3 Way Dumping Truck

Diunggah oleh

SIVAKUMARDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

3 Way Dumping Truck

Diunggah oleh

SIVAKUMARHak Cipta:

Format Tersedia

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 1

INTRODUCTION

A dump trolley is a trolley used for transporting materials (such as gravel, grain, sand, compost,

heavy rocks, etc.) for construction. A typical dump trolley is equipped with an open-box bed,

which is hinged at the rear and equipped with hydraulic pistons to lift the front, allowing the

material in the bed to be deposited (dumped) on the ground behind the trolley at delivery site. The

conveyor mechanism, in particular, includes a single continuous belt member wrapped around

rollers. A lever is connected to the first roller for driving the rollers and the surrounding belt

member wrapped around rollers. A lever is connected to the first roller for driving the rollers and

the surrounding belt member. This will unload tipper in left/right side. A hydraulic jack is a

powerful lifting or pushing tool designed to provide effective lift over greater distance than basic

mechanical jack. This tipper mechanism can be applied to both domestic and industrial use.

DEPT. OF MECHANICAL ENGINEERING Page 1

Seminar Report Design and fabrication of three way dumping trolley

DEPT. OF MECHANICAL ENGINEERING Page 2

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 2

HYDRAULIC SYSTEM

In the development of the submarine from pre-approval war classes, many changes and

improvements have occurred. One of the outstanding difference is the large variety of

submarine devices which are now operated by hydraulic power. Along with constantly

improving submarine design has gone a constant extension and diversion of the use of

hydraulic power.

Comparative advantage of hydraulic power.

Hydraulic systems possess numerous advantage over the other systems of power operation.

They are light in weight; they are simple and extremely reliable, requiring a minimum of

attention and maintenance. Hydraulic are sensitive, and afford precise controllability.

Because of the low inertia of moving bodies they start and stop in complete obedience to

the desire of the operator and their operation is positive. Hydraulic systems are self-

lubricated; consequently there is a little wear or corrosion. Their operation is not apt to be

interrupted by salt spray or water finally hydraulic units are quiet in operation.

DEPT. OF MECHANICAL ENGINEERING Page 3

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 3

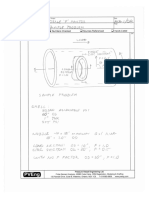

HYDRAULIC CYLINDER

A Hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is

used to give a unidirectional fore through a unidirectional stroke. It has many applications,

notably in construction equipment (engineering vehicles), Manufacturing machinery, and

civil engineering.

SINGLE ACTING HYDRAULIC CYLINDER: The single acting hydraulic cylinder

(see figure1), which is the simplest type of hydraulic motor, contains a spring-loaded

piston, with a piston Rod that extent through one end of the cylinder. In our project, the

single acting hydraulic cylinder is used.

DEPT. OF MECHANICAL ENGINEERING Page 4

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 4

HYDRAULIC PUMP

FIG 1-HYDRAULIC PUMP

DEPT. OF MECHANICAL ENGINEERING Page 5

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 5

TROLLEY

Tractor trolley is very popular and cheaper modes of good transport in rural as well as urban areas.

Trolleys are widely used for transporting agriculture product, building construction material and

industrial equipment. The main requirements of trolley manufacturing are high performance, easy

to maintain, longer working life and robust construction. In this work, the tractor trolley are used

for the agriculture work and sometimes used for transporting building construction material. These

trolleys are divided into two types such as two wheeler trolleys and fur wheeler trolleys. The

varieties of trolleys are available and use of particular trolleys depends upon their application.

They available in various capacities like 3 tones, 5 tones, 6 tones, 8 tones etc.

FIG3-TROLLEY

DEPT. OF MECHANICAL ENGINEERING Page 6

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 6

CHASSIS

A chassis is one of the key components of the trolley. It consists of an internal frame work that

supports the container of tractor in its construction and use. It is a dead vehicle which is connected

to the tractor to carry the load. It serves as a frame work for supporting the body. It should be rigid

to withstand the shock, twist, and other stresses & its principle function is to carry the maximum

load for static and dynamic condition safely. An important consideration in chassis design is to

have adequate bending stiffness along with strength for better handling characteristics. The chassis

is used to support the container on which the load is to be carried out. The trolley chassis main

frame is supported at two points over the axle.

