Cat Generator Paralleling Switchgear - Editorial EATON - 2016

Diunggah oleh

Manuel OrtegaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cat Generator Paralleling Switchgear - Editorial EATON - 2016

Diunggah oleh

Manuel OrtegaHak Cipta:

Format Tersedia

Cat Generator Paralleling Switchgear 40.

0-1

July 2016

Sheet 40 001

Cat Generator

Paralleling Switchgear

Contents 22

Cat® Generator Paralleling Switchgear

Introduction 23

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.0-2

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.0-4

24

Cat Switchgear Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.1-1

Standard and Custom Configurable Products . . . . . . . . . . . . . . . . . . . 40.1-2

Cat Switchgear Control Technology Features . . . . . . . . . . . . . . . . . . . . 40.1-3 25

Load Management & Emergency Transfer Controls

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.2-1 26

Standard Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.2-2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.2-3

Functional Sequences of Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . 40.2-4

27

Emergency Generator Paralleling Controls

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.3-1 28

Standard Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.3-2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.3-3 29

Functional Sequences of Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . 40.3-4

Additional Medium-Voltage Features

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.4-1

30

Custom Systems

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.5-1 31

Technical Data—One-Line Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.5-2

Power Platforms 32

Low-Voltage Arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.6-1

Medium-Voltage Arrangements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.6-13

Other Technical Data

33

Generator Interconnect Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.7-1

Specifications 34

See Eaton’s Product Specification Guide, available on CD or on the Web.

CSI Format: . . . . . . . . . . . . . . . . . . . . . . . . . 1995 2010 35

Low-Voltage XLM

UL 1558 Switchgear . . . . . . . . . . . . . . . . . Section 16426 Section 26 23 13

Medium-Voltage

36

Metal-Clad Switchgear . . . . . . . . . . . . . . . Section 16346 Section 26 13 26

37

38

39

40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.0-2 Cat Generator Paralleling Switchgear

Introduction July 2016

Sheet 40 002

General Description

22 Introduction Cat Switchgear combines the proven Reliable, flexible and powerful.

low-voltage Magnum DS power circuit Cat Switchgear is designed with the

breaker and Magnum Switchgear with most critical power needs in mind:

General Description Cat Switchgear control technology.

23 Cat® Generator Paralleling Switchgear ■ Data center/data processing

Cat controls technology is for optimal

is a product developed through a joint power generation and electrical ■ Healthcare

venture between Caterpillar and Eaton distribution system performance. ■ Critical industrial/chemical

24 Corporation. Caterpillar, an industry It provides advanced, industry- processes

leader in electric generator sets, and leading, microprocessor-based ■ Distributed generation/cogeneration

Eaton, an industry leader in Low and engine generator set control provided

■ Water/wastewater treatment

25 Medium-Voltage Switchgear have exclusively in Cat Switchgear.

combined forces to create Cat Medium-Voltage systems combine ■ Government/military

Generator Paralleling Switchgear... VCP-W breakers and VacClad Metal- ■ Banking/credit card processing

26 the most reliable and feature rich Clad switchgear with the same ■ Landfill gas power

product available in the market today! proven generator control technology.

Cat Switchgear Features

27 Cat Switchgear has been designed to

Applications

integrate hand-in-glove with Caterpillar’s ■ Built-in redundancy

on-package, microprocessor-based ■ Emergency/legally required ■ Reliability

28 engine control. Exclusively from your standby systems

■ Touchscreen interface

Caterpillar dealer, you can now get the ■ Optional standby backup systems

■ Simple, intuitive operation

market’s best efficiency, reliability and ■ Distributed generation

■ Advanced communications

29 dependability all in one package.

■ Peak shaving capabilities

■ Prime power ■ Integrated digital technology

30 ■ Combined Heat and Power (CHP) ■ Advanced generator control and

protection

■ Detailed engine and electrical reports

31 ■ Best-in-class footprint

32

33

34

35

36

37

38

39

40

Low Voltage Medium Voltage

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.0-3

July 2016 Introduction

Sheet 40 003

General Description

Standards

Low-Voltage Cat Switchgear conforms

22

to the following applicable standards:

■ NEMA® Standard SG-5 23

■ CSA®

■ ANSI C37.20.1 24

■ ANSI C37.51

■ UL® Standard 1558

■ NFPA 110, NFPA 99 and NFPA 70 25

The switchgear uses Magnum DS

Breakers that are designed to NEMA 26

Standard SG-3; ANSI Standards

C37.13, C37.16, C37.17 and UL 1066.

Optional switchboard construction 27

is available that is built to UL 891.

These switchboards use Magnum SB

Breakers for generator mains, utility 28

mains and electrically operated

feeders, and molded-case breakers Overview Screen

for non-switched feeders. 29

Medium-Voltage Cat Switchgear

conforms to the following applicable 30

standards:

■ NEMA SG-5

■ ANSI/IEEE C37.20.2

31

■ CSA-C22.2 No. 31-M89

■ EEMAC G8-3.2. 32

■ NFPA 70, 99, 110

The switchgear uses VCP-W vacuum 33

circuit breakers that are designed

to meet or exceed all applicable

IEEE/ANSI standards including C37.06. 34

Common Components

Throughout the Entire Facility 35

Cat Generator Paralleling Switchgear

is built with Eaton’s industry-leading 36

Magnum DS low-voltage drawout Generator Metering Screen

switchgear with Magnum DS

breakers and VacClad medium 37

voltage switchgear with VCPW

vacuum breakers. This allows the

use of common components on both 38

the normal power systems and the

generator power systems. Common

and interchangeable breakers, relays, 39

switchgear assembly parts, breaker

maintenance procedures, and so on

can be used to help reduce the overall 40

operating cost and increase the

maintainability of the entire facility.

41

42

43

Generator Set Control Screen

CA08104001E For more information, visit: www.eaton.com/consultants

40.0-4 Cat Generator Paralleling Switchgear

Introduction July 2016

Sheet 40 004

Definitions

22 Definitions Emergency Generator Bus Tie: A bus

tie breaker used in EGP type systems

Generator Tie Breaker: A feeder

breaker that is used to connect an

The terms and acronyms below are to segregate groups of generators and/ XLM type system to a separate piece

referenced throughout this section or loads. Emergency Generator Bus of Normal (utility) switchgear.

23 on Generator Paralleling Switchgear. Tie breakers are used where critical

Governor: A device that regulates

These definitions can help the reader loads, required to be powered in

prime mover speed by adjusting the

fully understand the topics discussed. 10 seconds, exceed the capacity of

fuel input to maintain constant speed.

24 Alternator: A device for converting

a single genset.

HMI Human Machine Interface:

mechanical energy into alternating EPS Emergency Power System:

Typically a touchscreen used by

current electrical energy. It may The emergency power sources and

25 also be called an AC or synchronous emergency distribution to down-

the operator for interfacing with the

paralleling generator system.

generator. stream loads.

LM Switchgear (Load Management

26 ATS: Automatic Transfer Switch. Emergency Standby Power

Switchgear): A single generator

Application: Typical usage of 50 hours

Automatic Transfer Switch: A switch used in distributed generation

per year with a maximum of 200 hours

designed to sense the loss of one power systems. Includes automation

27 power source and automatically

per year. Generators can be applied

controls that allow for the load to

at their Standby rating with a typical

transfer the load to another source be served simultaneously by both

variable load factor of 70%.

of power. utility and generator power sources

28 Emergency Tie Breaker: A feeder while managing how much each

Closed-Transition Transfer: A transfer breaker that is used to connect an source contributes.

between sources that provides a EGP type system to a separate piece

29 momentary paralleling of both power of Normal (utility) switchgear.

