SS

Diunggah oleh

Prakash KaleDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SS

Diunggah oleh

Prakash KaleHak Cipta:

Format Tersedia

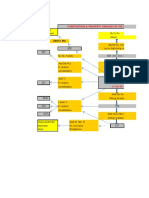

Ni-Cr-Fe Alloys

Superferritic 303, 303 Se

stainless steels

Add Ni for corrosion resistance in high

temperature environment Add S or Se for

machinability

Add Cr.

309, 310, 314, Duplex

330 stainless

Increase Cr,

430 steel

lower Ni for

Add Cr and Ni for

higher strength,

strength and

347 No Ni, ferritic Add austenising

oxidation resistance

agent

Add Nb to reduce Add Cu, Ti, Al, lower

Precipitation

sensitization 304 (“18-8”) Ni for precipitation

Hardening

Fe-18 to 20 Cr. hardening

stainless steels

8 to 10 Ni

Add Ti to reduce

321

sensitization

Add Mo for pitting resistance Add Mn and N,

lower Ni for higher

strength

304L

201, 202

316

316L Lower C to

No Ni addition,

reduce

lower Cr,

sensitization

Add more Mo for pitting martensitic

317L

resistance

403, 410,

420

Superaustenitic Add Ni, Mo, N for 317

stainless steel corrosion resistance

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

MARTENSITIC STAINLESS STEEL

•MARTENSITE MICRO STRUCTURE

•STRUCTURE FORMED DUE TO FAST COOLING

•CHROMIUM 10.5 TO 18%, CARBON GREATER THAN 1.2%

•NACE REQUIREMENT

– HARDNESS MAX 22HRC

•HEAT TREATMENT PROCEDURE

–NORMALISE OR AUSTENITIZE & QUENCH

–TEMPERING TWICE AT 620 DEG. CEL.AND THEN COOLING TO AMBIENT TEMP.

–AFTER COLD WORK STRESS RELIEVED AT 620 DEG CEL

• COMMON MATERIAL APPROVED BY NACE AND ARE COMMONLY USED ARE

–UNS S41000 (410 stainless steel SST) (FORGE)

–A217 GR CA 15 (CASTINGS)

–A486 CL CA6NM(CASTINGS)

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

FERRITIC STAINLESS STEEL

•HAVING FERRITIC MICROSTRUCTURE

•COMPOSITION MAINLY CHROMIUM 11 TO 30%

•NOT USUALY USED FOR INSTRUMENTATION ONLY FOR PIPES & AUTOMOTIVE

PARTS

•SUPERALLOYED FERRITE HAVING GOOD RESSTANCE AGAINST SSC

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

AUSTENITIC STAINLESS STEEL

•AUSTENITE MICRO STRUCTURE(FACE CENTRE CRYSTALLINE PHASE)

•COMPOSITION CHROMIUM 16 TO 26% ,NICKEL LESS THAN 35%, MANGENESE

LESS THAN 15%

•NACE REQUIREMENT

–MAX HARDNESS 22HRC

–GOOD RESISTANCE TO SSC IN ANNEALED CONDITION

–COMMONLY USED MATERIAL IN CAST FORM & WROUGHT FORM ARE

302,304,304L,305,308,309,310,316,316,316L,317,321,347 AND UNSN08020(ALLOY 20-

UPTO 32HRC)

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

PRECIPITATION -HARDENING STAINLESS STEEL

• CHROMIUM NICKEL GRADE STEEL HARDENED BY AGEING (AUSTENITIC (A-286),

SEMI AUSTENITIC(17-7PH), MARTENSITIC(17-4PH))

•HIGH YIELD STRENGTH,GOOD DUCTILITY & TOUGHNESS

•NACE REQUIREMENT

– 17-4PH CAN BE USED IN WROUGHT FORM(S17400) ALSO IN CAST FORM

(CB7Cu-1) FOR MAX 33HRC

–S66268(A286 GRADE 660) FOR MAX 35HRC

–S20910 (NITRONIC 50) FOR MAX 35 HRC COMMONLY USED FOR SHAFTS,STEM

&PINS

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

DUPLEX STEEL

•CONSIST OF TWO MICROSTRUCTURES(AUSTENITIC / FERRITIC)

•TYPICAL COMPOSITION CARBON LESS THAN

0.3%,MOLYBDENUM,NITROGEN,TUNGESTEN,COPPER,CHROMIUM(20 TO 30%) &

NICKEL (5 TO 8%)