Function of chassis

To carry load of the goods carried in the body.

To withstand the forces caused due to sudden breaking and acceleration.

To withstand the stresses caused due to the bed road condition.

FIG 3 CHASSIS

DEPT. OF MECHANICAL ENGINEERING Page 7

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 7

WORM DRIVE

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw)

meshes with a screw gear which is similar in appearance to spur . The two elements are also called

the worm screw and worm wheel. The terminology is often confused by imprecise use of the term

worm gear to refer to the work, worm gear, worm as driving unit.

Like other gear arrangement, a worm drive can reduce rotational speed or transmit high torque.

The image shows a section of gear box with worm gear driven by a worm. A worm is an example

of screw, one of the simple machines.

FIG-4 WORM GEAR

DEPT. OF MECHANICAL ENGINEERING Page 8

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 8

CONNECTING HOSES

A hose is a flexible hollow tube designed to carry fluids from one location to another. Hoses are

also sometimes called pipes, or one or more general tubing. The shape of hose is generally

cylindrical. To achieve a better pressure resistance, hoses can be reinforced with fiber or steel

chord.

Hydraulic hoses are graded by pressure, temperature and fluid comparability. Hoses are used when

pipes or tubes cannot be used, usually to provide flexibility to the machine operation. The hose is

built up with rubber and steel layers. A rubber interior is surrounded by multiple layer of woven

wire and rubber. The exterior is designed for abstraction resistance. The bend radius of hydraulic

hose is carefully designed into the machine, since hose failure can be deadly, and violating hoses

minimum bend radius will cause failure. Hydraulic hoses generally have steel fittings swaged on

the ends. The weakest part of high pressure hose is the connection of hose to the fittings. Another

disadvantage of hose is shorter life of rubber which requires periodic replacement, usually at five

to seven years interval.

FIG 5-CONNECTING HOSES

DEPT. OF MECHANICAL ENGINEERING Page 9

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 9

WHEEL ARRANGEMENT

A three wheeler is a vehicle with three wheels. Some are motorized tricycles, which may be legally

classed as automobiles or motorcycles. Tricycles without motor, some of them are human powered

vehicle and some are animal powered vehicle.

Many three wheelers exist in the form of motor cycle based machines are often called trikes and

often have the front single wheel and mechanism similar to that of a motorcycle and the rear axle

similar to that of a car. Often such vehicles are owner- constructed using a portion of a rear engine,

rear drive Volkswagen Beetle in combination with motorcycle front end.

DEPT. OF MECHANICAL ENGINEERING Page 10

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 10

VEHICLE MODEL FRAME

FIG-6 VEHICLE MODEL FRAME

DEPT. OF MECHANICAL ENGINEERING Page 11

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 11

WORKING PRINCIPLE

“A modern three way dumping trolley” is nothing but one of the lifting system in automobile in

case of emergency. In this lifting system hydraulic operated one. Here the additional hydraulic

cylinder and control valve is provided in the automobile itself.

In this paper the control valve is used to activate or deactivate the oil input. The valve is “ON” at

the time of emergency; the pressurized oil goes to the oil cylinder. Then the pressurized oil passes

through the tube and then pushes the hydraulic cylinder, so that the lifting is applied at the time of

valve is “ON” position.

The speed of hydraulic cylinder is controlled by varied by using control valve. This is the way of

controlling the lifting speed of trailer at the time of emergency. In this paper we have to apply this

hydraulic Modern trailer mechanism in load lifting vehicles.

The control valve is fixed in the near if driving persons in our four wheeler. The oil tank contains

the pressurized oil as already. The valve was ON at the time of emergency, the control valve is

activated.