Load Shed/Load Add: Automation

sources during a transfer in either controls to control distribution devices

direction. This results in no interrup- Feeder Breaker Controls: Automation (turn OFF and restore ON) when only

30 tion of power to the loads during the controls to allow control of the partial emergency engine gensets are

transfer. The closed transition transfer distribution feeder devices for load available for duty. Typically accom-

is only possible when the sources are shed/load add control and monitoring. plished by assigning Priority levels to

31 properly synchronized and interfaced.

Generator: A machine for converting

each controlled distribution device.

DGPS Distributed Generation Power mechanical energy into electrical Master Controls: All processors,

System: Typically a local engine energy. The electrical energy may HMI and programming to implement

32 genset and automation connected be direct current (DC) or alternating the desired modes of operation

to the utility system to peak shave current (AC). of engine gensets in a paralleling

or export power. switchgear system.

33 Generator Bus Tie: A bus tie used in

XLM type systems for separating the

EGP Switchgear (Engine Generator NFPA 110—Standard for Emergency

Paralleling Switchgear): Parallels generator bus and/or loads from the and Standby Power Systems:

34 multiple engine/gensets to serve loads normal utility fed bus and/or loads. Standard for the assembly, installa-

transferred via downstream ATS units. tion and performance of electrical

Generator Demand Priority: Controls

EGPT Switchgear: Same as EGP that automatically match the online power systems to supply critical and

35 except with a controlled emergency engine generator capacity to the essential needs during outages of the

primary power source.

generator bus tie breaker between load to avoid unnecessary engine

sets of generators to segregate loads genset operation when loads are NPS Normal Power System: The

36 or areas of the bus. low. (Alternatively called Load Sense utility service entrance equipment

Load Demand.) and distribution circuits to down-

EMCP Electronic Modular Control

Panel: A Caterpillar microprocessor stream loads.

37 module for engine/genset control. NPSS Normal Power System Supplier:

Supplier of all the components of the

38 NPS, such as the distribution equip-

ment vendor’s authorized distributor.

39

40

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.0-5

July 2016 Introduction

Sheet 40 005

Definitions

Paralleling: The procedure of connect- Station Battery: A power supply Utility Protection: A collection of

ing two or more generators, or other used for control of switchgear. protective relays or a multifunction 22

power sources, of the same phase, relay required by the utility to detect

Synchronizer: A device that will

voltage and frequency characteristics abnormal conditions and open the

synchronize an on-coming electric

supplying the same load.

generator set with the bus or another

utility breaker. 23

Peak Shaving: Process by which electric generator set, and allows XLM Switchgear (Emergency

utility customers minimize peak multiple power sources to be Transfer [Xfer] and Load Management

demand utility charges or exports connected in parallel. Switchgear): Parallels multiple 24

power to the utility grid. engine/gensets and the utility to serve

Synchroscope: An instrument that

downstream loads. Typically does

Prime Power Application: Prime Power provides a visual indication of proper

not include downstream ATS units. 25

is when the genset is the only power time for closing of the breaker when

source. synchronizing generators to connect XLMT Switchgear: Same as XLM

Processor: A specially configured

them in parallel with another source. except with a controlled generator 26

bus tie breaker between the utility

logic controller with appropriate input- TFT (Thin Film Transistor): A type

bus and the engine genset bus.

output capability and programming. of touchscreen display technology

used in HMI devices that offers high 27

SAW (Surface Acoustic Wave):

levels of brightness and clarity.

A premium touchscreen sensing

technology that offers maximum 28

protection from wear or contaminants.

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.0-6 Cat Generator Paralleling Switchgear

July 2016

Sheet 40 006

This page intentionally left blank.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.1-1

July 2016 Introduction

Sheet 40 007

Switchgear Selection

Cat Switchgear Applications 22

Table 40.1-1. Cat Switchgear Selector

Tab Voltage Available Modes of Operation Application

Section Range Switchgear Considerations 23

(Closed Transition)

Listings

Parallel Multiple

Peak Shaving

24

Parallel With

Load Shed/

Application

Emergency

(Standby)

Soft Load

Load Add

Switches

Standby

Gensets

Transfer

Export

Utility

25

Transfer and Load Management Paralleling Switchgear (XLM)

40.2 208–600 V UL 1558

UL 891

■ ■ ■ ■ ■ ■ ■ ■ XLM product is used when genera-

tors will be paralleled with a utility

26

G

(even if utility breaker is not located

2.4–27 kV ANSI C37.20.2 ■ ■ ■ ■ ■ ■ ■ ■ ■ in the same line-up as generator

ANSI C37.20.3 breakers). Allows closed transition 27

Arc-Resistant transfer to/from utility, continuous

Type 2B paralleling with utility for peak

XLM

shaving or exporting. 28

Emergency Generator Paralleling Switchgear (EGP)

40.3

G G

208–600 V UL 1558 ■ ■ ■ ■ ■ EGP product is used to parallel 29

UL 891 multiple gensets to a common bus

where interconnect with the utility

■ ■ ■ ■ ■ ■ ■ ■ ■

2.4–27 kV ANSI C37.20.2

ANSI C37.20.3

is not necessary. EGP systems are

typically used where there are

30

Arc-Resistant downstream Transfer Switches.

Type 2B

EGP

31

Additional Medium-Voltage Features

40.4 2.4–27 kV ANSI C37.20.2 ■ ■ ■ ■ ■ ■ ■ ■ ■ Medium-Voltage product is for 32

ANSI C37.20.3 applications in excess of 600 Vac.

Systems are available in any of

52 the configurations above (XLM or

EGP). Medium-Voltage systems use

33

vacuum circuit breakers for genera-

MV tor and distribution switching.

34

Custom Paralleling Switchgear Products

40.5 208–27 kV UL 1558 ■ ■ ■ ■ ■ ■ ■ ■ ■ Custom Products are available to

UL 891

ANSI C37.20.2

meet the most demanding or unique

system requirements. (Ex., multiple

35

ANSI C37.20.3 utilities, multiple ties, special load

Arc-Resistant control, custom sequence of

Type 2B operations, and so on) 36

37

38

39

40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.1-2 Cat Generator Paralleling Switchgear

Introduction July 2016

Sheet 40 008

Standard and Custom Configurable Products

22 Standard Configurable EGP Custom Products

Products EGP (Emergency Generator Parallel-

Custom switchgear is available to

ing) switchgear is used for paralleling

meet the needs of the most demand-

23 Cat Switchgear is available in two

standard product configurations:

multiple generators that are not

directly connected to a utility source.

ing, unique or complicated system

configurations. Custom engineered

EGP switchgear is primarily used

■ XLM (Emergency Transfer (Xfer) systems are available for special

24 and Load Management)

in applications where downstream

system requirements such as: custom

automatic transfer switches provide

■ EGP (Emergency Generator sequences of operation, special load

the switching between normal and

Paralleling) control requirements, multiple utility

25 emergency sources. This is what is

and tie combinations, unique switch-

typically required in medical facilities,

These configurations are available gear locations or layouts, and so on.

hospitals, and water/wastewater

for both low-voltage and medium No matter how complicated or unique

26 voltage applications and represent

treatment facilities when multiple

the system, Cat Switchgear has the

generator sets are paralleled.

the most typical paralleling switch- power and flexibility to handle it. For

For detailed EGP product description,

gear configurations seen in the detailed custom product description,

27 industry. Additionally, custom

specifications, layouts, and so on, refer

specifications, layouts, and so on, refer

to Section 40.3.

configurations are available to meet to Section 40.5.

the demands of even the most unique

28 and complicated systems. Medium-Voltage Switchgear

XLM Medium-voltage switchgear is

29 available in custom configurations,

XLM (Emergency Transfer (Xfer)

as well as standard configurations

and Load Management) switchgear

listed in this section. Medium-voltage

30 is used when the Generators are

Cat Switchgear uses the same control

paralleled with a normal utility

technology and operator interface,

(or multiple utility) power source(s).

and has all of the same features and

31 XLM switchgear allows closed transi-

functions as the low-voltage systems.

tion, soft-loading and unloading from

At the heart of all medium-voltage

utility, and peak shaving capability

Cat Switchgear systems is Eaton’s

32 where generators operate continu-

Vac-Clad metal-clad switchgear with

ously in parallel with the utility.

type VCP-W vacuum circuit breakers.

