2 - Sikadur-42 PC Plus - PDS - GCC - (05-2018) - 3

Diunggah oleh

Akhil VelayudhanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

2 - Sikadur-42 PC Plus - PDS - GCC - (05-2018) - 3

Diunggah oleh

Akhil VelayudhanHak Cipta:

Format Tersedia

Product Data Sheet

Edition: 28/05/2018

Identification no.

Version no: 3 GCC

Sikadur®-42 PC PLUS

Sikadur®-42 PC PLUS

3-Part Epoxy Grouting System for Pile Capping

Product Sikadur®-42 PC PLUS is a solvent-free, high strength, castable, three-component,

solvent free, moisture tolerant, impermeable epoxy grouting system specially

Description designed for pile cap applications.

Suitable for use under tropical and hot climatic conditions.

Construction

Uses Sikadur®-42 PC PLUS can be used for the following applications;

High strength grouting and topping of concrete pile caps and pile heads

Structural filling of cavities in concrete

Pile top waterproofing

Characteristics / Sikadur®-42 PC PLUS offers many benefits to the user:

Advantages Solvent-free

High early strength with excellent mechanical properties.

Watertight and waterproof

Moisture tolerant

Corrosion and chemically resistant to aggressive soils

Shrinkage-free hardening

Suitable for various waterproofing membranes and coatings (LAM)

Excellent adhesion to steel and concrete.

Product Data

Form Components A + B: Resinous liquid

Component C: Powders and aggregates

Appearance / Colour Mixed: Grey

Packaging 56 kg units (A+B+C)

Storage

Storage Conditions Store in dry conditions in original sealed packaging at temperatures between +5°C

and +35°C. Protect from heat and direct sunlight.

Shelf Life Minimum 12 months from date of production if stored properly in original unopened,

sealed and undamaged packaging.

Technical Data

Chemical Base Epoxy Resins and natural aggregates

Density (at 23°C) 2.10 ± 0.1 kg/lt (mixed)

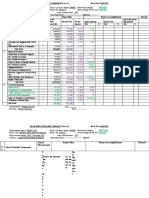

Mixing Ratio A : B : C = 5 : 1 : (50) parts by weight

Add component C according required consistency and desired application

behaviour.

Layer thickness 10 mm minimum 100 mm maximum

(per layer)

1 Sikadur®-42 PC PLUS 1/5

Resistance to water Nil:

Resistant to passage of water

Thermal Expansion 2.1 x 10-5 mm/mm/°C (Temp. range -30°C - +30°C) (ASTM C531)

Coefficient 3.8 x 10-5 mm/mm/°C (Temp. range +24°C - +100°C)

Thermal Stability Heat Deflection Temperature HDT:

HDT = +54°C (7 days / +23°C) (ISO 75)

Pot Life ~100 min at 20°C

~ 70 min at 35°C

~ 45 min at 40°C

Full Cure (at 25°C) Approximate 14 days

Mechanical /

Physical

Properties

Strengths (at 25°C)

Compressive strength ~ 65 N/mm2 @ 1 day (ASTM C579)

~ 95 N/mm2 @ 7 days (ASTM C579)

Flexural strength ~ 20 N/mm2 (ASTM C580)

2

Tensile Strength ~ 15 N/mm (ASTM D638)

2

Adhesion (on Concrete) > 2.0 N/mm (Concrete failure)

(Product cured and tested at temperatures indicated. Typical values at 7days)

E-Modulus 20’000 N/mm2 (Compressive) (ASTM D695-96)

Thermal Compatability No delamination / pass (ASTM C884)

Exotherm Peak ~38°C (at +25°C) (ASTM D 2471)

Strength Development Confirm the strength development by producing cubes on site and testing them for

compressive strength.

Application Details

Substrate Quality Mortar and concrete should be cured for 21-28 days or, it must achieve a minimum

strength requirement as per ACI 503R recommendations, where a minimum

compressive strength of 20.70 Mpa and pull off strength greater than 1.20 Mpa.

Verify the substrate strength (concrete, natural stone etc.).

The substrate surface (all types) must be clean, dry and free from contaminants

such as dirt, oil, grease, existing surface treatments and coatings etc.

Steel substrates must be de-rusted to a standard equivalent to SA 2.5.

The substrate must be sound and all loose particles must be removed.

Substrate must be dry or mat damp and free from any standing water, ice etc.

2 Sikadur®-42 PC PLUS 2/5

Substrate Preparation Concrete, mortar, stone:

Substrates must be sound, dry, clean and free from laitance, ice, standing water,

grease, oils, old surface treatments or coatings and all loose or friable particles

must be removed to achieve a laitance and contaminant free, open textured

surface.