•HIGH STRENGTH,DUCTILITY,GOOD RESISTANCE TO CHLORIDE SSC & PITTING

•GENERALLY NOT USED IN INSTRUMENT APPLICATION USED MOSTLY FOR VESSEL

MANUFACTURING DUE TO HIGH STRENGTH THIN WALL THICKNESS REQUIRED

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

F E R R IT IC M A R T E N S IT IC P R E C IP IT A T IO N A U S T E N IT E DUPLEX

H A R D E N IN G ( A U S T E N IT IC /F E R R IT I

C)

(W R O U G H T

C O N D IT IO N O N L Y )

A IS I A IS I ASTM A IS I U N S -S 3 1 2 6 0

405 410 A453 G R 660 302 U N S -S 3 1 8 0 3

430 501 A638 G R 660 304 U N S -S 3 2 4 0 4

304L U N S -S 3 2 5 5 0

305 U N S -S 3 2 7 6 0

308 U N S -S 3 9 2 7 4

309 U N S -S 3 9 2 7 7

310

316

316L

317

321

347

ASTM ASTM U N S S17400 ASTM C AST D U PLEX

A268 A217G R C A15 U N S S45000 A182 (A U S T E N T IC /F E R R IT IC

)

T P 405, A268 G R TP410 U N S S66286 A193 S T A IN L E S S S T E E L

T P 430

T P XM 27, A743 G R C A 15M G R B 8 R ,B 8 R A ,B 8 Z 6 C N D U 2 8 .0 8 M

T P XM 33

A487 C I C A 15M B 8 M ,B 8 M A N F A 3 2 0 -5 5 F R E N C H

A487 C I C A6N M A194 N A T IO N A L S T A N D A R D

U N S S42400 G R 8 R ,8 R A ,8 A ,8 M A U N S J93380

A320 U N S J93404

G R B 8 ,B 8 M

A351

G R C F 3 ,C F 8 ,C F 3 M

C F 8 M ,C F 7 M

A743

G R C N 7M

A744

G R C N 7M

B463

B473

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

HEAT TREATMENTS

Stress Relieving

•Mainly intended for relieving locked in stresses in weld joints & cold working stresses in

base metal by heating the metal below critical temperature holding the constant temp. and

then cooling slowly.No change in microstructure.

•Many people have the misunderstanding that stress relieving following machining is

required by MR0175. Provided good machining practices are followed using sharp tools

and proper lubrication, the amount of cold work produced is negligible. SSC resistance will

not be affected.

MR0175 actually permits the cold rolling of threads, provided the component will meet the

heat treat conditions and hardness requirements specified for the given parent material.

Cold deformation processes such as burnishing are also acceptable. Below table gives the

details of temperature at which the metal has to be heated as per MR0175.(BASED ON

THICKNESSES ASME SECTION VIII HAS ALSO TO BE REFFERED )

Sno. MATERIAL TEMPERATURE DEG CEN.

1 CARBON STEEL 595 (min)

2 MARTENSITIC STEEL 620 (MIN)

3 LOW CARBON MARTENSIC STEEL 620 (MIN)

3 LOW CARBON MARTENSIC STEEL 620 (MIN)

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

ANNEALING

Annealing is a generic term denoting a treatment that consists of heating to and holding at

a suitable to a suitable temperature followed by cooling at an appropriate rate,primarily for

softening of metallic materials.As the hardness of steel increases during cold working,

ductility decreases and additional cold reduction becomes so difficult that the material

must be annealed to restore its ductility.In this procedure the heating is above the critical

temperature and due to this micro structure changes occur.

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

NORMALISING

Heating a ferrous alloy to a suitable temperature above the transformation range and then

cooling in air to a temperature substantially below transformation range. With this process

basically the steel microstructure is getting uniformly distributed and the mechanical

properties are changing (e.g. carbon steel normalization leads to higher strength )

N.A.C.E FOR SULFIDE ENVIRONMENT

Z:\Dat\Training\Experienced\JBTermination

Anda mungkin juga menyukai

- Stainless Steel Family Alloys CompositionsDokumen2 halamanStainless Steel Family Alloys CompositionsBasavaraj MorabBelum ada peringkat

- Balachandar - Cast & Duplex SSDokumen155 halamanBalachandar - Cast & Duplex SSArunprasad MurugesanBelum ada peringkat

- 2020 - Bab 8 Pengelasan Baja Tahan Karat (Part A)Dokumen13 halaman2020 - Bab 8 Pengelasan Baja Tahan Karat (Part A)Febri AndriyudaBelum ada peringkat

- What Is Stainless Steel enDokumen6 halamanWhat Is Stainless Steel enPetar RadonjićBelum ada peringkat

