269-JMES-3235-Bennis - Ulei de Migdale 2017

Diunggah oleh

ionelia cringaruJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

269-JMES-3235-Bennis - Ulei de Migdale 2017

Diunggah oleh

ionelia cringaruHak Cipta:

Format Tersedia

Journal of materials and JMES, 2017 Volume 8, Issue 7, Page 2506-2512

Environmental Sciences

ISSN : 2028-2508

Copyright © 2017,University of

Mohammed Premier Oujda Morocco

http://www.jmaterenvironsci.com/

Evaluation of the effect of the Organo-bentonite on gelification of Almond oil

using a mixture design

S. Bennis*1, L. Yachi1, Y. Elalaoui 1, M. Bouatia2, N. Cherkaoui1, A. Laatiris1, Y. Rahali1

1. Laboratory of Pharmaceutics, Faculty of Medicine and Pharmacy of Rabat, University Mohamed V, Rabat, Morocco

2. Laboratory of Analytical Chemistry, Faculty of Medicine and Pharmacy of Rabat, University Mohamed V, Rabat, Morocco

Received 27 Jan 2017, ABSTRACT

Revised 28 Mar 2017,

Accepted 02Apr 2017 Oleogels are semisolid systems and consist of a lipophilic liquid phase with a gelling

Keywords agent. The aim of our study is to demonstrate how the concentration of bentone

changes the viscosity of the preparation as well as the influence of the polar activator

Viscosity; included in the composition of the formulae. In our study a design of experiments

Almondoil; approach was tested using a mixture design to evaluate the effects of the bentone and

Bentone; ethanol on enhancing viscosity of Almond oil. This viscosity was established by

Oleogel;

sensory analysis, which resulted in a score on a scale from 0 to 10. Formulation of

Mixture design

oleogel based on bentone as gellant agent and almond oil seems to improve the

S Bennis viscosity of the formulae.

soukainabennis90@gmail.com

+212674385534

1. Introduction

Oleogels, also referred to as organogels or lipogels, are defined as the semi-solid formulations, comprising of a

3D network structure of gelator molecules, which immobilizes apolar liquid. Oleogels can be synthesized using

a diverse group of gelators and organic solvents [1]. The microstructure of oleogels is characterized by either

permanent rigid networks or transient semiflexible meshes, both thermoreversible [2].

The applications of oleogels were investigated in several areas such as organic chemistry, environmental

chemistry and also in pharmaceutical and cosmetic fields. The majority of the applications reported in the

pharmaceutical area were related to transdermal systems, topical bases and preparations intended for

percutaneous absorption [3].

Oleogels are cosmetics themselves because of their lipid composition that serves as a barrier between the skin

and the outside ambient. When necessary, they help to regenerate the stratum corneum because of their rich

content in fatty acids, which are usually compatible with the epidermis. Nonetheless they are commonly used as

vehicles to incorporate active compounds to a therapeutic or cosmetic use [4].

Organoclays, organically modified montmorillonites/smectites, are being extensively used as rheological

modifier agent in a number of applications like paints, inks, adhesives, greases, and varnishes, as well as in

cosmetics and medicines. The adsorption of organic liquids/media, swelling and thixotropic gel forming

ability/behavior of organoclays has been widely studied [5]. They have several health benefits when applied

locally over the skin [6].

Bentone organoclays are produced for use in the oil phase. The fatty acid chains attached to the face of clay

platelet sallow the dispersion in the organic medium, while edge-to-edge hydrogen bonding of the platelets (via

water bridges) and the interaction of the alkyl chains provide formation for gel structure [6, 7].

A polar activator is necessary to promote the dispersion process for obtaining stable dispersion by forming gel

structure. The function of polar activator is to separate layers from each other and restrict agglomeration in the

organic medium. Once these layers are de-agglomerated, they allow the organic groups to free themselves from

close association with the clay surface. These organic groups are now free to solvate in the organic liquid [8].

Almond is a major tree nut crop cultivated mainly in the Mediterranean region and the USA, North to South,

under different environmental conditions, mostly on non-irrigated areas of poor soils and receiving little

attention from farmers. The climate is primarily Mediterranean, becoming more extreme toward the inland

regions and Saharian in the South. The resultant variability in environment and climate has turned into an

extensive diversity of almond genotypes in each producing region, due to the fact that about 50% of the almond

trees grown in Morocco are seedlings, located primarily in the north and the south [9].