Typically, XLM switchgear eliminates

For detailed medium-voltage (5 and

33 the need for automatic transfer

15 kV class) product descriptions,

switches. Data centers, industrial

specifications, layouts, and so on, refer

process, and other critical process

to Section 40.4.

34 loads are prime candidates for XLM

switchgear. For detailed XLM product

description, specifications, layouts,

35 and so on, refer to Section 40.2.

36

37

38

39

40

41

42

43

Cat C175 Genset

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.1-3

July 2016 Introduction

Sheet 40 009

Cat Switchgear

Cat Switchgear Control Technology Features 22

Abbreviations: 23

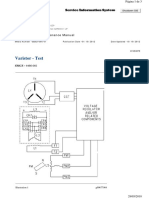

AP1—Primary PLC Gen (x)—Generator (x) PLC

TS AP2—Secondary PLC (Warm Standby) Tie—Tie PLC

ES—Ethernet Switch TS—Touchscreen 24

DTI—Data Table Interface PLC TSP—Touchscreen Processor

Dist.—Distribution Breaker PLC Utility—Utility PLC

EMCP—Electronic Modular Control Panel XD—Power Transducer 25

TSP ES—Ethernet Switch

ES ES ES ES ES ES ES ES 26

27

28

DTI AP1 AP2 Gen 1 Gen 2 Gen N Utility Tie Dist.

29

EMCP XD EMCP XD EMCP XD XD XD 30

Modbus Ethernet TCP Communications Network A 31

Network B

32

Figure 40.1-1. Distributed Processing—Ethernet Network—Dual Redundant Ring Option

Features are common to all low- and 2. Available Redundant System 4. Distributed Manual Control. In the 33

medium-voltage configurations. Masters (warm standby). highly unlikely case of a complete

Master functionality maintained loss of system automation, distrib-

Cat Switchgear uses an advanced,

industry-leading, microprocessor-

through primary and secondary uted manual control is available. 34

automation controller. Ensures

based generator set control designed system level redundancy without 5. Available Redundant Ethernet

to work exclusively with Cat engine- system interruption. Supervisory Networks. Available 35

generator sets. ring and dual ring topologies.

3. Available Redundant System

Redundancy and Fault Tolerance 6. Instant Auto Switch. If the touch-

Masters (hot standby).

screen fails, an “Instant Auto” 36

Cat Switchgear Control Technology Master functionality maintained

through synchronized primary switch is provided to place all

provides maximum efficiency and digital controls in the Auto

reliability. With Cat Switchgear, single and secondary controllers,

position, protecting your facility 37

points of failure are eliminated providing seemless and bumpless

transfer in the event of a master from power outages. A functional

because of the multiple levels of touchscreen is not required for

redundancy and fault tolerance that controller failure.

complete automatic operation of 38

are built into the system: Cat Switchgear.

1. Standard Distributed Processing. 39

A separate automation controller

for each power source ensures

the system continues to operate 40

even if a single controller fails.

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.1-4 Cat Generator Paralleling Switchgear

Introduction July 2016

Sheet 40 010

Cat Switchgear

7. Remote Operator Stations. The Touchscreen Interface

22 remote operator station functions

Cat Switchgear technology uses a

completely independent of the

local operator interface touch- touchscreen for operator interface,

23 screen. If the local operator inter- monitoring and control of the parallel-

ing switchgear. The screens give the

face touchscreen fails, it will not

affect the operation of the remote operator an instantaneous, easily

24 station connected to the system. understandable view of the entire

system status. This feature is standard

8. Hardwired Emergency Start in all Cat Switchgear.

25 Backup. Each system is designed

The easy-to-use touchscreen interface

with a hardwired emergency start

backup system installed in the makes it possible to view, monitor and Generator Control

perform multiple functions including:

26 event of a catastrophic network

communications failure. The ■ Metering

“hardwired” emergency start ■ Engine data

27 backup system will initiate a

■ Protective relay settings

“generator” start signal to ALL of

the generator controllers based on ■ Annunciators

28 any ATS start signal or a “Utility ■ Adjust load shed controls and

Failure” signal. This ensures that generator demand priority

the system is always alerted of a ■ Synchronize and parallel

29 utility outage or ATS Run Request

■ Set modes of operation

so generators can be started and

power can be restored. ■ Voltage and frequency adjustments

Generator Metering

30 9. Hardwired “First Up” Dead Bus With Cat Switchgear, it’s simple. All

Backup. Each system is designed the critical information you need is

with a hardwired hot bus backup displayed in a manner that is easy to

31 system installed in the event of a understand. Graphics look exactly like

catastrophic network communica- the meters and gauges on conventional

tions failure. This feature prevents switchgear. At a glance, users can easily

32 multiple units from closing to a see how the system is performing and,

“Dead Bus” at the same time. based on real-time information, can

Once the first generator breaker quickly do what’s necessary to correct

33 closes to the bus, a hardwired or optimize system performance.

“Hot Bus” signal is passed to all

controllers. Logins and Passwords

34 Generator Annunciator

Cat Switchgear comes with a

10. Best Source DC System. Control

login feature designed to prevent

power is protected against single

35 point of failure by the use of a

unauthorized use. Once activated,

three levels of access are provided:

24 Vdc Best Source DC system.

Each engine battery and an ■ Observer (default): When all users

36 optional station battery are are logged out, the HMI is in the

connected to a common DC bus. lowest level of access. Most screens

Each engine battery and the can be accessed to provide any

37 station battery are furnished with desired information to the user,

their own battery charger. The but no controls, settings or tuning

entire system is protected so that settings can be changed

38 no individual battery/charger fault ■ User: When a user is logged in,

will affect the rest of the system. the operator has access to all System Gen Demand

39 controls, but cannot change

settings or tuning settings

■ Admin: When an administrator is

40 logged in, the operator has full

access to all controls and settings.

This should be limited to site

41 administrators

■ Engineer: An additional password

is provided for factory access by

42 Caterpillar Switchgear and Cat

dealer personnel to operate the

switchgear. The Engineer access is

43 the same as the Admin access

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.1-5

July 2016 Introduction

Sheet 40 011

Cat Switchgear

Table 40.1-2. Cat Switchgear Control Configuration Comparison

Descriptions HMI (Standard) HMI (Enhanced) 22

Redundancy and Fault Tolerance Features

True distributed processing Standard Standard 23

Redundant master controller Optional Optional

Engine 24 Vdc best source system Standard Standard

Station 24 Vdc battery system Optional Optional 24

Automation Network Capabilities

Ethernet network (radial) Standard Standard

25

Ethernet ring network Optional Optional

Ethernet redundant ring network Optional Optional

HMI Touchscreen Display Options 26

19-inch high resolution SAW touchscreen display (widescreen) Standard Standard

22-inch high resolution SAW touchscreen display (widescreen) Optional Optional

27-inch high resolution SAW touchscreen display (widescreen) Optional Optional

27

Custom high resolution touchscreen displays Optional Optional

Individual genset touchscreen display Optional Optional 28

Redundant touchscreen displays Optional Optional

Display Features

Intuitive menu navigation system Standard Standard

29

Dynamic system overview one-line Standard Standard

Control, metering and settings screens Standard Standard 30

Password entry system (minimum 2 levels) Standard Standard

Logging and Reporting Features

Alarm “light box” type annunciation screens Not available Standard

31

Alarm and event summary (1 second time and date stamp) Standard Standard

Tuning and settings reports Standard Standard 32

Joint Commission Test reports Optional Optional

Custom reports Not available Optional

Real-time trend Not available Standard 33

Historical trending Not available Optional

Save/export alarm logs Optional Standard

34

Messenger (SMS messaging, voice email) Not available Optional

Remote Monitoring and System Access

Remote monitoring/control Optional Optional 35

Factory support connectivity Optional Optional

Gateways to BMS/SCADA Optional Optional

36

Ancillary Monitoring and/or Control

Balance of plant (NGR, SCR, CHP, etc.) Not available Optional

Cat ATS/UPS via communications Optional Optional 37

Other ATS/UPS via contact interface Optional Optional

Applications

Emergency standby Standard Standard

38

Utility paralleling Standard Standard

Prime power Standard Standard 39

Landfills, natural gas and diesel Standard Standard

Alternative fuels Not available Optional

Multisource management (MicroGrid) Not available Optional

40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.1-6 Cat Generator Paralleling Switchgear