The pressurized oil valve is controlled by the valve called “FLOW CONTROL VALVE”. The

hydraulic cylinder is move forward at the time of pressurized oil inlet to the cylinder. The hydraulic

cylinder moves towards the lifting arrangement.

FIG 7-SCHEMATIC DIAGRAM

DEPT. OF MECHANICAL ENGINEERING Page 12

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 12

ADVANTAGES

1. Lifting cost less.

2. Free from wear adjustment.

3. Less power consumption.

4. Less skill technicians is sufficient.

5. Installation is very much easy.

DISADVANTAGES

1. Need separate oil tank.

2. Efficiency is low.

3. Additional cost is required to install the system in four wheelers.

DEPT. OF MECHANICAL ENGINEERING Page 13

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 13

CONCLUSION

Trolley has lot of applications in today’s world. In industrial and domestic consideration, tippers

can pull a variety of products including gravel, grain, sand, fertilizer, heavy rocks, etc. The older

dropping trolley/dumper has been conceived by observing the difficulty in unloading the materials.

MODERN THREE WAY DUMPING TROLLEY is not nothing but one of the lifting system in

automobile at the time of emergency. In this system hydraulic operated one. Here the hydraulic

cylinder and control valve is provided in automobile itself. In this paper control valve is used to

activate/deactivate the oil input. The valve is on at the time of emergency; the pressurized oil goes

to the hydraulic cylinder. Then the pressurized oil passes through the tube and then pushes through

the hydraulic cylinder, so that the lifting is applied at the time of valve is in “ON” position.

DEPT. OF MECHANICAL ENGINEERING Page 14

Seminar Report Design and fabrication of three way dumping trolley

CHAPTER 14

REFERENCES

1. http://www.ijetae.com/files/volume4issue9/IJETAE_0914_121.pdf

2. http://www.paperpublications.org/journal/IJRRCME

3. http://www.mechengg.net /2015/10/three-axis-pneumatic-modern-trailer-mechanical-

project.html

4. https://www.scribd.com/doc/277951200/THREE-AXIS-PNEUMATIC-MODERN-

TRAILER-pptx

DEPT. OF MECHANICAL ENGINEERING Page 15

Anda mungkin juga menyukai

- Structural Condition Assessments GuidelineDokumen24 halamanStructural Condition Assessments GuidelineHardeep Sohl83% (6)

- Shear Walls and Diaphragms PDFDokumen76 halamanShear Walls and Diaphragms PDFCharbel Saad SaadBelum ada peringkat

- Some Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentDari EverandSome Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsDari EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsBelum ada peringkat

- Design and Fabrication of Hydraulic FlooDokumen35 halamanDesign and Fabrication of Hydraulic FlooEric RogersBelum ada peringkat

- Gravity Roller Conveyor Design: Technical ReportDokumen22 halamanGravity Roller Conveyor Design: Technical ReportAnonymous lFvgGOGcuBelum ada peringkat

- RCD Module 2 NSCP Updates and OthersDokumen47 halamanRCD Module 2 NSCP Updates and OthersHannylet OcateBelum ada peringkat

- Scissor Jack Design ReportDokumen76 halamanScissor Jack Design ReportSelemon Assefa100% (2)

- Design of Hydraulic Portable Crane Ijariie17796Dokumen9 halamanDesign of Hydraulic Portable Crane Ijariie17796Diogo VidinhaBelum ada peringkat

- Gravity Roller Conveyor Design PDFDokumen21 halamanGravity Roller Conveyor Design PDFabdallah391Belum ada peringkat

- Fabrication of Mechanical Scissor LiftDokumen27 halamanFabrication of Mechanical Scissor LiftNävèéñ Tëjâ83% (6)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshDari EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshBelum ada peringkat

- Hydraulic Brake DesignDokumen30 halamanHydraulic Brake DesignkarthikBelum ada peringkat

- Design and Development of 3-Way Dropping DumperDokumen10 halamanDesign and Development of 3-Way Dropping Dumperlaukik_rautBelum ada peringkat