Bennis et al., JMES, 2017, 8 (7), pp. 2506-2512 2506

Almond oil contains a substantial quantity of triacylglycerols, which are stored as intracellular oil droplets in the

cotyledon tissues of the kernel. Almond oil is composed predominantly of mono and di-unsaturated fatty acids

(FA). The major FA in Almond oil is oleic acid, representing 50–80% of the total FA content. Linoleic, palmitic

and stearic acids are present at levels of 10–26%, 5–9%, and 1.5–4%, respectively[10].

In this work, Almond oil was used as a lipid phase, and bentone as a gelling agent. For the formulation of this

gel we based our study on planning experiments. The use of this method of experiments provides predictive

models studied responses, and optimal conditions and with minimal testing and maximum credibility [11].

The viscosity of the gels is evaluated by sensory analysis. The sensory evaluation is a scientific discipline that

applies principals of experimental design and statistical analysis to the use of human senses (sight, smell,

hearing...) for the purposes of evaluating consumer products. It is the most direct method for evaluating and

understanding the texture [12].

The aim of our study is to demonstrate how the concentration of bentone changes the viscosity of the

preparation as well as the influence of the polar activator included in the composition of the formulae.

Moreover, this study aims to find the most suitable formulation by using a mixture design.

2. Experimental details

2.1.Instruments and Reagents

An organically modified bentonite, quaternium-18 bentonite supplied by RiedeL-De Haen with, the commercial

name of Bentone® 34. The clay powder had a density value of 1.7; Ethanol supplied by Riedel-De Haen had a

density value of 0.788. Cosmetic Almond oil purchased by Biopur company (Morocco). The almoid oil used in

this work was obtained as a commercial product.

The materials used for the preparation were: a stirring and heating plate (VELP scientifica). Thermometer

(Brannan, England) weighing machine AA&D Company, limited, graduated burette (Hirschmanntechcolor

Germany), magnetic bar, micropipette a 20-200 l (Finpepette).

The software Design Expert was used for the experimental design and statistical tools.

2.2.Preparation of the samples

The formulation of oleogels took place in the laboratory of Galenic Chemistry at the Faculty of Medicine and

Pharmacy of Rabat. The oleogels formulation per se consists of the repartition of three components in tubes of

20 ml. The bentone powder was first dispersed thoroughly in an organic liquid using mixing method. An

activator polar is then added and mixing continued [13].

Firstly, Bentone powder was prepared by accurately weighing the appropriate quantity, by adding the exact

volume of oil with the help of graduated burette in the tubes of 20 ml. The dispersion is submitted to a constant

magnetic mixing at 500 rpm and 100 °C for 10 min. while heating from ambient temperature to 40 °C.

Secondly, after 10 min, a solution of ethanol has been added by micropipette precision under the same

conditions, which were tried for 10 min.

The viscosity score is attributed just after the gelification of Almond oil in ambient temperature according to a

scale from 0 to 10. Score 0 corresponds to an absence of viscosity, however score 10 allows gel consistency.

2.3.Experimental design and mathematical modelling

To define the formulation space for the Almond oil viscosity, we tested an experimental design by using

software Design-Expert® that is a statistical tool that enables calculation for factorial designs and drawing

graphs for design evaluation [14].

In this article, a D-optimal experimental design (mixture design) was selected to evaluate and model the effects

of bentone and ethanol on enhancing viscosity of Almond oil. This provides maximum information from a

limited number of experiments. The studied factors were: the amounts of Almond oil (X1 = A), Ethanol (X2 =

B) Bentone®34 (X3 = C).To make this experimental design, the lower and upper limits of components were

fixed (Table I).

2.4. Viscosity determination

The sensory qualities of cosmetic products are studied by employing discriminatory or descriptive methods of

international renown. The descriptive sensorial profile is the essential tool for this experiment, which allows the

evaluation of qualitative and quantitative concerning sensorial characteristics of product panel. The results

subsequent to this method allows to elicit a precise sensorial image of this product [15].

The viscosity score is attributed by sensory analysis just after the gelification of Almond oil in ambient

temperature according to a scale from 0 to 10. Score zero corresponds to an absence of viscosity, however score

10 allows gel consistency.

Bennis et al., JMES, 2017, 8 (7), pp. 2506-2512 2507

Table I. Lower and upper limits of components used to made experimental design.