- Mitusha: Corrosion of Base Metals in ContactDokumen1 halamanMitusha: Corrosion of Base Metals in ContactAVINASHRAJBelum ada peringkat

- Bolts and Nuts Stainless SteelDokumen2 halamanBolts and Nuts Stainless SteelfedemochileroBelum ada peringkat

- Selection Chart For Welding and Brazing Rods - Weldclass - 2021.08Dokumen2 halamanSelection Chart For Welding and Brazing Rods - Weldclass - 2021.08velan73Belum ada peringkat

- Gould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Dokumen2 halamanGould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Gourav SharmaBelum ada peringkat

- Catalogue JointDokumen7 halamanCatalogue Jointdermeche hakimaBelum ada peringkat

- Material - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural SteelDokumen1 halamanMaterial - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural Steelaniketgupta05Belum ada peringkat

- Sae 1022Dokumen1 halamanSae 1022talebimahdi924Belum ada peringkat

- Astm a743 Cf8mDokumen1 halamanAstm a743 Cf8makdrnlBelum ada peringkat

- Trim Number Chart API Valve PDFDokumen2 halamanTrim Number Chart API Valve PDFtungxuanbrBelum ada peringkat

- API Valve Trim ChartDokumen2 halamanAPI Valve Trim ChartkhaireddinBelum ada peringkat

- Stainless Steel 304Dokumen3 halamanStainless Steel 304jay mamucayBelum ada peringkat

- Stainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16Dokumen10 halamanStainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16ManuelBelum ada peringkat

- Carbide GradesDokumen51 halamanCarbide GradesRicardo BravoBelum ada peringkat

- Stainless Steel 304 Data Sheet from thyssenkruppDokumen3 halamanStainless Steel 304 Data Sheet from thyssenkruppYoucef KherroubiBelum ada peringkat

- Material GradesDokumen32 halamanMaterial GradesMarius PopaBelum ada peringkat

- ISO-designated Steel GroupsDokumen6 halamanISO-designated Steel Groupsjithin.rjn4055Belum ada peringkat

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Dokumen3 halamanAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouBelum ada peringkat

- Copper and Copper Alloys EN Standards For Copper AlloysDokumen4 halamanCopper and Copper Alloys EN Standards For Copper AlloysNesanBelum ada peringkat

- Copper and Copper Alloys EN Standards For Copper AlloysDokumen4 halamanCopper and Copper Alloys EN Standards For Copper AlloysAttef BedaweBelum ada peringkat

- Copper and Copper Alloys EN Standards For Copper AlloysDokumen4 halamanCopper and Copper Alloys EN Standards For Copper AlloysAkshayBhatkandeBelum ada peringkat

- Copper and Copper Alloys EN Standards For Copper AlloysDokumen4 halamanCopper and Copper Alloys EN Standards For Copper AlloysLuis ReyesBelum ada peringkat

- High Performance Stainless Takes The Gall: Properties & General DataDokumen2 halamanHigh Performance Stainless Takes The Gall: Properties & General Datajoker63000Belum ada peringkat

- ISO 3506 stainless steel designation system breakdownDokumen3 halamanISO 3506 stainless steel designation system breakdownPaulo Henrique NascimentoBelum ada peringkat

- US Series W X F (New) 8-19Dokumen1 halamanUS Series W X F (New) 8-19Heriberto MejiaBelum ada peringkat

- AISI 301 Stainless Steel vs. AISI 304 Stainless SteelDokumen8 halamanAISI 301 Stainless Steel vs. AISI 304 Stainless SteelFSAAVEDRAFBelum ada peringkat

- Aalco Metals LTD Stainless Steel 14301 Sheet and Plate Quarto Plate CPP Plate 343Dokumen3 halamanAalco Metals LTD Stainless Steel 14301 Sheet and Plate Quarto Plate CPP Plate 343saravananBelum ada peringkat

- Taxonomy of MetalsDokumen28 halamanTaxonomy of MetalsArlita RahmaBelum ada peringkat

- Guide to Low-Carbon, Medium-Carbon & High-Carbon SteelsDokumen2 halamanGuide to Low-Carbon, Medium-Carbon & High-Carbon SteelsPAKBOYS TVBelum ada peringkat

- Metal Heat Treatment: D. Navaja MSE101Dokumen21 halamanMetal Heat Treatment: D. Navaja MSE101Ebook DownloadBelum ada peringkat

- Stainless Steel 1.4305 (303) Bar: Specifications Supplied FormsDokumen2 halamanStainless Steel 1.4305 (303) Bar: Specifications Supplied FormsElla ChanBelum ada peringkat