Introduction July 2016

Sheet 40 012

Cat Switchgear

Cat Switchgear System Advanced Communications Communications with Building

22 Advantages Capabilities (optional) Management or SCADA Systems

Cat Switchgear can also easily

Cat Switchgear performs generator Cat Switchgear technology is equipped communicate data to third party

23 protective functions internal to the with secure password protected Building Management, SCADA or

automation controller. With Cat remote communications technologies, other monitoring systems. For these

technology, you can monitor, process, enabling you to control and monitor

applications, a Data Table Interface

24 compare, display and transmit data your engine generator sets from

acts as a “firewall” between your Cat

with a high degree of precision and anywhere at anytime. Whether at

Switchgear system and the Building

control—and that control translates home, in the office, or on the road, you

Management or SCADA System.

25 into high reliability and functionality. can access controls and information

The Data Table Interface serves up

on a real-time basis and respond

Cat Switchgear has enhanced features immediately...even control multiple the requested data to the third-party

monitoring system, but stays

26 that set the standards for the industry. facilities from a single centralized site.

completely independent of all critical

■ Unequaled fault tolerance Whether on-site or off-site, the “available generator control automation. This

■ World-leading operator interface remote communications package ensures remote communication

27 gives you the identical interface and devices or systems will not affect

■ Sophisticated communications abilities

same capabilities as standing in front the reliability of your Cat Switchgear.

■ Superior connectivity

of the generator or Cat Switchgear.

28 The remote communications run Other systems of communication

Additional Cat Switchgear

completely independent of the interfaces with either Modbus or

advantages include:

paralleling switchgear automation. Bacnet would be specific to the third-

29 ■ Less installation wiring This ensures remote communication party building management—listed

■ Smaller footprint provides better devices or systems will not affect the typically as Building Automation

utilization of available space reliability of your Cat Switchgear. Systems (BAS).

30 Figure 40.1-2 gives an example of

■ Available detailed engine and

electrical reports remote communication connections

31 ■ Low cost redundancy to the Cat Switchgear.

■ Enhanced performance

■ UL, NFPA, CSA and IEEE compliant

32 ■ Higher mean time between failure

■ Lower mean time to repair

33

34 On-Site Off-Site

Provided with View Only Remote Client

Cat Switchgear - Web Browser

35 View Only

Your Company

Remote Client

Network - Web Browser

36 VPN Device

Cat Switchgear VPN TUNNEL

37 Firewall Device

VP

- VPN Access

N

Ethernet Port

TU

38

N

N

Remote Client

EL

Switchgear PC Cat. 5 cable - Web Browser

- 1 Web Server (up to approx. 300')

39 - Ethernet Port Remote Client

- Web Browser

40 Firewall Device

- VPN Access

41

Figure 40.1-2. Off-Site Remote—(TCP-IP) Web-Based Connection with Multiple Users (View Only)

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.2-1

July 2016 Load Management & Emergency Transfer Controls

Sheet 40 013

General Description

XLM General Description ■ Closed transition transfer to

Cat XLM Controls—Generator

Emergency Mode to facilitate 22

maintenance, or for storm threat

Paralleling Controls for Emergency avoidance with soft loading and

Transfer (Xfer) and Load Management unloading of generator system 23

control of multiple engine generator

■ Load shed/load add

sets with one utility source. For

■ Generator demand priority

systems with multiple utility and/or 24

tie breakers, please refer to the ■ Cost-effective, technically superior

Custom Configurable Switchgear alternative to conventional ATS

Section 40.5. For medium-voltage arrangement 25

applications, refer to Section 40.4.

Cat Switchgear brings the power and

■ Automatic transfer to emergency reliability of microprocessor technology

upon utility failure to your generator switchgear 26

■ Automatic start, synchronize, application. Through the use of the

parallel, and load share on a com- operator interface touchscreen display

mon bus for emergency operation with easy-to-follow graphical represen- 27

■ Closed transition transfer back to tations, the Cat Switchgear merges the

features of:

utility upon stable return of power, 28

with soft generator unloading ■ Power monitoring

■ Closed transition Load Management ■ Switchgear automation

Mode with soft loading and unload-

■ Generator set control

29

ing of generator system

■ Optional remote communications

30

XLM2 Switchgear

31

32

33

34

햲

35

36

37

38

39

40

41

42

Figure 40.2-1. XLM2 Controls in Low-Voltage Switchgear

1 PR = Protective Relay.

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.2-2 Cat Generator Paralleling Switchgear

Load Management & Emergency Transfer Controls July 2016

Sheet 40 014

Standard and Optional Equipment

Equipment ■ Automatic load shed control with Tie Breaker Application

22 on-screen operator adjustments for

Many systems require the use of tie

Standard Equipment—XLM Controls essential, critical, and non-essential

loads. Manual load shed/load add breakers to meet Code or system per-

■ XLM controls can be implemented

23 in LV or MV switchgear lineups. control formance requirements. Tie breakers

can be used anywhere throughout the

For complete technical details on ■ Automatic generator demand prior- line-up to segment or isolate desired

Magnum DS switchgear or VacClad ity with on-screen operator adjust-

24 MV switchgear, see Tab 20 or Tab 5 ments for automatic addition and

sources, loads or sections of bus.

■ Operator Interface Touchscreen— removal of generator to the load bus Generator Bus Tie

surface acoustic wave color ■ System status and alarm annucia- Generator Bus Ties can be used to

25 touchscreen with key switch tion with color display and 85 dbA separate the normal electric service

(choose one of the following): alarm horn with silence button sources from the generator sources.

26 ❑ 19.00-inch ■ Password secured settings and This can also allow separation of load

adjustments for generator and sys- breakers to either side of the generator

❑ 22.00-inch

tem setups and protective relaying bus tie breaker in order to allow

❑ 27.00-inch isolation of load banks, or dedicated

27 ■ Alarm summary reports

emergency loads. This separation

■ Direct data communication to ■ Settings reports

Cat microprocessor-based engine also may be required by NFPA or

■ Engine and generator load charts

28 generator set control network local codes.

■ Full function 0.5% accuracy analog ■ Engine data (available with ADEM 3

or ADEM 4 Governor) Generator bus tie breakers can be

and digital AC metering for utility: applied to serve several purposes.