Components Lower limit (%) Upper limit (%)

X1: Almond oil 80.50 95.50

X2: Ethanol 1.50 6.50

X3: Bentone 34 3.00 13.00

2.5. Statistical analysis

The software Design Expert is a statistical tool that permits calculation for factorial designs and drawing graphs

for design evaluation. It can handle many models of experimental design, such as factorial or mixture design.

The statistical analysis of variance, the R-squared, the precision and mathematical modelling of the responses by

polynomial equation at D0, D6, D7 D10 and D12 were carried out by Design Expert [16].

3. Results and Discussion

3.1.Viscosity of Almond oil

All the mixture experiments were conducted in random order and the calculations were performed by the Design

Expert®Software. The viscosity score results of the 16 mixtures in various ratios of Almond oil, bentone and

ethanol are shown in Table II.

Table II: Mixture design of experiments and score of viscosity results of the 16 mixtures.

Run X1: X2: X3: Y: score Y: score Y: score Y: score Y: score

Almond oil Ethanol Bentone Day 0 Day 6 Day 7 Day 10 Day 12

1 95.50 1.50 3.00 1 1 1 1 0

2 88.83 4.83 6.33 4 4 4 4 4

3 85.50 6.50 8.00 4 4 4 4 4

4 90.50 6.50 3.00 2 2 2 0 0

5 85.50 1.50 13.00 10 10 10 10 10

6 95.50 1.50 3.00 1 1 1 1 0

7 90.50 1.50 8.00 5 5 5 7 7

8 90.50 1.50 8.00 5 5 5 7 7

9 83.00 4.00 13.00 8 9 10 10 10

10 85.50 1.50 13.00 10 10 10 10 10

11 87.17 3.17 9.67 6 6 6 8 8

12 80.50 6.50 13.00 10 10 10 10 10

13 80.50 6.50 13.00 10 10 10 10 10

14 84.25 5.25 10.50 8 10 10 10 10

15 93.00 4.00 3.00 2 2 2 0 0

16 90.50 6.50 3.00 2 2 2 0 0

3.2.Mathematical modelling

Experiments were carried out to determine the mathematical relationship between the factors influencing the

performance and the characteristics of the formulation. A second order polynomial regression model represented

by a special quadratic equation at D0, D6, D7 D10 andD 12 was selected as follows:

Where Y is the score of viscosity prediction of Almond oil, a1, a2 and a3 are the estimated coefficients from the

observed experimental values of viscosity for X1 (Almond oil), X2 (ethanol), X3 (bentone). The response of

Almond oil viscosity expressed by a quadratic equation at D0, D6, D7, D10 and D12 was as follows:

Bennis et al., JMES, 2017, 8 (7), pp. 2506-2512 2508

Yday0 = −2.02X1 + 3.57X2 + 3.08X3 − 0.03X1X2 − 0.02X1X3 − 0.08X2X3

Yday6 = −0.01X1 − 4.40X2 + 2.93X3 + 0.04X1X2 − 0.02X1X3 + 0.01X2X3

Yday7 = −0.01X1 − 8.53X2 + 3.50X3 + 0.09X1X2 − 0.03X1X3 + 0.05X2X3

Yday10 = −0.02X1 − 3.98X2 − 2.31X3 + 0.03X1X2 + 0.03X1X3 + 0.10X2X3

Yday12 = −0.04X1 − 5.35X2 − 2.90X3 + 0.05X1X2 + 0.04X1X3 + 0.10X2X3

®

With viscosity score, mixtures were designed by Design Expert to explore the feasibility zone presenting the

maximum viscosity score for Almond oil. Figures 1, 2, 3, 4 and 5 represent the experimental domain inside the

ternary diagram at different day

These equations predict the score of viscosity of the Almond oil in experimental domain. Also the variation of

the score of viscosity coefficient during 12 days.

Design-Expert® Software

A: Almond oil Day 7

Design-Expert® Software 95.5 Design points above predicted value

2

Design points below predicted value

Day 0 10 11

Design Points

10 1 9

1 X1 = A: Almond oil

D ay 7

3 X2 = B: Etanol 6

2 2 X3 = C: Bentone 34

X1 = A: Almond oil 4

X2 = B: Etanol 4

X3 = C: Bentone 34 1

3.0 5 1.5

A (95.5) B (1.5) C (18.0)

7

2

C (3.0) A (80.5)

2

B (16.5)

16.5 80.5 18.0

B: Etanol C: Bentone 34

Day 0

Figure 1: Contours plots and surface plots of estimated viscosity score of almond oil at Day 0.