- Smallman 2014 PDFDokumen2 halamanSmallman 2014 PDFAldi RayhanBelum ada peringkat

- Astm a351 Cf8Dokumen1 halamanAstm a351 Cf8akdrnlBelum ada peringkat

- Iron Wafer Type Check Valve: Kitz Cast Iron ValvesDokumen1 halamanIron Wafer Type Check Valve: Kitz Cast Iron ValvesAndy SetyawanBelum ada peringkat

- ASTM A 108 Grade 1020Dokumen1 halamanASTM A 108 Grade 1020juan ormacheaBelum ada peringkat

- Chap 11Dokumen27 halamanChap 11Qwe QBelum ada peringkat

- Fiche Technique Joint SpiraleDokumen1 halamanFiche Technique Joint SpiraleHakima DermecheBelum ada peringkat

- Uns S44800Dokumen1 halamanUns S44800Mohammad TaherBelum ada peringkat

- BS2789 420-12 SG Iron StockholdersDokumen2 halamanBS2789 420-12 SG Iron StockholdersSama UmateBelum ada peringkat

- Cast Metal RestorationDokumen16 halamanCast Metal RestorationNellin Igop BariasBelum ada peringkat

- YG-1 Complete CatalogueDokumen1.156 halamanYG-1 Complete CatalogueMuchamad Fajar NugrohoBelum ada peringkat

- Astm A487 4 (A)Dokumen1 halamanAstm A487 4 (A)baladiroyaBelum ada peringkat

- Stainless Steel Data Sheet Explains Grades, Properties and ApplicationsDokumen2 halamanStainless Steel Data Sheet Explains Grades, Properties and ApplicationsGoBelum ada peringkat

- AISI 4130 Alloy Steel (UNS G41300) 1Dokumen4 halamanAISI 4130 Alloy Steel (UNS G41300) 1shubham soni100% (1)

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4307 - 304LDokumen3 halamanThyssenkrupp Materials (UK) LTD Stainless Steel 1.4307 - 304LpabloBelum ada peringkat

- BS 970 En8dDokumen1 halamanBS 970 En8djobseekerarulkumarBelum ada peringkat

- Joining of Dissimilar Materials - Problems and SolutionsDokumen23 halamanJoining of Dissimilar Materials - Problems and Solutionssungjun parkBelum ada peringkat

- Invalved Valve Trim Materials Standard Trim ConfigurationsDokumen1 halamanInvalved Valve Trim Materials Standard Trim ConfigurationsmanishkapriBelum ada peringkat

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDokumen3 halamanAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesMellierBelum ada peringkat

- Microstructures of Iron-Carbon Alloys: Fine Pearlite 3000XDokumen9 halamanMicrostructures of Iron-Carbon Alloys: Fine Pearlite 3000XVaishu 07Belum ada peringkat

- Standard Bolt Identification Markings: No Grade MarkDokumen8 halamanStandard Bolt Identification Markings: No Grade MarkDerick MendozaBelum ada peringkat

- AISI 4140 Alloy SteelDokumen4 halamanAISI 4140 Alloy Steelzd55h2754kBelum ada peringkat

- Chapter 11: Metal Alloys Applications and Processing: Issues To Address..Dokumen21 halamanChapter 11: Metal Alloys Applications and Processing: Issues To Address..Naufal PutraBelum ada peringkat

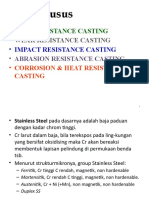

- Baja Khusus - Kuliah Material 3Dokumen13 halamanBaja Khusus - Kuliah Material 3Ikhsan IkhsanBelum ada peringkat

- Low Cutting Resistance Next Generation Face Milling Cutter Double Sided InsertsDokumen12 halamanLow Cutting Resistance Next Generation Face Milling Cutter Double Sided InsertssahBelum ada peringkat

- Spec PDFDokumen1 halamanSpec PDFcrysBelum ada peringkat

- Heat Load CalculationDokumen45 halamanHeat Load CalculationPrakash KaleBelum ada peringkat

- Latest Eil Vessel Std.Dokumen50 halamanLatest Eil Vessel Std.Prakash KaleBelum ada peringkat

- Latest Eil Heat Exchangers STDDokumen36 halamanLatest Eil Heat Exchangers STDPrakash KaleBelum ada peringkat

- Drawing of General Arrangement and Details of Trolley AssemblyDokumen1 halamanDrawing of General Arrangement and Details of Trolley AssemblyPrakash KaleBelum ada peringkat