- Design and Fabrication of Hydraulic Floor CraneDokumen6 halamanDesign and Fabrication of Hydraulic Floor CraneSuryansh SharmaBelum ada peringkat

- Name: A Rghya de Roll No.: Stream: Subject: Subject Code: 1690071 5020 Mechanical Engineering Design of Mechanical System ME 881Dokumen65 halamanName: A Rghya de Roll No.: Stream: Subject: Subject Code: 1690071 5020 Mechanical Engineering Design of Mechanical System ME 881Yummy BeatsBelum ada peringkat

- Hydraulic CraneDokumen20 halamanHydraulic CraneRavi Donga55% (11)

- Advantages of Using STAADDokumen10 halamanAdvantages of Using STAADJovy NotorioBelum ada peringkat

- Wind Farm Modelling PSSEDokumen6 halamanWind Farm Modelling PSSERahul Chakrabarti100% (2)

- "Hydraulic Crane": Ashish Shejwal, Kishor Giri, Mahesh Solunke, Gaurav Rathod, Suraj Balkhande, Prof. M. D. SirsatDokumen4 halaman"Hydraulic Crane": Ashish Shejwal, Kishor Giri, Mahesh Solunke, Gaurav Rathod, Suraj Balkhande, Prof. M. D. SirsatSaurabh gargBelum ada peringkat

- Method Statement For Plumbing Piping Works Rev 01Dokumen46 halamanMethod Statement For Plumbing Piping Works Rev 01sakhrs2000Belum ada peringkat

- Automatic Screw JackDokumen46 halamanAutomatic Screw JackAnonymous YfpcmA100% (1)

- Fabrication of Hydraulic Fork LiftDokumen41 halamanFabrication of Hydraulic Fork LiftElakkiya Karthic50% (2)

- Gravity Roller Conveyor DesignDokumen22 halamanGravity Roller Conveyor DesignIsna DamayantiBelum ada peringkat

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsDari EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsBelum ada peringkat

- Fyp Hydraulic CraneDokumen29 halamanFyp Hydraulic CraneGaganMaan71% (17)

- Design and Fabrication of Modern Three Way Dumping Trolley MechanismDokumen8 halamanDesign and Fabrication of Modern Three Way Dumping Trolley MechanismvenkataBelum ada peringkat

- ELECTRIC POWERED STAIR CLIMBING TROLLEY Ijariie11499Dokumen5 halamanELECTRIC POWERED STAIR CLIMBING TROLLEY Ijariie11499nelsonsanthosh27Belum ada peringkat

- Advanced Structural Design & System: Submitted By: Aayushmaan Kaul A1904015046 B. Arch, Sec-A, Sem-9 2015-2020Dokumen16 halamanAdvanced Structural Design & System: Submitted By: Aayushmaan Kaul A1904015046 B. Arch, Sec-A, Sem-9 2015-2020aayushmaan kaulBelum ada peringkat

- Chapter-1: Design & Fabrication of Hydraulic Floor Crane 2014Dokumen35 halamanChapter-1: Design & Fabrication of Hydraulic Floor Crane 2014Habtamu GeremewBelum ada peringkat

- Chapter-1: Design & Fabrication of Hydraulic Floor Crane 2014Dokumen35 halamanChapter-1: Design & Fabrication of Hydraulic Floor Crane 2014Habtamu GeremewBelum ada peringkat

- 2-Wheel Drive Industrial Fork Lifter For Ware Houses: Chapter - 1Dokumen48 halaman2-Wheel Drive Industrial Fork Lifter For Ware Houses: Chapter - 1142 Sanjaykumar S RBelum ada peringkat

- CITATION 1 /L 1033Dokumen15 halamanCITATION 1 /L 1033Abdirahman DhooreBelum ada peringkat

- JETIR1902975Dokumen6 halamanJETIR1902975simpi.kunalBelum ada peringkat

- Sample Chapter 1 5Dokumen68 halamanSample Chapter 1 5Antonio Miguel DizonBelum ada peringkat

- 3 Side Dumping TrolleyDokumen32 halaman3 Side Dumping TrolleyPriyanka mestryBelum ada peringkat