Design-Expert® Software

A: Almond oil

Design-Expert® Software 95.5 Day 10

2

Design points above predicted value

Day 6 Design points below predicted value

Design Points 10 11

10

0

1 3 8

D a y 1 0

2 2 X1 = A: Almond oil

X1 = A: Almond oil 4

X2 = B: Etanol 5

X2 = B: Etanol X3 = C: Bentone 34

X3 = C: Bentone 34 1

6

3.0 1.5

-2

7

2

A (95.5) B (1.5) C (18.0)

9

C (3.0) A (80.5)

2

16.5 80.5 18.0

B: Etanol C: Bentone 34

Day 6 B (16.5)

Figure 2: contours plots and surface plots of estimated viscosity score of almond oil at day 6.

A: Almond oil

Design-Expert® Software 95.5 Design-Expert® Software

2

Day 7 Day 6

Design Points Design points above predicted value

10 Design points below predicted value

10 11

1 3

1 8

2 2

X1 = A: Almond oil X1 = A: Almond oil

D ay 6

4

X2 = B: Etanol X2 = B: Etanol 6

X3 = C: Bentone 34 X3 = C: Bentone 34

6

3.0 1.5 3

7 1

2

9 B (1.5)

A (95.5) C (18.0)

C (3.0) A (80.5)

2

16.5 80.5 18.0

B: Etanol C: Bentone 34

Day 7 B (16.5)

Figure 3: contours plots and surface plots of estimated viscosity score of almond oil at day 7.

Bennis et al., JMES, 2017, 8 (7), pp. 2506-2512 2509

A: Almond oil Design-Expert® Software

Design-Expert® Software 95.5

2 Day 0

Day 10 Design points above predicted value

Design Points Design points below predicted value

10 10

10

1

1 8

0

3 X1 = A: Almond oil

Day 0

2 2 X2 = B: Etanol 6

X1 = A: Almond oil X3 = C: Bentone 34

5

X2 = B: Etanol 3

X3 = C: Bentone 34

7

3.0 1.5 1

A (95.5) B (1.5) C (18.0)

8

2

C (3.0) A (80.5)

2

B (16.5)

16.5 80.5 18.0

B: Etanol C: Bentone 34

Day 10

Figure 4: contours plots and surface plots of estimated viscosity score of almond oil at day 10.

A: Almond oil

Design-Expert® Software 95.5

2 Design-Expert® Software

Day 12

Day 12

Design Points

Design points above predicted value

10

Design points below predicted value

1

10 11

0

3

2 2

0 8

X1 = A: Almond oil

D ay 12

5 X1 = A: Almond oil

X2 = B: Etanol

X2 = B: Etanol 5

X3 = C: Bentone 34

7 X3 = C: Bentone 34

3.0 1.5

1

9

2 -2

A (95.5) B (1.5) C (18.0)

2

C (3.0) A (80.5)

16.5 80.5 18.0

B: Etanol C: Bentone 34

Day 12

B (16.5)

Figure 5: contours plots and surface plots of estimated viscosity score of almond oil at day 12.

3.3. Statistical analysis

The statistical significance of the model has been evaluated by using the analysis of variance (ANOVA). It is a

statistical technique which subdivides the total variation in a set of data in linked components for the aim of

testing the hypotheses on the model parameters [17]. Table III shows the results of the ANOVA.

Score F is a link of two independent estimations for the experimental error. Associated to this report, the value

of the probability P quantifies the probability of making a mistake by linking an effect with a given factor. This

score also provides the exact level of the significant of hypothesis test. The results show that the model is very

significant evidence, the same as score F (FD0 model= 61.58 FD6 model=39.04 FD7 model= 50.54 FD10 model =75.09 and

FD12 model=74.54) and low probability score (p<0,0001). The low probability score indicates that the model is

considered statistically significant [18]. Values under 0.05 % were considered statistically significant. The R-

squared beyond 0.93 is in reasonable agreement. Precision measurements of the signal to-noise ratio should be

greater than 4: our ratios are beyond 20.94.

Table III:Significance of the results and mathematical model used.