29 voltage 1-2, 2-3, 3-1; current 1, 2, 3; ■ Plug together control connections

frequency; power factor; kW; kvar across shipping split 1. Starting of large loads—the

■ Full function 0.5% accuracy analog generator bus tie can be opened to

30 Optional Equipment—XLM allow multiple generators to be

and digital AC metering for genera-

■ Distribution control of electrically paralleled before being connected

tors: voltage 1-2, 2-3, 3-1; current 1, 2,

operated circuit breakers to large load(s). Once multiple

3; frequency; power factor; kW; kvar

31 ■ Full function engine gauges; RPM,

■ NFPA 110 engine/generator status, generators are paralleled, the

pre-alarm, lamp test button, shut- generator bus tie can be closed

DC battery voltage, oil pressure,

down fault annunciation and 85 dBA to power the large loads.

32 engine coolant temperature, engine

alarm horn with silence button

hours, number of starts 2. Load banks—the generator bus

■ Trip unit metering and communica-

■ Full function synchronizing and tie can allow the generators to be

tions (LV only, with Digitrip 520M,

33 paralleling controls with selection for

520MC and 1150+ electronic trip units)

isolated from the normal utility fed

automatic or manual synchronizing bus. Having a distribution breaker

■ Remote monitoring and control or set of load take-off lugs on the

■ Full function 0.5% accuracy analog

34 and digital AC metering for utility: ■ Building Automation System generator side of the bus allows

voltage 1-2, 2-3, 3-1; current 1, 2, 3; or SCADA communications— the generators to be load bank

frequency; power factor; kW; kvar Modbus or Ethernet tested without affecting any

35 ■ System control functions for auto ■ Remote notification normal utility fed loads.

(standby for emergency), closed ■ Historical data trending 3. Emergency standby systems

transition to emergency and load with automatic transfer switches—

36 management the generator bus tie provides

isolation between the normal and

emergency buses. During a loss

37 of utility power, the generator

bus tie can be opened to isolate

all normal loads and allow

38 restoration of power to emergency

loads. Once emergency loads are

restored, the emergency bus tie

39 can be reclosed to restore power

to normal loads.

40 Note: See Page 40.6-4 for an example

of an XLM system with generator bus

tie breaker.

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.2-3

July 2016 Load Management & Emergency Transfer Controls

Sheet 40 015

Features

Cat XLM Switchgear Generator Metering System Metering

■ 0.5% accuracy ■ 0.5% accuracy 22

System Control ■ Voltage 1-2, 2-3, 3-1; current 1, 2, 3; ■ Voltage 1-2, 2-3, 3-1; current 1, 2, 3;

■ Automatic standby mode frequency; power factor; kW; kvar; frequency; power factor; kW; kvar

■ Emergency mode with closed synchroscope

23

transition to normal System Protective Relaying

Generator Protective Relaying ■ 27/59—bus under/overvoltage relay

■ Closed transition to emergency mode

■ 27/59—under/overvoltage relay ■ 81 O/U—bus under/overfrequency

24

■ Load management mode

■ 81 O/U—under/overfrequency relay relay

■ Automatic load shed control with

bus underfrequency protection and ■ 32—reverse power relay

Power Supply 25

one four-pole, 10 A, 120 Vac, Form C, ■ 40—loss of excitation

■ Power from 24 Vdc engine

dry contact output for each load (reverse var) relay

cranking batteries 26

shed level (1 level for each ■ 25—sync check relay

■ Automatic best DC source selector

generator in the system) Note: Medium-voltage applications utilize

■ Optional 24 Vdc station battery,

■ Automatic generator demand multi-function relays to provide above

priority control protectives plus 50/51 as a minimum sealed jar, 4-hour, external 120 Vac 27

(optional 51G, 87). emergency power required for

■ Master shutdown button charger

Utility Metering Engine Data 28

Technology Communications

■ 0.5% accuracy ■ RPM meter

■ Automation network—high speed,

■ Voltage 1-2, 2-3, 3-1; current 1, 2, 3; ■ Engine battery volt meter 29

high reliability, industrially hardened

frequency; power factor; kW; kvar; ■ Oil pressure meter ■ Optional remote communications

synchroscope ■ Engine coolant temperature meter network—Ethernet, modem

Utility Protective Relaying ■ Optional communication to

30

Engine Monitoring and Alarms

■ 15—automatic synchronizer building automation or SCADA

■ Low coolant temperature pre-alarm

systems for general monitoring—

■ 86—reverse power lockout relay, ■ High coolant temperature pre-alarm Modbus® RTU or Ethernet

31

manual reset and shutdown

■ Multi-function utility grade, ■ Low oil pressure pre-alarm and

drawout with: shutdown

32

❑ 81 O/U—under/overfrequency ■ Low fuel alarm (diesel only)

relay ■ Low engine battery alarm 33

❑ 47—phase sequence/phase ■ Overcrank shutdown

failure relay

■ Overspeed shutdown

❑ 32—reverse direction relay, 34

utility grade, drawout Engine/Generator Control

❑ 32/51—reverse direction ■ Automatic engine start

overcurrent relay, utility grade, ■ Adjustable engine cool-down timer

35

drawout ■ 15—automatic synchronizer

❑ 32/62—reverse direction timing ■ 65—microprocessor engine 36

relay, utility grade, drawout governor load sharing and soft

❑ 27/59—under/overvoltage relay loading control

❑ 25—sync check relay ■ 90—Var/PF and cross current 37

compensation controller

38

39

40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.2-4 Cat Generator Paralleling Switchgear

Load Management & Emergency Transfer Controls July 2016

Sheet 40 016

Functional Sequence of Operations

22 XLM Functional Sequence of Operations 5. [With Generator Bus Tie Breaker]

When all generator sets are on the bus, they are

A. The EPS automation shall be provided with the paralleled across the generator bus tie breaker.

following modes of operation: They are then soft ramp loaded until the generator

23 1. Automatic/Standby Mode plant assumes the entire load on the bus and the

utility main breaker is opened.

a. The utility main breaker is closed serving utility

6. The system is now running in emergency mode.

24 power to the generator/load bus.

b. The generator set main breakers are open. b. Exit

c. The automation is standing by to act in response 1. The operator returns the system to the

25 to a utility failure. Automatic Mode.

2. Emergency Mode 2. Following an adjustable time delay, the generator

plant is synchronized and paralleled to the utility

26 a. Utility Failure source by closing the utility main breaker.

b. Utility protective relaying senses utility voltage 3. The generator plant is soft ramp unloaded until

or frequency out of tolerance.

27 the utility source assumes the entire system load.

c. The utility main breaker is opened. 4. [With Generator Bus Tie Breaker]

d. Load shed sequence is executed. The generator bus tie breaker is opened.

28 e. A run request is sent to the generator plant. 5. The generator set breakers are opened.

f. The first generator set up to voltage and frequency 6. The generators are allowed to run for their

29 is closed to the bus. programmed cool down period and shut down.

g. [With Generator Bus Tie Breaker] 7. The system is returned to the Automatic/

The generator bus tie breaker is closed after the Standby Mode.

30 minimum # of gensets required to perform transfer 4. Load Management Mode

(user adjustable) are synchronized and paralleled to

the bus, or the maximum time to transfer expires. a. Entry

31 (User adjustable) The remaining generator sets are 1. The operator selects one of the following modes

synchronized and paralleled to the bus as they come of operation:

up to voltage and frequency. i. Import Limit—The system maintains utility kW

32 h. The system is now in Emergency Mode. import level at an operator defined minimum

i. Utility Restoration and Exit from Emergency Mode. utility import limit.

33 j. Utility protective relaying senses utility voltage and ii. Export Limit—The system maintains utility

frequency within tolerance. kW export level at an operator defined utility

export setpoint.

k. Following an adjustable time delay to assure that the

34 utility power source is stable, the generator plant is iii. Base Load Import—The system maintains

synchronized and paralleled to the utility source by an operator defined base load kW setpoint,

closing the utility main breaker. subject to a minimum utility kW import limit.