- Design and Analysis Ofindustrial Scissor Lift - 1604658254Dokumen8 halamanDesign and Analysis Ofindustrial Scissor Lift - 1604658254SamBelum ada peringkat

- Project Report 2Dokumen10 halamanProject Report 2Ananya MauryaBelum ada peringkat

- Optimum Redesign of An Agricultural Water BowserDokumen16 halamanOptimum Redesign of An Agricultural Water BowserBerhanu DiribaBelum ada peringkat

- Modified Screw Jack For Lifting Operation in Industrial SettingDokumen12 halamanModified Screw Jack For Lifting Operation in Industrial SettingAdi PutraBelum ada peringkat

- Jack Lifter ReportDokumen13 halamanJack Lifter ReportMahrukh ShabbirBelum ada peringkat

- Dinesh (2015) - Analysis of Crane Hook Using ANSYS Simulation ToolDokumen5 halamanDinesh (2015) - Analysis of Crane Hook Using ANSYS Simulation ToolGogyBelum ada peringkat

- 4 Thesis DATA - New3Dokumen37 halaman4 Thesis DATA - New3Kailas DBelum ada peringkat

- Vi - Three Axis Modern Trailer: 3. Components and DescriptionDokumen14 halamanVi - Three Axis Modern Trailer: 3. Components and Descriptionpramo_dassBelum ada peringkat

- 4 Thesis DATA - NewDokumen18 halaman4 Thesis DATA - NewKailas DBelum ada peringkat

- Mechanically Advanced Scissor JackDokumen41 halamanMechanically Advanced Scissor JackAmit VishwakarmaBelum ada peringkat

- Quick Lifting JackDokumen3 halamanQuick Lifting JackKaran JainBelum ada peringkat

- Inter IIT Tech Meet 12 0Dokumen11 halamanInter IIT Tech Meet 12 020me02022Belum ada peringkat

- Final Project ReportDokumen33 halamanFinal Project Reportv.v.ransing22Belum ada peringkat

- Natnael Getasew, Abel Gebremedhin, Yonatan Yakob, Abel TesfayeDokumen24 halamanNatnael Getasew, Abel Gebremedhin, Yonatan Yakob, Abel TesfayeYonatan YakobBelum ada peringkat

- Modified Screw Jack For Lifting Operation in Industrial SettingDokumen12 halamanModified Screw Jack For Lifting Operation in Industrial SettingRoyce RomeroBelum ada peringkat

- Design and Fabrication of Motorized Screw Jack For Four WheelersDokumen23 halamanDesign and Fabrication of Motorized Screw Jack For Four WheelersmujeebBelum ada peringkat

- ProjectDokumen32 halamanProjectJai RajeshBelum ada peringkat

- Addis Ababa Bole Internationa Airport InterpriseDokumen21 halamanAddis Ababa Bole Internationa Airport Interprisegari100% (1)

- Trolley Jack ProposalDokumen8 halamanTrolley Jack Proposaladebayo gabriel100% (1)

- Introduction To Rotor TugDokumen9 halamanIntroduction To Rotor TugMoe Oo ZunBelum ada peringkat

- Review of Overhead Crane and Analysis of Components Depending On SpanDokumen5 halamanReview of Overhead Crane and Analysis of Components Depending On SpanBalamanikandan ABelum ada peringkat

- Jack ContentsDokumen45 halamanJack ContentsVenkata DineshBelum ada peringkat

- Scissor LiftDokumen27 halamanScissor LiftKalai100% (1)

- Excavator: TerminologyDokumen8 halamanExcavator: TerminologySenna KesavanBelum ada peringkat

- Trolley Turning and Lifting Mechanism: Ayneendra B, Mohd Salman, Jimmy Thaddeus Ojyok Attari, Marvan EDokumen8 halamanTrolley Turning and Lifting Mechanism: Ayneendra B, Mohd Salman, Jimmy Thaddeus Ojyok Attari, Marvan ERahul PrasadBelum ada peringkat