Mathematical F0, 05 P value Significance R-squared Precision

model for alpha at (R2)

5%

D0 Quadratic 61.58 <0.0001 Significant 0.9528 18.660

D6 Quadratic 39.04 <0.0001 Significant 0.9269 15.217

D7 Quadratic 50.54 <0.0001 Significant 0.9429 17.718

D10 Quadratic 75.09 <0.0001 Significant 0.9611 21.216

D12 Quadratic 74.54 <0.0001 Significant 0.9608 20.491

Bennis et al., JMES, 2017, 8 (7), pp. 2506-2512 2510

3.4. Model and results analysis

The significance of the statistical analysis at D0, D5, D10 andD15 shows that the responses of viscosity are

modeled successfully. However, this indicates that if the colloidal structures have been contaminated, statistical

analysis could not be significant and the signal will be disturbed by noises.

These experiments show an improvement of viscosity by reaching the score 10 with run 5, 9, 10, 12, 13 and 14.

For these runs, the gelling agent percentage Bentone®34 is 13% representing therefore the maximum value for

obtaining a gel of score 10. In comparison with the runs with a lowest score 1, the Bentone ®34 percentage is

reduced to 3%; this result is observed with the runs 1 and 6.

It is observed that the degree of gel stability, and viscosity of this Almond oil–organoclay dispersions increased

with the increase of Bentone concentration from 3 to 13 %. As explained earlier, the magnitude of interaction

between Almond oil and quaternary ammonium cations increases with he increase of the concentration of

Bentone in the dispersions. Therefore, the bentone contributes, to a bigger formula stability by increasing its

viscosity. When polar molecules, such as ethanol, are added to the organoclay suspension, there is an additional

contribution to the viscosity of the dispersion as a consequence of the production of a new internal phase [19].

Increasing the proportion of the bentone and ethanol together is in favor of higher viscosity as the optimum

composition (figures 1, 2, 3, 4 and 5), which permitted to gellify the Almond oil, contains the maximum of

bentone in our matrix.

Considering the coefficients a1 (Almond oil), a2 (ethanol) and a3 (bentone) given by our model’s viscosity

equation at day0, it has been noticed that a3 are the coefficient that affects the most Almond oil viscosity.

However, high values of viscosity are observed with high proportions of bentone.

Taking into account that organobentonites are clays partially covered by alkyl ammonium molecules adsorbed

at their surface, the structure and, consequently, the flow behaviour of these dispersions may be related to the

interactions developed between the organophilic ions and the solvent, the organic chain density between

platelets and the chemical nature of the medium. These interactions, which normally increase with clay

concentration, lead to an increase in viscosity, as it has been pointed out above [20].

The analysis by infrared spectroscopy (Figure 6) confirmed the presence of alkyl ammonium ions in

Bentone®34 by cation exchange. Characteristic bands intercalated surfactant (valence vibration bands of the

methylene group (CH2) of the long chain to 2921cm-1 and 2849cm-1) showing the effectiveness of the cation

exchange. Thus the alkyl chains were easily to enwind each other, resulting physical attraction. In addition, oil

molecules would also intercalate into the interspace. Finally, bentone /Almond oil gel formed and the viscosity

and gel strength of the system increased [21].

The weakest score value of our matrix was observed with run 1 and run 6 that contain a lower limit of Bentone

3% and ethanol 1.5%. The analysis of model 3D shows a correlation between bentone concentration and ethanol

in the formula and the improvement of dispersion’s viscosity; however, this impact becomes no more significant

for a certain level of each component, we can consider the existence of an optimum essay of bentone.

Figure 6: Infrared spectra of Bentone®34.

3.5. Ripening process

After 7 days, and starting from Bentone®34 « run number 9 and run number 14 » concentration, we have

observed an increase of viscosity as shown by figure 3. This leads to the assumption thatthe remaining free

platelets take more time to find a disposable site in the structure.

Bennis et al., JMES, 2017, 8 (7), pp. 2506-2512 2511

The obtained gel during the sol-gel transition still contains an important fraction reactive group. So it could

continue to develop, especially, by the condensation reactions between the nearby groups. The formation of

these new groups of links increases the reticulation degree of gel, as shown by the increase of viscosity score

« run number 9 and run number 14 » [22].

Gelification results from the formation of small particles, which grow in number and size and then join together

to fill the available space. Ripening takes place through a dissolution/reprecipitation mechanism.