35 iv. Base Load Export—The system maintains

l. The generator plant is soft ramp unloaded until

the utility source is nominally serving the entire an operator defined base load setpoint,

regardless of whether power is being

36 system load.

imported or exported.

m. [With Generator Bus Tie Breaker]

The generator bus tie breaker is opened once 2. The operator places the system in the load

37 kW is below the disconnect kW value. management mode.

n. The generator set breakers are opened. 3. A run request is sent to the generator plant.

4. The generator sets are allowed to run for an

38 o. The generator sets are allowed to run for their

adjustable warm-up time.

programmed cool down period and shut down.

p. The system is returned to Automatic/Standby Mode. 5. The generator sets are synchronized and

39 paralleled to the bus at no load after completion

3. Transfer to Emergency Mode of the warm-up time.

a. Entry 6. [With Generator Bus Tie Breaker]

40 1. The operator places the system into the closed When all generator sets are on the bus, they are

transfer to emergency mode. paralleled across the generator bus tie breaker.

7. When all generators are on the bus, they are soft

41 2. A run request is sent to the generator plant.

ramp loaded until the generator plant assumes

3. The generator sets are paralleled to the bus at the required amount of the load on the bus to

no load and allowed to warm up. meet the mode of operation selected.

42 4. [Without Generator Bus Tie Breaker] 8. Should the utility fail at any time during load

When all generator sets are on the bus they management operation, the utility protective

are soft ramp loaded until the generator plant

43 assumes the entire load on the bus and the

relays shall cause the utility main to open and be

locked out, thus placing the system in Emergency

utility main breaker is opened. Mode until the utility is restored (as described in

Emergency Mode exit).

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.2-5

July 2016 Load Management & Emergency Transfer Controls

Sheet 40 017

Functional Sequence of Operations

b. Exit B. The EPS Automation shall support two (2) sub-modes:

1. The operator returns the system to the Load Shed/Load Add, and Generator Demand Priority. 22

Automatic Mode. 1. Load Shed

2. The generator plant is soft ramp unloaded until

a. Conditional Load Shed: Upon entrance into 23

the utility source assumes the system load.

emergency mode of operation, the load shed

3. [With Generator Bus Tie Breaker] control shall open all sheddable circuit breakers.

The generator bus tie breaker is opened. As generator sets come to the bus, essential priority 24

4. The generator set breakers are opened. level loads shall be added conditionally based on

the number of generator sets on line. When the

5. The generator sets are allowed to run for their

first generator set comes to the bus, priority level 1 25

programmed cool down period and shut down.

loads shall be added; second generator set, priority 2,

6. The system is returned to the Automatic/ etc. After a time delay that allows all operational

Standby Mode. generator sets to come to the bus, the system shall 26

5. No Load Test Mode shift to load sensitive mode.

a. Entry

b. Load Sensitive Load Shed: The system shall compare 27

generator on-line capacity (in kW) to system load. If

1. No load test is initiated by the operator. surplus generator capacity exists, load shed priority

2. All available generator sets are started and level(s) are added. If system load exceeds generator 28

come up to voltage and frequency. on-line capacity, load shed priority level(s) are shed.

The load shed control, in its automatic shedding and

3. [With Generator Bus Tie Breaker]

The generator sets are synchronized and

adding of loads, shall not override any manual load 29

shed/add operation.

paralleled to the bus at no load.

c. Bus Underfrequency: Should the load bus frequency

4. The system is now in no load test mode.

fall below the bus underfrequency setpoint, all 30

b. Exit priority level loads shall be shed. Load addition

shall not resume until manually reset. The bus

1. No load test is terminated by the operator. 31

underfrequency protection shall override any

2. [With Generator Bus Tie Breaker] manual load add operation.

The generator main breakers are opened.

2. Generator Demand Priority Control

3. The generator sets are allowed to run for their 32

programmed cool down period and shut down. a. Upon entrance into emergency or load management

modes, all generator sets shall be started and

4. The system is returned to the Automatic/ 33

paralleled to the bus. After a load stabilization

Standby mode.

delay, generator sets are automatically added to

6. Utility Fail Test Mode or removed from the bus according to system

load demand. 34

a. Entry

b. Generator Demand Priority Control shall have two

1. Utility fail test is initiated by the operator. modes of operation.

2. Voltage sensing at the utility protective relay

35

1. Engine Hour base Generator Demand—Engines

is opened, which simulates a loss of utility. are automatically reassigned priority levels

3. The system enters into emergency mode each time the generators are started in order 36

as described in the emergency mode to maintain them within a user settable amount

sequence above. of hours.

b. Exit 2. Operator manual selection of Generator

37

1. Utility fail test is terminated by the operator. Demand—An operator can disable Engine House

based Generator Demand and manually set the 38

2. Voltage sensing at the utility protective relay priority level for each generator.

is restored, which simulates the return of

utility power.

3. The system exits from emergency mode

39

as described in the emergency mode

sequence above. 40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.2-6 Cat Generator Paralleling Switchgear

July 2016

Sheet 40 018

This page intentionally left blank.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.3-1

July 2016 Emergency Generator Paralleling Controls

Sheet 40 019

General Description

EGP General Description Cat Switchgear brings the power and

22

reliability of microprocessor technology

Cat Emergency Generator to your generator switchgear application.

Paralleling (EGP) Switchgear for Through the use of the operator inter-

multiple engine generator sets. face touchscreen display with easy-to- 23

■ Automatic start, synchronize, follow graphical representation, Cat

parallel and load/var share on Switchgear merges the features of:

a common bus 24

■ Power monitoring

■ Main lugs output to feed down- ■ Switchgear automation

stream emergency distribution

■ Generator set control 25

■ Optional emergency distribution

■ Optional remote communications

circuit breakers

■ Load shed/load add 26

■ Generator demand priority

■ For use with multiple downstream

Automatic Transfer Switches 27

■ Cat Switchgear is designed to

integrate hand-in-glove with 28

Cat Automatic Transfer Switches.

EGP Switchgear is optionally

EGP Switchgear

available with direct communication 29

to Cat ATSs to provide “fingertip”

control and monitoring of all your

facility ATSs from one convenient 30

central location

31

32

33

34

35

36

37

38

39

40

41

42

Figure 40.3-1. EGP3 Low-Voltage Switchgear (Three Generator Sources)

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.3-2 Cat Generator Paralleling Switchgear

Emergency Generator Paralleling Controls July 2016

Sheet 40 020

Standard and Optional Equipment

Equipment ■ Automatic load shed control with Tie Breaker Application

22 on-screen operator adjustments

Many systems require the use of tie

Standard Equipment—EGP for essential (Life/Safety), critical

and non-essential loads. Manual breakers to meet Code or system per-

■ EGP controls can be implemented

23 in LV or MV switchgear lineups. load shed/load add control formance requirements. Tie breakers

can be used anywhere throughout the

For complete technical details on ■ Automatic generator demand line-up to segment or isolate desired

Magnum DS switchgear or VacClad priority with on-screen operator

24 MV switchgear, see Tab 20 or Tab 5 adjustments for automatic addition

sources, loads or sections of bus.

■ Operator Interface Touchscreen— and removal of generator to the Emergency Generator Bus Tie

surface acoustic wave color load bus Certain NFPA Codes require all life

25 touchscreen with key switch ■ System status and alarm annuncia- safety and critical loads (Priority 1

(choose one of the following): tion with color display and 85 dbA loads) to be restored in a maximum

26 ❑ 19.00-inch alarm horn with silence button of 10 seconds. If the total Priority 1

■ Password secured settings and load that must be restored in ten

❑ 22.00-inch

adjustments for generator and seconds exceeds the capacity of

❑ 27.00-inch a single generator, an emergency

27 system setups and protective

generator bus tie breaker should be

■ Direct data communication to Cat relaying

microprocessor-based engine gen- ■ Alarm summary reports used. This allows one generator on

28 erator set control network (EMCP) ■ Settings reports

each side of the tie to restore power

■ System overview screen with to Priority 1 loads in under 10 seconds.