- 588-608 Syambabu NutalapatiDokumen21 halaman588-608 Syambabu NutalapatiSyam RajuBelum ada peringkat

- Mechanically Advanced Scissor JackDokumen41 halamanMechanically Advanced Scissor JackAnkur Goldar84% (25)

- Mechanically Advanced Scissor JackDokumen41 halamanMechanically Advanced Scissor Jackestifanos100% (1)

- Front End Loaders.Dokumen8 halamanFront End Loaders.kartheek GBelum ada peringkat

- Cover & Table of Contents - Fundamentals of Structural Analysis (2nd Edition) PDFDokumen14 halamanCover & Table of Contents - Fundamentals of Structural Analysis (2nd Edition) PDFAle Ignacio PinillaBelum ada peringkat

- Altivar 71 CatalogueDokumen334 halamanAltivar 71 CataloguerubysultanaBelum ada peringkat

- BridgeDokumen12 halamanBridgesoumyakuriakoseBelum ada peringkat

- Mapping of Diploma Courses For Undergraduate CoursesDokumen2 halamanMapping of Diploma Courses For Undergraduate CoursesTo SecretBelum ada peringkat

- State of Mechanical Engineering Today and BeyondDokumen24 halamanState of Mechanical Engineering Today and BeyondSanthosh ReddyBelum ada peringkat

- Ads 51 HDBKDokumen494 halamanAds 51 HDBKhplchagasBelum ada peringkat

- Artificial Intelligence and Expert Systems: Narayana Engineering College NelloreDokumen10 halamanArtificial Intelligence and Expert Systems: Narayana Engineering College NelloreGirish ChowdaryBelum ada peringkat

- Allotted List Round 1 PDFDokumen169 halamanAllotted List Round 1 PDFkathirvelBelum ada peringkat

- Cim Lab QustionsDokumen6 halamanCim Lab Qustionsஅன்புடன் அஸ்வின்Belum ada peringkat

- Códigos de ErroDokumen2 halamanCódigos de ErroFranciscoOliveiraBelum ada peringkat

- Nozzle F Factor CalculationsDokumen5 halamanNozzle F Factor CalculationsSivateja NallamothuBelum ada peringkat

- Industrial Waste Management: Che 3101 G1 1/N 00 1/1Dokumen2 halamanIndustrial Waste Management: Che 3101 G1 1/N 00 1/1JAN JERICHO MENTOYBelum ada peringkat

- CNC and Robotics (Me1968) : Rakesh V AdakaneDokumen43 halamanCNC and Robotics (Me1968) : Rakesh V AdakaneRakeshAdakaneBelum ada peringkat

- Ag Aircraft Safety Review CompleteDokumen400 halamanAg Aircraft Safety Review CompleteJair HernandezBelum ada peringkat

- Gaddhsumit Sumit-GaddhDokumen2 halamanGaddhsumit Sumit-GaddhSumit GaddhBelum ada peringkat

- 5e Consulting Company ProfileDokumen33 halaman5e Consulting Company Profilesourabh.agBelum ada peringkat

- Ffirs Rev1Dokumen3 halamanFfirs Rev1Iqemal Sakri SBelum ada peringkat

- Master Thesis Topics in Industrial EngineeringDokumen5 halamanMaster Thesis Topics in Industrial Engineeringpbfbkxgld100% (1)

- Object Oriented - AnalysisDokumen43 halamanObject Oriented - AnalysisAbdela Aman MtechBelum ada peringkat

- Resume of JameelhnDokumen5 halamanResume of Jameelhnapi-23802556Belum ada peringkat

- P 11Dokumen2.380 halamanP 11Almohin Haron SamaBelum ada peringkat

- Students Industrial Work Experience ScheDokumen16 halamanStudents Industrial Work Experience Schejoseph emmanuelBelum ada peringkat

- Chvac GuideDokumen18 halamanChvac Guidesas999333Belum ada peringkat

- IndexDokumen1 halamanIndexjin feiBelum ada peringkat