3.6. Syneresis phenomenon

The increase of gelification is represented by a gel rigidication; with the ultimate stage, the syneresis

phenomenon produces the contraction of the gel and exudation of a part in the liquid phase. This phenomenon

has been observed with run number 4. Syneresis of oil from the formed gel is a natural phenomenon during

which unbound excess oil comes out from the formed gel matrix. This is an undesirable phenomenon, which can

be reduced by the selection of appropriate concentration of bentone.

Conclusions

The gelification process was found to be a complex phenomenon affected by several parameters such as the

percentage of gelling agent, the percentage of the polar activator and the nature of oil. The study shows that, the

percentage of the bentone has a significant effect on gelation.

The mixture experimental design indicates clearly that concentration of Bentone determines the viscosity of the

studied Almond oil. The influence of variable concentration is a key criterion in order to define conditions to

have adequate viscosity.

References

1. Sagiri S.S., Singh Vinay K., Pal, K., Banerjee, I., Bassak, Piyali., Mater.Sci. Engi. 688 (2015) 48.

2. Sanchez R., Franco J.M., Delgado M.A., Valencia C., Gallegos C., Rheolo. Oleogel. 328 (2011) 62.

3. Almeida Isabel F., Bahia, Fernanda M., Intern. J. Pharma.77 (2006) 327.

4. Gallardo V, Munoz M, Ruiz MA., J. Cosme. Dermato. 4 (2005)187-92.

5. Bhatt Juggnu, Somani, Rajesh S., Mody, Haresh M.,Bajaj, Hari C., Appl. Clay Sci. 114 (2013) 84.

6. Viseras C., Aguzzi, C.,Cerezo, P., Lopez-Galindo, A., Appl. Clay Sci. 37-50 (2007) 36.

7. Matsuzaki F., Acad. Press. Burlington. 46 (2001) 45.

8. Patel H.A., and Bajaj H.C., Focus.hi-tech ingre. 31 (2010) 35.

9. Kodad, Ossama., Estopanan, Gloria., Juan, Teresa., Socias i Company, Rafel., J. Food. Composit. Analysis.

161-165 (2014) 33.

10. Maestri, Damian., Martinez, Marcela., Bodoira, Romina., Rossi, Yannina., Oviedo, Alejandro., Pierantozzi,

Pierluigi., Torres, Mariela., Food.Chemi.,55-61 (2015) 170.

11. Rahali Y., Pense-Lheritier A.-M., Mielcarek C., and Bensouda Y., Intern. J. Cosme. Sci. 451-460 (2009)

31.

12. Hayakawa, Fumiyo.,Kazami, Yukari., Ishihara, Sayaka., Nakao, Satomi., Nakauma, Makoto., Funami,

Takahiro., Nishinari, Katsuyoshi., Kohyama, Kaoru., Food Hydrocolloids. 95-103 (2014) 38.

13. F., L. and M. A. Appl. Rheol. (2009).

14. EL Alaoui, Y., Sefrioui R., Bensouda Y., Rahali Y., J.Chemi.Pharma. Resear.39-46. (2014) 6.

15. Pensé-lhéritier, A.-M., Intern. J. Cosme. Sci. 465-473 (2015) 37.

16. Rahali, Y., Saulnier P., Benoit JP., Bensouda Y., J. Drug. Delivery. Sci. Techn. 255-260 (2013) 23.

17. Myers, R.H., Montgomery D.C., Anderson-Cook C.M., Willey, New York. (2009) 3.

18. Hadj sadok, A., N. Moulai-Mostefa., and A. Bouda., Rev. Sci. Technol. Synt. 96-102 (2013) 26.

19. J, H., M.-B. F., and C. Gallegos., J. Industr. Eng. Chemi. (2014) 9.

20. J. Hermoso F., Martinez-Boza G. C., Appl. Clay Sci. (2014) 87.

21. Zhuang, G., Zhang Z., Sun J., Liao L., Appl. Clay Sci.125 21-30 (2016) 124.

22. Vega, A.J., and S. G.W., NMR. J., Non-Cryst. Solids. 153-166 (1989) 111.

(2017) ; http://www.jmaterenvironsci.com

Bennis et al., JMES, 2017, 8 (7), pp. 2506-2512 2512

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Introduction to MEMS Etching TechniquesDokumen16 halamanIntroduction to MEMS Etching TechniquesArjit GoswamiBelum ada peringkat

- Analysis of Water Quality ParametersDokumen50 halamanAnalysis of Water Quality ParametersSoumya SreeBelum ada peringkat