Steel:

Must be cleaned and prepared thoroughly to an acceptable quality standard

equivalent to SA 2.5 i.e. by blastcleaning and vacuuming. Avoid dew point

conditions. Surface and base plate contact area must be clean and sound. For best

results, the substrate shall be dry. Remove dust, laitance, oils, grease, curing

compounds, impregnations, waxes, foreign particles, coatings, and disintegrated

materials by mechanical means, i.e. chipping with a chisel, blastcleaning etc.

All anchor pockets or sleeves must be free of water. Apply grout immediately to

prevent re-oxidizing / rust formation.

Substrate Temperature +8°C min. / +40°C max.

Application Temperature +8°C min. / +40°C max.

Material Temperature Sikadur®-42 PC PLUS is recommended to be applied and mixed within a

temperature range between +18°C and +32°C. (As per ACI 351.1R-12)

Store material at temperatures of between 20°C -25°C (room temperature) for at

least 48 hours prior to its use.

Substrate Moisture ≤ 4% pbw

Content

Dew Point Beware of condensation!

Substrate temperature during application must be at least 3°C above dew point to

avoid condensation.

Application

Instructions

Mix Ratio Standard pourable consistency : Solid / liquid ;Part (A + B) : C = 1 : 8.33 by weight

Mixing Time Pour all of component B into the component A container. Mix

with a basket type stirrer connected to an electric mixer of low

speed (300-450 rpm). Mix thoroughly until uniformly blended

in colour and viscosity and avoid entraining air. Pour the

mixture into a suitable mixing vessel and slowly add component C (to keep air

entrapment at a minimum). Stir for approximately 5 minutes until mortar of a

homogeneous consistency is obtained.

Mix only that quantity which can be used within its potlife.

Note: Never mix only Component A and B without adding component C (as the

exothermic reaction between A and B alone generates excess heat)

Application Methods/ Prior to application, allow the mix to stand for a short time to allow entrained air to

Tools escape.

The consistency of the Sikadur®-42 PC PLUS epoxy grout system requires the use

of forms to contain the material on top of pile head or pile cap and around base

plates. In order to prevent leakage or seepage, all of these formers must be sealed.

Pour the Sikadur®-42 PC PLUS mortar onto the pile cap surface or into a prepared

opening (hopper) and maintain enough static pressure to achieve the desired flow.

The mortar may be spread by steel trowel to the required thickness levels. Ensure

that entrapped air can easily escape.

Large volumes have to be poured in layers. Pour next layer as soon as the

previously applied layer has hardened and started to cool.

Allow the grout to harden and set prior to removal of formwork

Opened containers (Comp A & B) must be closed immediately after use.

Cleaning of Tools Clean all tools and application equipment with Sika® Colma Cleaner immediately

after use. Hardened/cured material can only be mechanically removed.

Sweep excess grout into appropriate containers for disposal before it has hardened.

Dispose of in accordance with applicable local regulations.

3 Sikadur®-42 PC PLUS 3/5

Notes on Application / Do not thin with solvents. Solvents will prevent proper curing and change

Limitations mechanical properties.

Sikadur®-42 PC PLUS is a vapour barrier when cured.

Cold ambient, substrate or material temperatures will influence the curing and flow

characteristics of Sikadur®-42 PC PLUS.

Do not subject cured epoxy grout to sudden temperature changes especially during

early curing stages.

Protect from direct sunlight. The higher the temperature of the product the quicker

the reaction time and the shorter the potlife.

For large or specific grouting projects please contact Sika Technical Services

Department for advice.

4 Sikadur®-42 PC PLUS 4/5

All technical data stated in this Product Data Sheet are based on laboratory tests.

Value Base Actual measured data may vary due to circumstances beyond our control

Please note that as a result of specific local regulations the performance of this

Local Restrictions product may vary from country to country. Please consult the local Product Data

Sheet for the exact description of the product uses.

Health and Safety For information and advice on the safe handling, storage and disposal of chemical

products, users shall refer to the most recent Material Safety Data Sheet containing

Information physical, ecological, toxicological and other safety-related data

The information, and, in particular, the recommendations relating to the application

Legal Notes and end-use of Sika products, are given in good faith based on Sika's current

knowledge and experience of the products when properly stored, handled and

applied under normal conditions in accordance with Sika’s recommendations. In

practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose,

nor any liability arising out of any legal relationship whatsoever, can be inferred

either from this information, or from any written recommendations, or from any other

advice offered. The user of the product must test the product’s suitability for the

Construction

intended application and purpose. Sika reserves the right to change the properties

of its products. The proprietary rights of third parties must be observed. All orders

are accepted subject to our current terms of sale and delivery. Users must always

refer to the most recent issue of the local Product Data Sheet for the product

concerned, copies of which will be supplied on request.