■ Engine and generator load charts The system can then parallel all

one line mimic diagram that

29 ■ Engine trend data generators across the emergency

depicts real-time metering, status

and control generator bus tie breaker so the full

Optional Equipment—EGP generator plant capacity is available.

■ Full function 0.5% accuracy analog ■ Distribution sections with

30 and digital AC metering for genera- electrically operated drawout Note: Priority 1 loads must be split to

tors: voltage 1-2, 2-3, 3-1; current either side of the generator tie breaker.

UL 1066 circuit breakers

1, 2, 3; frequency; power factor; See Page 40.6-11 for an example of a

31 kW; kvar

■ NFPA 110 engine/generator status, system with an emergency generator

pre-alarm, lamp test button, shut- bus tie breaker.

■ Full function engine gauges: RPM, down fault annunciation and 85 dBA

32 DC battery voltage, oil pressure, alarm horn with silence button

engine coolant temperature,

■ Remote monitoring and control

engine hours, number of starts

■ Building Automation System

33 ■ Full function synchronizing and par-

or SCADA communications—

alleling controls with selection for

Modbus or Ethernet

automatic or manual synchronizing

■ Remote notification

34 ■ Full function 0.5% accuracy analog

and digital AC metering for system: ■ Historical data trending

voltage 1-2, 2-3, 3-1; current 1, 2, 3; ■ Communication to Cat ATS units

35 frequency; power factor; kW; kvar ■ Automated Joint Commission report

■ System control functions for auto

(standby for emergency), test

36 without load and test with load

37

38

39

40

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.3-3

July 2016 Emergency Generator Paralleling Controls

Sheet 40 021

Features

Cat EGP Switchgear System Metering

■ 0.5% accuracy 22

Generator Metering ■ Analog and digital voltage 1-2, 2-3,

■ 0.5% accuracy 3-1; current 1, 2, 3; frequency; power

■ Analog and digital voltage 1-2, 2-3, factor; kW; kvar

23

3-1; current 1, 2, 3; frequency; power

factor; kW; kvar; synchroscope System Protective Relaying

■ 27/59—bus under/overvoltage relay

24

Generator Protective Relaying ■ 81 O/U—bus under/overfrequency

■ 27/59—under/overvoltage relay relay 25

■ 81 O/U—under/overfrequency relay

System Control

■ 32—reverse power relay

■ Automatic standby mode

■ 40—loss of excitation 26

(reverse var) relay ■ Emergency mode

■ 25—synch check relay ■ Test without load

Note: Medium-voltage applications utilize ■ Test with load 27

multi-function relays to provide above ■ Automatic load shed control with

protectives plus 50/51 as a minimum bus underfrequency protection

(optional 51G, 87). 28

■ Automatic generator demand

priority control

Engine Gauges

■ RPM meter

■ Master shutdown 29

■ Engine battery volt meter Power Supply

■ Oil pressure gauge ■ Power from 24 Vdc engine 30

■ Engine coolant temperature gauge cranking batteries

■ Automatic best DC source selector

Engine Monitoring and Alarms

■ Optional 24 Vdc station battery, 31

■ Low coolant temperature pre-alarm sealed jar, 4-hour, external 120 Vac

■ High coolant temperature pre-alarm emergency power required for

and shutdown charger 32

■ Low oil pressure pre-alarm and

shutdown Communications

■ Automation network—high 33

■ Low fuel alarm (diesel only)

speed, high reliability, industrially

■ Low and high engine battery alarm hardened

■ Battery charger alarm ■ Optional remote communications

34

■ Overcrank shutdown ■ Optional communication to

■ Overspeed shutdown building automation or SCADA 35

systems or general monitoring—

Engine/Generator Control

Modbus RTU or Ethernet

■ Automatic engine start

36

■ Adjustable engine cool-down timer

■ 15—automatic synchronizer

■ 65—microprocessor engine 37

governor load sharing and soft

loading control

■ 90—Var/PF and cross current

38

compensation controller

39

40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.3-4 Cat Generator Paralleling Switchgear

Emergency Generator Paralleling Controls July 2016

Sheet 40 022

Functional Sequence of Operations

22 EGP Functional Sequence of Operations 6. Utility Fail Test Mode

a. Entrance into Utility Fail Test Mode

A. The EPS automation shall be provided with the

1. The utility fail test switch is placed in the

following modes of operation:

23 1. Automatic/Standby Mode

“on” position.

2. A contact output signals downstream automatic

a. The automatic transfer switches are in the normal transfer switches to enter utility failure test mode.

24 position serving utility power to the loads.

3. The system enters into emergency mode

b. The generator set main breakers are open. as described in the “Emergency Mode”

c. The automation is standing by to act in response sequence above.

25 to a run request from associated automatic b. Exit from Utility Fail Test Mode

transfer switches.

1. The utility fail test switch is placed in the

26 2. Emergency Mode “off” position.

a. Automatic Transfer Switch Run Request. 2. A contact output signals downstream automatic

b. Where applicable, load shed sequence is executed. transfer switches to exit utility failure test mode.

27

c. All available generators are started. 3. The system exits into emergency mode as

d. The first generator up to voltage and frequency is described in the “Exit from Emergency Mode”

28 closed to the bus. sequence above.

e. Critical loads and load shed priority 1 loads are B. The EPS Automation shall support two (2) sub-modes:

powered in less than 10 seconds. Load Shed/Load Add, and Generator Demand Priority.

29

f. The remaining generator sets are synchronized 1. Load Shed

and paralleled to the bus as they come up to voltage

a. Conditional Load Shed: Upon entrance into

30 and frequency.

emergency mode of operation, the load shed

g. As additional generators are paralleled to the control shall open all sheddable circuit breakers.

emergency bus, Load Shed Priority levels are added, As generator sets come to the bus, essential priority

31 powering their associated loads. level loads shall be added conditionally based on

h. The system is now in Emergency Mode. the number of generator sets on line. When the

first generator set comes to the bus, priority level 1

32 3. Exit from Emergency Mode

loads shall be added; second generator set, priority 2,

a. Automatic transfer switches sense the utility source is etc. After a time delay that allows all operational

within acceptable operational tolerances for a time generator sets to come to the bus, the system shall

33 duration set at the automatic transfer switch. shift to load sensitive mode.

b. As each automatic transfer switch transfers back b. Load Sensitive Load Shed: The system shall compare

to utility power, it removes it’s run request from the

34 generator plant.

generator on-line capacity (in kW) to system load. If

surplus generator capacity exists, load shed priority

c. When the last automatic transfer switch has level(s) are added. If system load exceeds generator

35 retransferred to the utility and all run requests on-line capacity, load shed priority level(s) are shed.

have been removed from the generator plant, all The load shed control, in its automatic shedding and

generator set main circuit breakers shall opened. adding of loads, shall not override any manual load

36 d. The generator sets are allowed to run for their shed/add operation.

programmed cool down period and shut down. c. Bus Underfrequency: Should the load bus frequency fall

e. The system is returned to Automatic/Standby Mode. below the bus underfrequency setpoint, all priority level

37 loads shall be shed. Load addition shall not resume until

4. No Load Test Mode manually reset. The bus underfrequency protection

a. Entrance into No Load Test Mode. shall override any manual load add operation.