- Sensors 3Dokumen59 halamanSensors 3zubairawBelum ada peringkat

- MalachiteDokumen2 halamanMalachiteAkhil KumarBelum ada peringkat

- Assignment 3 Due:: May 07, 2020: Z Z Z ZDokumen1 halamanAssignment 3 Due:: May 07, 2020: Z Z Z ZwatsopBelum ada peringkat

- CM5241 Literature Review Project TopicsDokumen3 halamanCM5241 Literature Review Project TopicsCheryldine LimBelum ada peringkat

- Intermolecular ForcesDokumen29 halamanIntermolecular ForcesemilyBelum ada peringkat

- Ionic EquilibriumDokumen91 halamanIonic EquilibriumGabrielBelum ada peringkat

- PhysicsDokumen396 halamanPhysicsIndroneil KanungoBelum ada peringkat

- Alchemical SymbolDokumen6 halamanAlchemical SymbolMilind Goel ReplexBelum ada peringkat

- Local Treatment of Electron Correlation-Svein SaeboDokumen24 halamanLocal Treatment of Electron Correlation-Svein SaeboAndré RojasBelum ada peringkat

- Brchembase LRDokumen4 halamanBrchembase LRRavindra PawarBelum ada peringkat

- RonNielsen NuclearReactionsDokumen471 halamanRonNielsen NuclearReactionsr_nielsenBelum ada peringkat

- Approximate Design of Multiple Feed Side Stream Distillation Systems 1987 Industrial and Engineering Chemistry ResearchDokumen7 halamanApproximate Design of Multiple Feed Side Stream Distillation Systems 1987 Industrial and Engineering Chemistry ResearchDevaucayBelum ada peringkat

- Exp#05Dokumen8 halamanExp#05RiazBelum ada peringkat

- Limiting Reagent ProblemsDokumen7 halamanLimiting Reagent ProblemsKaiRisBelum ada peringkat

- DNA BananasDokumen9 halamanDNA BananasNigar CəlilovaBelum ada peringkat

- Wae Oarp WebDokumen8 halamanWae Oarp WebRoberto Leon MendezBelum ada peringkat

- STABILITYDokumen11 halamanSTABILITYNandyBelum ada peringkat

- 3.7.12. Metal Matrix Composites: Matrices and Processing: T.W.ClyneDokumen14 halaman3.7.12. Metal Matrix Composites: Matrices and Processing: T.W.ClyneVizay KumarBelum ada peringkat

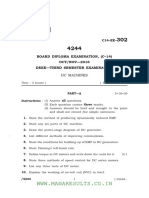

- WWW - Manaresults.Co - In: Board Diploma Examination, (C-14) OCT/NOV-2016 Deee-Third Semester Examination DC MachinesDokumen3 halamanWWW - Manaresults.Co - In: Board Diploma Examination, (C-14) OCT/NOV-2016 Deee-Third Semester Examination DC Machinesanon_550578171Belum ada peringkat

- Applied Metallurgy and CorrosionDokumen2 halamanApplied Metallurgy and Corrosiongetavijit.asheshBelum ada peringkat

- LPG PropertiesDokumen2 halamanLPG Propertiesvvk557Belum ada peringkat

- CHEM 101 General Chemistry I: Dr. Kawkab Al-NaimiDokumen88 halamanCHEM 101 General Chemistry I: Dr. Kawkab Al-NaimiRayan BaigBelum ada peringkat

- The Ocean Answer BookDokumen545 halamanThe Ocean Answer BookKira Koorsen100% (4)

- The Role of Thickeners in Optimizing Coatings PerformanceDokumen13 halamanThe Role of Thickeners in Optimizing Coatings PerformanceArturo Antonio Matencio Arroyo100% (1)

- 40 International Chemistry Olympiad: Preparatory ProblemsDokumen104 halaman40 International Chemistry Olympiad: Preparatory ProblemsLê Hoàng MinhBelum ada peringkat

- Hadighi AliDokumen66 halamanHadighi AliMousaBelum ada peringkat

- JIS G3466 - Thailand - CONTENT1011579693989745Dokumen1 halamanJIS G3466 - Thailand - CONTENT1011579693989745Nguyễn Tiến TùngBelum ada peringkat

- Freeze-Drying Process Development For Protein PharmaceuticalsDokumen23 halamanFreeze-Drying Process Development For Protein Pharmaceuticalsboddarambabu100% (1)