All products are manufactured under a management system certified to conform to the requirements of the

quality, environmental and occupational health & safety standards ISO 9001, ISO 14001 and OHSAS 18001.

Sika UAE L.L.C Sika Gulf B.S.C (c) Sika Saudi Arabia Co. Ltd

P.O. Box 126212 P.O. Box 15776 P.O. Box 112356,

Dubai, Adliya, Jeddah 21371,

United Arab Emirates Kingdom of Bahrain Saudi Arabia

Phone: +971 4 4398200 Phone: +973 17738 188 Phone: +966 2 692 7079

info@ae.sika.com sika.gulf@bh.sika.com jeddah@sa.sika.com

http://gcc.sika.com http://gcc.sika.com http://gcc.sika.com

5 Sikadur®-42 PC PLUS 5/5

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- HEYER VizOR - Product List - 1015Dokumen7 halamanHEYER VizOR - Product List - 1015kalandorka92Belum ada peringkat

- Data Management For Human Resource Information SystemDokumen14 halamanData Management For Human Resource Information SystemRajeshsharmapurangBelum ada peringkat

- Summary Scholten's GroupsDokumen8 halamanSummary Scholten's GroupsLily Samardzic-Rafik100% (4)

- Vicat Apparatus PrimoDokumen10 halamanVicat Apparatus PrimoMoreno, Leanne B.Belum ada peringkat

- EDAH EnglishDokumen2 halamanEDAH EnglishMaría SanchoBelum ada peringkat

- Understanding Senior Citizens Outlook of Death Sample FormatDokumen14 halamanUnderstanding Senior Citizens Outlook of Death Sample FormatThea QuibuyenBelum ada peringkat

- Edgie A. Tenerife BSHM 1108: Page 1 of 4Dokumen4 halamanEdgie A. Tenerife BSHM 1108: Page 1 of 4Edgie TenerifeBelum ada peringkat

- Citizen's 8651 Manual PDFDokumen16 halamanCitizen's 8651 Manual PDFtfriebusBelum ada peringkat

- Lead Avr PDFDokumen9 halamanLead Avr PDFsiddharthBelum ada peringkat

- OA Standard 050505Dokumen75 halamanOA Standard 050505fido_dagemBelum ada peringkat

- Injection MouldingDokumen241 halamanInjection MouldingRAJESH TIWARIBelum ada peringkat

- 5L ReductionsDokumen20 halaman5L ReductionsCarlos Javier Orellana OrtizBelum ada peringkat

- The Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayDokumen356 halamanThe Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayClinica MonserratBelum ada peringkat

- Kes MahkamahDokumen16 halamanKes Mahkamahfirdaus azinunBelum ada peringkat

- Social Connectedness and Role of HopelessnessDokumen8 halamanSocial Connectedness and Role of HopelessnessEmman CabiilanBelum ada peringkat

- Reference Document GOIDokumen2 halamanReference Document GOIPranav BadrakiaBelum ada peringkat

- Ammonia Synthesis ConverterDokumen26 halamanAmmonia Synthesis ConverterKvspavan Kumar100% (1)

- Wa0016Dokumen3 halamanWa0016Vinay DahiyaBelum ada peringkat

- Installation Manual (DH84309201) - 07Dokumen24 halamanInstallation Manual (DH84309201) - 07mquaiottiBelum ada peringkat

- Ammonium Chloride: Product InformationDokumen2 halamanAmmonium Chloride: Product InformationusamaBelum ada peringkat

- Quarterly Progress Report FormatDokumen7 halamanQuarterly Progress Report FormatDegnesh AssefaBelum ada peringkat

- Mini Project 2Dokumen9 halamanMini Project 2gunjan_pattnayak2007Belum ada peringkat

- UIP ResumeDokumen1 halamanUIP ResumeannabellauwinezaBelum ada peringkat

- Power of AttorneyDokumen10 halamanPower of AttorneyRocketLawyer82% (17)

- D05 Directional Control Valves EngineeringDokumen11 halamanD05 Directional Control Valves EngineeringVentas Control HidráulicoBelum ada peringkat

- Aircaft Avionics SystemDokumen21 halamanAircaft Avionics SystemPavan KumarBelum ada peringkat

- Palf PDFDokumen16 halamanPalf PDFKamal Nadh TammaBelum ada peringkat

- Analyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioDokumen12 halamanAnalyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioLukas ArenasBelum ada peringkat

- Open Cholecystectomy ReportDokumen7 halamanOpen Cholecystectomy ReportjosephcloudBelum ada peringkat

- Drill Site Audit ChecklistDokumen5 halamanDrill Site Audit ChecklistKristian BohorqzBelum ada peringkat