- Mechanical Agitator Power Requirements for Liquid BatchesDokumen24 halamanMechanical Agitator Power Requirements for Liquid BatchesAixa BerchiBelum ada peringkat

- ENDokumen1 halamanENreacharunkBelum ada peringkat

- Flux Core Arc WeldingDokumen8 halamanFlux Core Arc Weldingamirhazwan100% (1)

- 2014 Production Cem II-A 42,5 NDokumen13 halaman2014 Production Cem II-A 42,5 Nmkpasha55mpBelum ada peringkat

- Palu Mallet KrisbowDokumen1 halamanPalu Mallet Krisbowhamidin_syarifBelum ada peringkat

- Is 4431Dokumen19 halamanIs 4431Nav TalukdarBelum ada peringkat

- Wet Processing Technology LAb DocumentDokumen3 halamanWet Processing Technology LAb DocumentSanjana Islam Nilima0% (1)

- BS en Iso 01514-2016Dokumen22 halamanBS en Iso 01514-2016Krishna Vacha50% (2)

- Woodworking 101 PDFDokumen33 halamanWoodworking 101 PDFGhita HerdeanBelum ada peringkat

- Application Instructions for HEMPADUR MASTIC 45880/45881Dokumen6 halamanApplication Instructions for HEMPADUR MASTIC 45880/45881Mohamed NouzerBelum ada peringkat

- QB1 Quick Break Tester - Operating Manual - Jun18Dokumen3 halamanQB1 Quick Break Tester - Operating Manual - Jun18aravindanBelum ada peringkat

- MachineDokumen18 halamanMachineLouie Ludeña VillegasBelum ada peringkat

- Gujarat Packaging IndustriesDokumen7 halamanGujarat Packaging IndustriesKhyati KamdarBelum ada peringkat

- 11.asme CA 360 Nbic Part3Dokumen50 halaman11.asme CA 360 Nbic Part3udomBelum ada peringkat

- HeliCoil Tapping ChartDokumen2 halamanHeliCoil Tapping ChartPurushothama Nanje GowdaBelum ada peringkat

- ASME VIII Div 1 Part UCS Pressure Vessels Constructed of Carbon and Low Alloy SteelsDokumen2 halamanASME VIII Div 1 Part UCS Pressure Vessels Constructed of Carbon and Low Alloy SteelsAmanda Ariesta ApriliaBelum ada peringkat

- Understanding Lathe Machine Parts, Operations and Tool-Workpiece ContactDokumen12 halamanUnderstanding Lathe Machine Parts, Operations and Tool-Workpiece Contactfaizan997Belum ada peringkat

- Part Cat Dp70Dokumen6 halamanPart Cat Dp70boy qsi100% (1)

- Civil4M Aluminium Sliding Works ChecklistDokumen1 halamanCivil4M Aluminium Sliding Works ChecklistKishoreBelum ada peringkat

- Deck - Calistoga Spa SurroundDokumen4 halamanDeck - Calistoga Spa SurroundHelicon1Belum ada peringkat

- Blow Mould DesignDokumen75 halamanBlow Mould DesignKamal Krishna Kashyap100% (1)

- WWW Steelss Com Carbon Steel St37 3u HTMLDokumen4 halamanWWW Steelss Com Carbon Steel St37 3u HTMLdjpinguimBelum ada peringkat

- Elements of Mechanical EngineeringDokumen3 halamanElements of Mechanical EngineeringHarish Murthy60% (5)

- Corro-Coat PE Series 50 TDSDokumen3 halamanCorro-Coat PE Series 50 TDSBiju_PottayilBelum ada peringkat

- Introduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415Dokumen24 halamanIntroduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415VaikunthtendulkarBelum ada peringkat

- Catalogo Engimax Motores IsuzuDokumen38 halamanCatalogo Engimax Motores IsuzuAlexis SanchezBelum ada peringkat

- SKFP COEXTRUSION SOLUTIONS Jan 31 2022Dokumen26 halamanSKFP COEXTRUSION SOLUTIONS Jan 31 2022李万福Belum ada peringkat

- C Staehle Kalt Datenblatt en 1511Dokumen7 halamanC Staehle Kalt Datenblatt en 1511Yokesh SamannanBelum ada peringkat

- Bangalore Aircraft FacilitiesDokumen2 halamanBangalore Aircraft FacilitiesAmit YadavBelum ada peringkat

- Iron and Steel Making ProcessDokumen22 halamanIron and Steel Making Processmaghfira100% (1)

- 2024 Aluminium SheetDokumen1 halaman2024 Aluminium SheetGeorge ChachlakisBelum ada peringkat