamanNorris Maximum Torque Values For PCP ApplicationsJorgeArraizBelum ada peringkat

- API - 6D - Plant 3 - 2015Dokumen1 halamanAPI - 6D - Plant 3 - 2015Adam GordonBelum ada peringkat

- GlossaryDokumen17 halamanGlossaryPRASAD326100% (1)

- Contracción ElastomerosDokumen2 halamanContracción ElastomerosAdam GordonBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Reedswitch HYR-2003Dokumen2 halamanReedswitch HYR-2003Adam GordonBelum ada peringkat

- Team Mate+AM+IT+Overview+12Dokumen41 halamanTeam Mate+AM+IT+Overview+12epajueloBelum ada peringkat

- 07-GB Column BasesDokumen14 halaman07-GB Column BasesAUNGPSBelum ada peringkat

- Hydraulic BrakeDokumen29 halamanHydraulic Brakerup_ranjan532250% (8)

- Tabla 1-1 (W Shapes)Dokumen17 halamanTabla 1-1 (W Shapes)Leonardo ZambranoBelum ada peringkat

- Tyre RetradingDokumen4 halamanTyre RetradingdskjajkdsaBelum ada peringkat

- Atul Gaonkar Resume 2017Dokumen6 halamanAtul Gaonkar Resume 2017Vinod KaleBelum ada peringkat

- Astm A325mDokumen8 halamanAstm A325mChitra Devi100% (1)

- Palmtop Computer (Report of Early Usage)Dokumen8 halamanPalmtop Computer (Report of Early Usage)rodrigur8036100% (2)

- 8060056-ELIVAC Smart Vacuum Systems ENDokumen8 halaman8060056-ELIVAC Smart Vacuum Systems ENseimarfelipeBelum ada peringkat

- Hand Free DrivingDokumen8 halamanHand Free DrivingNurulAfikaBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Accomplishment Report in ESPDokumen7 halamanAccomplishment Report in ESPAldrin Perez85% (39)

- Eaton Lumark Nightfalcon SpecDokumen4 halamanEaton Lumark Nightfalcon Specluis torresBelum ada peringkat

- Booz Allen - Strategy & BusinessDokumen18 halamanBooz Allen - Strategy & BusinessPaul AllenBelum ada peringkat

- Dap 018 ADokumen28 halamanDap 018 AajoaomvBelum ada peringkat

- Water System Validation ExampleDokumen6 halamanWater System Validation Exampledvdynamic1100% (2)

- ME8595 SyllabusDokumen1 halamanME8595 SyllabusDeepak sakthiBelum ada peringkat

- Aadhaar Application FormDokumen4 halamanAadhaar Application Formpan cardBelum ada peringkat

- Física Básica II - René CondeDokumen210 halamanFísica Básica II - René CondeYoselin Rodriguez C.100% (1)

- AIS - 007 - Rev 5 - Table - 1Dokumen21 halamanAIS - 007 - Rev 5 - Table - 1Vino Joseph VargheseBelum ada peringkat

- Abuyog 2018 PDFDokumen503 halamanAbuyog 2018 PDFJackelyn Fortaliza RosquettesBelum ada peringkat

- Patch Apply Instructions 19852360.HTMLDokumen60 halamanPatch Apply Instructions 19852360.HTMLdineshBelum ada peringkat

- Sense Amplifier For SRAMDokumen28 halamanSense Amplifier For SRAMPrateek AgrawalBelum ada peringkat

- Kinematic Analysis of 5 Dof Lynx ArmDokumen6 halamanKinematic Analysis of 5 Dof Lynx ArmsathyaBelum ada peringkat

- Director, Policy and Research (SEG 3 Et Al - Ministry of Culture, Gender, Entertainment and Sport PDFDokumen12 halamanDirector, Policy and Research (SEG 3 Et Al - Ministry of Culture, Gender, Entertainment and Sport PDFvernon whiteBelum ada peringkat

- MM LabDokumen4 halamanMM LabJstill54Belum ada peringkat

- Type of Ac StatementDokumen3 halamanType of Ac StatementRoberto SmithBelum ada peringkat

- TravelerSafe ReadMe PDFDokumen17 halamanTravelerSafe ReadMe PDFnatadevxBelum ada peringkat

- SAFMC 2023 CAT B Challenge Booklet - V14novDokumen20 halamanSAFMC 2023 CAT B Challenge Booklet - V14novJarrett LokeBelum ada peringkat

- Sp. Reserve MagazineDokumen21 halamanSp. Reserve MagazineViraf DasturBelum ada peringkat

- Civil Engineering and SocietyDokumen23 halamanCivil Engineering and Societyyeah100% (3)