38 b. The no load test switch is placed in the “on” position. 2. Generator Demand Priority Control

c. All available generators are started. a. Upon entrance into emergency mode, all generator

39 d. The first generator up to voltage and frequency is sets shall be started and paralleled to the bus.

closed to the bus. After a load stabilization delay, generator sets are

e. The remaining generators are synchronized and automatically added to or removed from the bus

40 paralleled to the bus as they come up to voltage according to system load demand.

and frequency. b. Generator Demand Priority Control shall have two

f. The system is now in No Load Test Mode. modes of operation.

41 5. Exit from No Load Test Mode. 1. Engine Hour base Generator Demand—Engines

a. The no load test switch is placed in the “off” position. are automatically reassigned priority levels each

42 b. All generator breakers are opened. time the generators are started in order to main-

tain them within a user settable amount of hours.

c. The generators are allowed to run for their

programmed cool down period and shut down. 2. Operator manual selection of Generator

43 d. The system is returned to automatic/standby mode.

Demand—An operator can disable Engine House

based Generator Demand and manually set the

priority level for each generator.

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.4-1

July 2016 Additional Medium-Voltage Features

Sheet 40 023

General Description

Other Available Protective Generator bus tie breakers can be

Functions and Options applied to serve several purposes: 22

A. (87B) Switchgear Bus Differential 1. Starting of large loads—the

—Bus differential relays are high generator bus tie can be opened to 23

speed protective devices that are allow multiple generators to be

used to limit damage from faults paralleled before being connected

within the switchgear by quickly to large load(s). Once multiple 24

isolating the faulted “zone.” generators are paralleled, the

Differential relays measure the generator bus tie can be closed

difference between the current to power the large loads. 25

flowing into and the current flow- 2. Load banks—the generator bus

ing out of a given “zone.” Systems tie can allow the generators to be

with multiple utilities and/or tie isolated from the normal utility fed 26

breakers will typically have more bus. Having a distribution breaker

than one bus differential zone. In or set of load take-off lugs on the

this configuration, during a differ- generator side of the bus allows

27

ential fault, only breakers feeding the generators to be load bank

in and out of the faulted zone are tested without affecting any

tripped and locked out. The other normal utility fed loads.

28

zone(s) are unaffected and can

continue to operate. 3. Emergency Standby systems with

Automatic Transfer Switches—the 29

B. Generator Neutral Grounding generator bus tie provides isola-

Resistors—provide added tion between the normal and

protection for generator windings emergency buses. During a loss 30

by limiting the fault current during of utility power, the generator

line to ground faults. bus tie can be opened to isolate all

normal loads and allow restora- 31

Tie Breaker Application tion of power to emergency

Many systems require the use of loads. Once emergency loads

tie breakers to meet code or system are restored, the emergency bus 32

performance requirements. Tie tie can be reclosed to restore

breakers can be used anywhere power to normal loads.

throughout the line-up to segment 33

or isolate desired sources, loads Emergency Generator Bus Tie

or sections of bus. Certain NFPA codes require all life

safety and critical loads (Priority 1 34

Generator Bus Tie loads) to be restored in a maximum of

Generator bus ties can be used to 10 seconds. If the total Priority 1 load

separate the normal electric service that must be restored in 10 seconds 35

sources from the generator sources. exceeds the capacity of a single

This can also allow separation of load generator, an emergency generator

breakers to either side of the generator bus tie breaker should be used. This 36

bus tie breaker in order to allow allows one generator on each side

isolation of load banks, or dedicated of the tie to restore power to Priority 1

emergency loads. This separation loads in under 10 seconds. The system 37

also may be required by NFPA or can then parallel all generators across

local Codes. the emergency generator bus tie

breaker so the full generator plant 38

capacity is available.

Note: Priority 1 loads must be split to 39

either side of the emergency generator

bus tie breaker.

40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

40.4-2 Cat Generator Paralleling Switchgear

Additional Medium-Voltage Features July 2016

Sheet 40 024

General Description

Other Recommended Protective 4. Extensive information on Surge Surge capacitors are recommended

22 Functions and Options Protection, Arresters and to protect the alternator on 5 kV or

Capacitors can be found in Tab 5 15 kV Gensets.

Generator Neutral Grounding “Metal-Clad Switchgear—

23 Resistors are recommended to VacClad-W—Medium-Voltage.” 1. Surge capacitors should be used

protect generator windings. to protect AC alternators.

5. Recommended minimum protec-

2. Surge capacitors are used to

24 1. NGRs provide added protection tion: surge arrester for protection

prevent regular electric flow

for generator windings by limiting from high overvoltage peaks, or

the fault current during line to surge capacitor for protection from being grounded.

25 ground faults. from fast-rising transient. Please 3. Protective Surge Capacitor

note that the surge arresters or systems should be designed

2. Cat Switchgear recommends a surge capacitor alone may not

Low Resistance Grounding system to operate in conjunction with

26 with a Neutral Grounding Resistor

provide adequate surge protection lightning arresters to provide

from escalating voltages caused surge protection for generator

tied to the Generator Neutral rated by circuit resonance.

at10 seconds and the Line to alternators.

27 Neutral voltage. 6. Good protection: Surge arrester in 4. The capacitor should reduce the

parallel with surge capacitor for steepness of the wave front of the

a. NGRs protect the alternator protection from high overvoltage

28 windings on MV and HV peaks and fast rising transient.

voltage surge, thereby reducing

gensets with 87G schemes. the stress on the turn and line-to-

This option may not provide ground insulation.

b. On 4160 V systems, 2400 V adequate surge protection from

29 10 seconds, 200 A NGRs are escalating voltages caused by 5. Surge capacitors function best

commonly specified. circuit resonance. When applying when located as close as possible

surge capacitors on both sides of to the generator alternator output

30 c. On 13.8 kV systems, 8000 V

a circuit breaker, a surge capacitor leads.

10 seconds, 100 A NGRs are

commonly specified. on one side of the breaker must be

6. Surge capacitors should be

31 RC Snubber or ZORC, to mitigate

Surge Arresters are recommended to connected line-to-ground, and

possible virtual current chopping.

protect Switchgear. be on the load side of the breaker

7. Better protection: RC snubber in to eliminate the chance of a bus

32 1. A surge arrester is used to prevent parallel with surge arrester for short-circuit in the event of

large surges from power inconsis- protection from high frequency capacitor failure.

tencies, lightning, switching, etc., transients and voltage peaks.

33 from reaching electronic instru- 7. Maximum effectiveness is

ments and ensure the safety of 8. Recommended best protection: achieved in limiting impulse

individuals nearby by limiting the ZORC, plus proper surge arrester voltages, if a low-resistance and

34 crest of impending voltage surges preceding ZORC where needed for low-inductance ground connection

to safe values. protection against lightning. ZORC is established. All ground

provides protection from high connections need to be tied

35 2. Surge arrestors are connected frequency voltage transients together with a minimum

between each electrical conductor and limits peak magnitude of the #6 AWG copper conductor.

in a power system and the ground, transient to 1 to 2 PU (see ZORC

8. Although surge capacitors are

36 which provides a short-circuit to description in Tab 5 on Page 5.4-19

installed line-ground, they should

the ground. for more detail). Surge arrester

be rated for line-to-line voltage in

provides protection from higher

3. Surge arrestors are typically the event they are installed on an

37 installed on utility feeders, and

voltage peaks resulting from

ungrounded or poorly grounded

lightning surges.

feeders exiting the building to system.

other loads.

38 9. Cat Switchgear recommends

the following values based on

system voltage: 0.5 ?f on 5 and

39 7.5 kV, 0.25 mf on 15 kV, and

0.13 ?f on systems operating

at 24 kV and higher.

40

10. Where applicable, the surge

capacitor shall conform to

41 NEMA CP-1 standards.

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Cat Generator Paralleling Switchgear 40.5-1

July 2016 Custom Systems

Sheet 40 025

General Description

Custom Systems 22

General Description

Cat Generator Paralleling Switchgear has the power and 23